Introduction:

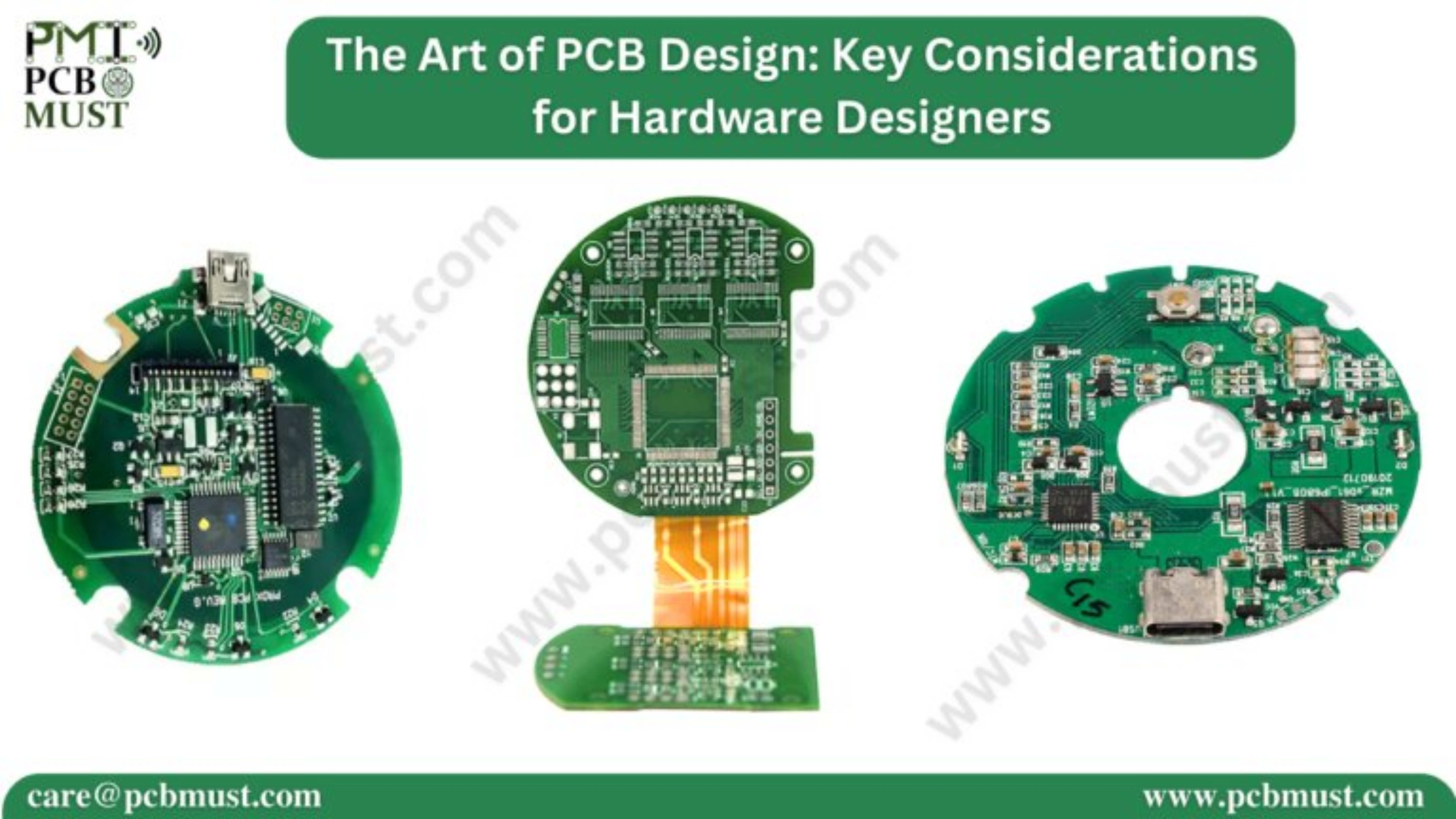

Printed Circuit Board (PCB) design is a critical aspect of hardware design that involves creating the physical layout and interconnections of electronic components. It is often referred to as the “art” of hardware design due to its intricate nature and the significant impact it has on the overall performance, reliability, and manufacturability of electronic devices. In this blog, we will explore the key considerations and best practices that hardware designers should keep in mind when approaching PCB design. From component placement and routing to signal integrity and manufacturability, mastering the art of PCB design is essential for creating successful hardware solutions.

Benefits of Effective PCB Design:

1. Signal Integrity and Performance: A well-designed PCB layout plays a crucial role in maintaining signal integrity and ensuring optimal performance of electronic circuits. Careful consideration of trace routing, signal paths, and ground planes helps minimize signal interference, crosstalk, and noise. By optimizing signal integrity, hardware designers can achieve faster data transfer rates, reduced latency, and improved overall performance of electronic devices.

2. Thermal Management: Efficient thermal management is essential for the reliable operation of electronic components. PCB design factors such as component placement, thermal vias, and copper planes influence the dissipation of heat generated during operation. By implementing proper thermal design techniques, hardware designers can prevent overheating, extend the lifespan of components, and enhance the overall reliability of the device.

3. Miniaturization and Space Optimization: With the continuous demand for smaller and more compact electronic devices, PCB design plays a critical role in achieving miniaturization and space optimization. By carefully arranging components, employing multilayer PCBs, and utilizing surface mount technology (SMT), hardware designers can maximize the utilization of available space, enabling sleek and compact devices without compromising functionality.

4. Electromagnetic Compatibility (EMC): EMC is the ability of electronic devices to operate without causing interference or being susceptible to interference from other devices. Effective PCB design helps ensure electromagnetic compatibility by employing proper grounding techniques, minimizing loop areas, and separating sensitive analog and digital components. By addressing EMC considerations during PCB design, hardware designers can minimize the risk of electromagnetic interference (EMI) and enhance the overall reliability and performance of the device.

5. Manufacturability and Cost Optimization: A well-designed PCB layout takes into account manufacturability and cost optimization. Design considerations such as component availability, ease of assembly, and efficient production processes help reduce manufacturing costs and minimize the time-to-market. Collaboration with manufacturers during the design phase facilitates the smooth transition from prototype to mass production, ensuring high-quality and cost-effective manufacturing.

Other Factors in PCB Design:

1. Component Placement and Routing: Careful component placement is crucial for optimal signal integrity, thermal management, and space optimization. Placing components in close proximity to minimize trace lengths reduces signal propagation delays and improves performance. Hardware designers must also consider factors such as power and ground plane placement, decoupling capacitors, and proper routing techniques to minimize noise and interference. Additionally, the layout should consider accessibility for assembly and repair, as well as comply with safety and clearance requirements.

2. Layer Stackup and Routing Strategy: The layer stackup and routing strategy are key considerations in PCB design. Deciding the number of layers, their arrangement, and the routing strategy impact signal integrity, EMC, and manufacturability. Multilayer PCBs provide greater flexibility in routing and allow for better power and ground plane distribution. Proper layer stackup planning considers factors such as impedance control, signal integrity, and separation of sensitive circuitry to optimize the performance of the device.

3. Power and Ground Plane Design: Power and ground plane design is crucial for minimizing noise, achieving proper signal return paths, and ensuring effective power distribution. A solid ground plane and a well-designed power distribution network help reduce voltage drops, maintain signal integrity, and prevent electromagnetic interference. Proper placement of decoupling capacitors and careful routing of power traces enhance power integrity and stability, especially for high-speed and mixed-signal designs.

4. Design for Testability (DFT): Design for Testability (DFT) considerations enable efficient testing and troubleshooting of PCBs during production and maintenance. Hardware designers need to incorporate test points, such as test pads and vias, to facilitate electrical testing and inspection. DFT techniques also include designing for in-circuit testing (ICT), boundary scan testing (JTAG), and built-in self-test (BIST) capabilities to enhance test coverage and fault detection.

5. Design Rule Checking (DRC) and Design for Manufacturability (DFM): Design Rule Checking (DRC) and Design for Manufacturability (DFM) are essential aspects of PCB design. DRC ensures that the design adheres to manufacturing rules and constraints, minimizing the risk of errors, shorts, and other manufacturing issues. DFM considerations focus on optimizing the design for efficient production processes, such as panelization, solder mask, and silkscreen alignment, component placement, and proper footprints, resulting in cost-effective and high-quality manufacturing.

Conclusion:

The art of PCB design is a crucial element in the creation of successful electronic devices. By considering the key factors and best practices discussed above, hardware designers can achieve optimal performance, reliability, and manufacturability. Effective PCB design ensures signal integrity, thermal management, miniaturization, and electromagnetic compatibility while optimizing manufacturability and reducing costs. As technology continues to advance, mastering the art of PCB design becomes increasingly important in delivering innovative and efficient solutions. By prioritizing these considerations, hardware designers can create devices that excel in performance, reliability, and user experience, driving technological progress and shaping the future of electronics.

About the Author:

Avi Gupta, Founder of PCB Must Innovations, is a dynamic force in the world of electronics design. With a wealth of industry experience, Avi thrives on solving intricate problems and delivering dependable solutions. A tech enthusiast, Avi stays ahead of trends while cherishing precious moments with family.

Avi could be reached at care@pcbmust.com

Avi Gupta

Avi Gupta

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.