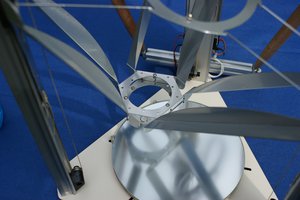

This is a preliminary write up of V2 of my Pellet Extruder that I worked on last year. I have already designed V3, but that requires a custom made extrusion screw on a 4 axis cnc mill. I likely won't provide much more information on this version unfortunately mainly because the next step will be working on V3. The next version may take a while for me to complete though, so this write up is to help anyone that wants to modify my current design, or use this as reference to create their own.

The idea was to create a pellet extruder that is open source and relatively affordable. I have worked on and off this project for about a year and a half. There are some large printers that use these types of extruders, but they have always been closed-source or really expensive. I wanted something more compact, cheaper, and easier to build, while still maintaining the large flowrate. The ultimate goal is to put this on the end of an 6 axis Industrial Robot Arm for large format 3D printing.

Construction

- Nema 23 motor with a 47:1 gearbox on it.

- Off the shelf 1/2" wood auger

- Machined 303 Stainless Steel heater barrel, nozzle, etc.

- Machined Phenolic Resin Heat Break

- Machined aluminum brackets

- Laser cut acrylic windows

- Machined aluminum coupler

- 1/2 thrust bearing

- 3D printed body

- 2X 25mm 110v 300W heater bands

Testing

I have run some PLA through the V2, but there needs to be more testing in relation to how much plastic it can deposit. I have also designed more upgrades in V3 that solves some issues that came up in V2.

Files

You can find all the files to V2 Here

This has the Fusion 360 model, as well as the dxf files for the laser cut parts and the mechanical drawings of the heater barrel.

Ian Coll McEachern

Ian Coll McEachern

FabLab München

FabLab München

Julien OUDIN

Julien OUDIN

Hi Haqnmaq, what kind of volume were you able to extrude in mm3/s or similar unit? I'm building a printer with 1.6m3 volume and looking at most efficient extruder possible (quantitywise)... Cheers, B.