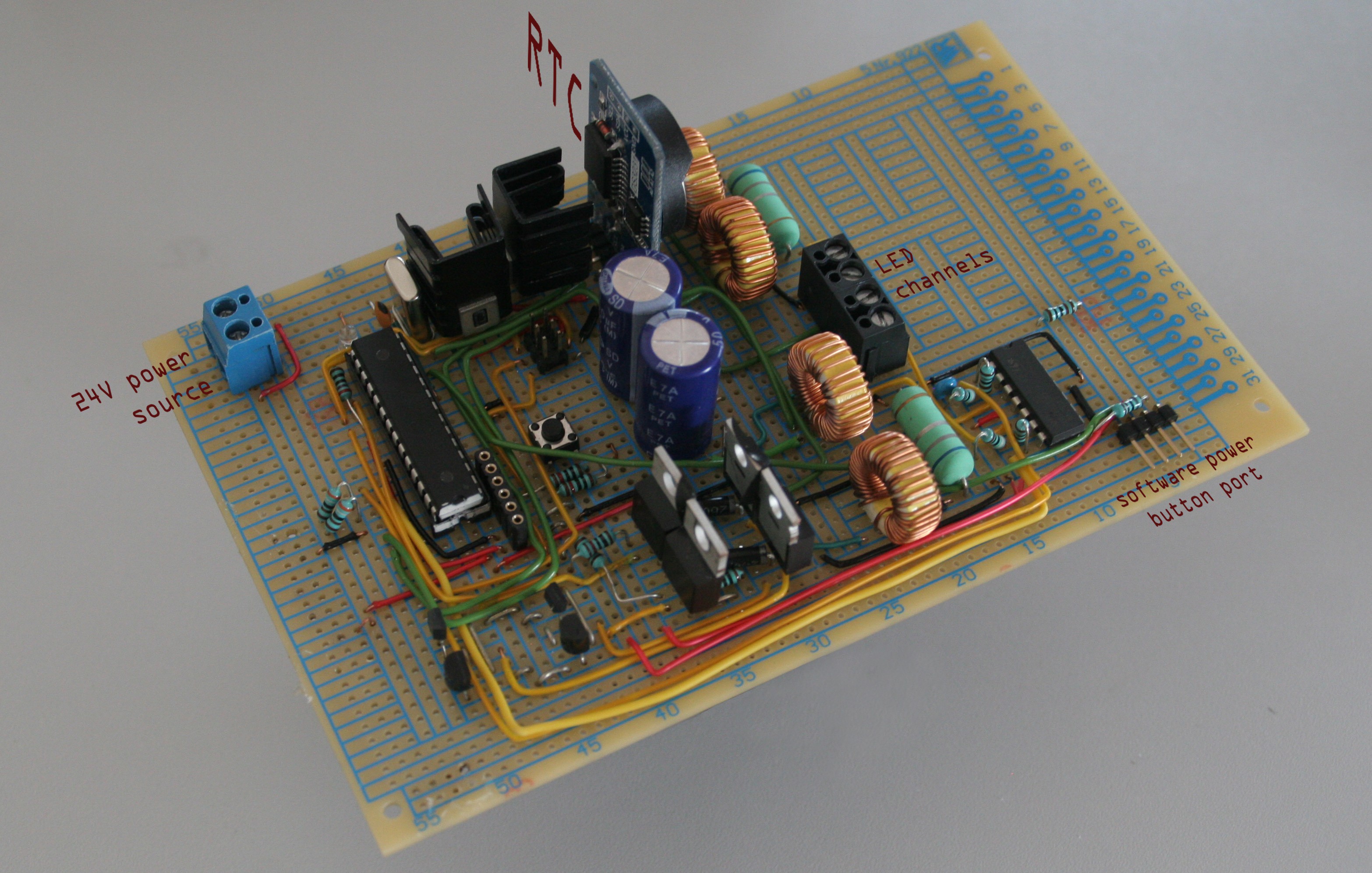

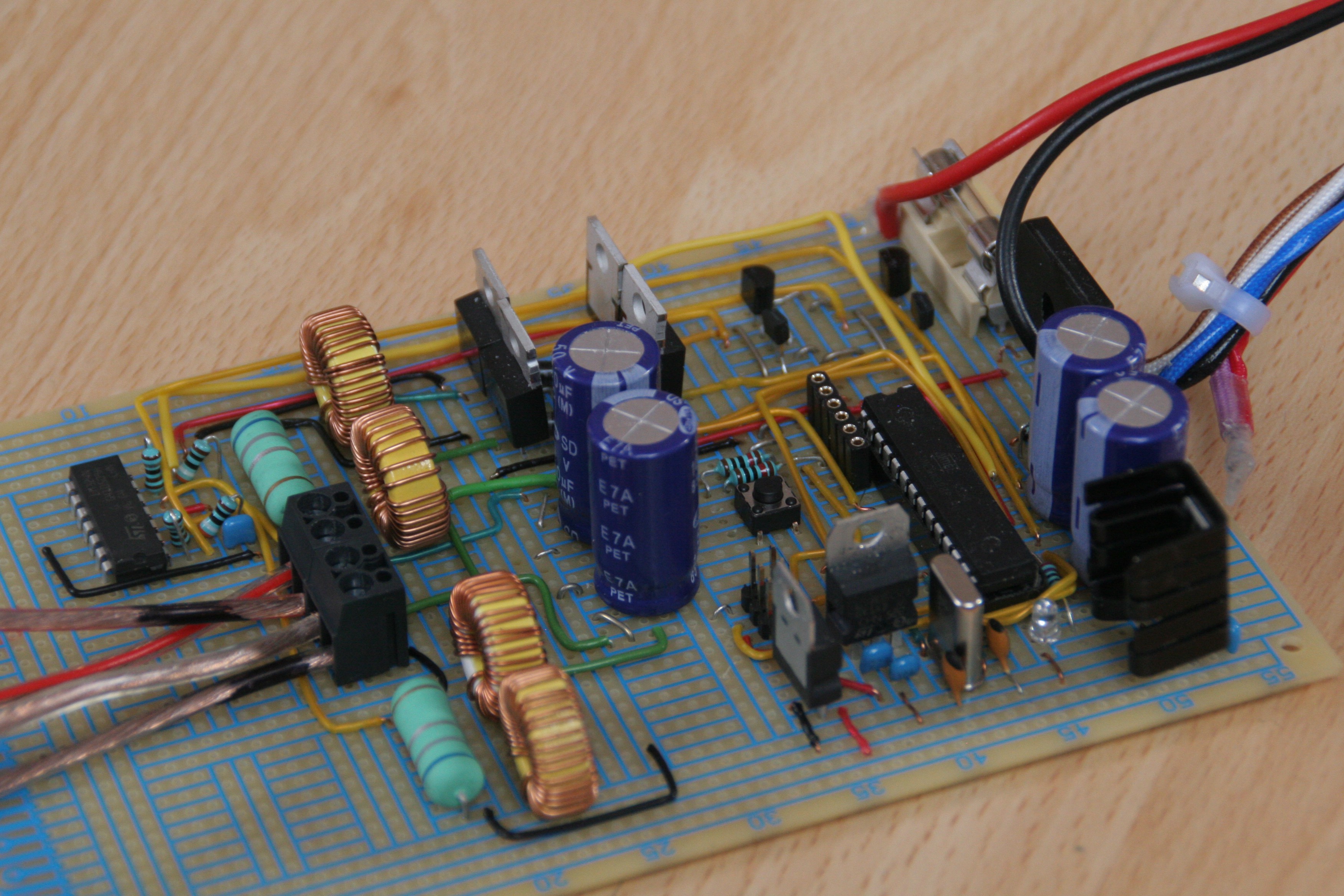

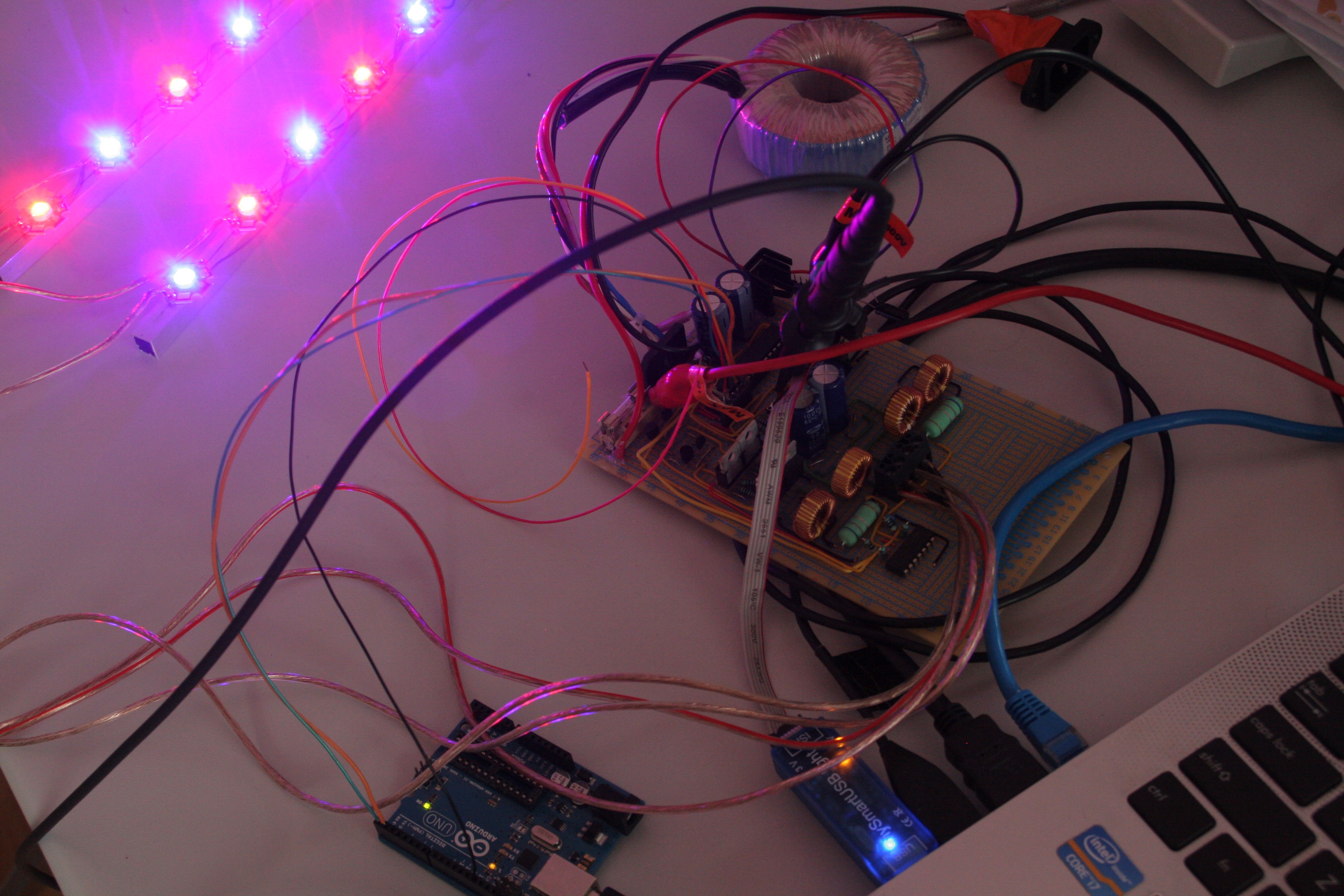

Currently the Vegeterrium (a combination of vegetation and terrerium) is only capable of simulating a day and night cycle hardware-wise. This is accomplished through a control board involving an ATMEGA328, RTC and self built current drivers to power red and blue 15W LED chains (30W total). It is powered by a simple 24V power supply over an ATX cable. The next stage will involve mounting the electronics in the acryllic enclosure and sourcing some plants to grow. If you have any suggestions for small and interesting plants please let me know!

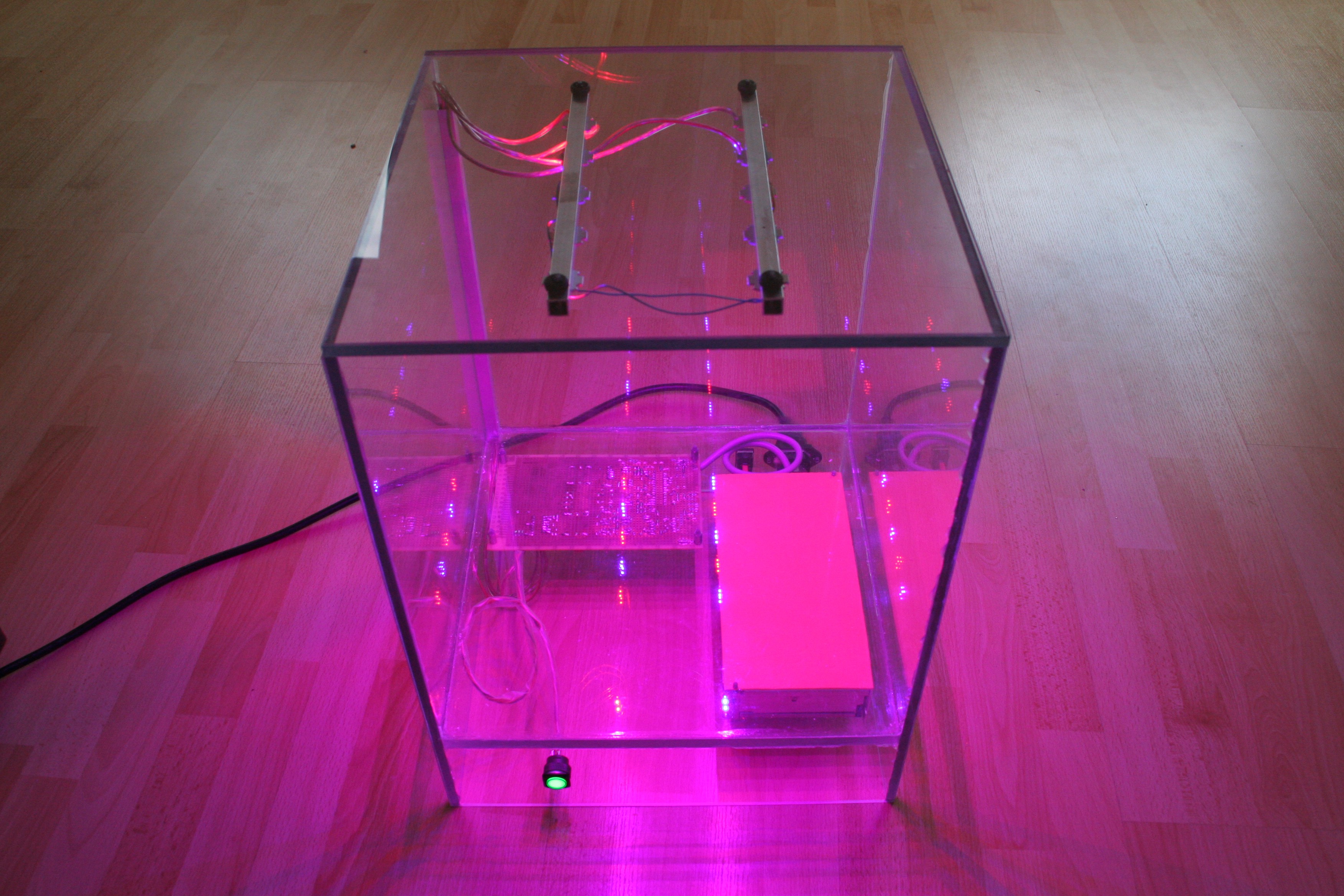

This is my enclosure with all electronics mounted and LED's on full power

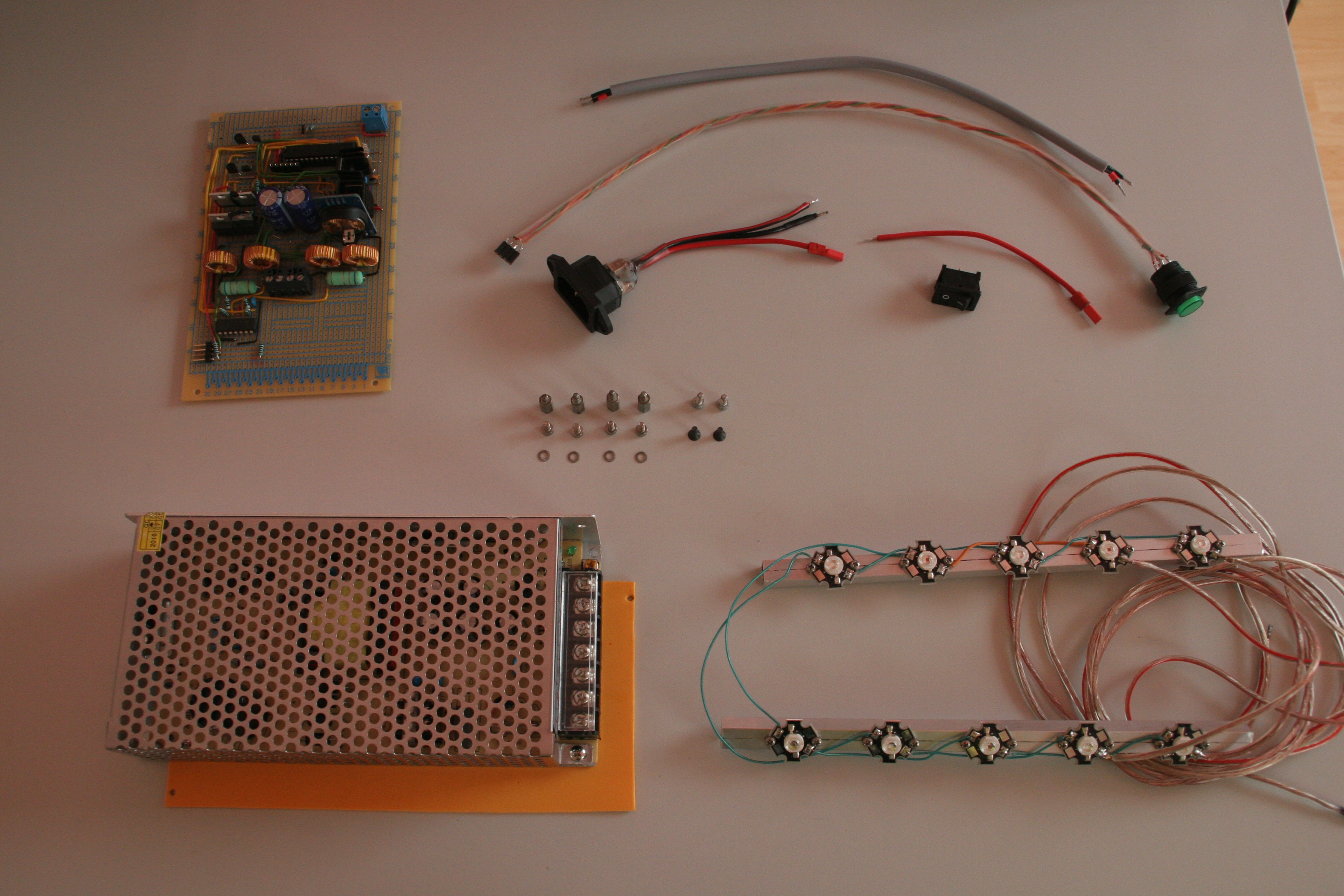

This is my enclosure with all electronics mounted and LED's on full power These are all of the hardware components that were mounted (and used to mount)

These are all of the hardware components that were mounted (and used to mount)

Denis

Denis

CaptMcAllister

CaptMcAllister

M. Bindhammer

M. Bindhammer

Savo

Savo

Hey

Are there any news about the project?