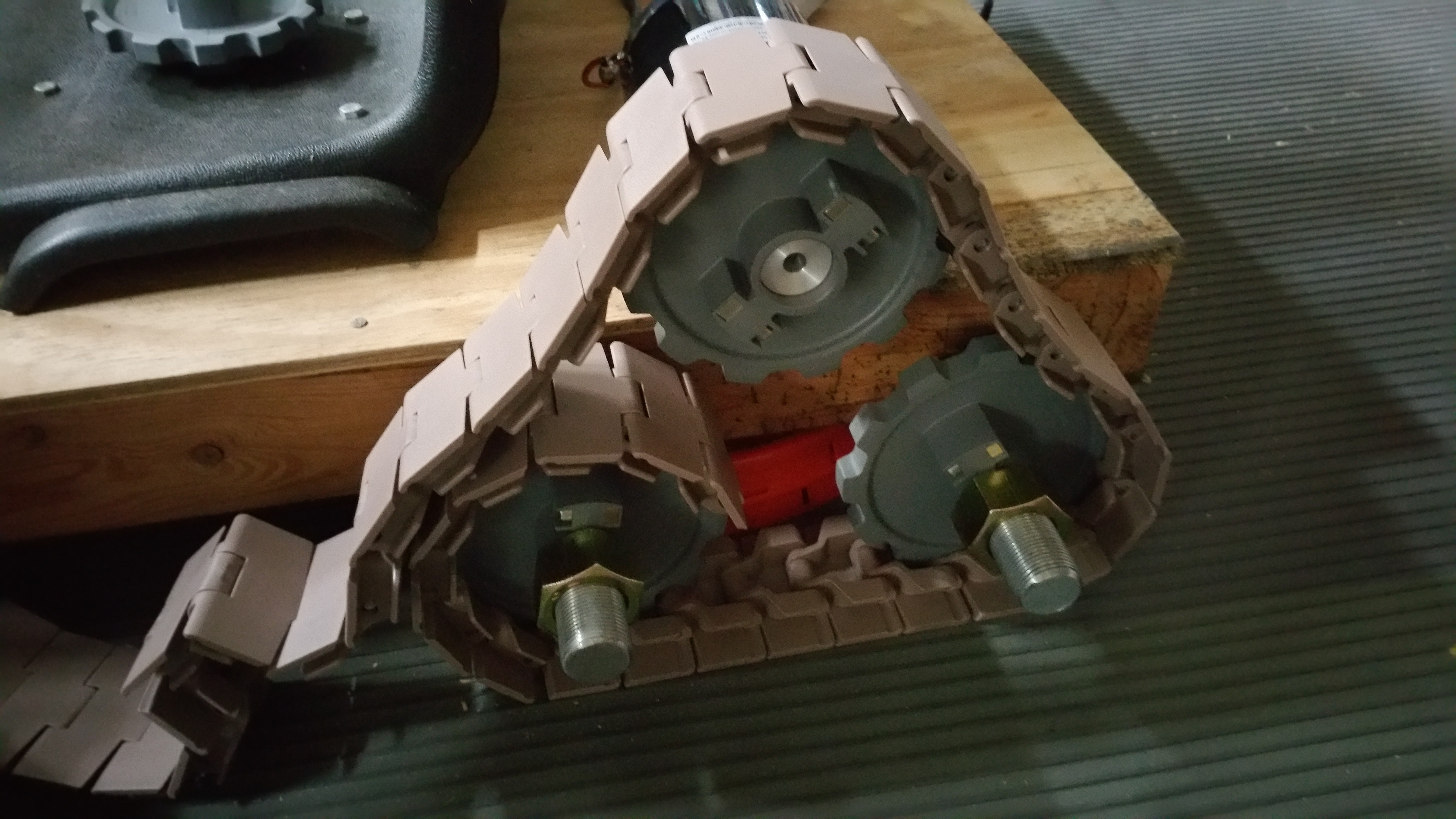

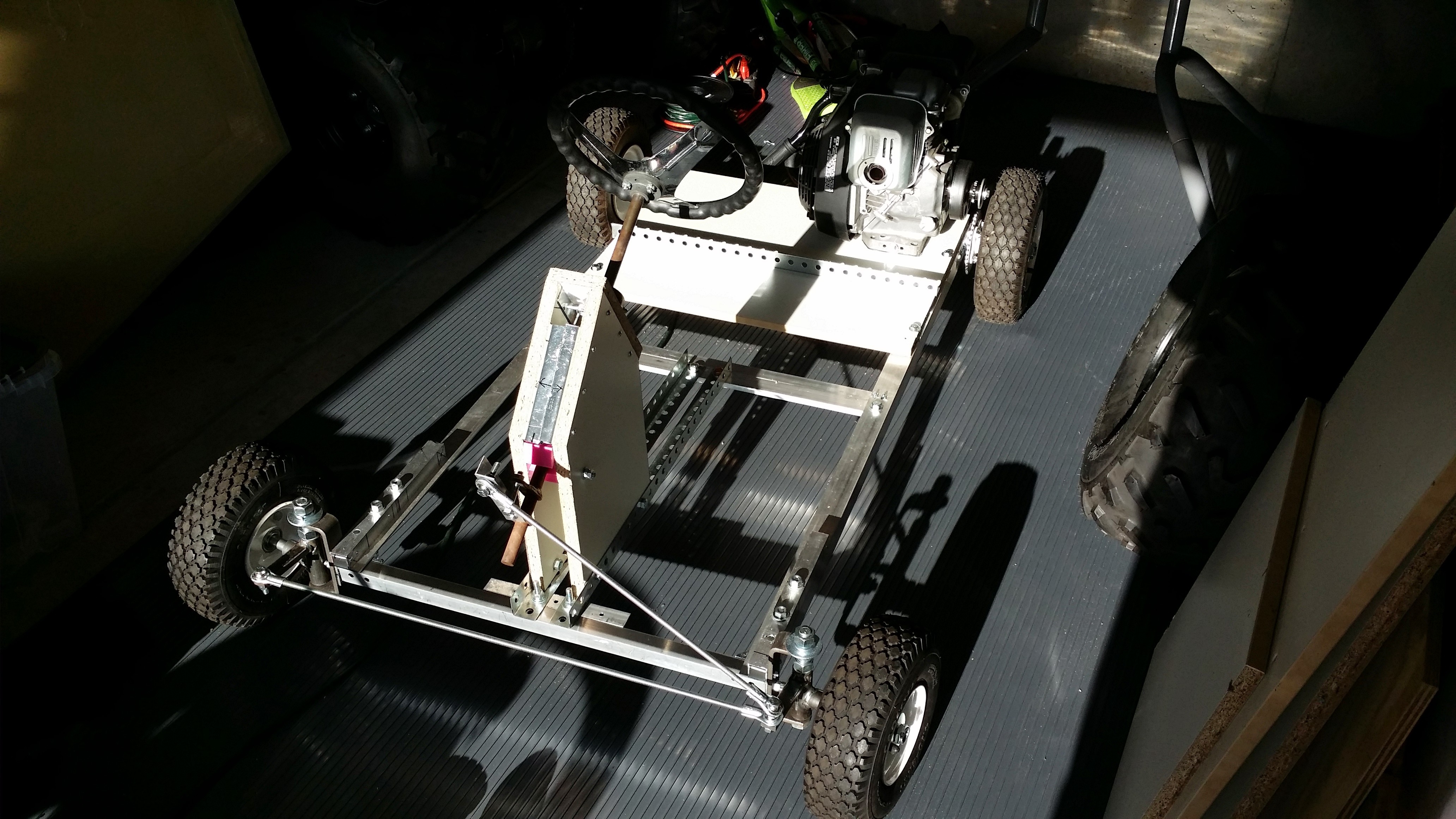

This started as an ATV build using big tires with the hope of using rubber tracks made from a treadmill. But over time it evolved into converting my very fast (30mph+) go kart. Originally, a differential was planned so that I could use differential braking and the same gasoline motor. But an invitation to a Maker Faire and the prospect of rolling it around indoors as well as outdoors said "no exhaust", so I went all electric. What is cool is that the throttles are small thumb throttles, so if this turned all tank, the steering can be handled with all of 2 fingers.

Update: It's all done! In the end I had to device a track tension/sprung bogie system to keep track tension. Used a BMX bike shock, some pieces of angle and a small piece of square tubing. Works like a charm. The is underpowered though. I might convert it to gasoline engine power just because I can put a 6.5hp motor that ways 30lbs in place of the 80lbs of motor and batteries and get triple the power. Very happy with the outcome. I had a 100lb kid ride it just fine, but a 200lb adult is too much for the 2.5hp I can get out of the electric motors.

Quinn

Quinn

jellmeister

jellmeister

polyfractal

polyfractal