So, with the cabinet assembly manual version .001 done and the materials list entered, I decided to get back to the fun part: Trying it out! For a material I settled on an acrylic/methylene chloride mix in a 70/30 ratio by volume.

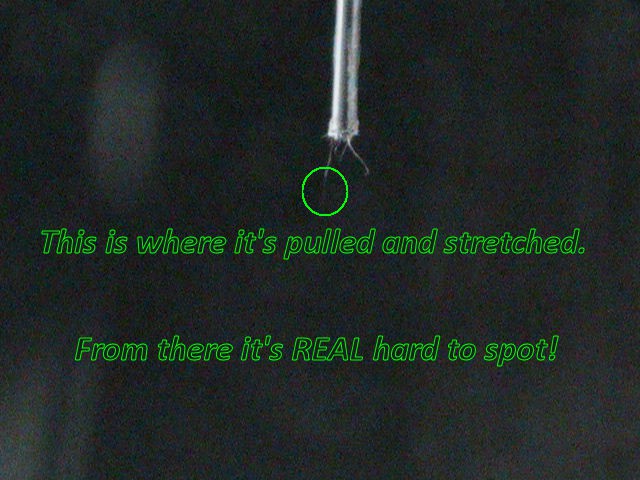

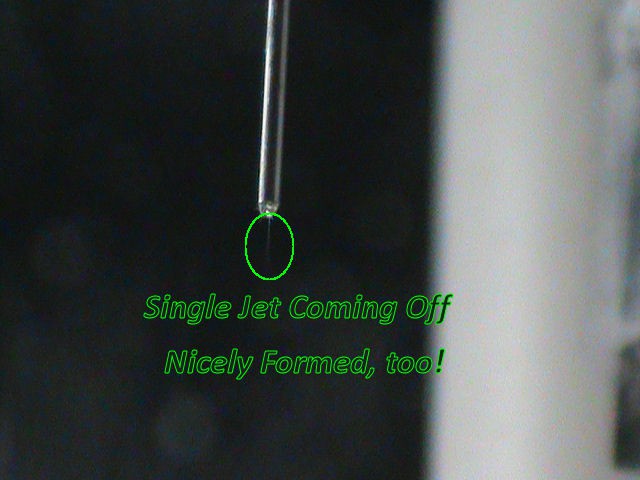

It pulls very nicely, probably my favorite material of those I've tried so far. I'll start by showing you what a decent jet looks like. Not perfect, but good enough.

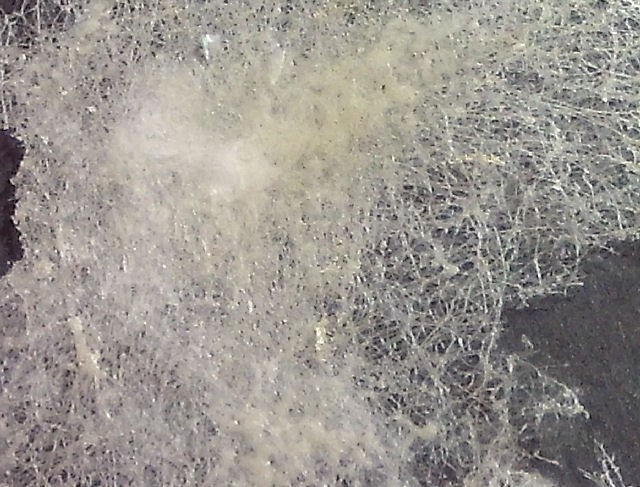

The mat is very flexible and holds together nicely. It takes a bit to pull it apart. I was surprised at that, and by how flexible it is. Not use to being able to cold bend acrylic like that. Average thickness is about .15mm.

The mat is very flexible and holds together nicely. It takes a bit to pull it apart. I was surprised at that, and by how flexible it is. Not use to being able to cold bend acrylic like that. Average thickness is about .15mm.

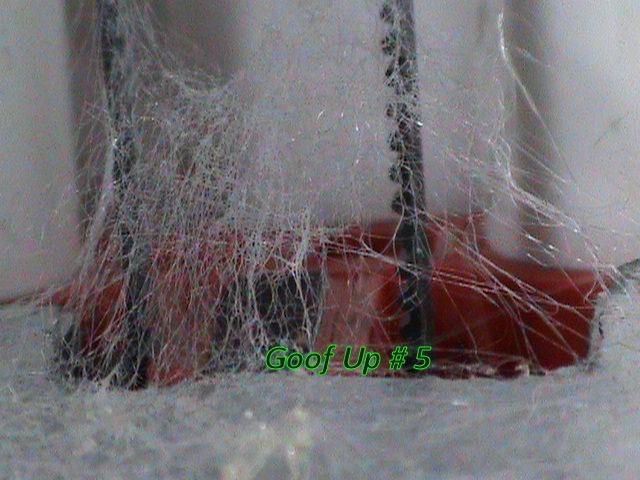

Now to the goof. No biggie, but I left bed plate all the way down when I started, and went at 18.5 kV. I based that on what the other materials had been doing, and as it turns out acrylic loves to be pulled. So what happened is it went about everywhere. Anywhere it could find a landing spot, it did. And the fibers were longer than I had expected, too. I was getting some that were 250mm long, as no thicker than a human hair. The REAL thin ones were impossible to see. I stuck my hand in the cabinet after a small run and I could feel them on the back of my arm, but still couldn't see them.

As you can imagine with them going all over the place the inside of the cabinet looked like a bunch of tiny spiders had moved in. Fibers large and small, everywhere...

See what I mean? Lol.

See what I mean? Lol.

Now I can get to what that mat looked like through a home made webcam microscope. The finest fibers I could spot through this contraption worked out to about .0065mm thick.

I really like the tiny little air bubbles in some of the fibers. :)

I really like the tiny little air bubbles in some of the fibers. :)

I'll finish this post by explaining why it was a goof. I didn't take the time to try to dial in the settings before I just let it run. As a matter of fact, for a while I just let it do it's thing and left the room.

The second goof was I didn't have the materials mixed up as well as I should have. I will have some video later today or tomorrow that shows what I'm hereby officially calling 'blossoms'. It's going to take the video to show you what happened, so I'll get that up as soon as I can. It's kinda neat, but not really something I want to happen too often.

I'm learning here as much as you are, and doing it the hard way. But that's okay, that's what it's going to take to open up a whole new area for us amateur scientists and makers and tinkerers to explore.

Douglas Miller

Douglas Miller

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.