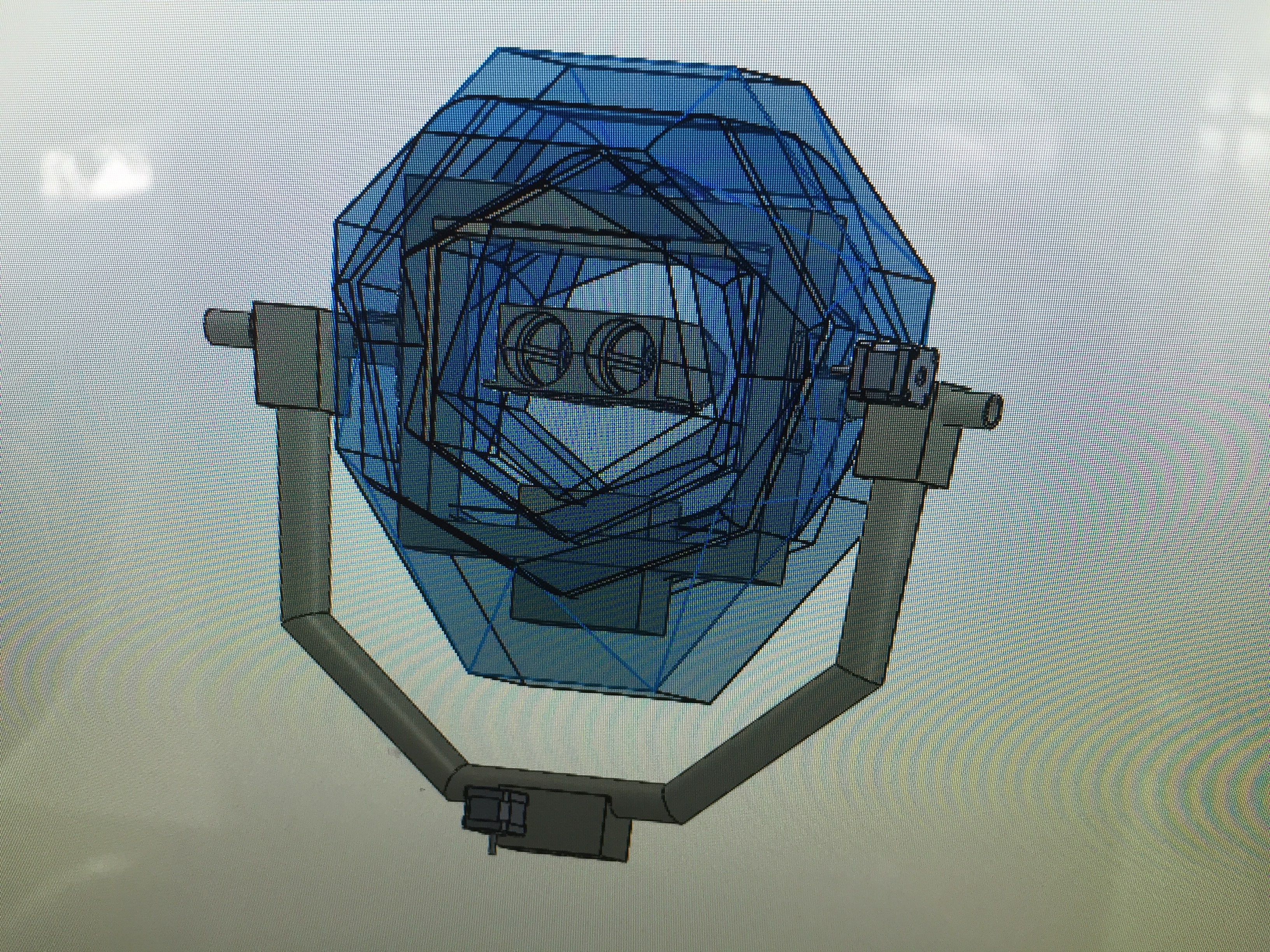

Now that we've got a good sense of the internal layout, the big focus of this past week has been getting all the pieces in together to make the positive of the shell for vacuum forming.

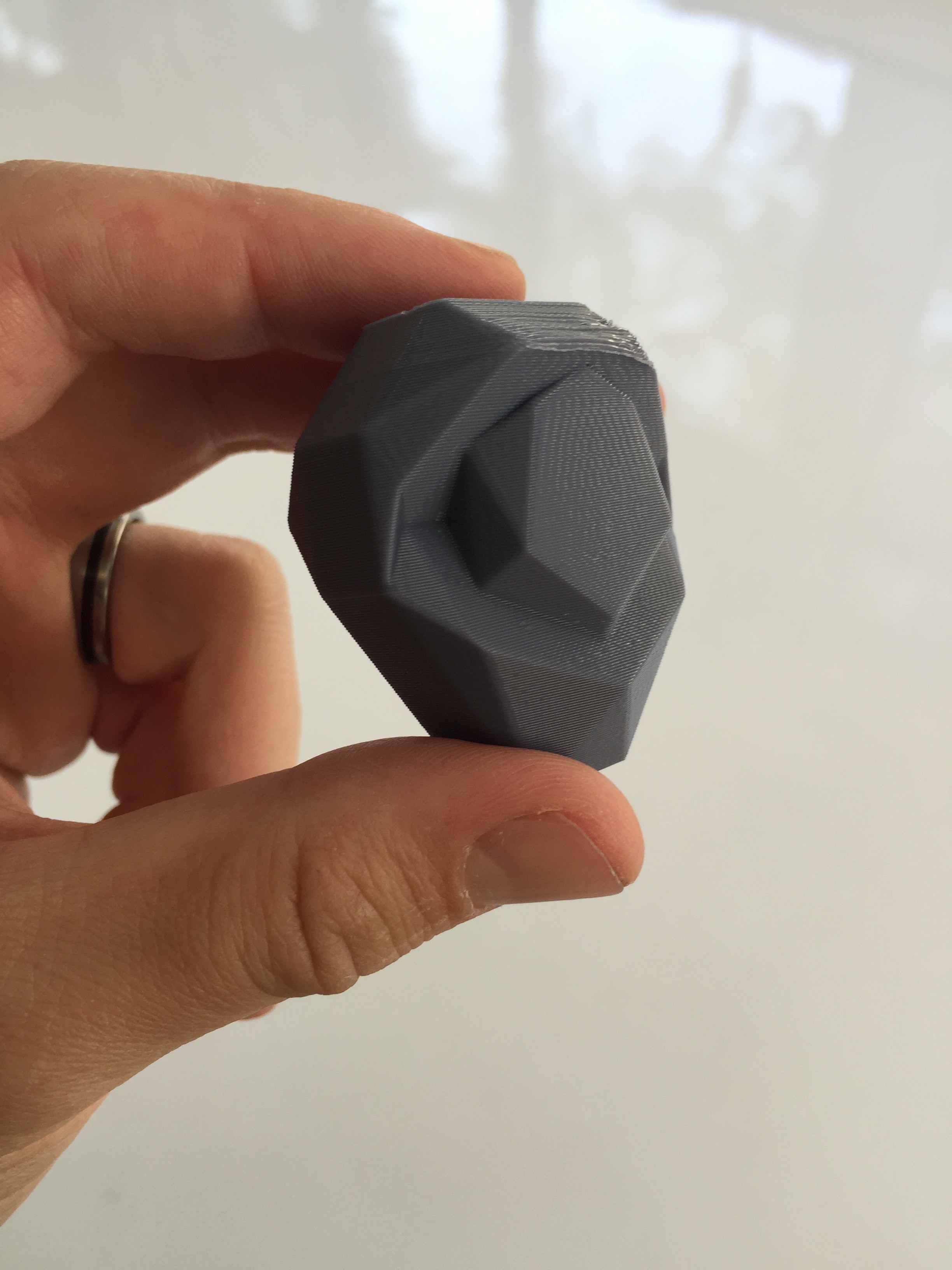

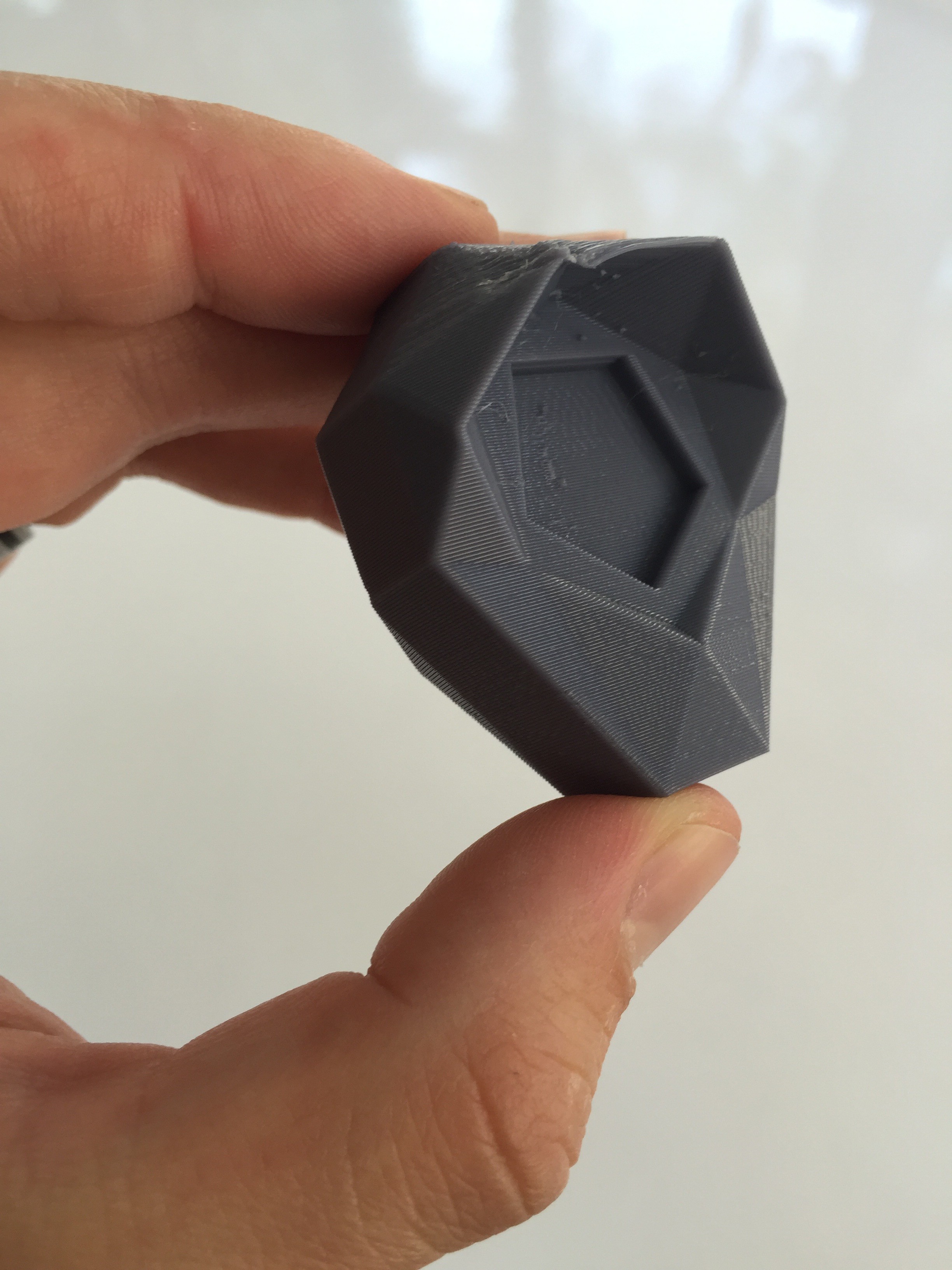

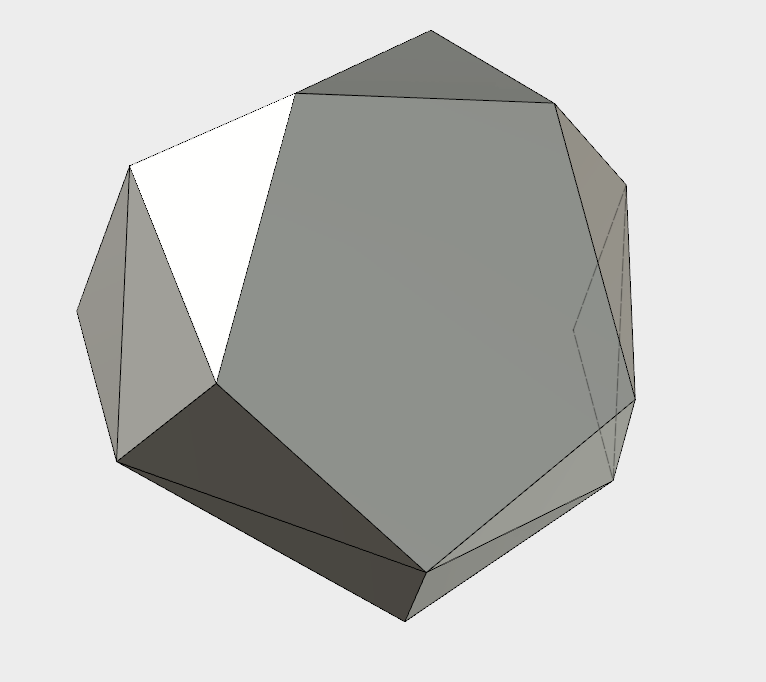

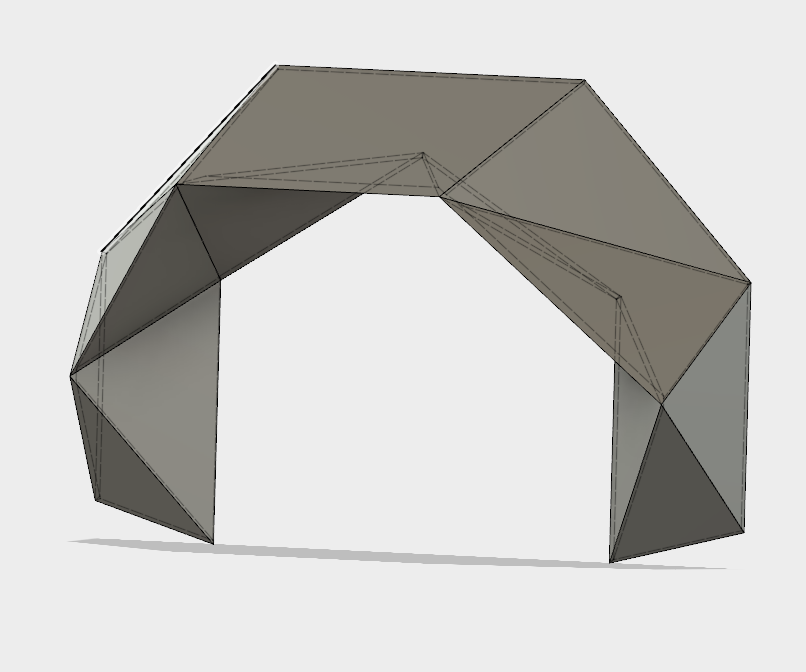

It took of lot of CAD work to get things feeling and fitting just right, and I never could have anticipated all the challenges ahead with actually making it full size. To start, I 3D printed another scale model. This is the model we'll use when producing the final mold.

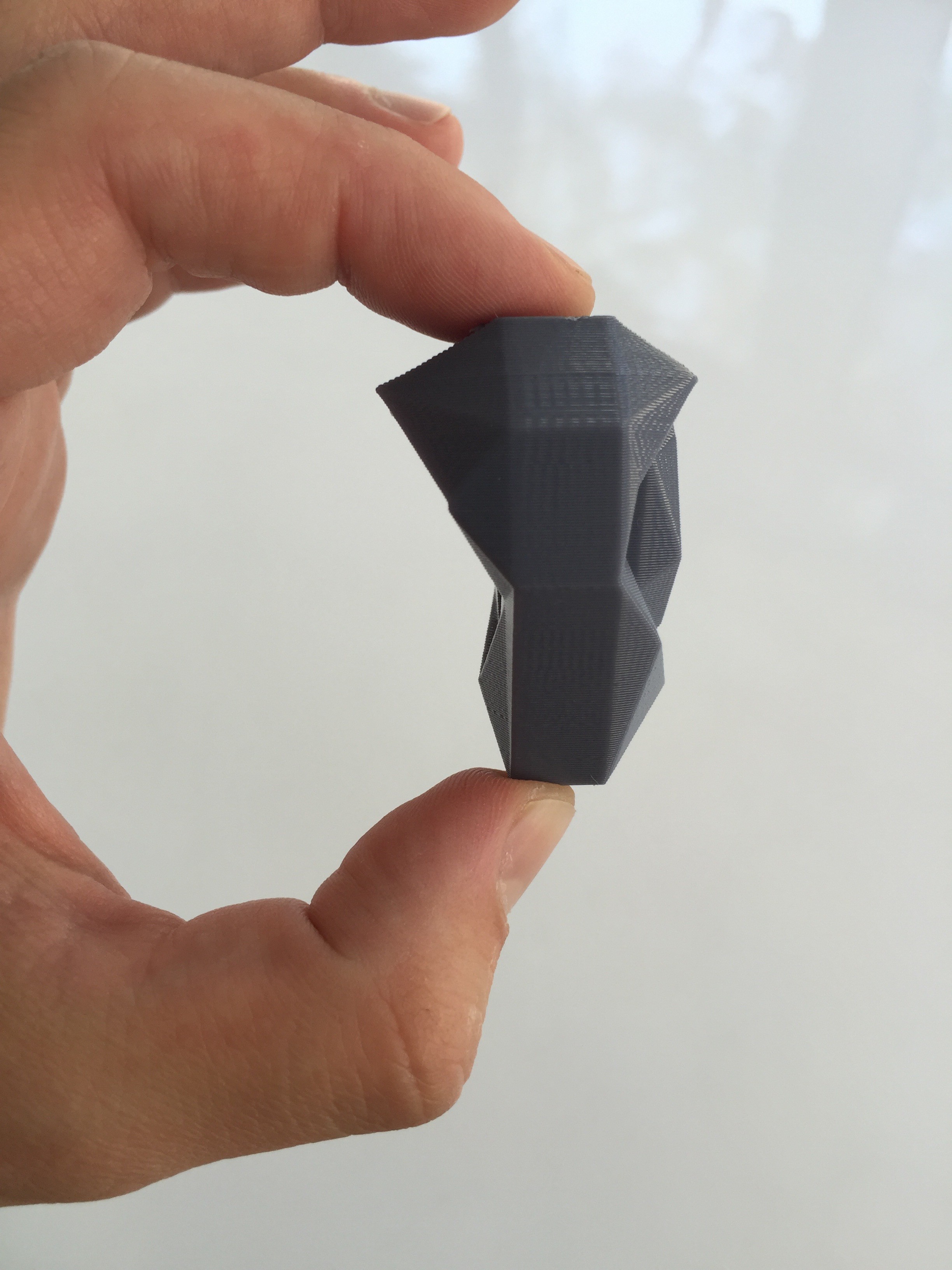

It got a little melty on the printer, particularly over the shroud that will surround the eye-piece area, but I'm really liking how this turned out.

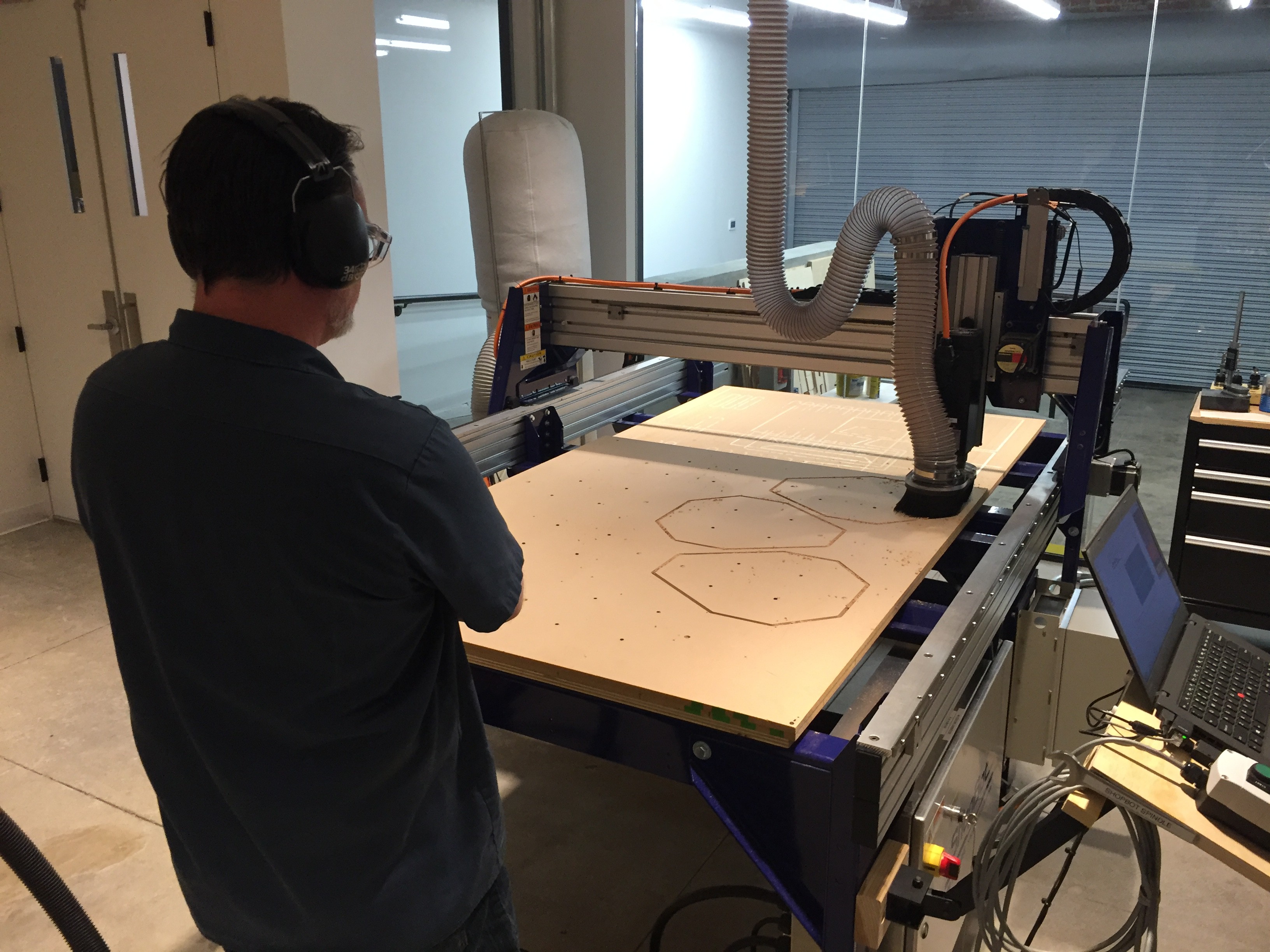

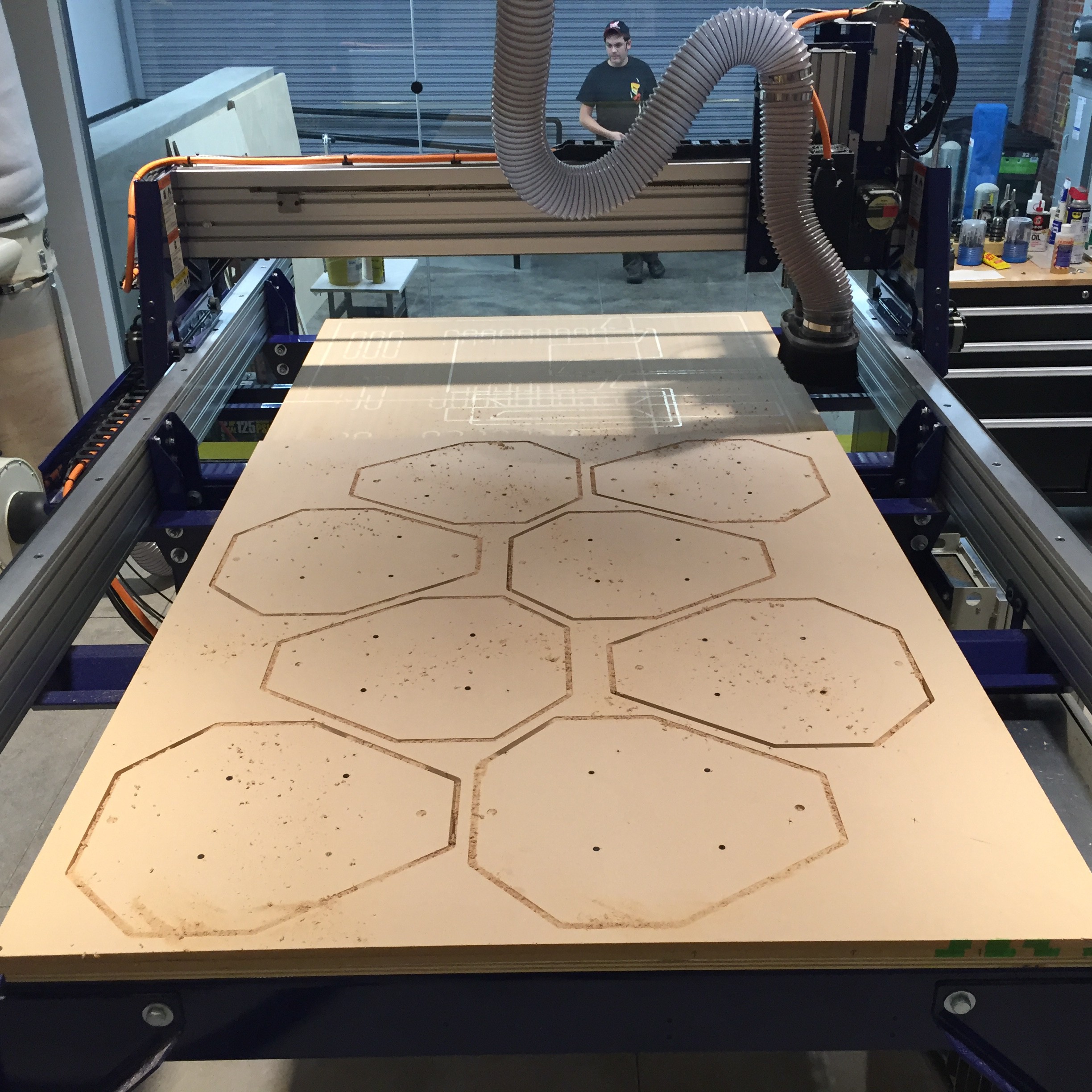

Milling it on the ShopBot out of MDF has proven to be its own set of challenges. For one, I was trying to slice the model for 3D carving but with all the different tool paths required the ShopBot would have had to run for 4 days straight. Clearly there's a better way to go.

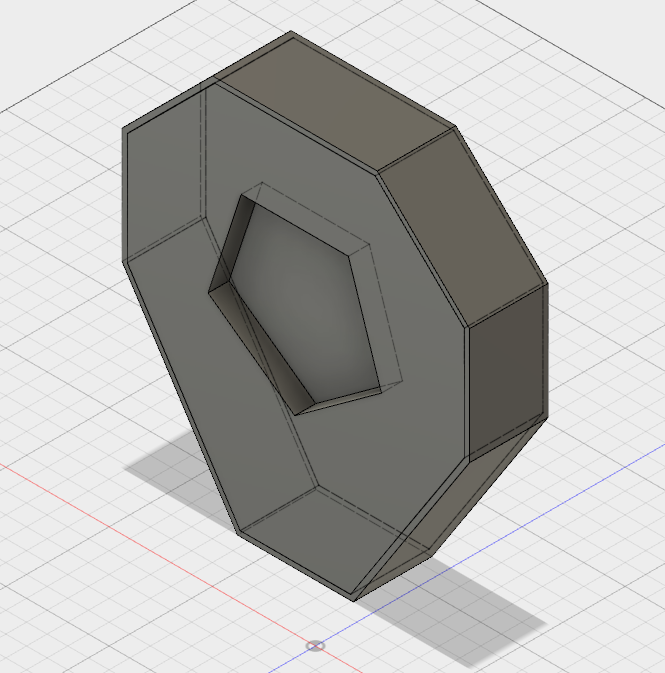

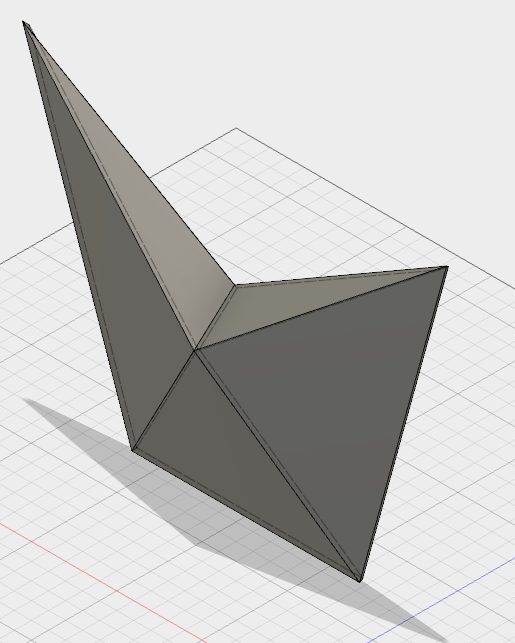

I started by manually slicing the model into easier to manufacture individual components. There are six parts total -- one main large body that's pretty easy to produce with 2D operations, and then another set of accoutrements that help the end users understand functional issues like front and back, or help shade them as they use it.

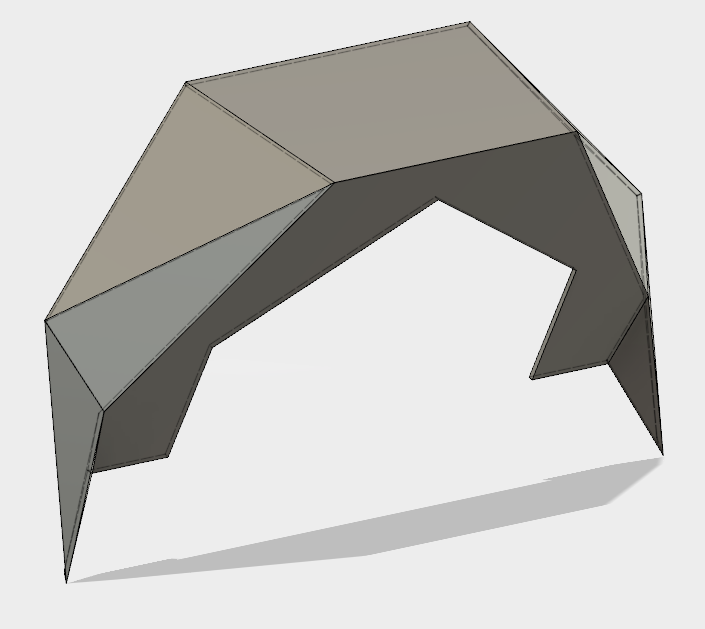

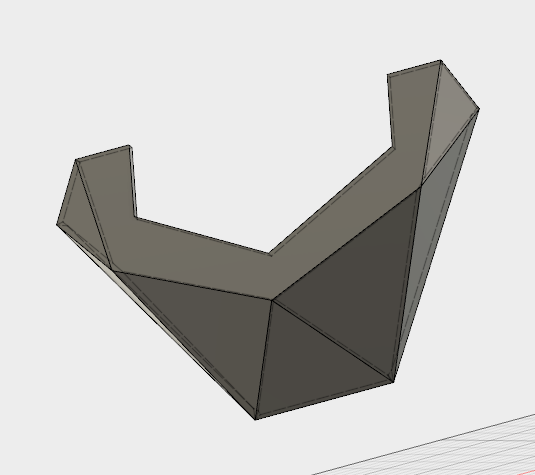

These next three components are on the side opposite of the viewer's eyepiece, and the round geode component will be made out of a semitransparent material so the binoculars can see through it.

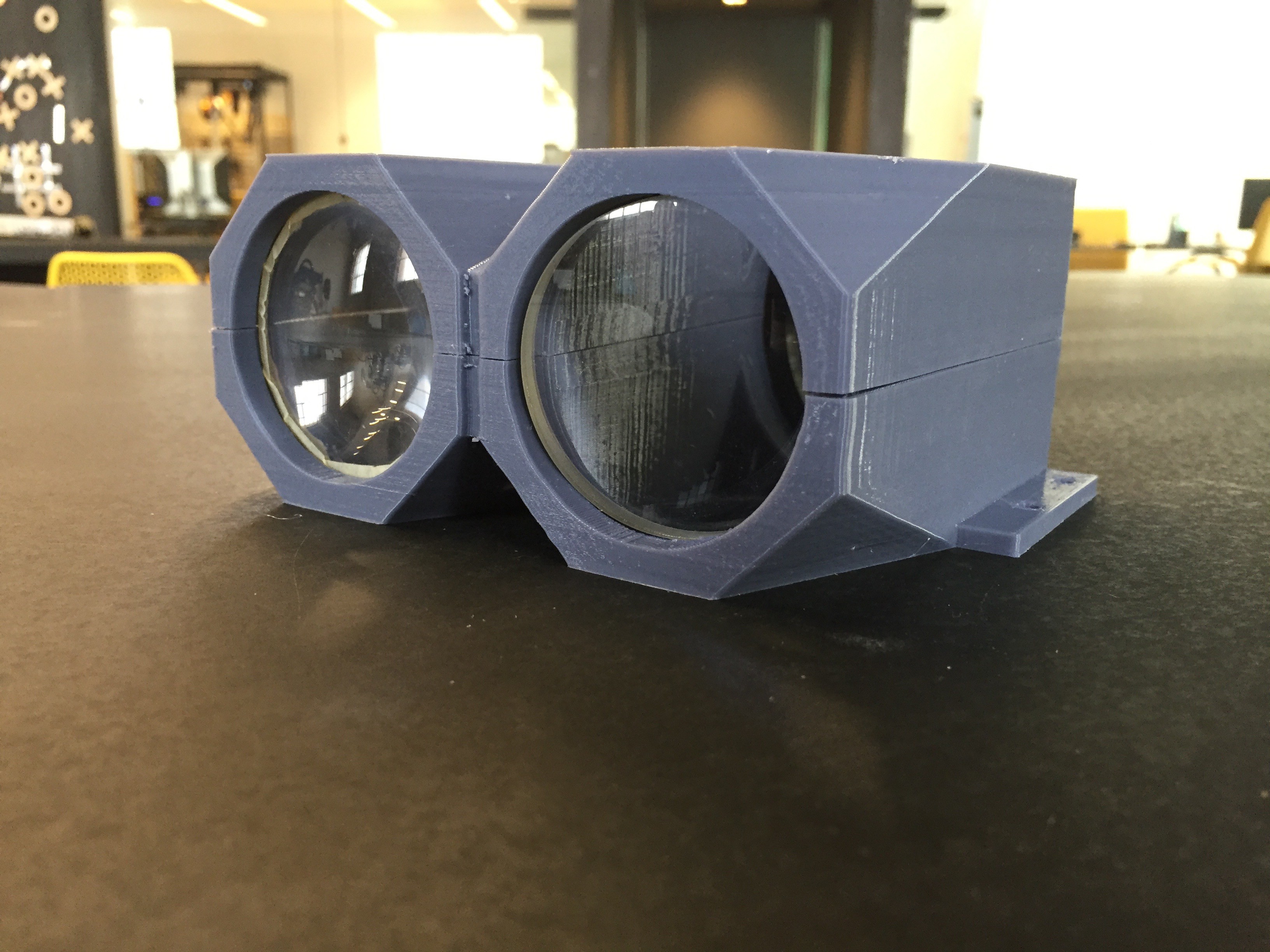

These next two piece are on the eye-piece side of the Scope, and hopefully will be inviting enough to pull a passerby to look through.

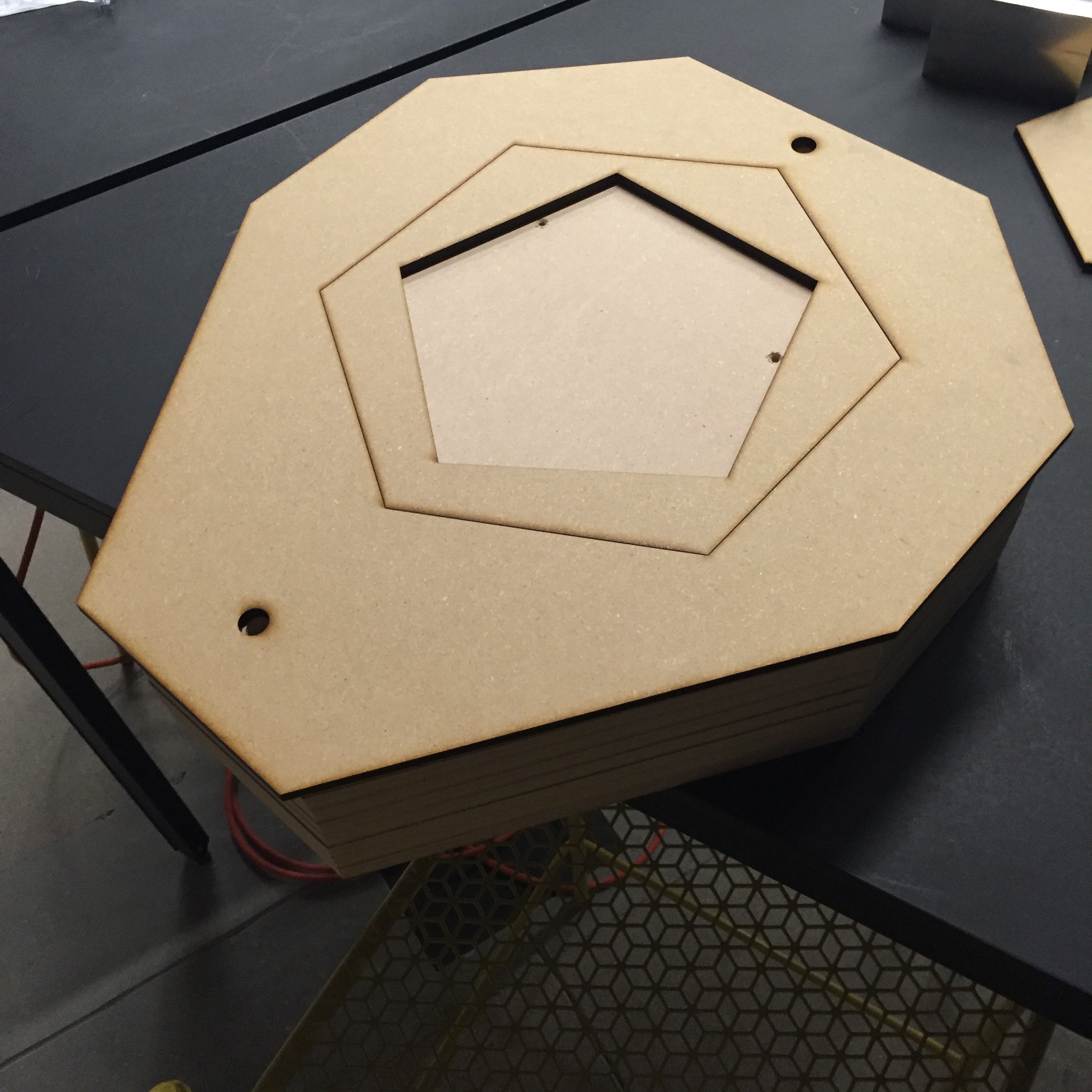

Dan and I were able to get the main body component milled out in slices of 1/2" MDF on the ShopBot towards the end of last week.

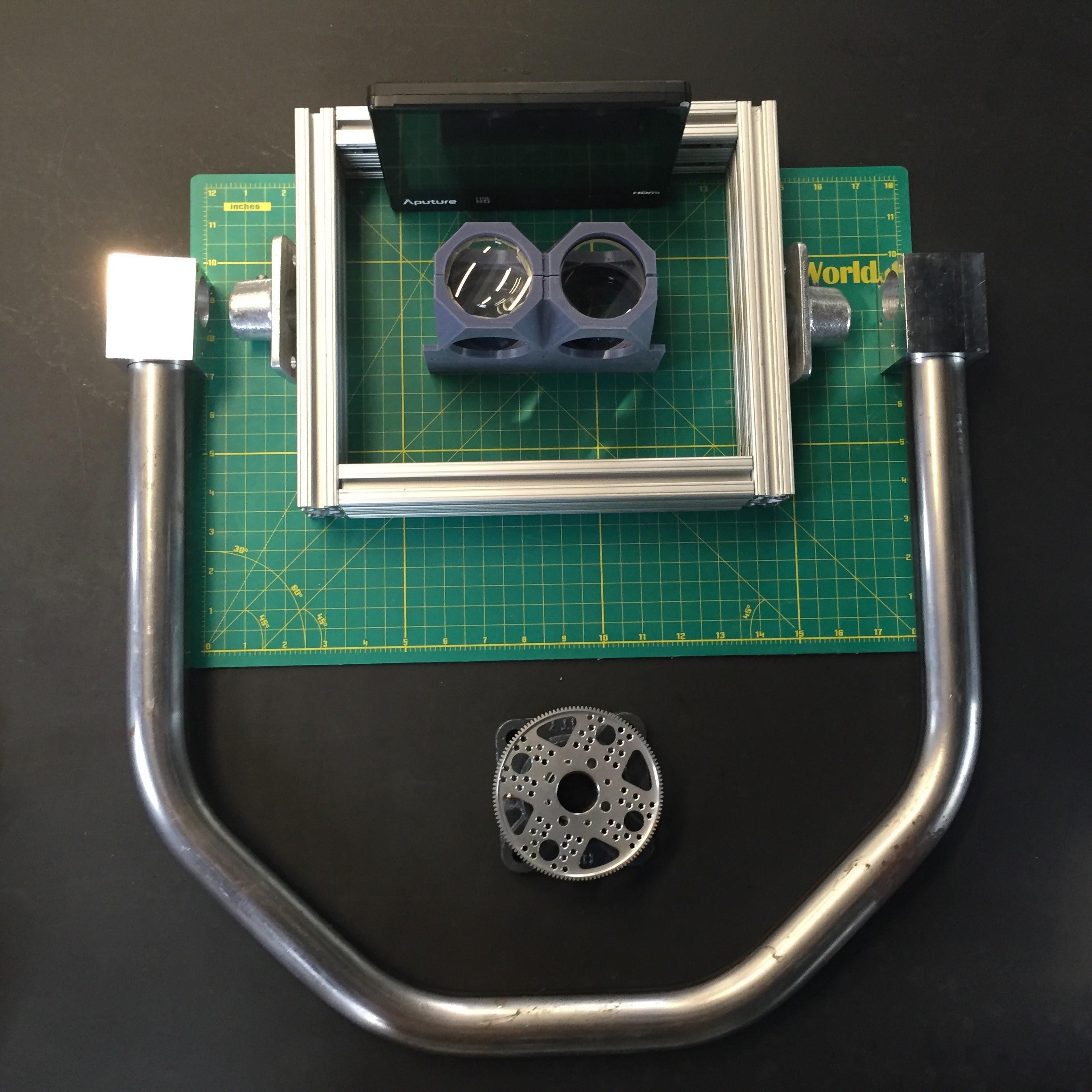

I also laser cut a panel out of 1/4" MDF to use as an adaptable faceplate for each side of the vacuum form pull. Thickness and physicality of the whole thing is looking just right.

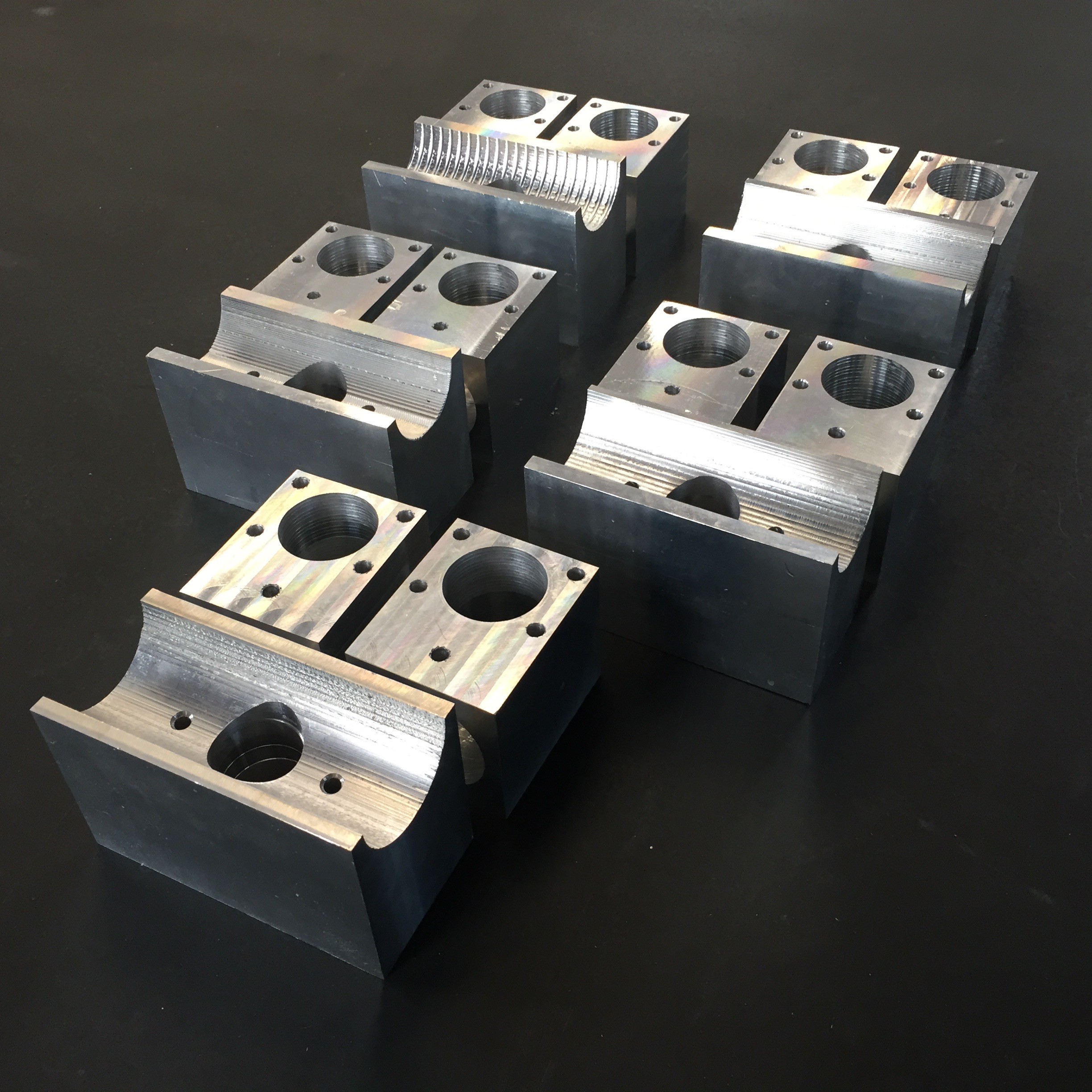

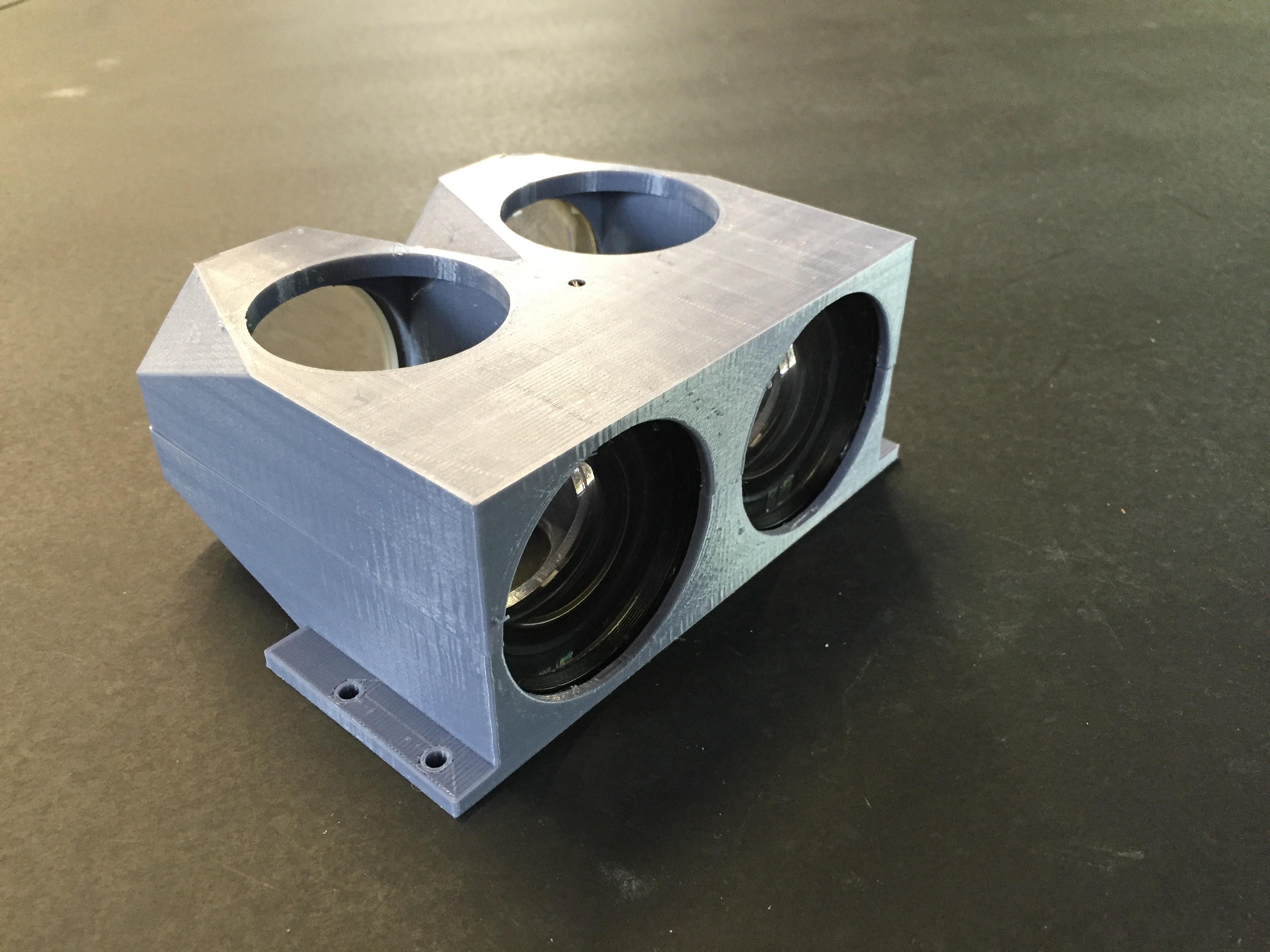

In terms of there rest of the project, I made some progress on assembling the internal frame out of 80/20 T-Slot. We also finished up producing enough bearing blocks to make five new Scopes, and I came up with a cool design for my final optical housing.

With just a week left in the residency there's still a decent amount of things left to do, but at the very least I should be able to walk out of here ready to scale this project significantly.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Really like the shape of that shell

Are you sure? yes | no

Thanks Richard! I'm pretty excited to see how it feels full sized.

Are you sure? yes | no