Here's the deal...

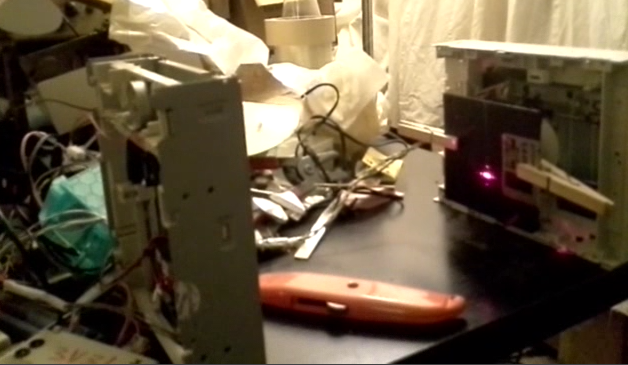

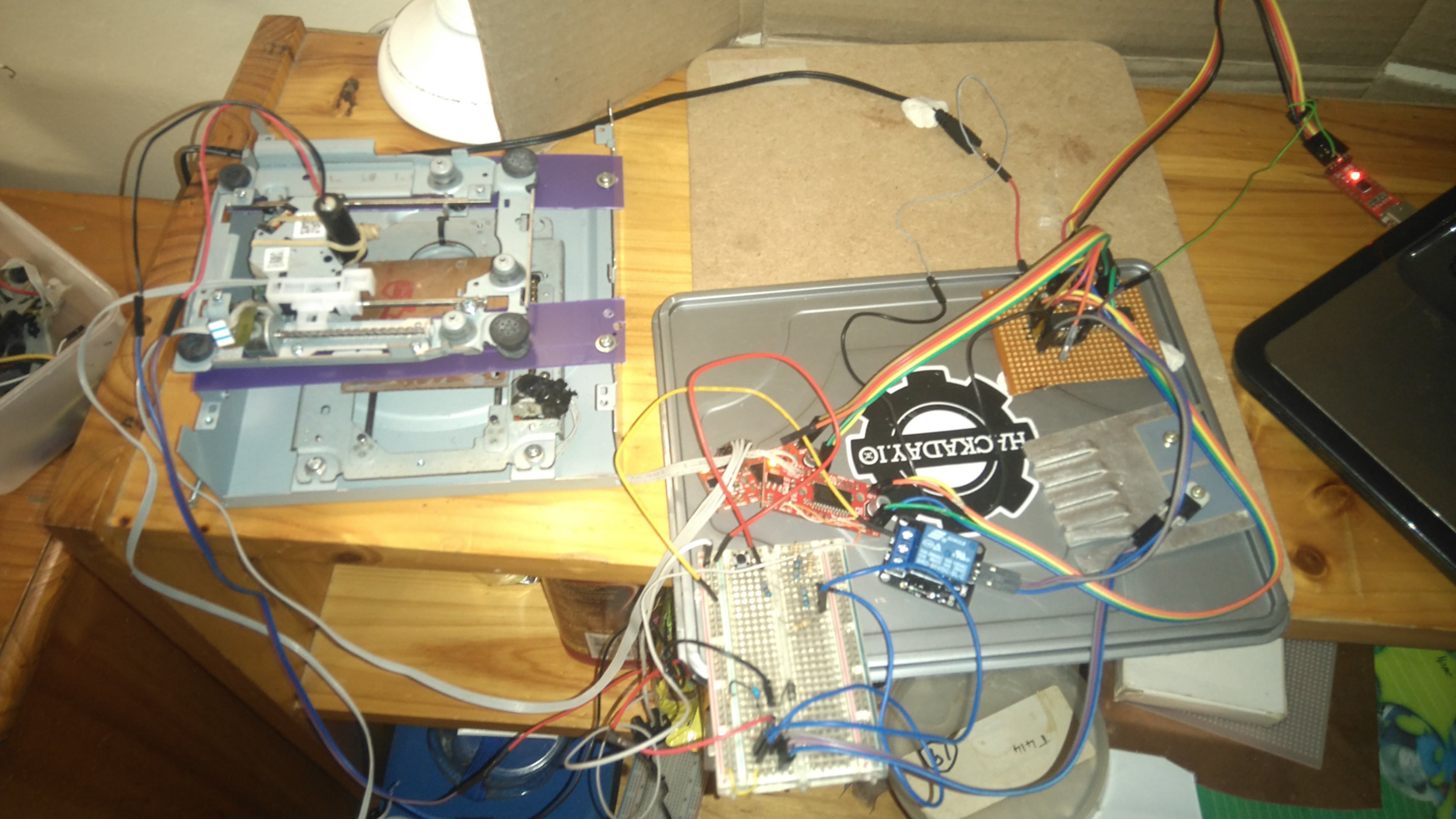

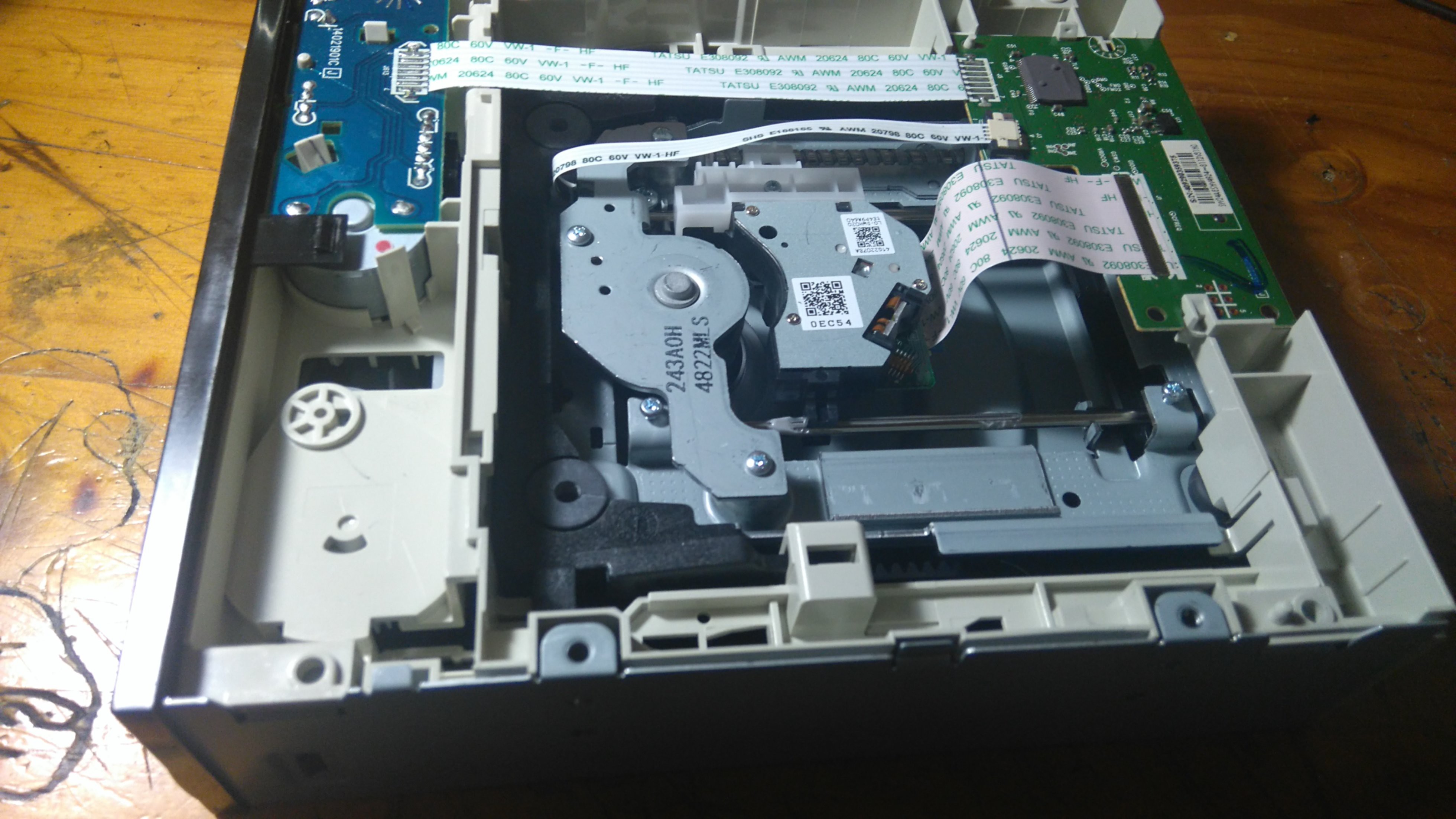

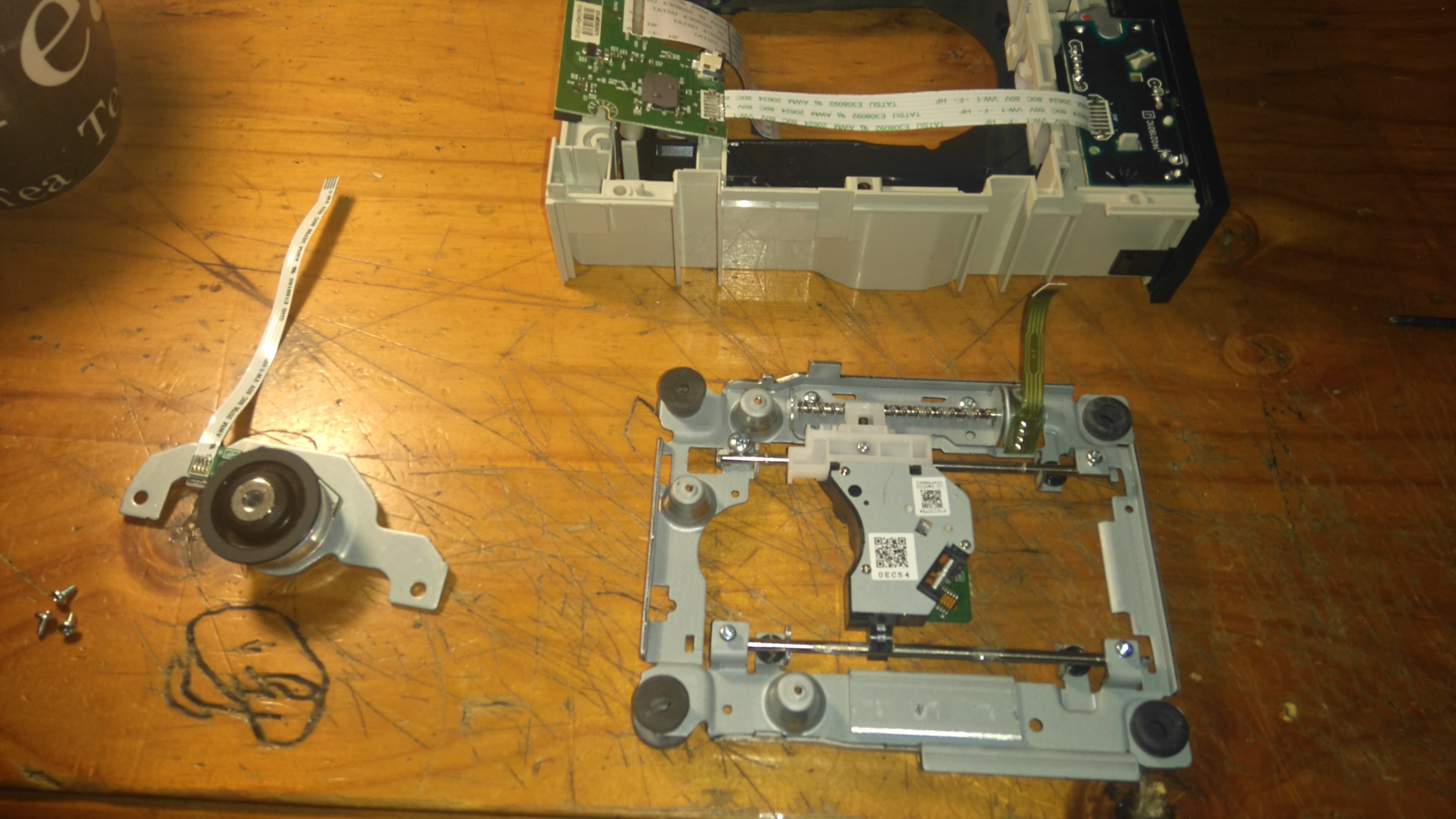

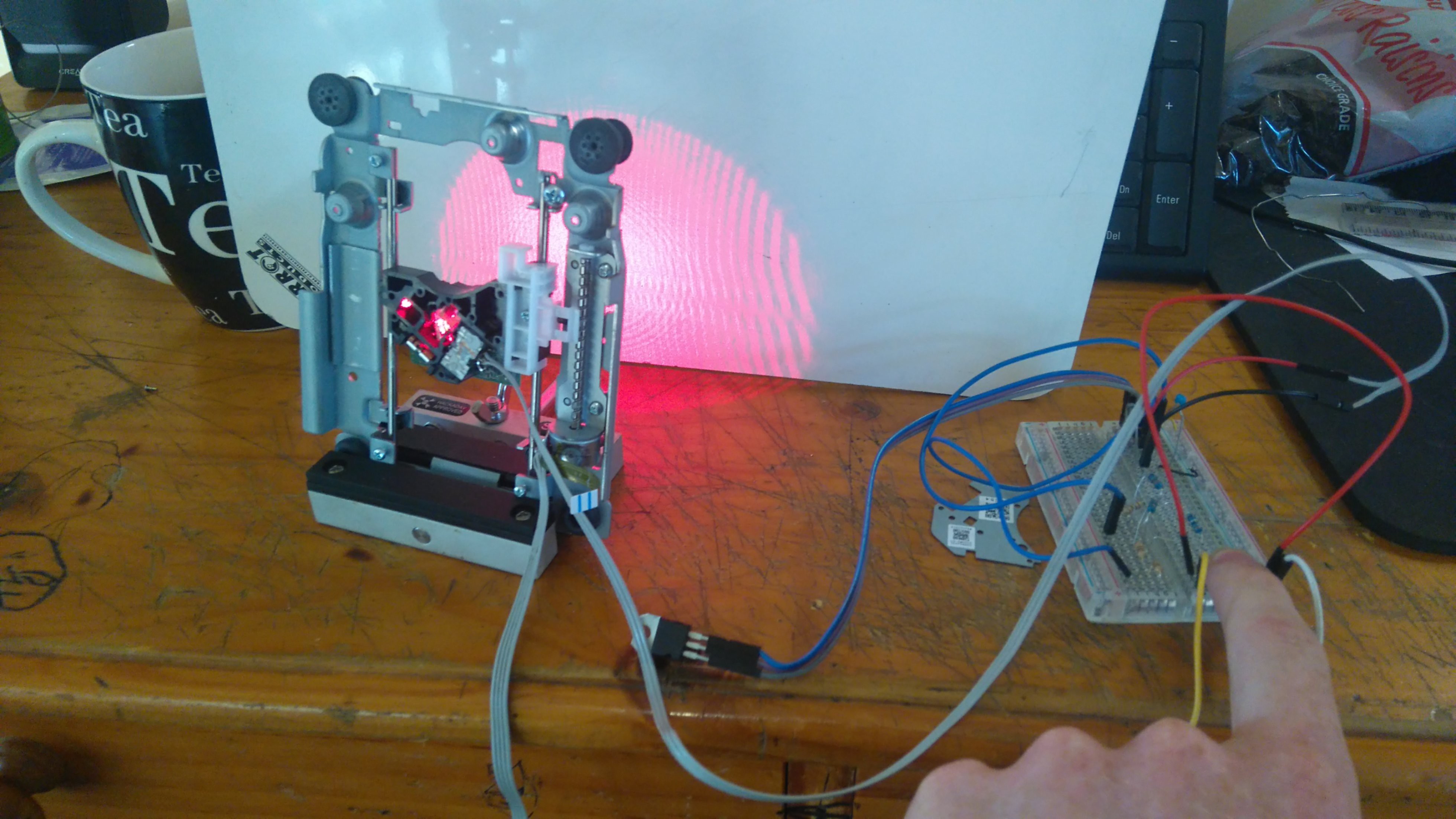

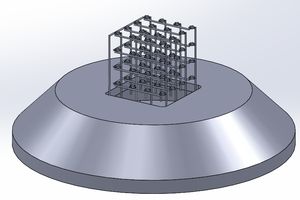

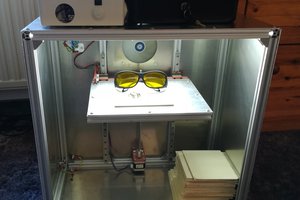

So, you've got a couple spare DVD drives sitting 'round...

And an office down the street is throwing away an old ("empty") laser-printer toner-cartridge...

And you'd like to make Printed Circuit Boards!

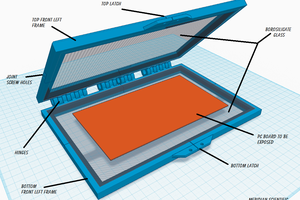

So, briefly:

- coat your regular-old copper-clad board with a mixture of toner and alcohol

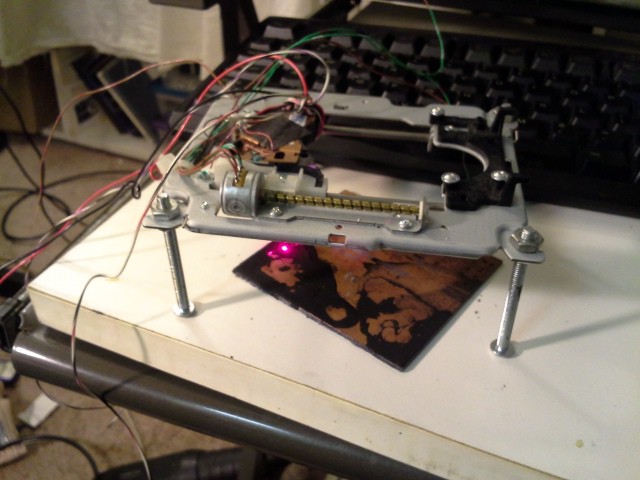

- use your old DVD-drive's laser to melt that toner wherever you want traces

- clean off the unmelted toner

- (Heat the board to set the traces)

- etch your PCB

This technique can also, likely, be used for e.g. silkscreened labels on instrument panels, and more!

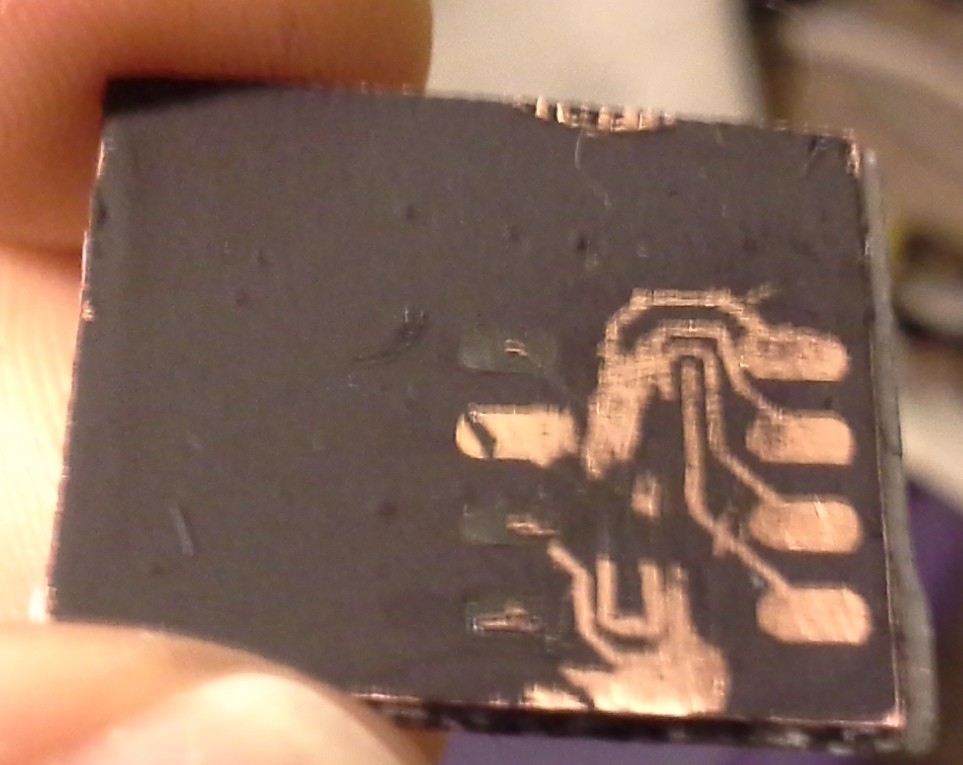

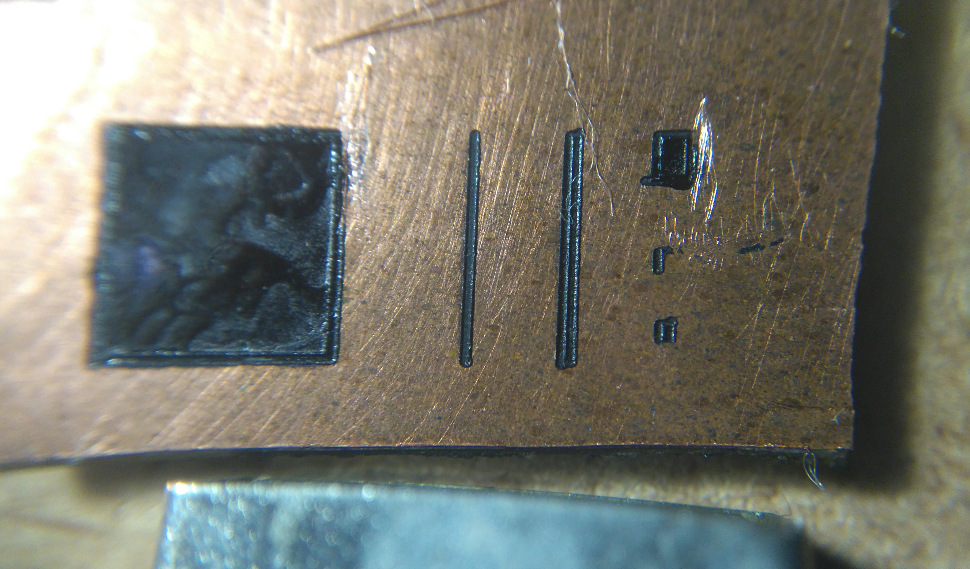

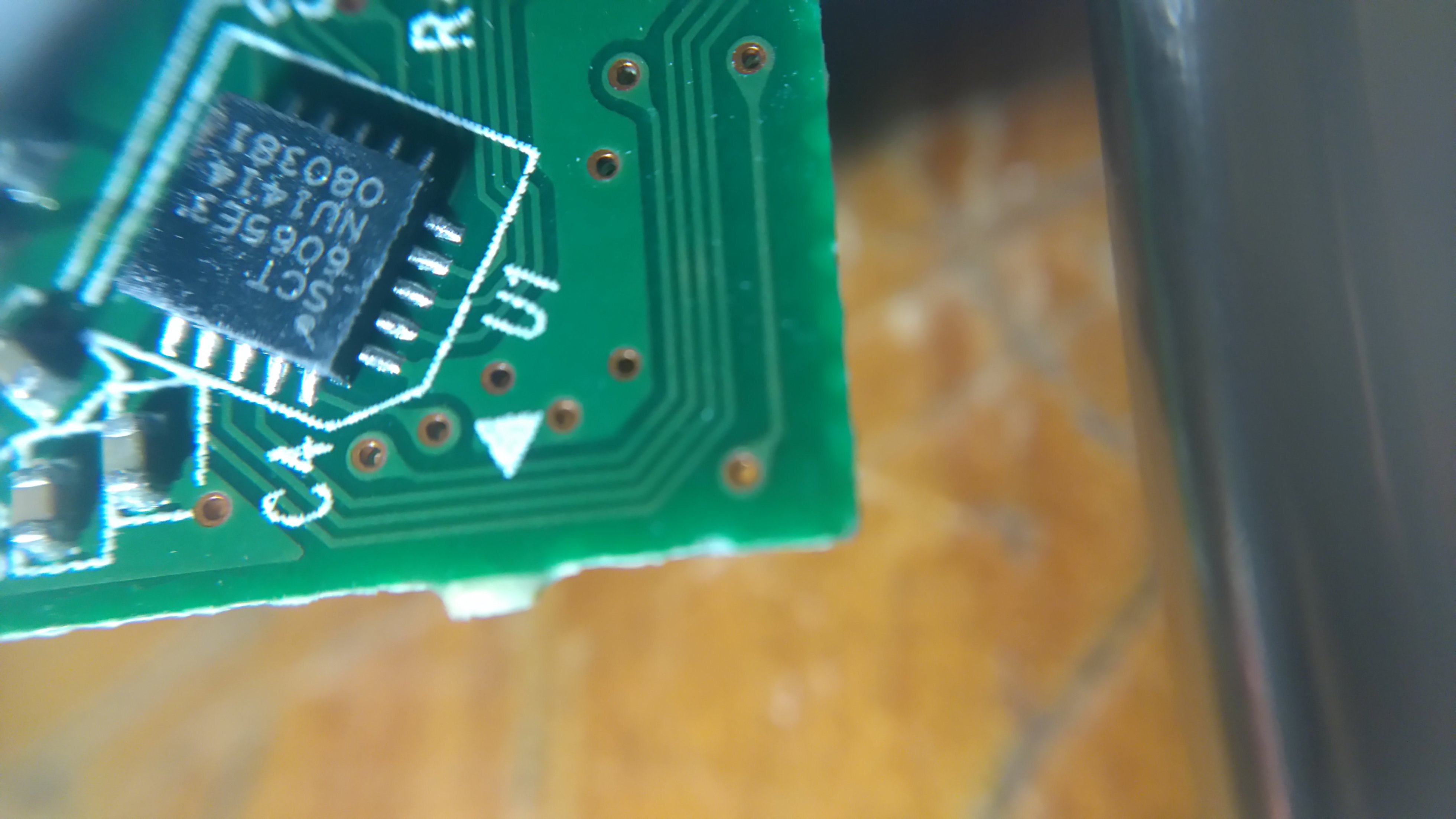

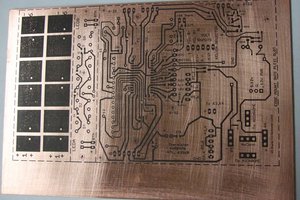

Here's some early proof-of-concept experiments!

johnowhitaker

johnowhitaker

(

(

Jarrett

Jarrett

Dominik Meffert

Dominik Meffert

mosaicmerc

mosaicmerc

fl@C@

fl@C@

Did try by any chance applying the laser to a PCB coated with permanent marker or a etching ink carbon ? . i'm wondering if it will carve away or stick more .