After the ceramic green tape is blanked and via punched via a laser, printed with inks, the various layers stacked on a fixture it is necessary to laminate the layers together via the isostatic press.

To laminate the tape, the various stacked layers are placed in a pouch and vacuum sealed. So, I thought to myself, why go to the trouble, "not really that much trouble", of vacuum bagging when I could just manually press the pouch free of most of the air and rely on the extreme pressure of the hydraulics to overcome whatever air is present within the pouch? Wouldn't that be enough? I think the answer is yes. However, there is a problem.

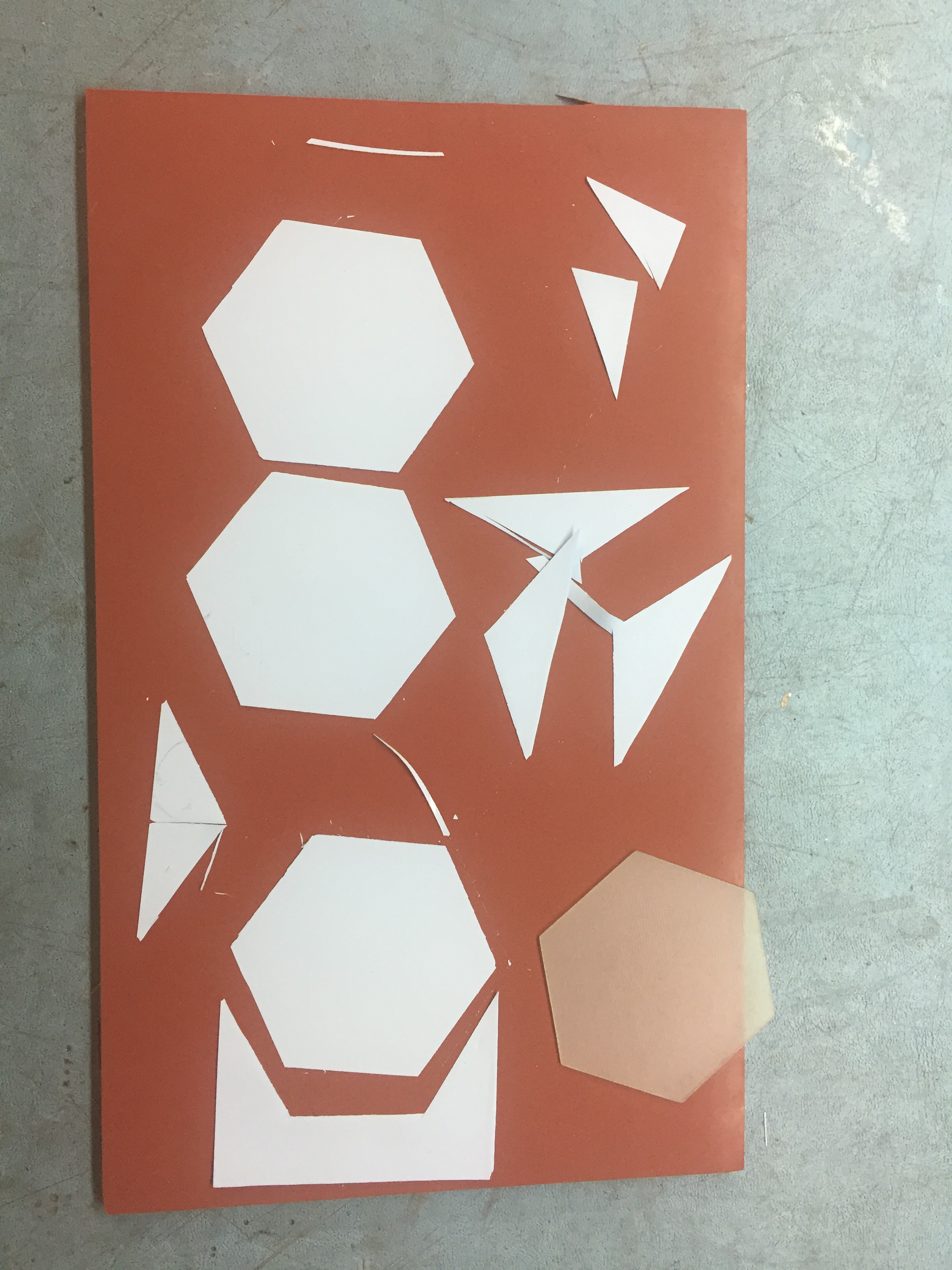

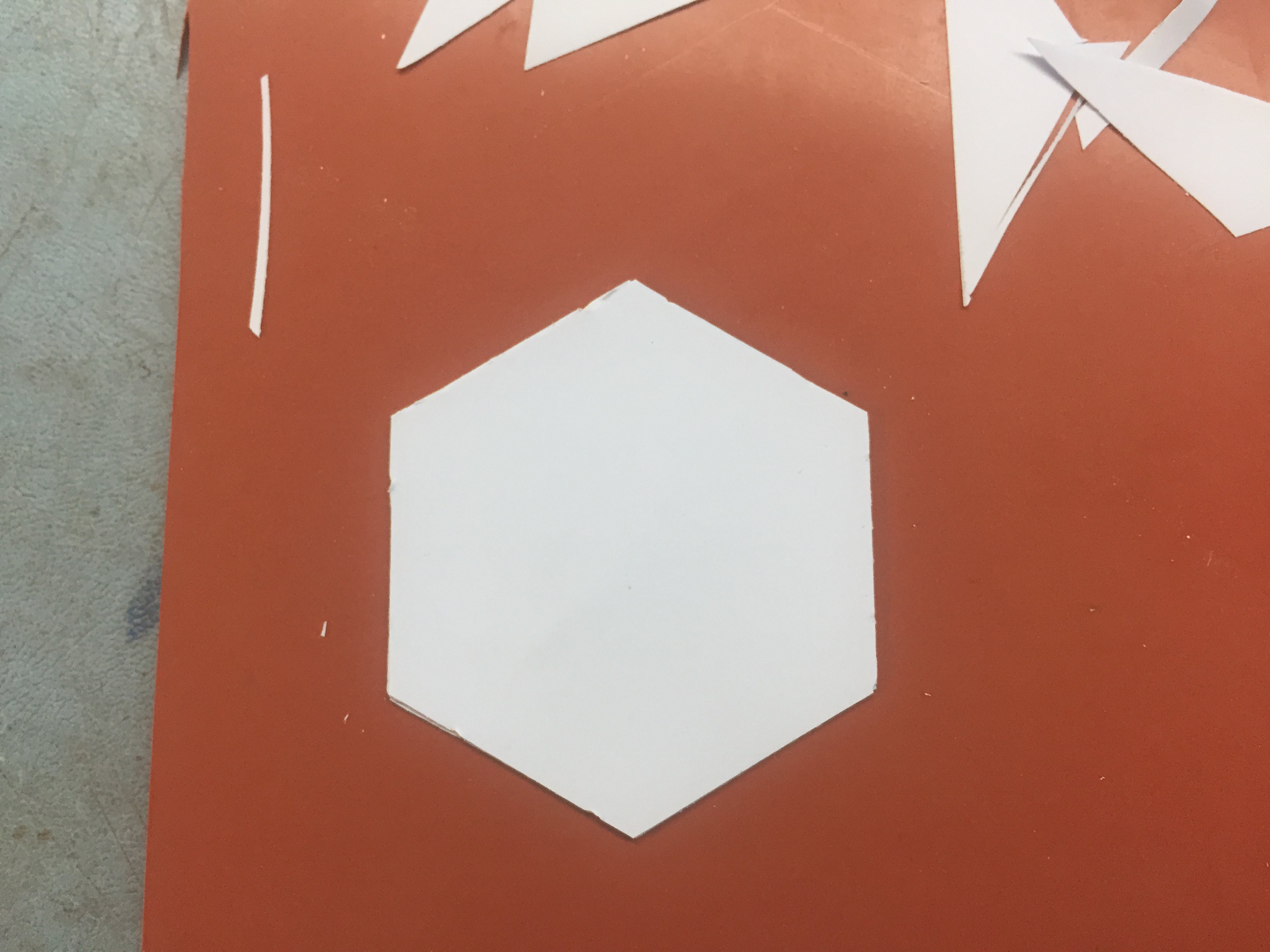

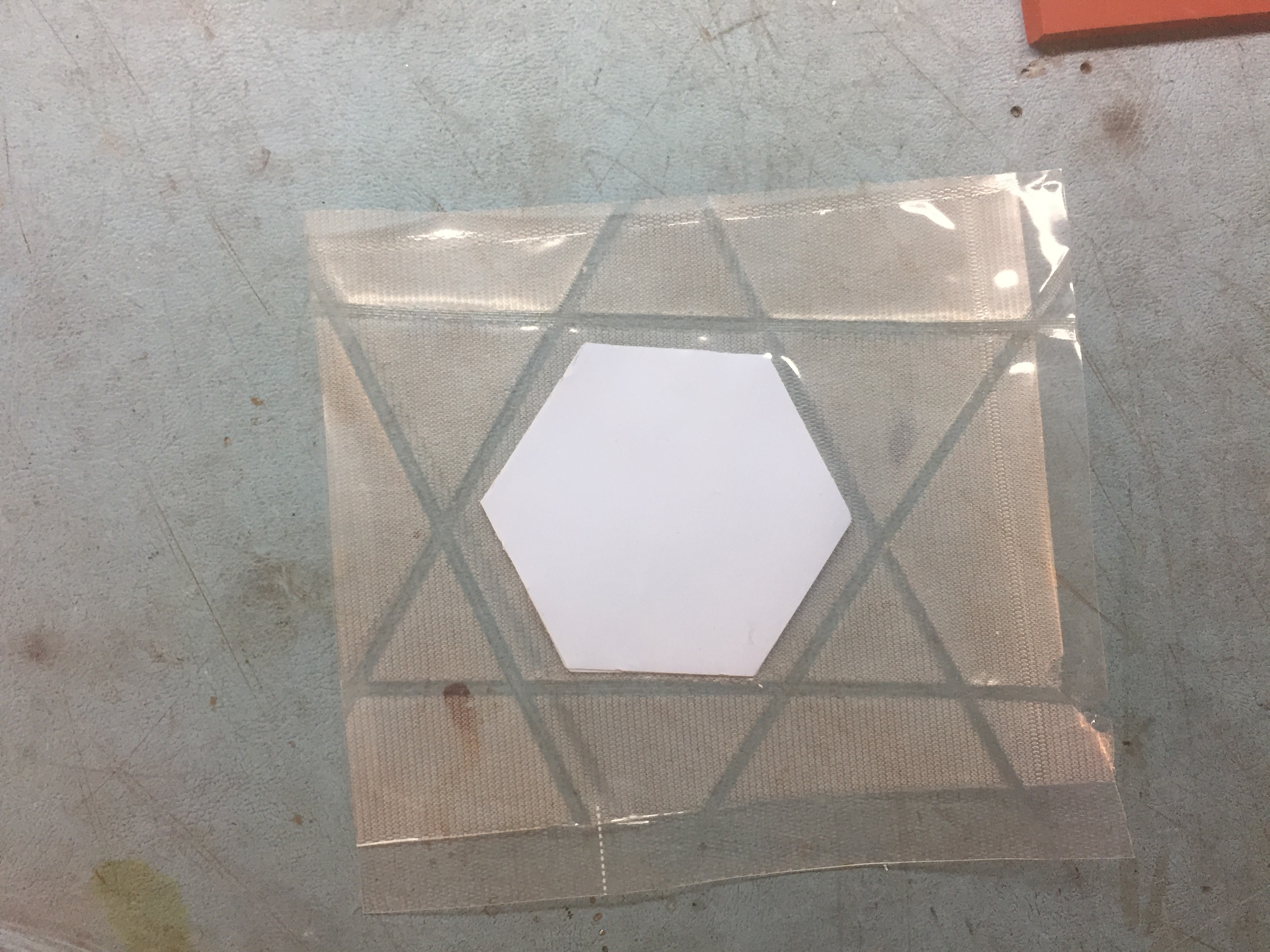

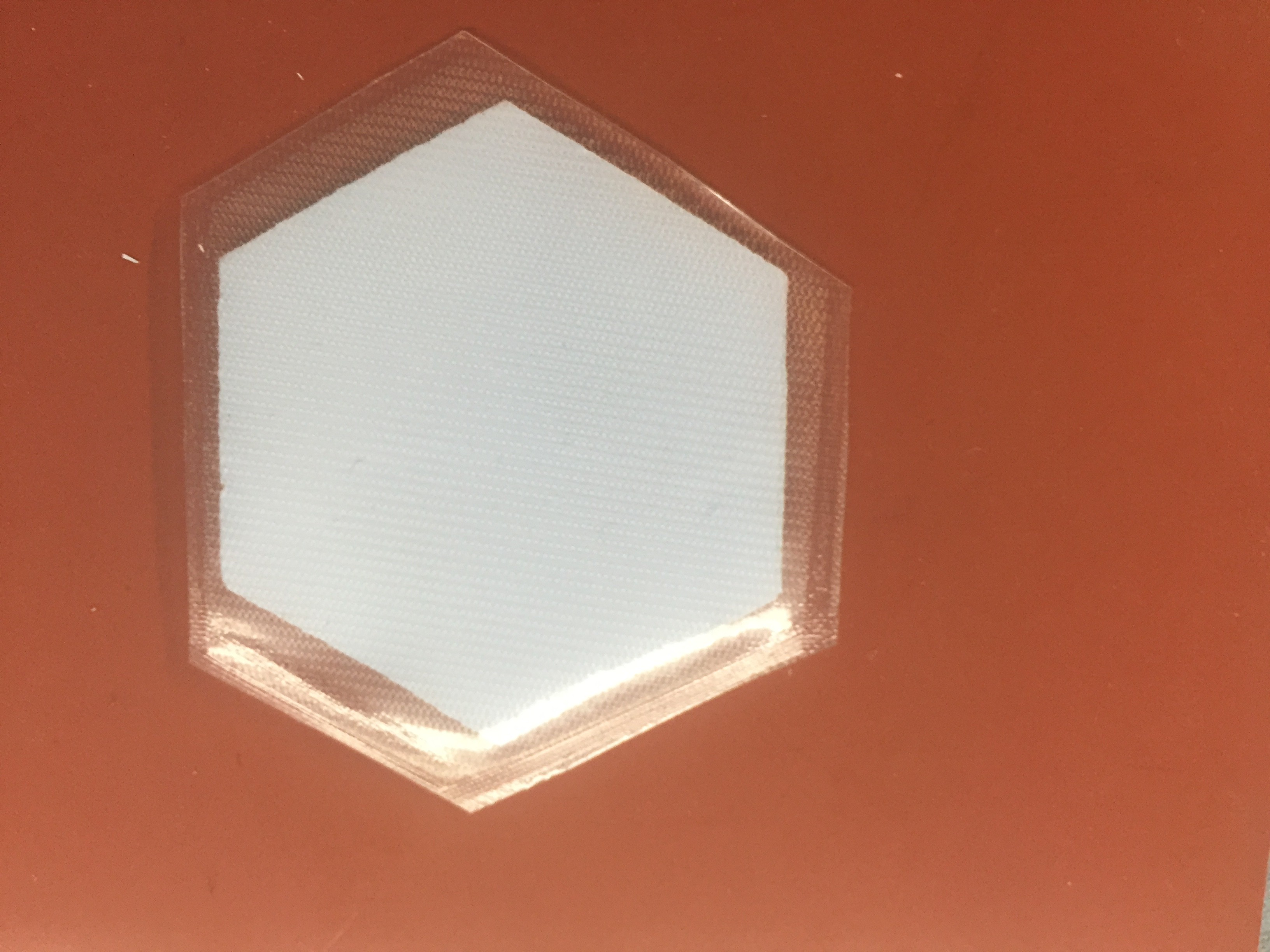

A few layers of tape were cut out using the template at the lower right,

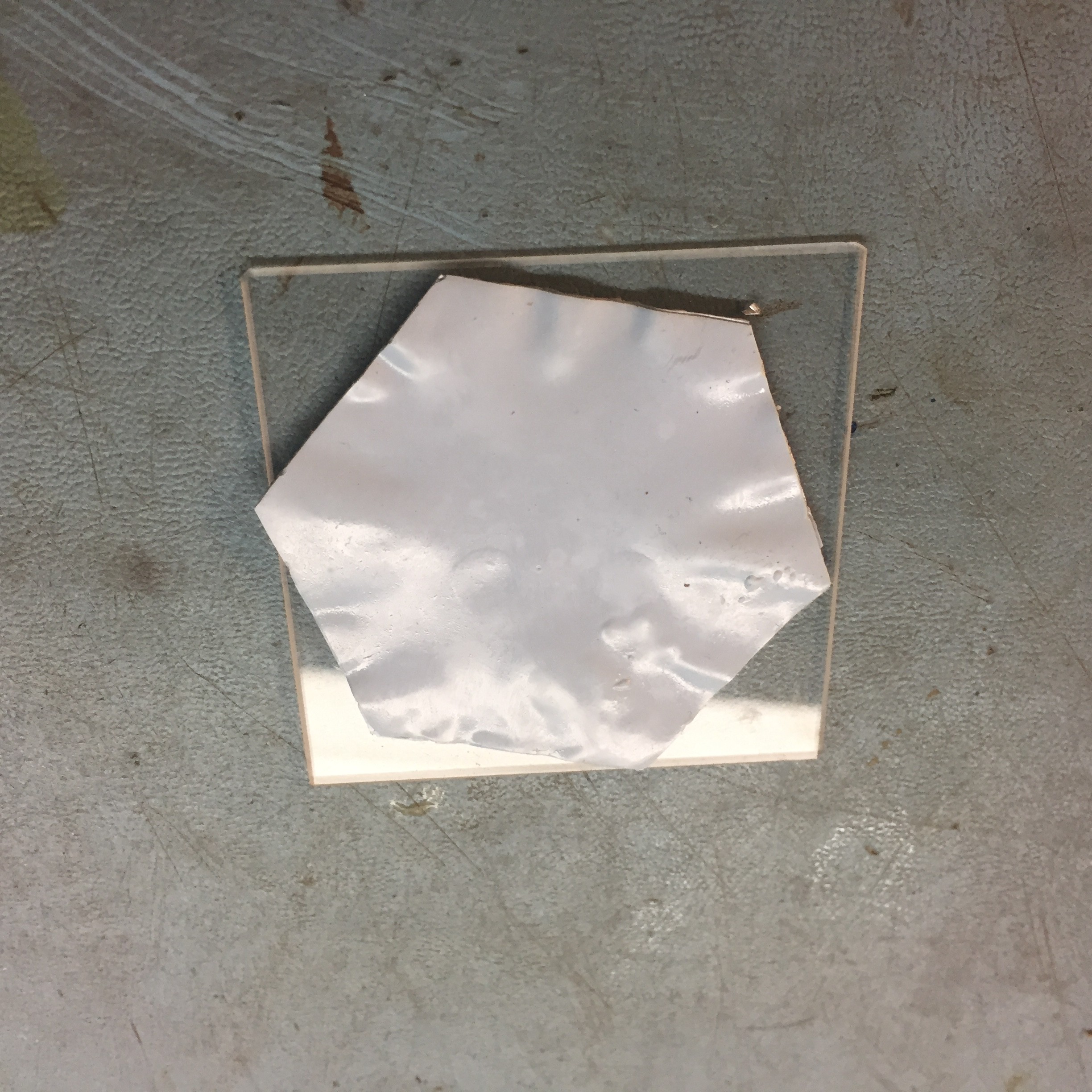

stacked

and sealed in a bag which was then sealed.

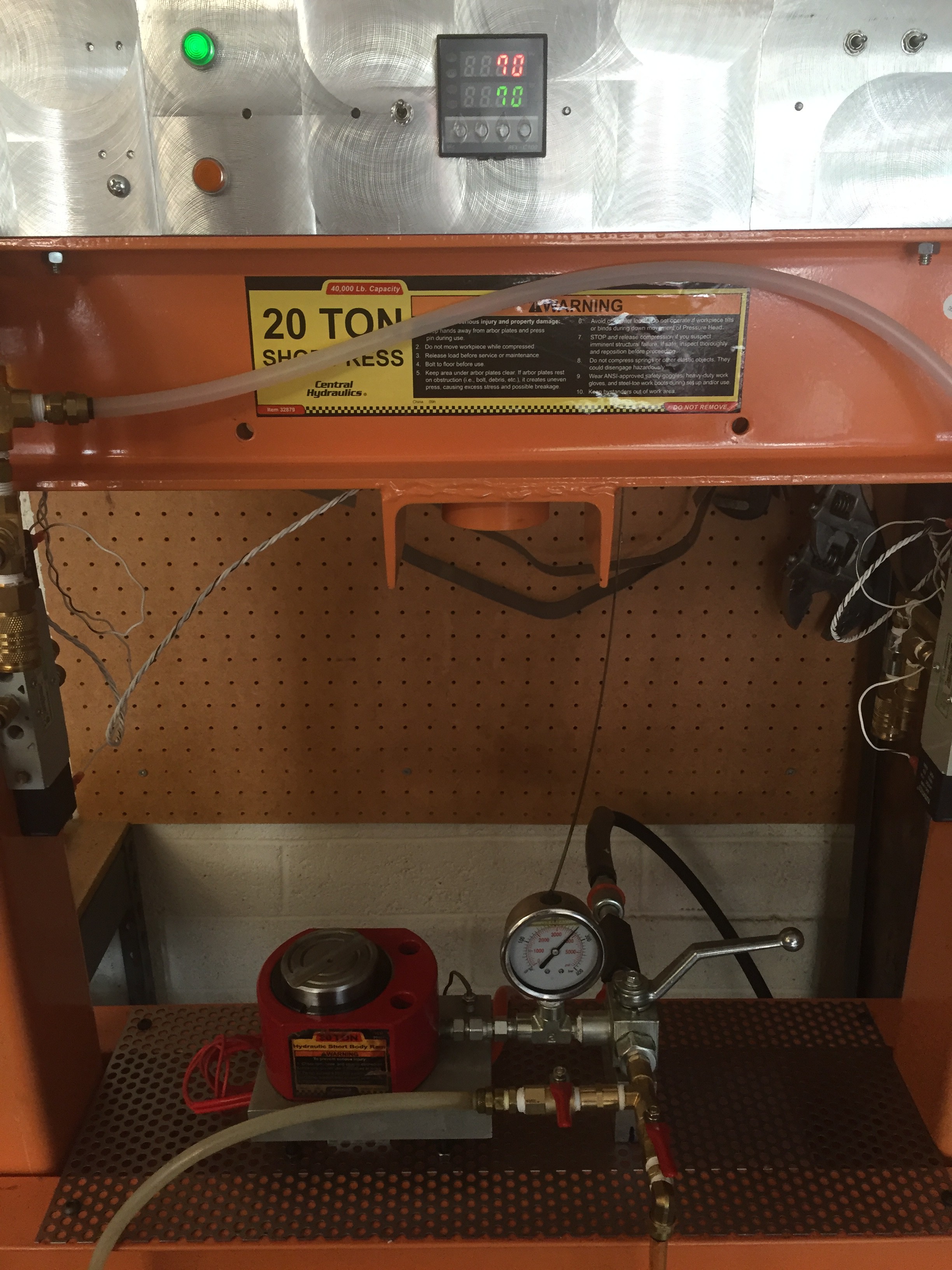

Then pressure is applied for around 10 minutes. You can see on the gauge that the pressure is around 4,000 PSI.

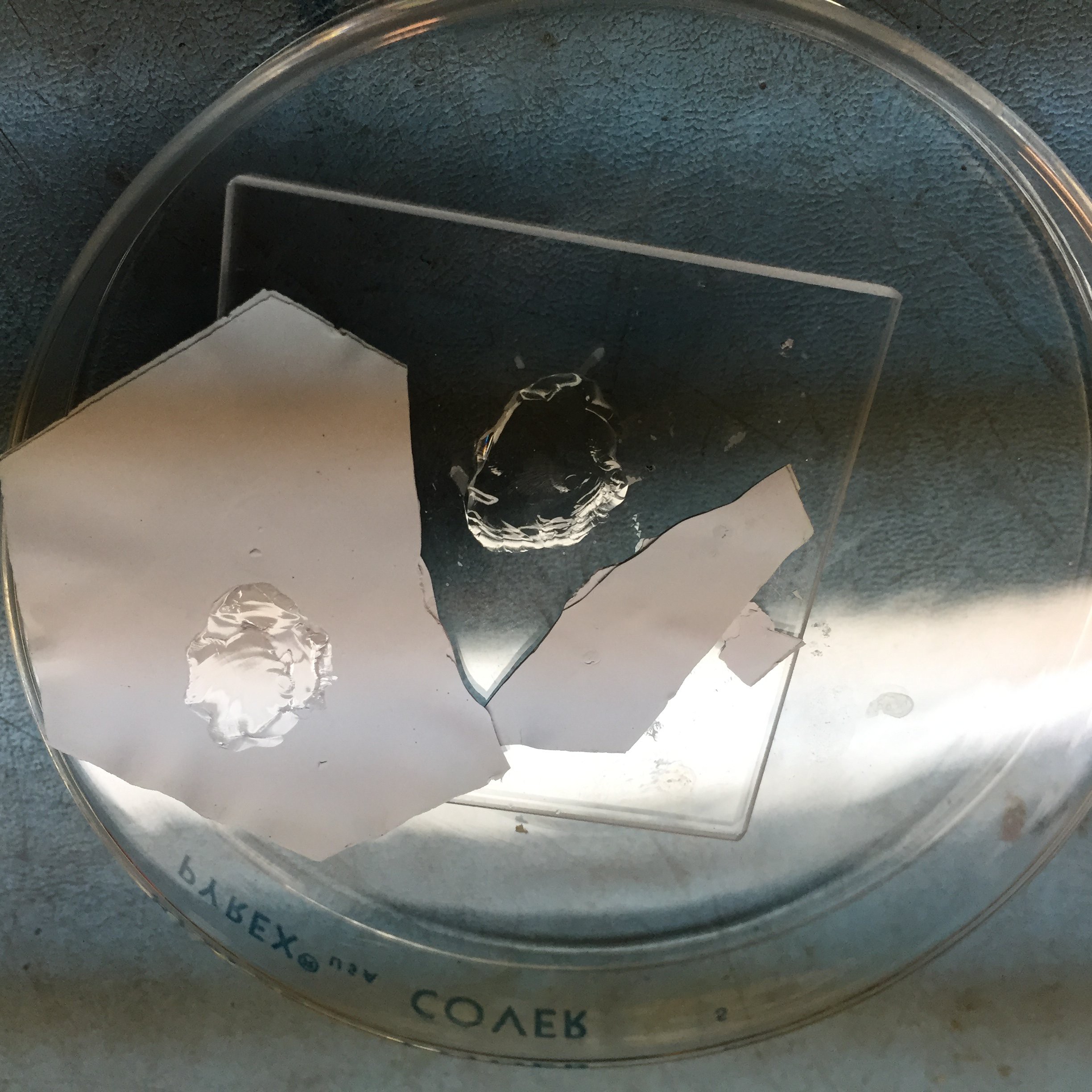

Hydraulic oil in the bag. Dang, and double dang. Note that the tape does not appear flat. That has nothing to do with the failure of the pouch, it just the nature of the details of this step.

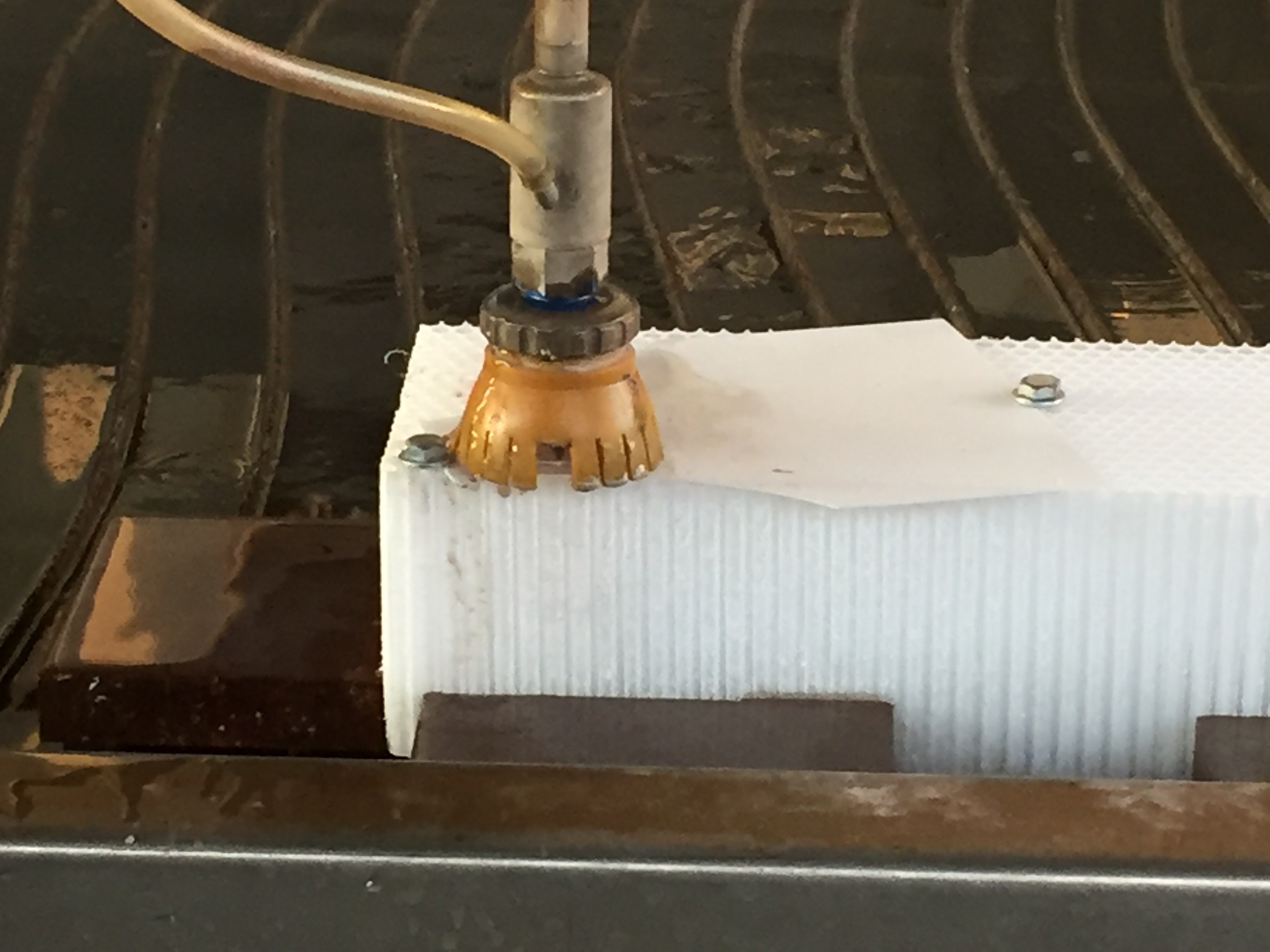

The stack was cleaned with a towel and placed on a quartz substrate. Not even close to being flat!

Oh, what to do?

Fundamentally, the reason for vacuum bagging the contents is that a bag that has a good seal is visibly different than one that has a leak. Now I know.

Alumina, Al2O3, otherwise know as aluminum oxide is a fundamental industrial material. Almost as hard as diamond. Very, very refractory! In one of it's many forms it comes in sheets. Very flat sheets. Along with making up 50% of composition of the LTCC green tape.

Considering the materials extreme hardness, how exactly is it conveniently cut?

The waterjet works brilliantly! It takes about 55 seconds to cut a 25 mil thick plate with a 2.25" circle.

Chuck Glasser

Chuck Glasser

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.