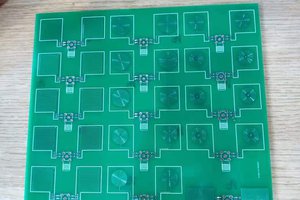

A custom laser cut template permits the direct mounting of TO-220 heat sinks (oversized for extra cooling) to the 4 x small TQFP trigger chips that run hot. Direct screw clamping pressure is achieved via plastic 6-32 hardware mounted on the bottom of the O'scope case aligned to the heat sinks for optimum results. Plastic screws limit the max. pressure that can be applied as a safety vs flexing the multilayer PCB. A 30°C improvement has been measured.

Tektronix TDS 694C Trigger cooling & workaround

This 3Ghz scope suffers trigger chip burn out- this project suggests workarounds/repairs & mods to mitigate this problem.

mosaicmerc

mosaicmerc

Roger

Roger

baaskaas

baaskaas

MG

MG

Costa

Costa