I've decided to keep a log here of the costs to fix the printer so far. I don't count filiment because it's an expected cost.

| Description | Qty | Price |

| Printer | 1 | $200.00 |

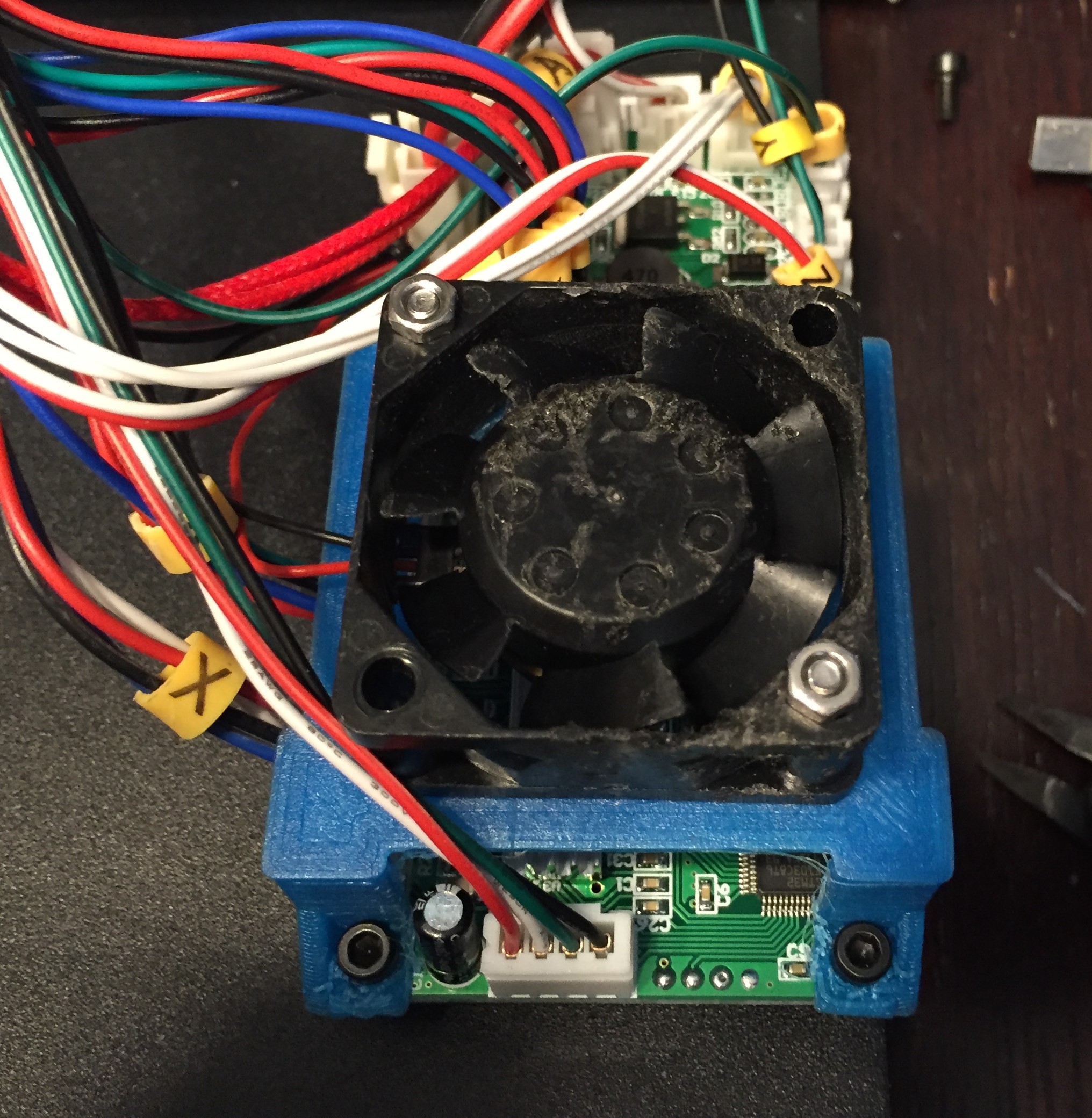

| Cooling Fan 40mm | 1 | $7.20 |

| M3 Screw Kit | 1 | 15.69 |

| BuildTak 4.5in x 4.5in | 1 | 8.20 |

| Total | $231.09 USD |

Adam M

Adam M

Michael

Michael

Zoé

Zoé

Andrew McAteer

Andrew McAteer

Nice one, it will be much helpful for the small business needs. https://fantaserye.su/