The components for this project are following:x1 NeoGeo Pocket.

- x1 NeoGeo Pocket

![]()

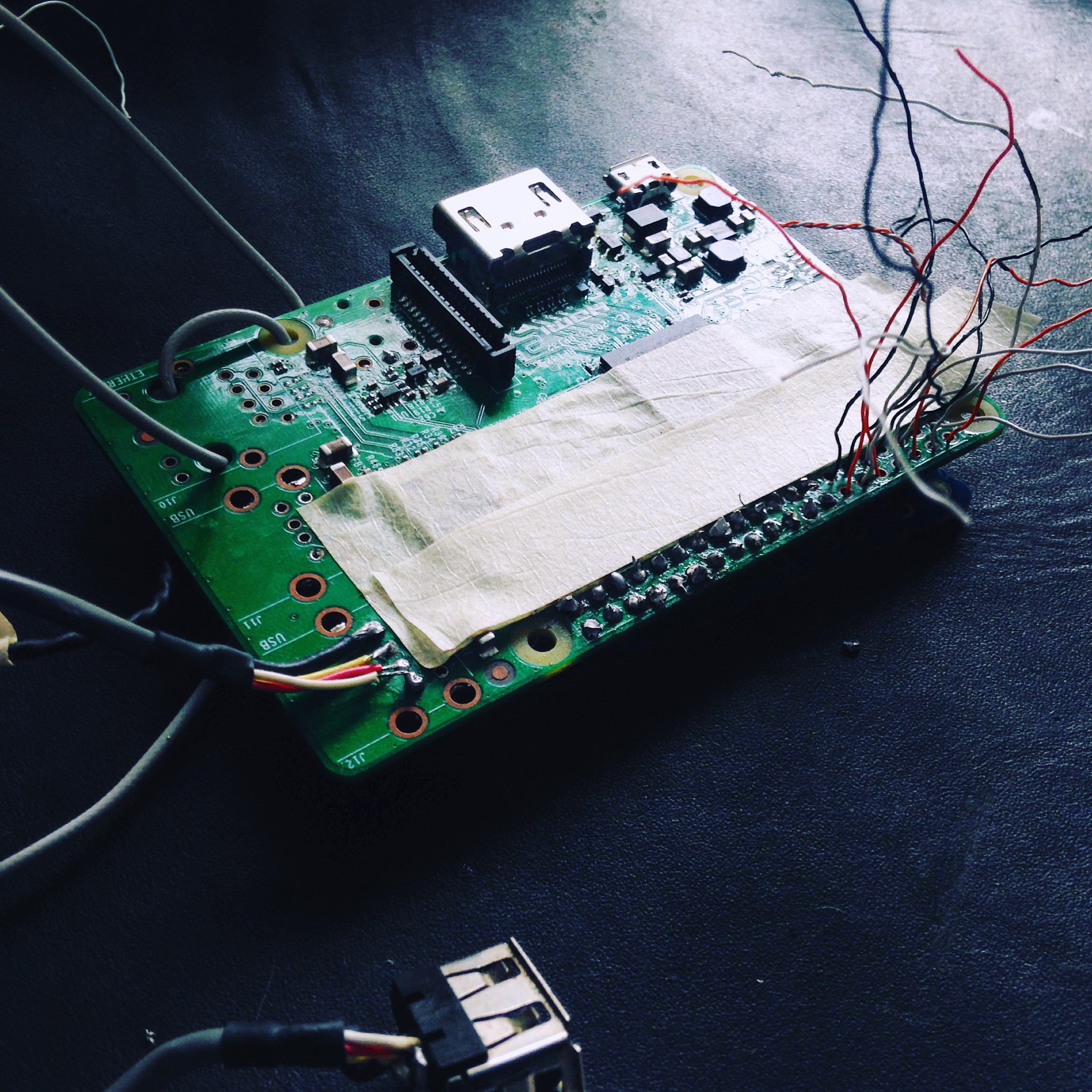

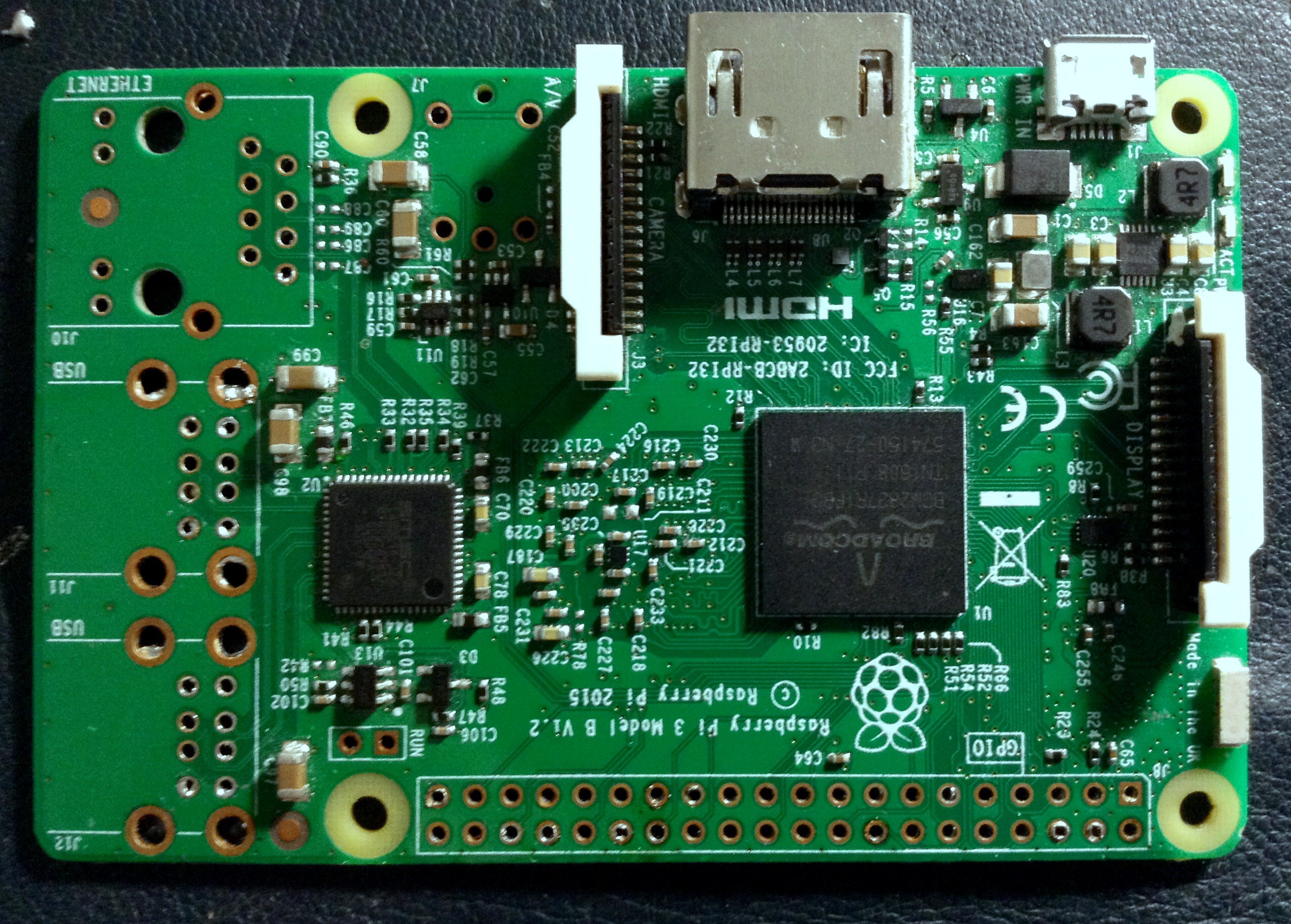

- x1 Raspberry Pi 3 or Rpi2 (less power consumption but less performance).

![]()

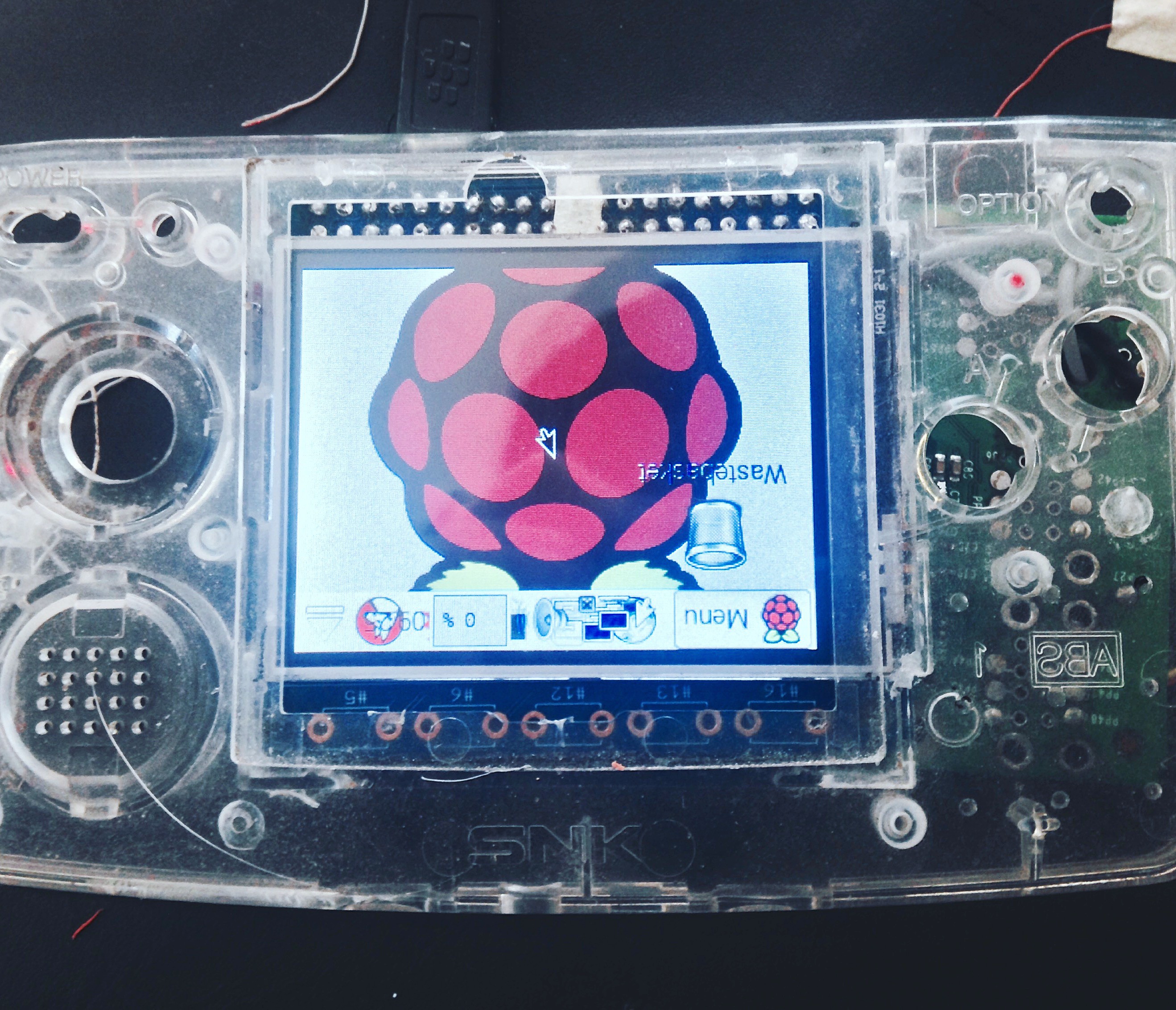

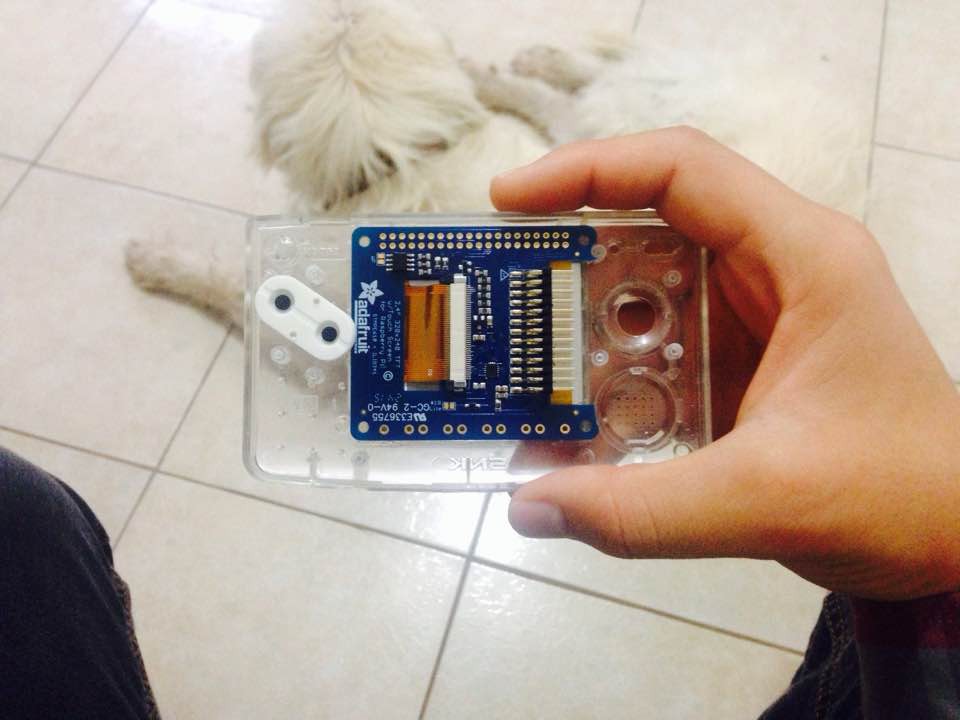

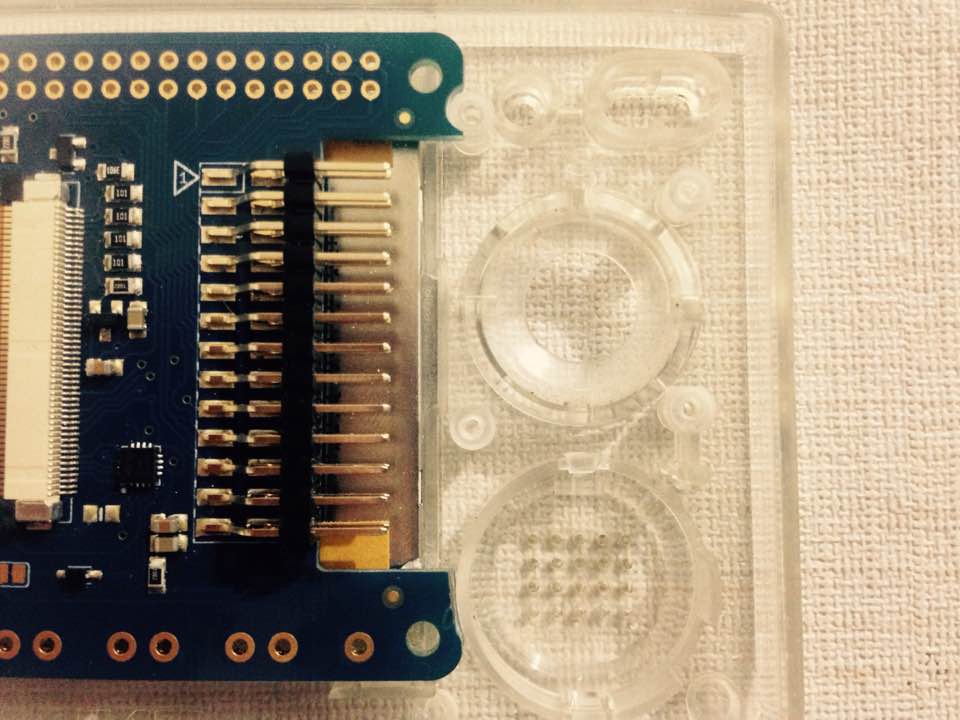

- x1 2.4 PiTFT from adafruit

![]()

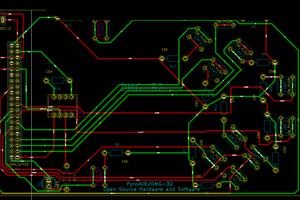

- x1 Teensy 3.2.

![]()

- x1 blackberry trackball breakout board from SparkFun or Icstation (which is a lot more affordable and has almost no difference. I'll explain this later).

![]()

![]()

- x1 powerboost 1000c, there are other option that are better for the pi3 but sadly, I bought this without knowing at the time. I'll share the alternatives later.

![]()

- an stereo audio amp from Adafruit or a mono one. I got the mono since it was obviously cheaper; around 3 US dlls compared to 9dlls (I'm on a tight budget!)

![]()

- x10 Domed tactile switches by C&K components https://www.arrow.com/en/products/ksj0m21180shlft/ck-components

![]()

- x10 "Legendary" squared Tactile switches by Panasonic https://www.arrow.com/en/products/evq-p0d07k/panasonic

![]()

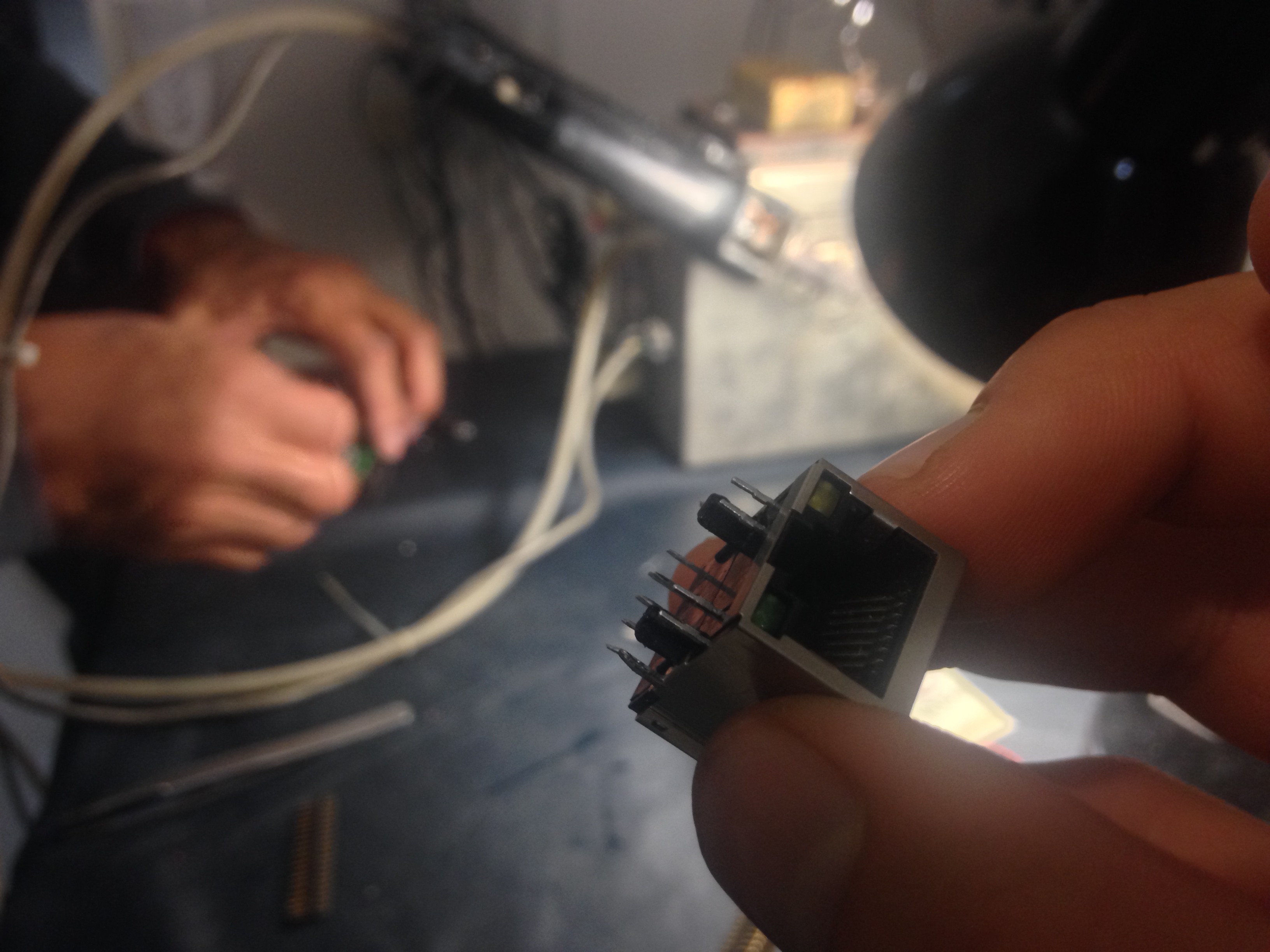

- x4 "short" USB ports, I got mine from an old and broken Toshiba Satellite A15 laptop. short ones are important because space is critical here!!!.

![]()

- x2 generic cellphone loud speakers (quite tiny as well but they output clear sound at a nice volume thanks to the amp).

![]()

- x2 cellphone vibrator motor (the smallest you can find)

- wires

![]()

- The hard part is to find the proper Li-Polymer battery, one that fits and has enough juice to power the device for 3-4 hours minimum. But we'll get to it :) I'll show some alternatives to properly power the Rpi3 specifically.

Kevin Osuna

Kevin Osuna

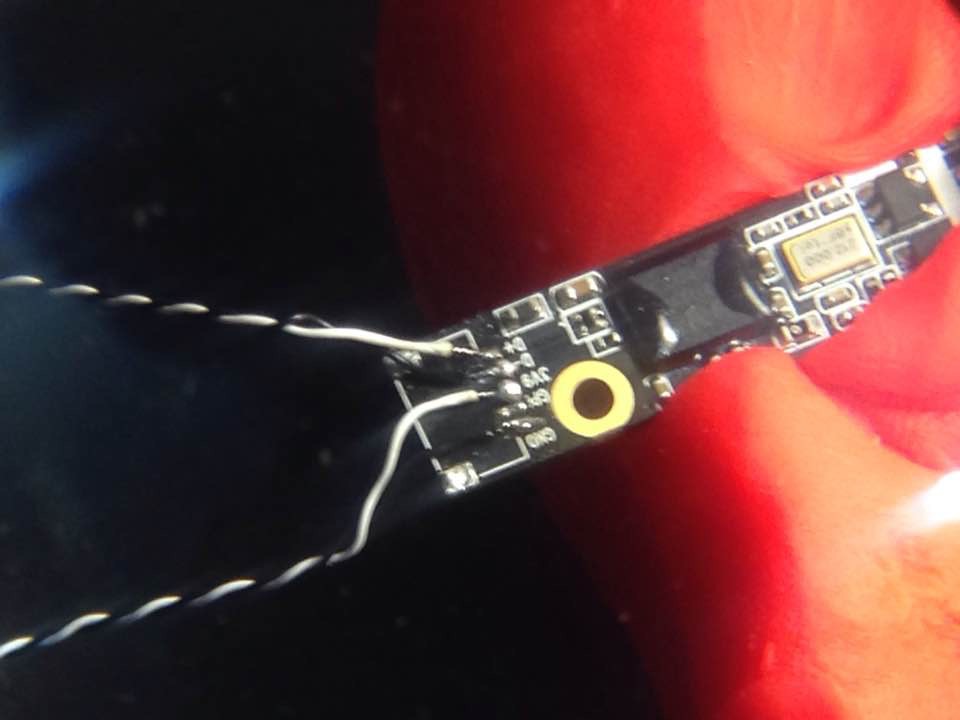

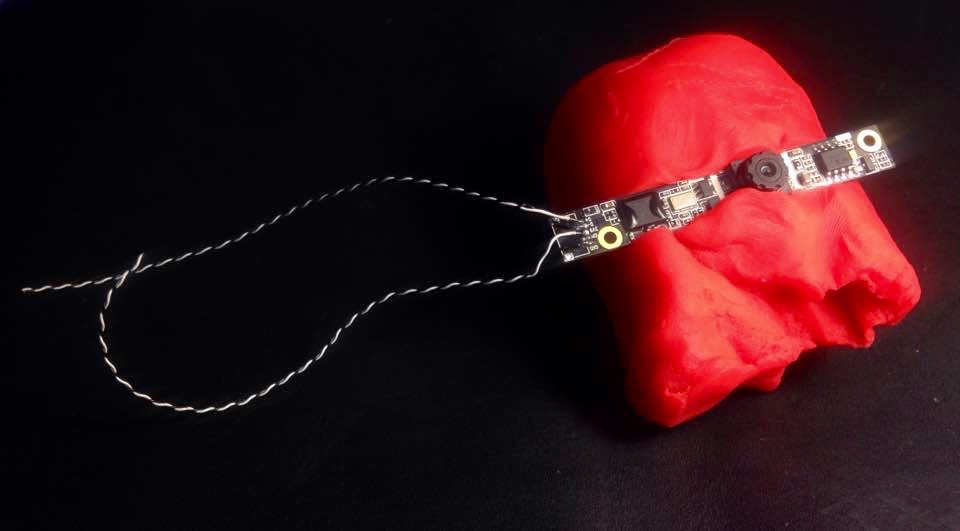

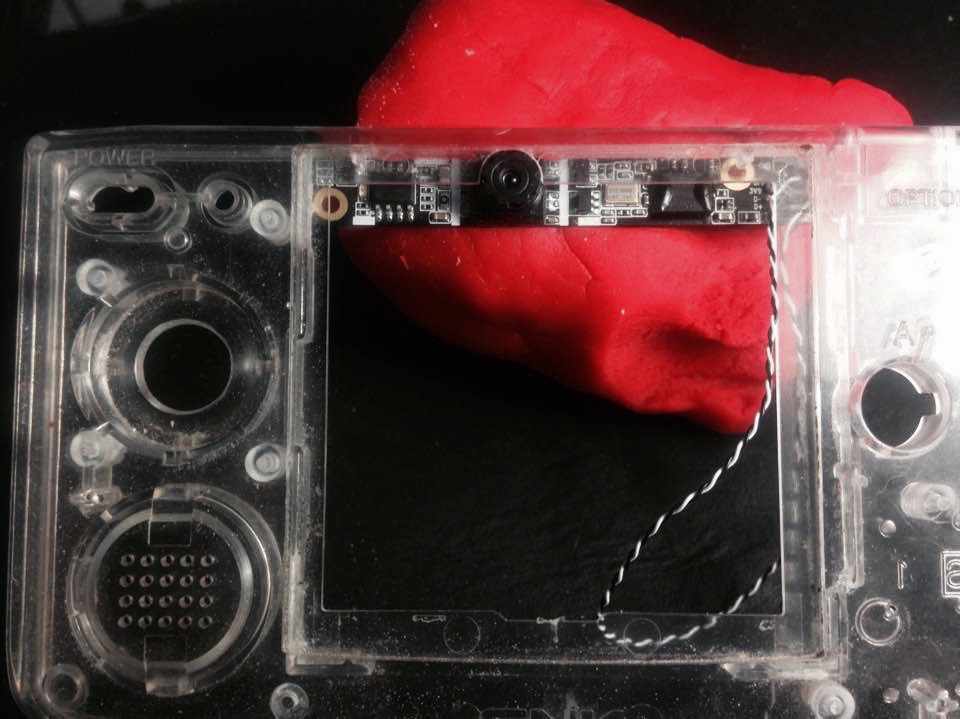

Then I carefully added some hot glue to secure the wires I had just soldered, at the end it looked very clean. After that, using the engraving tool, I made a hole through which the camera lense could go. I had to be very precise on how far I had to dig, I wanted it to be the perfectly sized and shaped. That way, there would be no need for glue on that part, after all, this is a very visible part but even if a had made a mistake, that can be covered with a custom, acrylic faceplate.

Then I carefully added some hot glue to secure the wires I had just soldered, at the end it looked very clean. After that, using the engraving tool, I made a hole through which the camera lense could go. I had to be very precise on how far I had to dig, I wanted it to be the perfectly sized and shaped. That way, there would be no need for glue on that part, after all, this is a very visible part but even if a had made a mistake, that can be covered with a custom, acrylic faceplate.

Please leave a comment or question, your feedback is of big interest to me. that's all for today! Thanks a lot

Please leave a comment or question, your feedback is of big interest to me. that's all for today! Thanks a lot

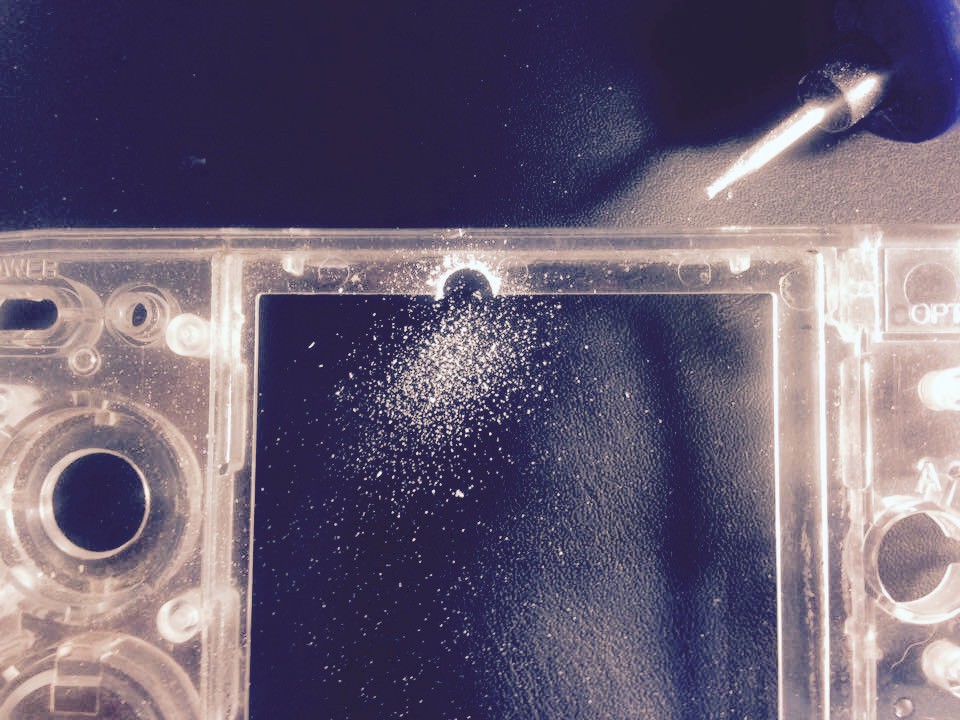

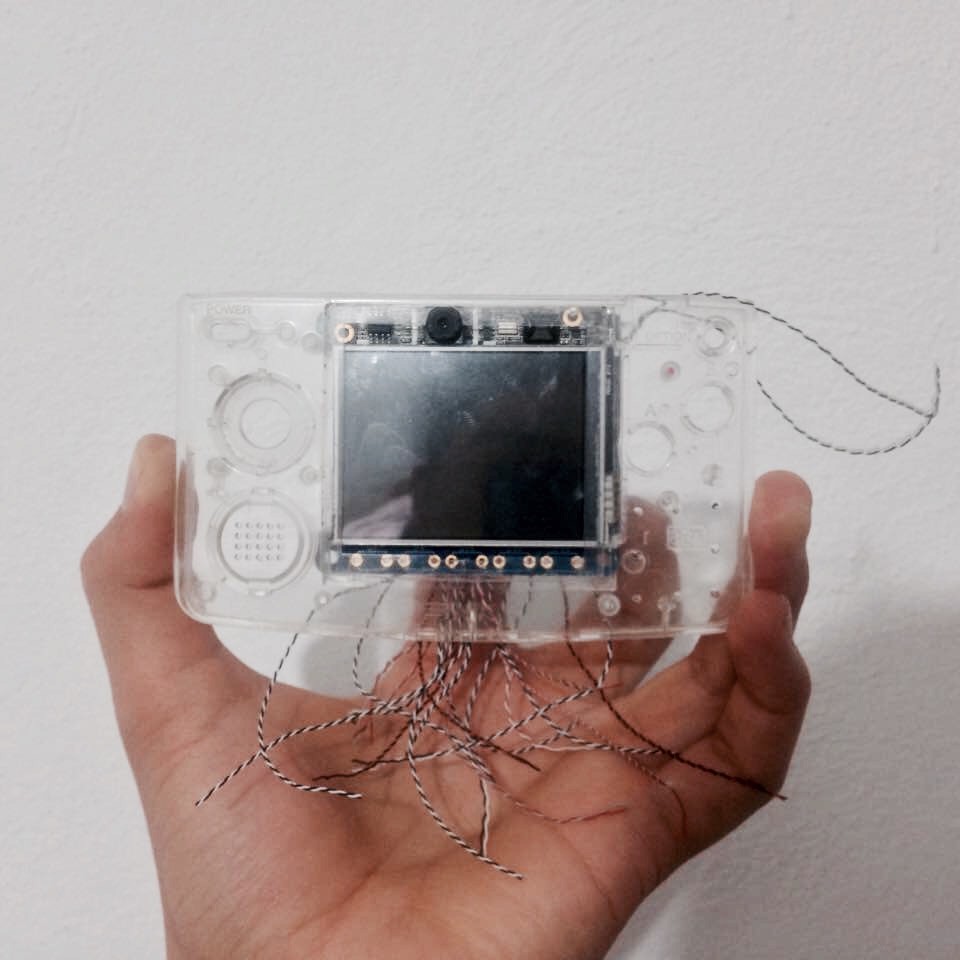

here it is already modified:

here it is already modified: And here it is with the port in place (more less):

And here it is with the port in place (more less): I'll be using a different cable for the USB, this one's too thick.

I'll be using a different cable for the USB, this one's too thick.

So I guess this isn't bad for the first modification I make for this project, everything seems, fits and feels like it is meant to be. I'll keep you updated.

So I guess this isn't bad for the first modification I make for this project, everything seems, fits and feels like it is meant to be. I'll keep you updated.

origamimavin

origamimavin

Tom Nardi

Tom Nardi

Andy

Andy

Leonard

Leonard

Hey there, something new ?? ;-)