Using a floating head on corrugated tin seemed it was the ticket. Especially when torch height control is still not implemented. Touch off of the material, back off the material to allow an arc to fire, plunge the head down on top of the material so the plasma cutter drags along the height changes of the tin. Then the head drops into a hole and gets ripped off the first time. No big deal, the v'd plastic guides that support the floating head deform enough to allow the head to pop off. The second time wasn't as fortunate:

So new pulleys were made out of more rigid bearings and the v'd guide itself made out of aluminum. In the picture below, the old plastic piece is off to the left with the bearings that popped out laying beside it. The left side of the plastic pulley has a black line where it was sheared:

In the process of machining the aluminum pieces, the bearing bore was too large on one. The installed bearing would slide in and out smoothly. Instead of making another one, the pulley was dinged with a punch to help trap the bearing:

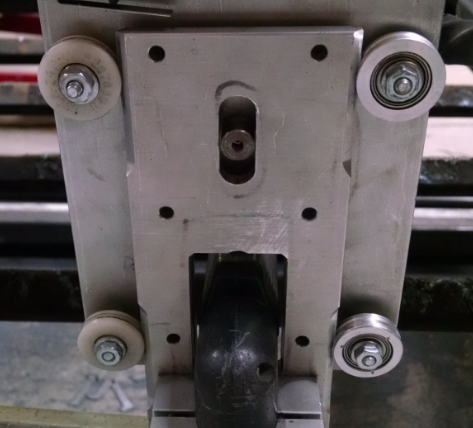

With two new v'd guides created it was assembled and installed. Back in business:

To help with this kind of problem in the distant future, a magnetic break away floating head should probably be built.

willbaden

willbaden

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.