Hi there!

It’s been a long time since the last time I wrote a log! I’m back!

Thor’s community is growing fast! There are (at least) 4 Thors assembled & operational around the world and another 17 being built! There are schools and universities relying on Thor for teach robotics… Great yaaay!

The more people are interested in this project, the more feedback I get. Recently I have received several questions about the sensors I’m using to establish the home position of Thor (opto-couplers, opto-transistors, opto-switches… whatever). To be honest, until now it was pretty tricky… I made my own sensors using a DIY CNC for the PCBs and soldering the components by myself. As this project has attracted different kinds of people, I thought that it could be nice to simplify this issue: making Thor compatible with commercial sensors instead of creating the custom ones. Let’s try to not reinventing the wheel!

The first thing was to find a cheap commercial sensor which could fit inside Thor. To make things easier, I was looking for a single model which could fit in the 4 articulations. For the first three ones was an easy task, but the sensor located in the Art3body piece for the 4th Articulation had to be pretty small to not collide with the Art4TransmissionColumn piece.

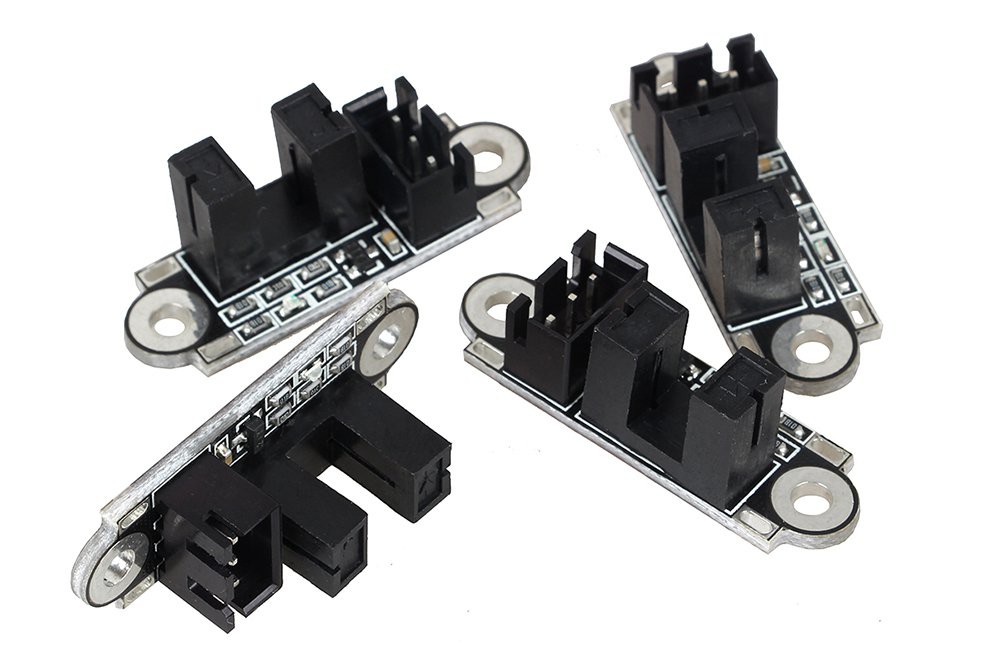

Finally I found this one in Aliexpress which met all my needs. I think that it won’t be hard to find that kind of sensors in other online-shops, but I tend to use Aliexpress because of its large catalogue.

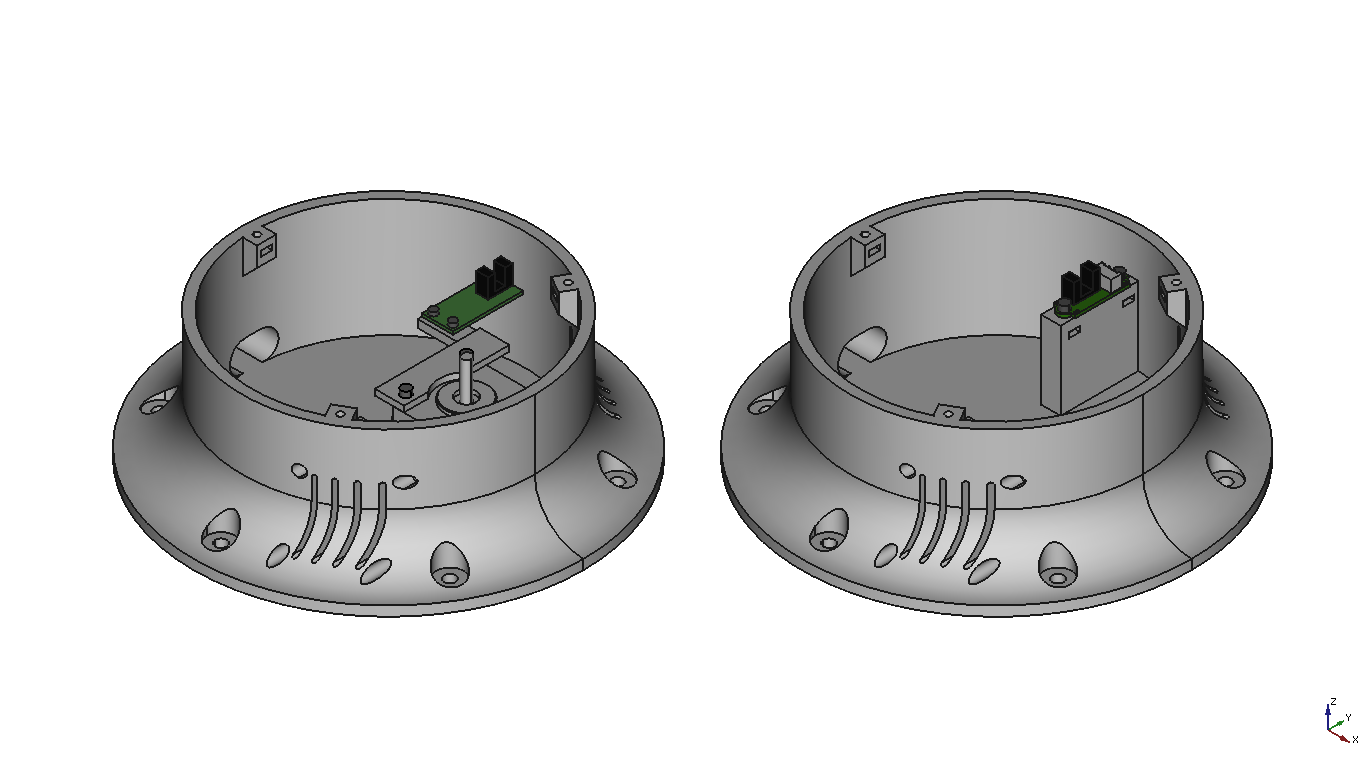

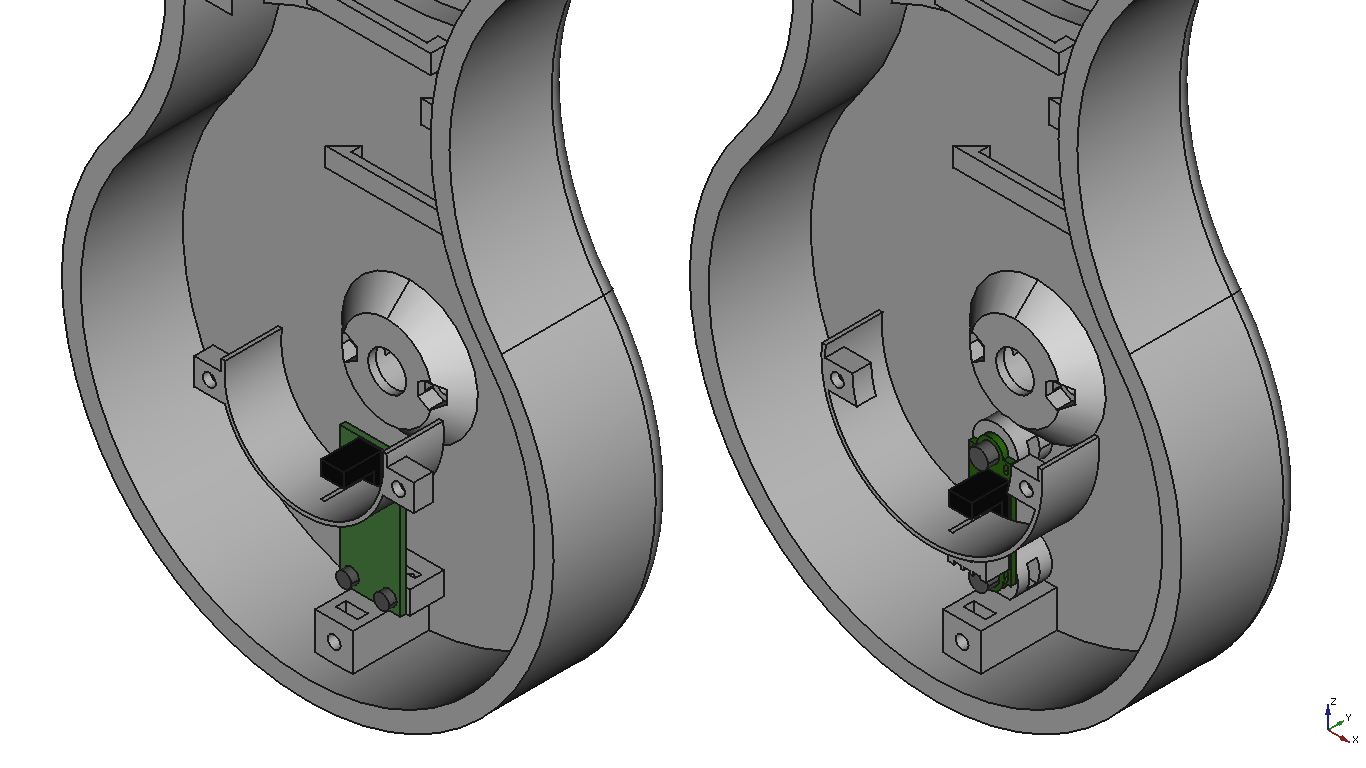

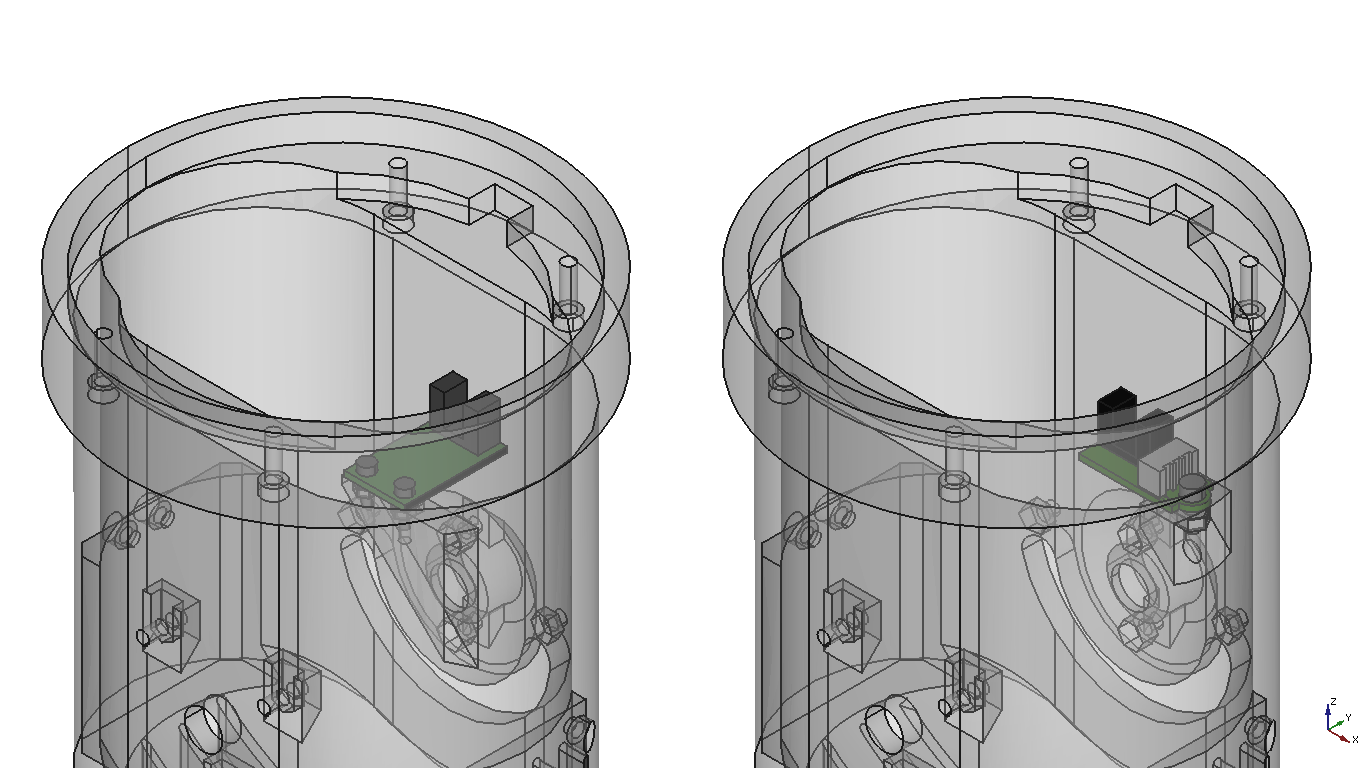

So, without further ado, these are the changes I made in the design (on the left side the old design and on the right side the new design):

The sensor for the 1st Articulation is now fixed to the BaseBot piece.

The sensor for the 2nd and 3rd Articulations are placed in a similar position as the custom ones, I modified the Art2BodyB piece adding fixing point for them. Also, the Art23Optodisk has been redesigned to work properly with the new distances.

The Art3Body piece has been redesigned to fix the sensor of the 4th Articulation. The board of this sensor has to be cut to avoid the collision with the Art4TransmissionColumn piece. Do not worry about that cut, there are no circuits in that zone of the PCB, so can be cut gently.

I have only tested it using the 3D models. The sensors fit, but presumably the connector of each sensor will have to be replaced with other flatter.

FYI: the last commit where you can find the older files (the ones for the custom sensors) is this one: b86594c4d48fa64d71cc373a52b4e3dac6e4bde9

Do you like it?

Ángel L.M.

AngelLM

AngelLM

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.