Trumpf has this neat video about laser processing of carbon fiber composites where they show cutting and ablation of the material.

It seems like some of their laser systems can just punch through the composite without making much of a mess (TruMark). Notice the distinct concave surface though as the laser ablates the material.

Since I need an array of holes drilled into a lightweight yet strong beam, I thought I'd give it a go. The starting parameter set was taken from a preset for ceramics marking, where more power equals more better.

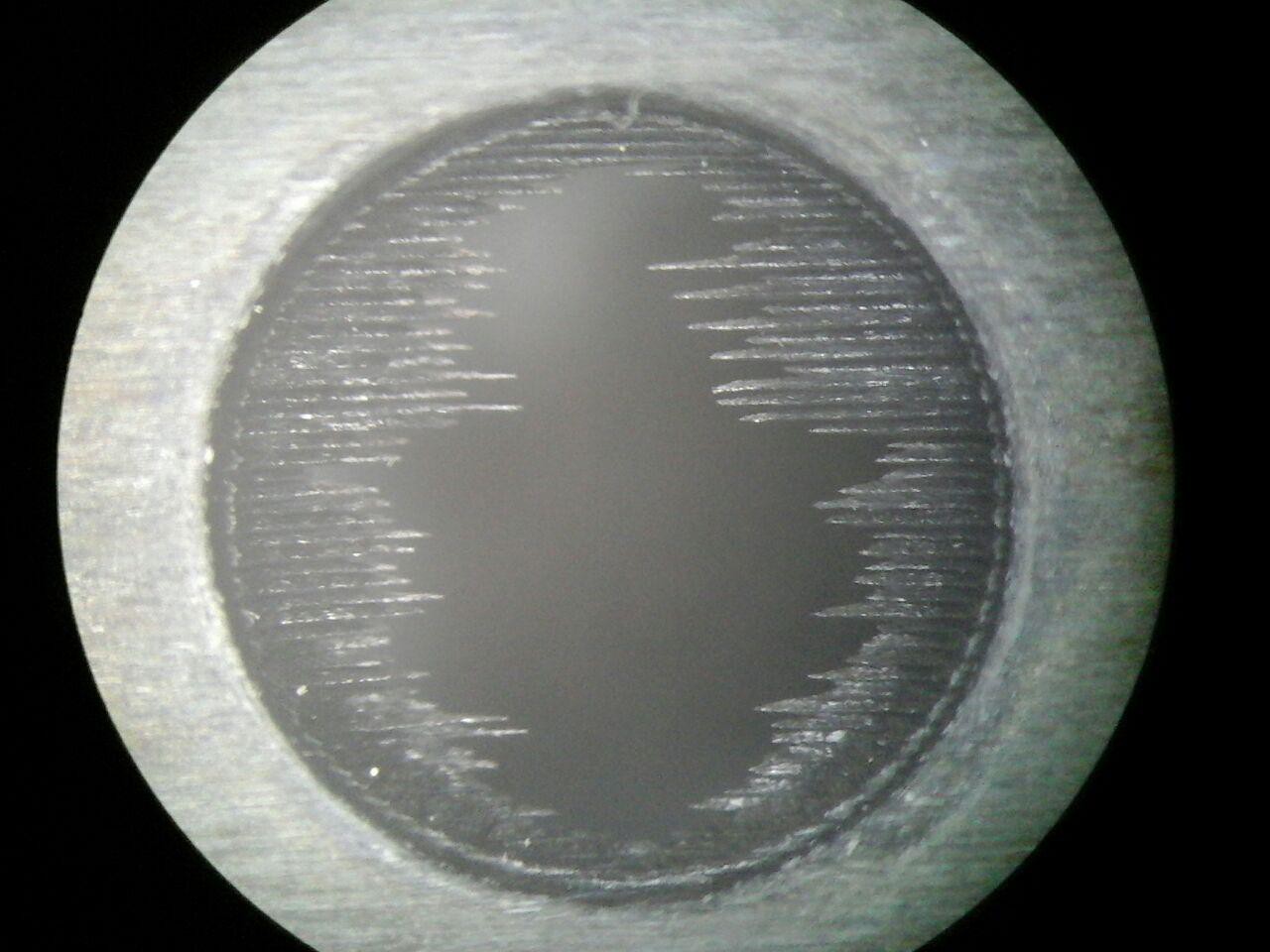

The first image shows the result of a woven tube being "drilled".

This tube has a distinct weaving pattern and it feels like the top roving was a bit more resistant to ablation than the rest. Most importantly though, this is not a cylindrical hole by any standard.

This tube has a distinct weaving pattern and it feels like the top roving was a bit more resistant to ablation than the rest. Most importantly though, this is not a cylindrical hole by any standard.

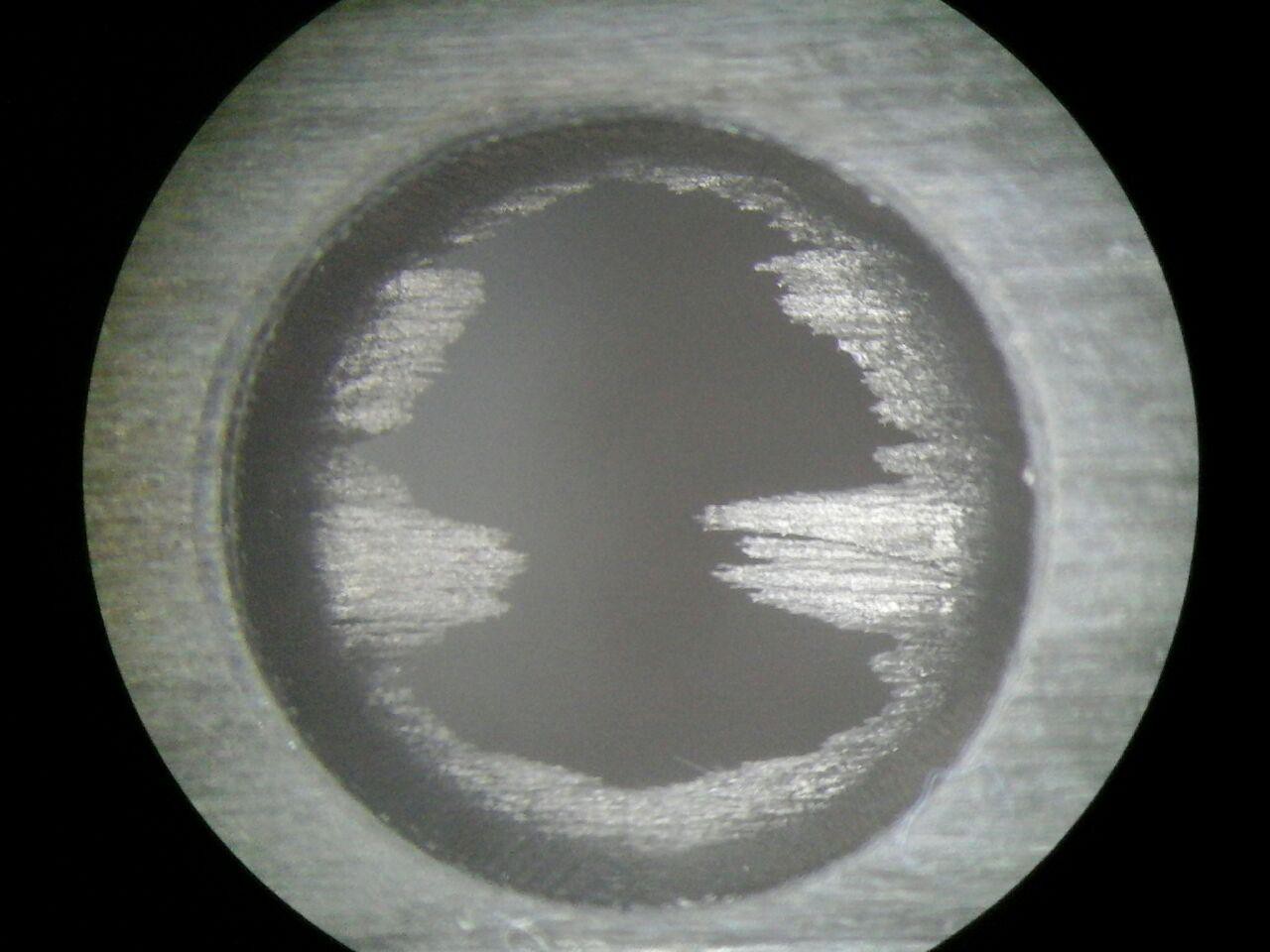

The pultruded material behaves a bit more convincingly though the process leaves a stubborn fringe and exhibits a visible draft angle.

I also tell myself that the perpendicular cut creates more fraying. Decreasing the spot size to 20µm does not make things any better.

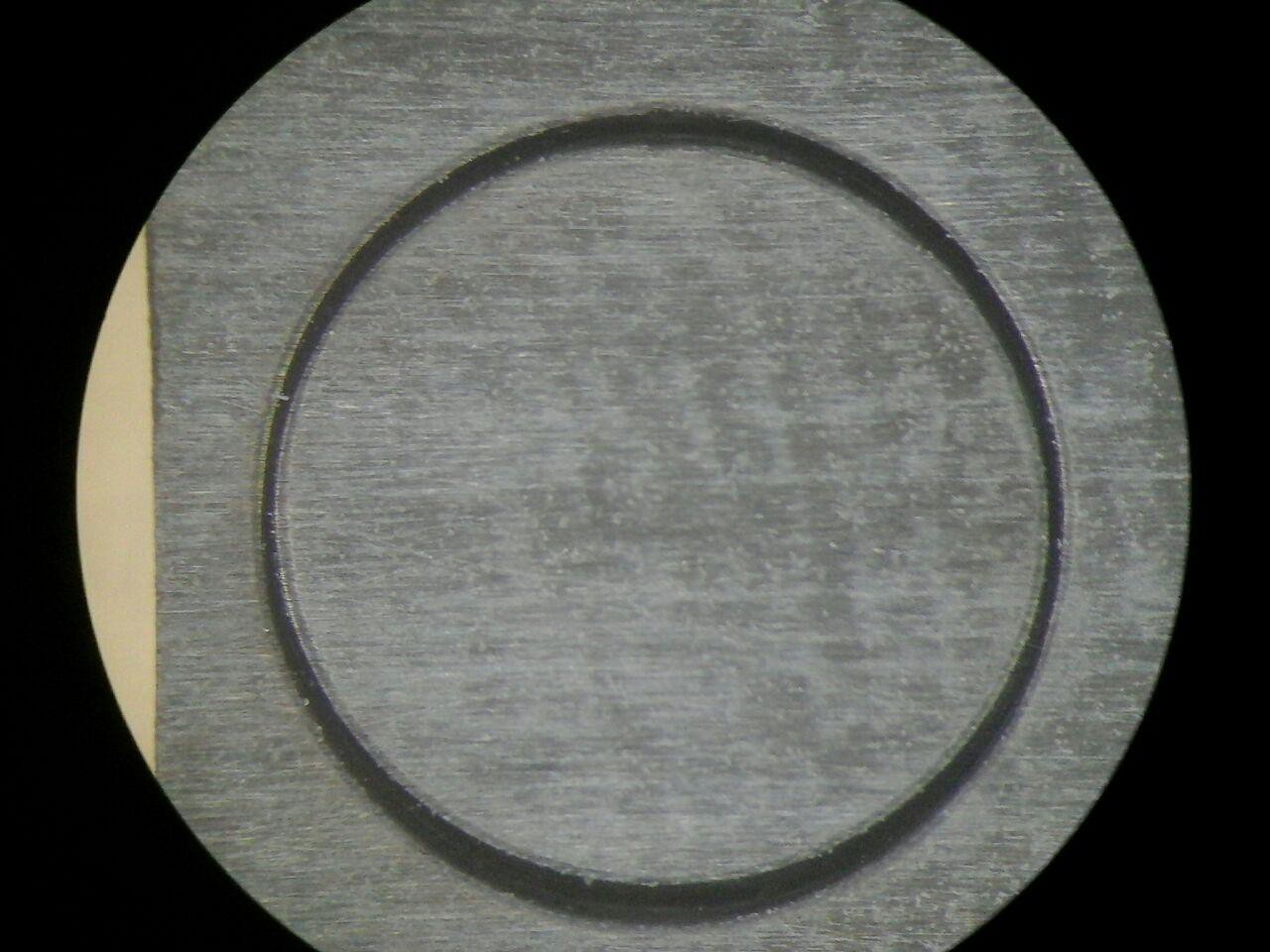

After looking at the machine scribing a circle for 15 minutes and not getting anywhere I had seen enough. As for the difference in line width for x and y directions: either something shifted on me (I did reproduce the linewidth directionality though), the material ablates anisotropically or the laser mode is unstable (it jumped from being bright do being much less so, then back to bright over a couple of minutes). Maybe it even has something to do with anisotropic heat transport.

After looking at the machine scribing a circle for 15 minutes and not getting anywhere I had seen enough. As for the difference in line width for x and y directions: either something shifted on me (I did reproduce the linewidth directionality though), the material ablates anisotropically or the laser mode is unstable (it jumped from being bright do being much less so, then back to bright over a couple of minutes). Maybe it even has something to do with anisotropic heat transport.

It would be interesting to hear if anyone had already tried laser ablation with a Nd:YAG marking laser before and encountered similar issues, maybe even found a set of paramters that work.

Maybe the laser head or pump diodes are at their end of useful life, maybe the alignment has shifted over the years ... or maybe it's just not enough grunt to process carbon fiber.

So... back to the mill?

ps. well... seems like I was even quite lucky when compared to what steaming mess a lower power CO2 laser produces...

And if that's not weird enough, some types of carbon fiber exhibit polarisation dependent absorption.

https://www.osapublishing.org/oe/fulltext.cfm?uri=oe-22-2-1474&id=277015

helge

helge

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.