One of the most challenging and error-prone steps in building the LipSync has been assembling the force-sensing resistors (FSRs). The delicate FSRs can be easily damaged by people who have never worked with them before.

The most common problem during Makers Making Change build events was kinked or overheated FSRs. Multiply that by four FSRs for each LipSync and it doesn’t look great, especially since it’s the most expensive component.

True story: Jake, now our Mechanical Engineer, accidentally destroyed two FSRs when he was volunteering during our first Buildathon.

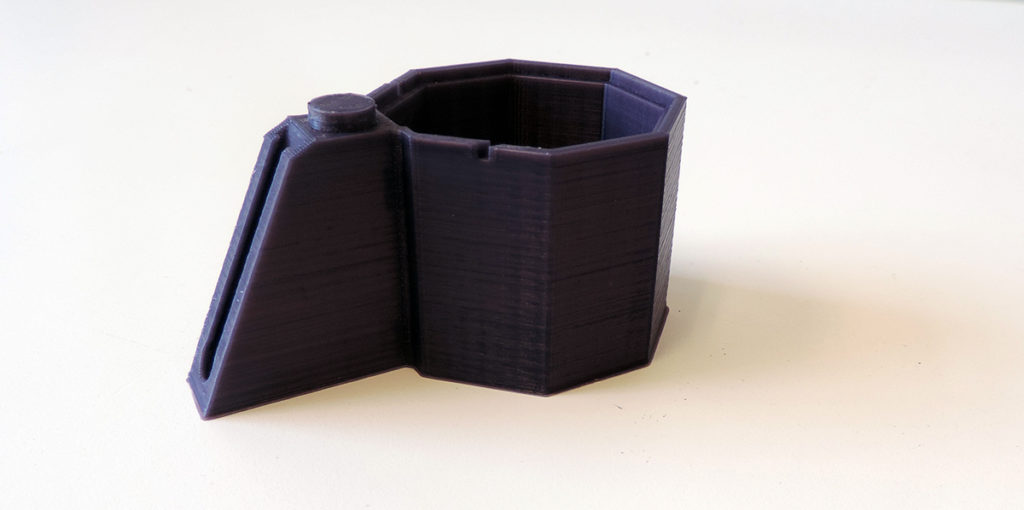

The old joystick jig in white (left) and the new one in black (right)

Enter the new joystick jig, which helps makers install each FSR correctly onto the board. The notched slot holds each FSR in place as you solder and ensures correct alignment.

Since we debuted this design, the number of damaged FSRs has reduced dramatically – also reducing the frustration associated with it. This means we can speed up our build time, so it’s a win-win all around.

Justin, a local maker from Hedgehog Technologies, made this cool colour-changing version of the joystick jig

This is a testament to how 3D printing tools can make work more efficient. It’s relatively quick and easy to improve upon your design and make more effective solutions.

Makers Making Change

Makers Making Change

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.