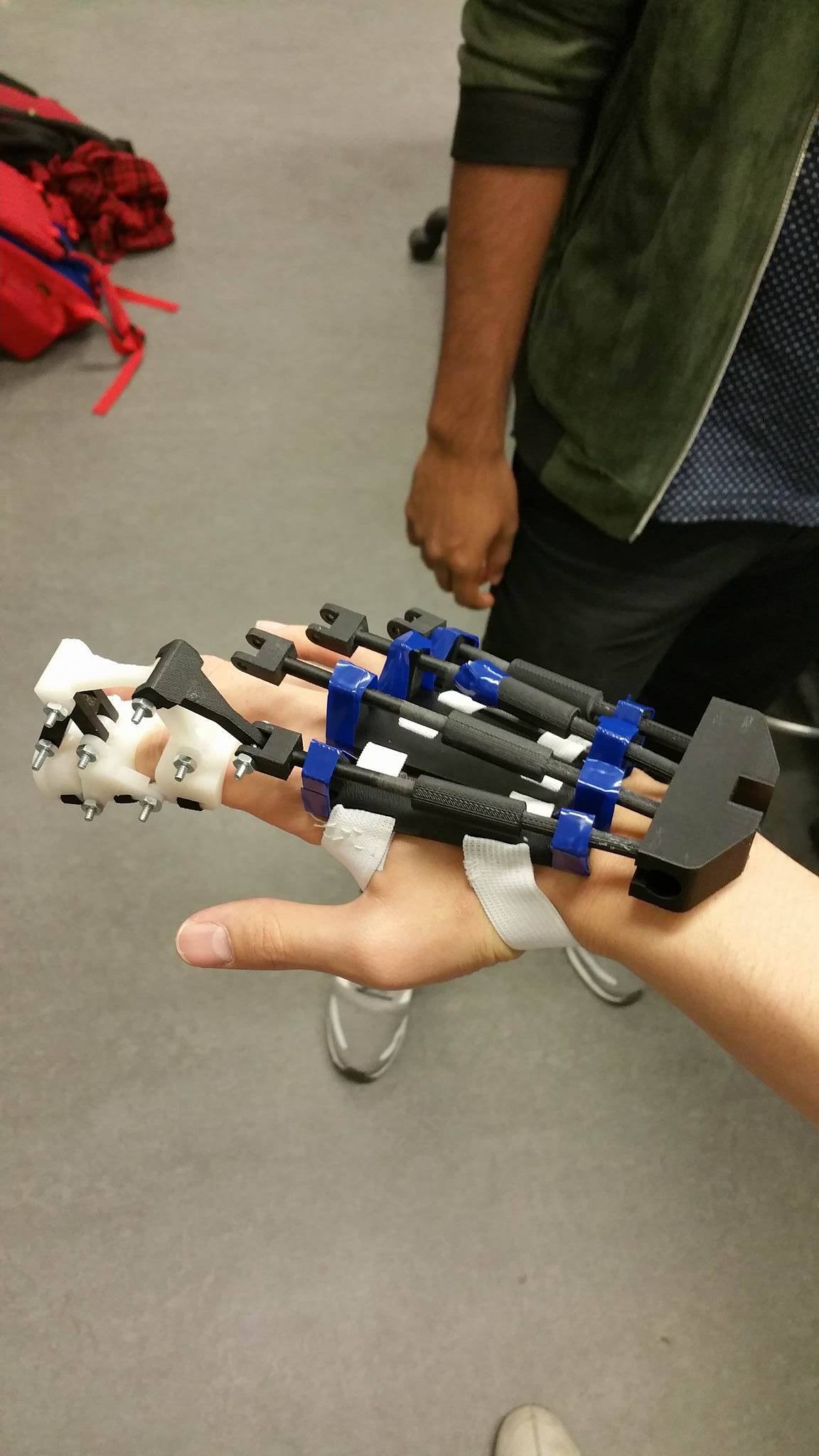

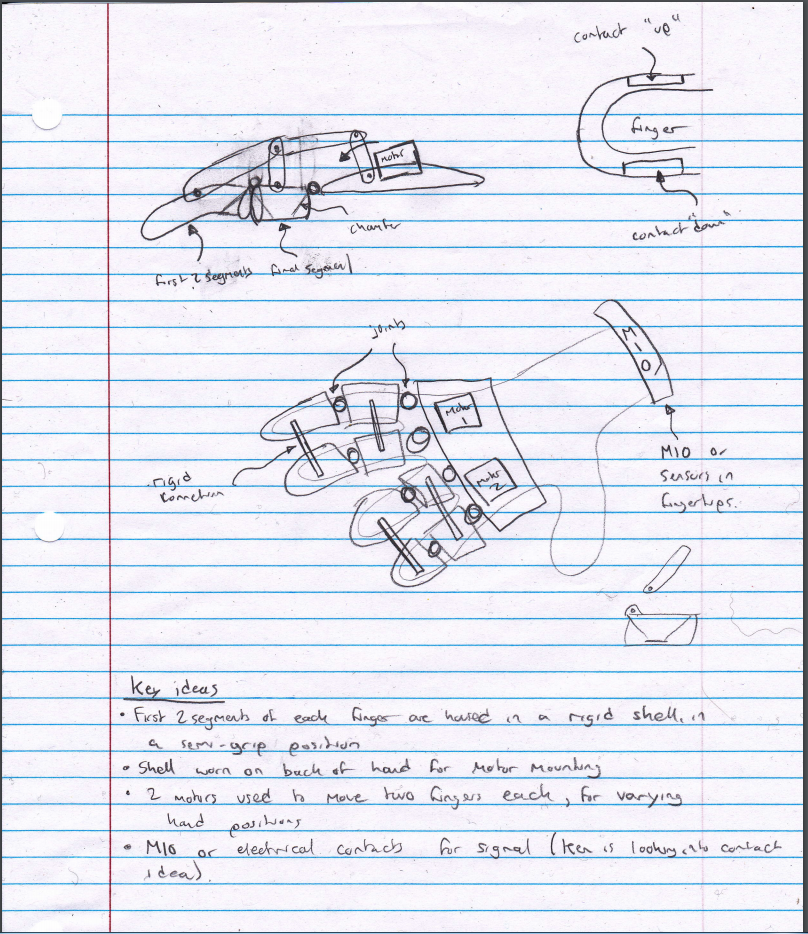

Our original idea was to create an exoskeleton for people with weakened grip strength. However, as our design was being made, the goal of the product has shifted into rehabilitating stroke victims.

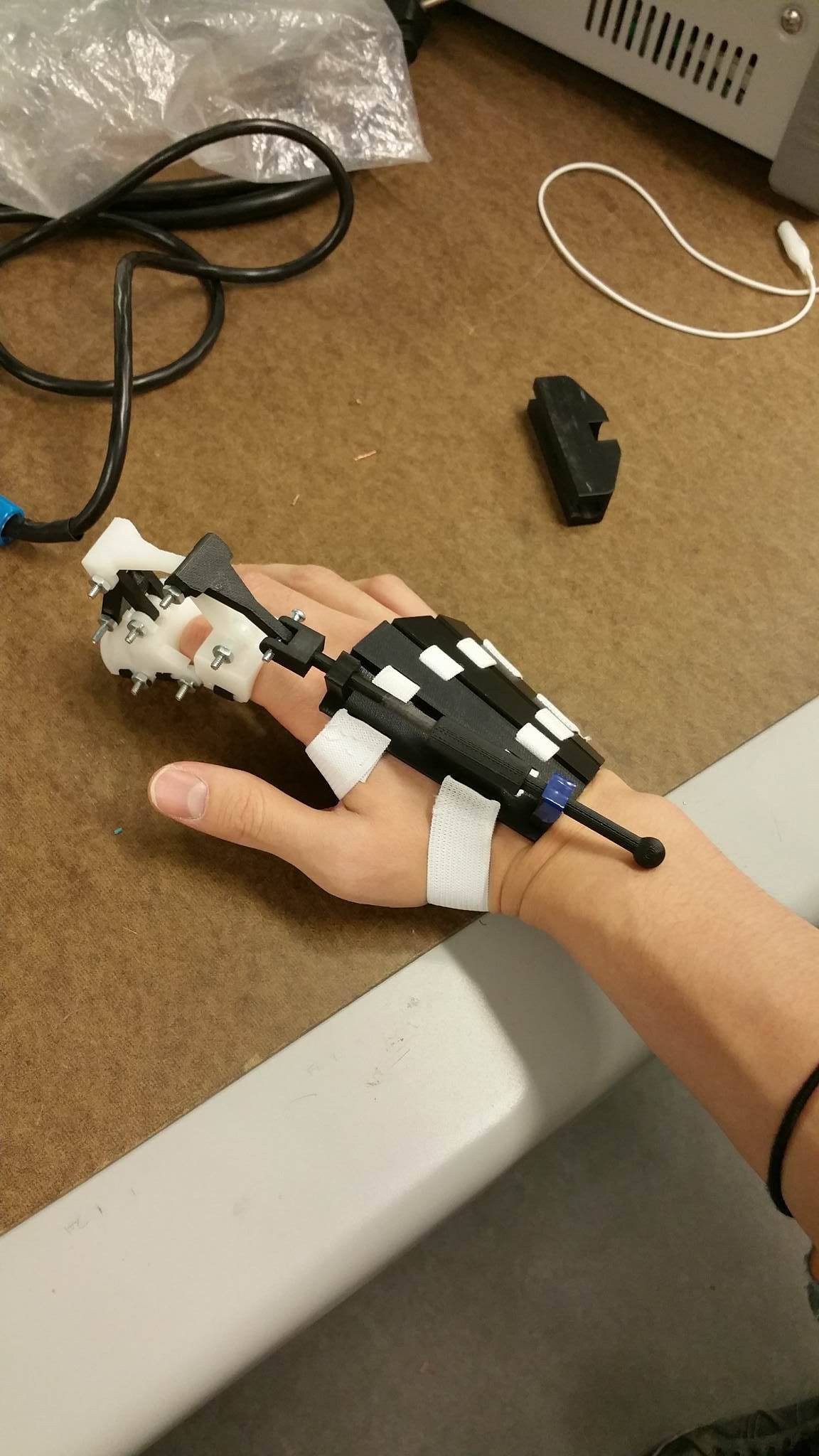

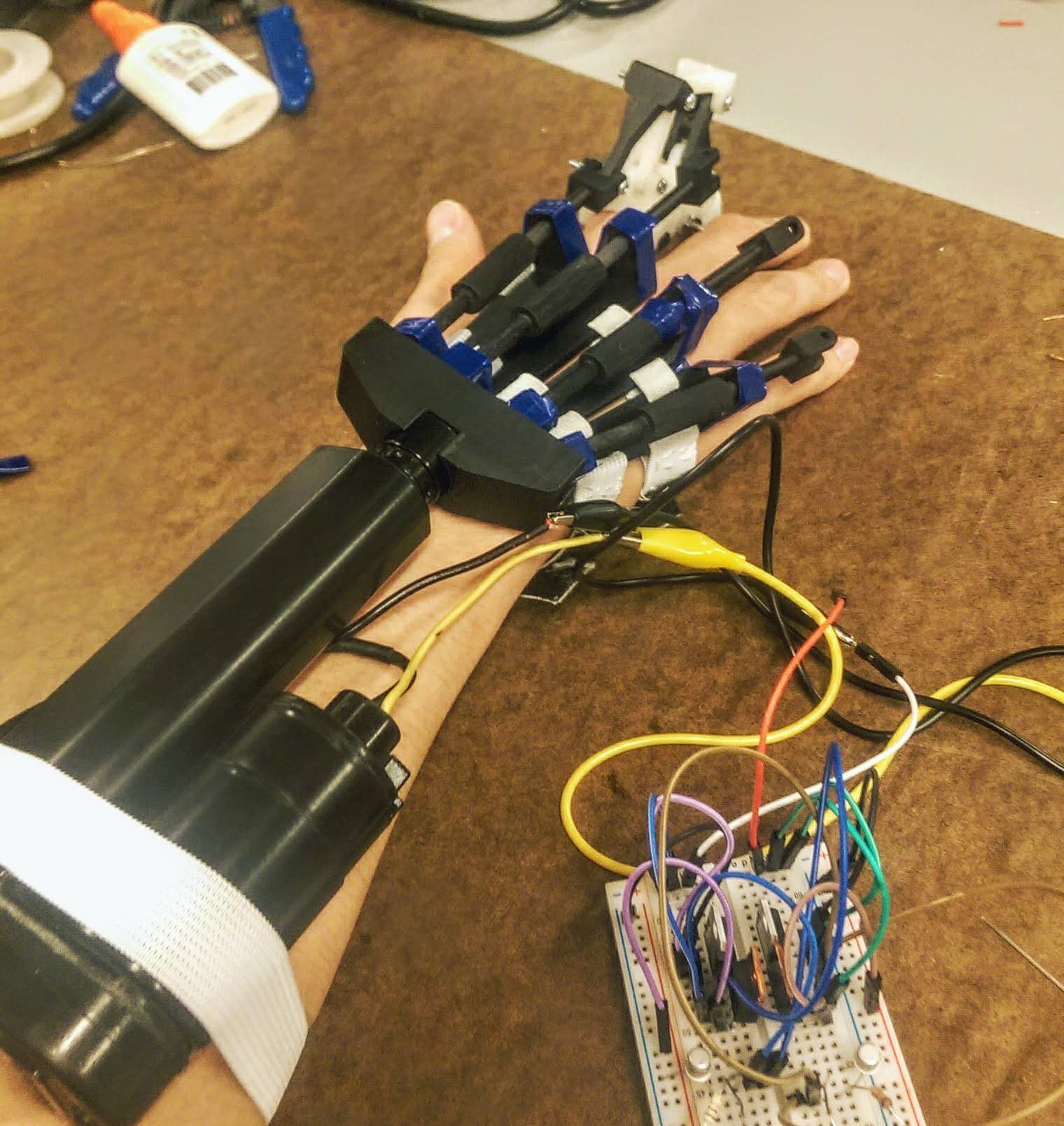

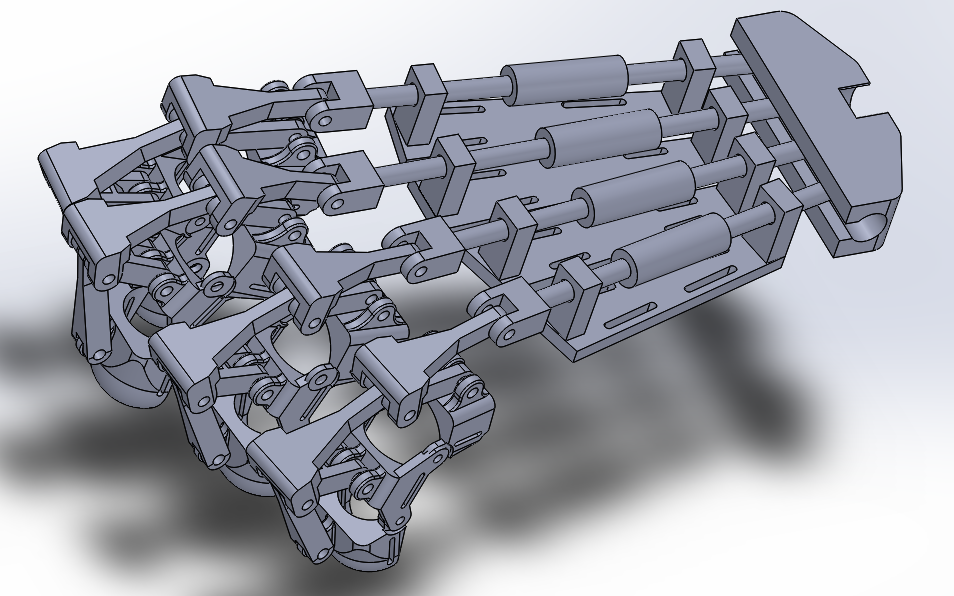

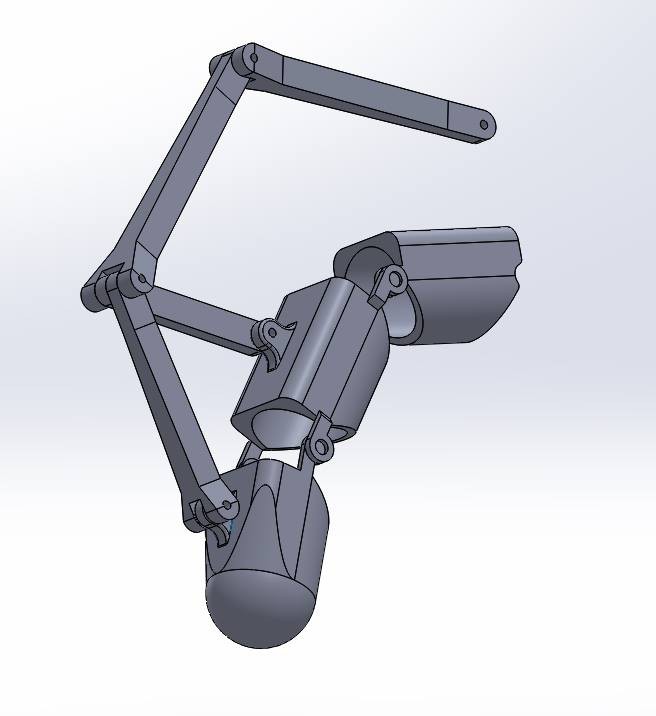

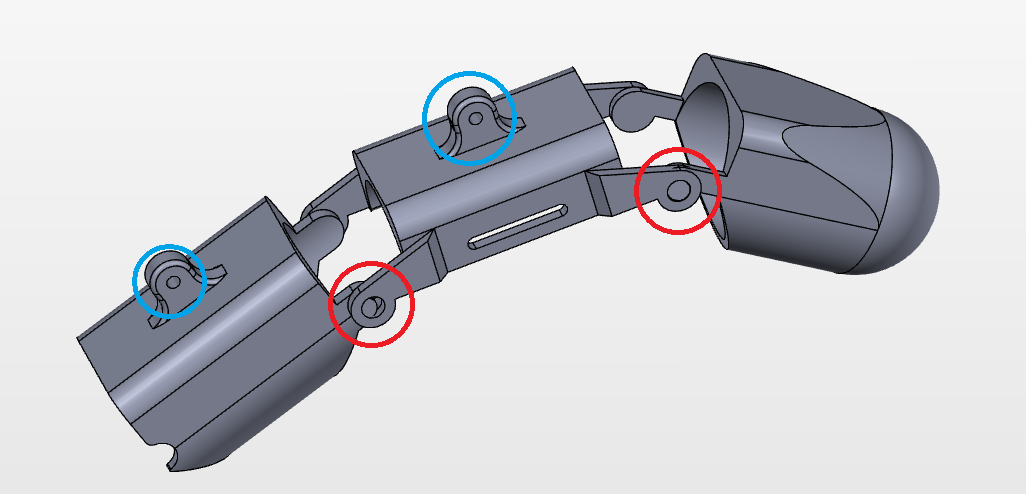

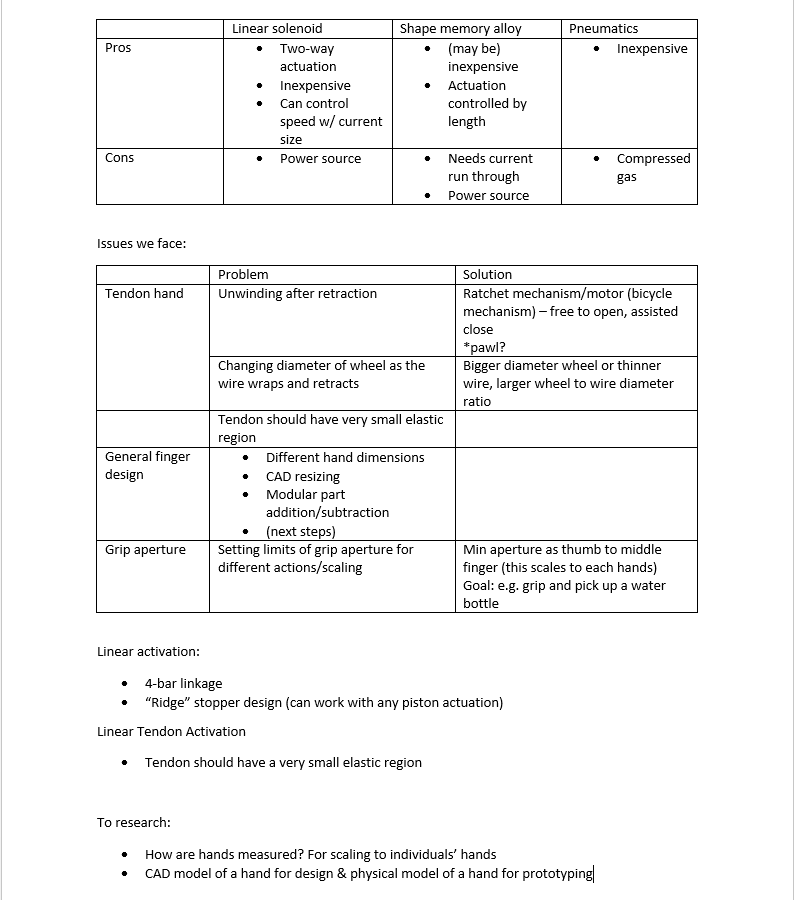

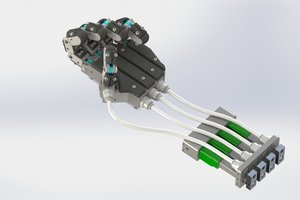

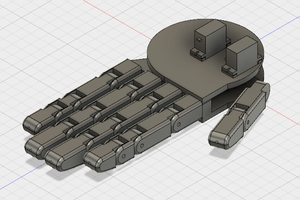

The device is powered by one linear actuator placed on the forearm. This actuator evenly distributes power across the fingers thanks to the linear differentials in the exoskeleton itself. The linear actuator can also automatically lock in place, allowing grip to be maintained over long periods of time without fatigue.

The device is controlled by a an Atmel microprocessor which uses force sensors and muscle activity sensors to determine how to deliver power to the hand. Force sensors are placed in the fingertips and a Thalmic Labs Myo is currently used to tell when the user is attempting to grip. We are currently developing a custom muscle activity sensor which is much more compact and effective for our purposes.

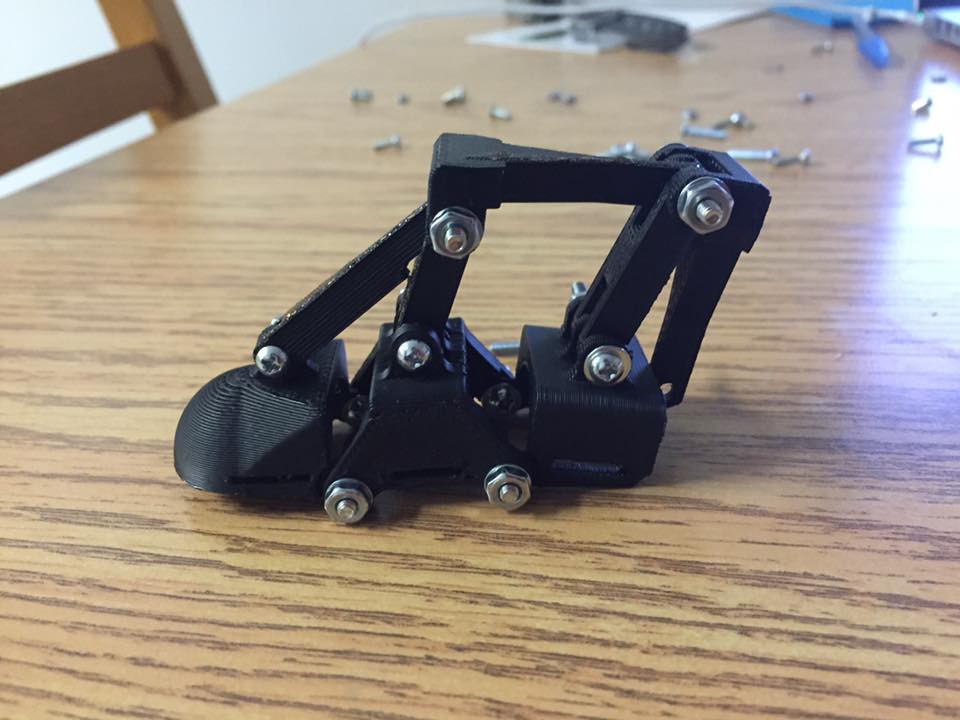

We hope that we can approach our goal of helping stroke victims as we iterate on our first prototype.

Chad Paik

Chad Paik

Supercell

Supercell

Your project helps me a lot while finding idea for my graduate project. Moreover, this is an useful topic and can be developed further, hope I can join the team.