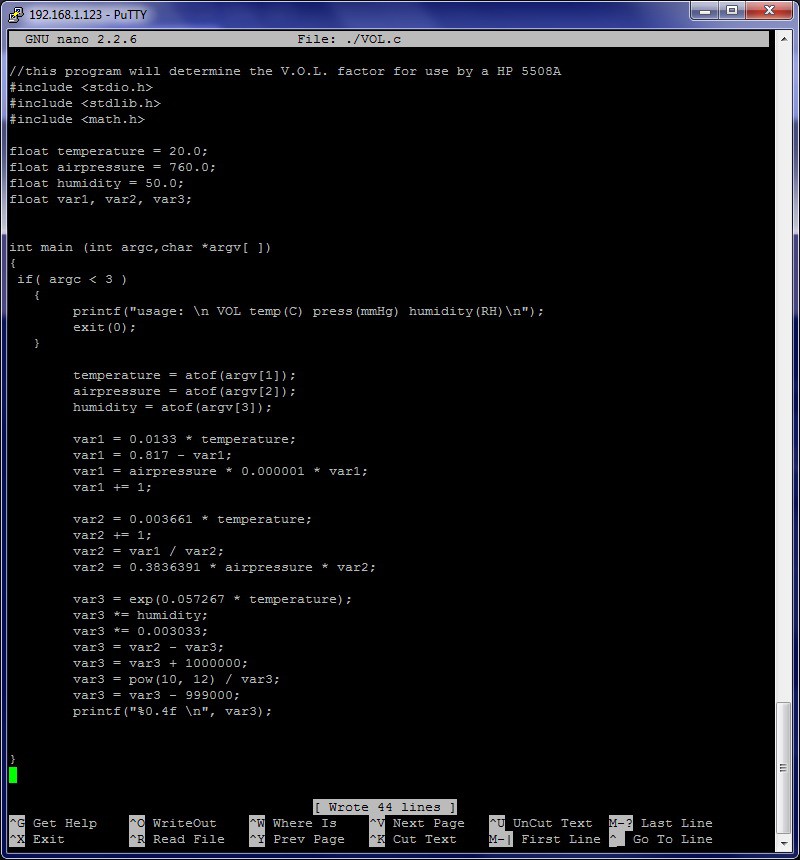

I learned about the Michaelson Morley Experiment about 20 years ago in college. At that time we also built a Michaelson interferometer on an optical breadboard. I was amazed at the sensitivity of the interferometer. Even with the optics levitated on pneumatic isolation legs on the optical bench, we could easily see people's foot-falls from the hall way outside of the lab and we could see vibrations caused by trucks driving down the road outside. A few years ago I read an article about commercially made interferometers. I became enamored the HP5528A laser interferometer manufactured by Hewlett Packard in the 1970's. I became interested in building a linear measuring machine which would be capable of making calibrated length measurements

repurposed luminiferous aether detector

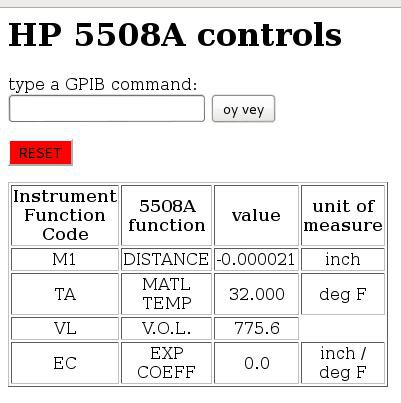

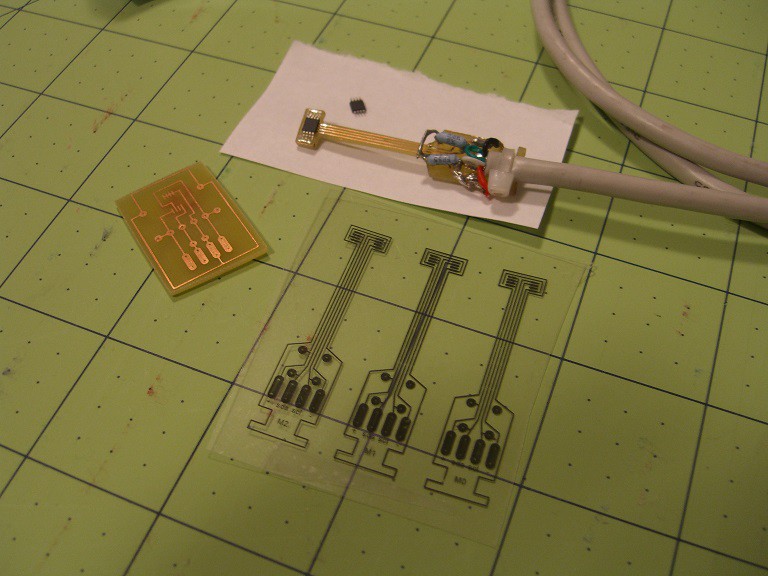

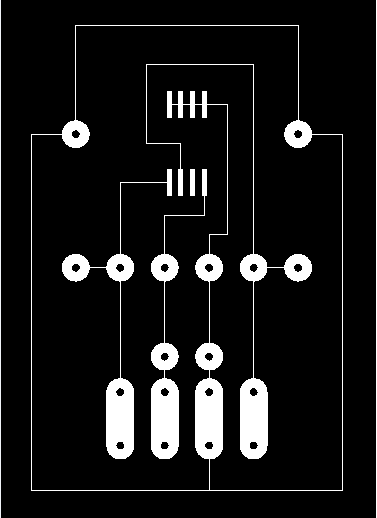

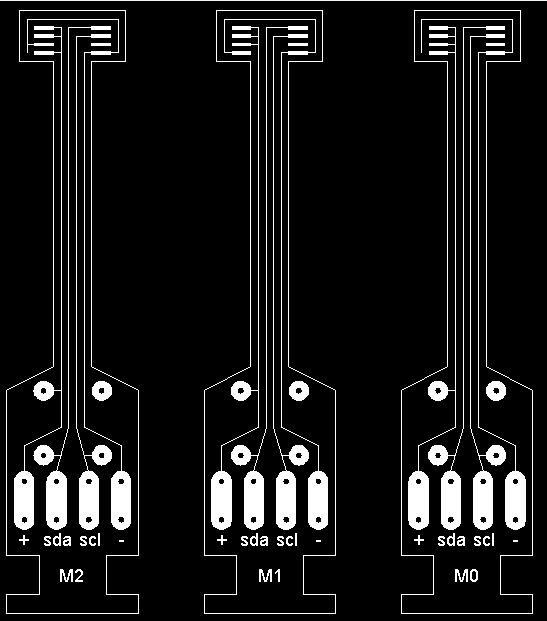

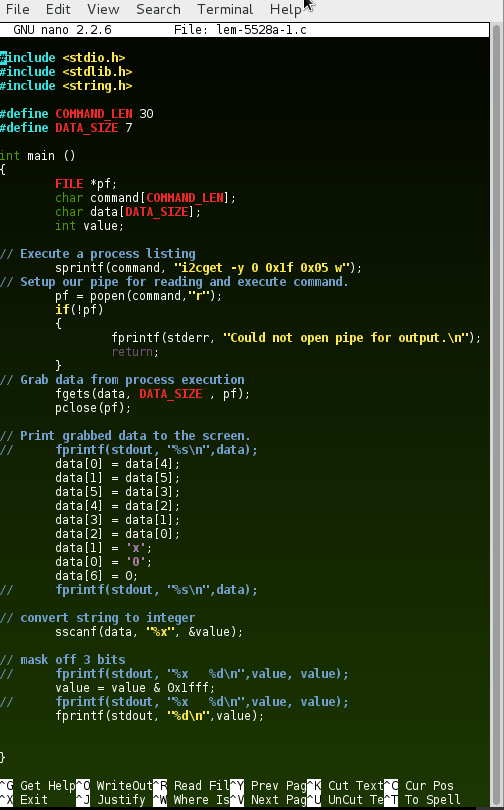

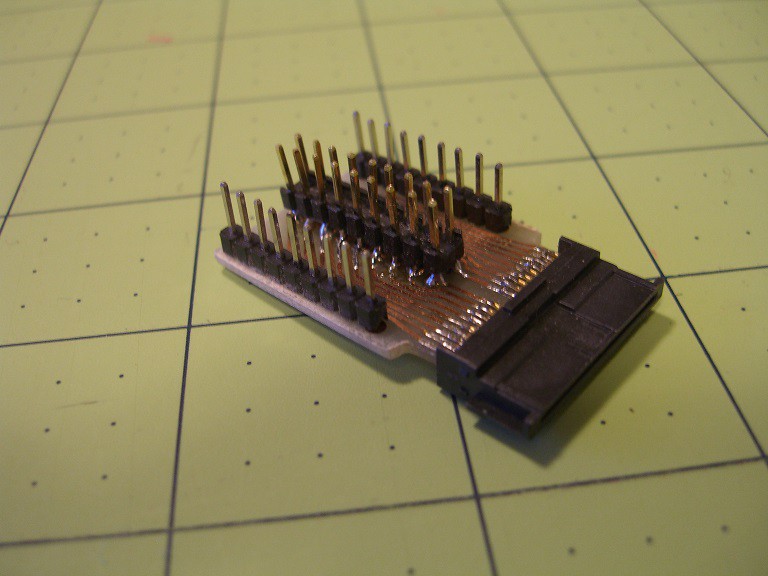

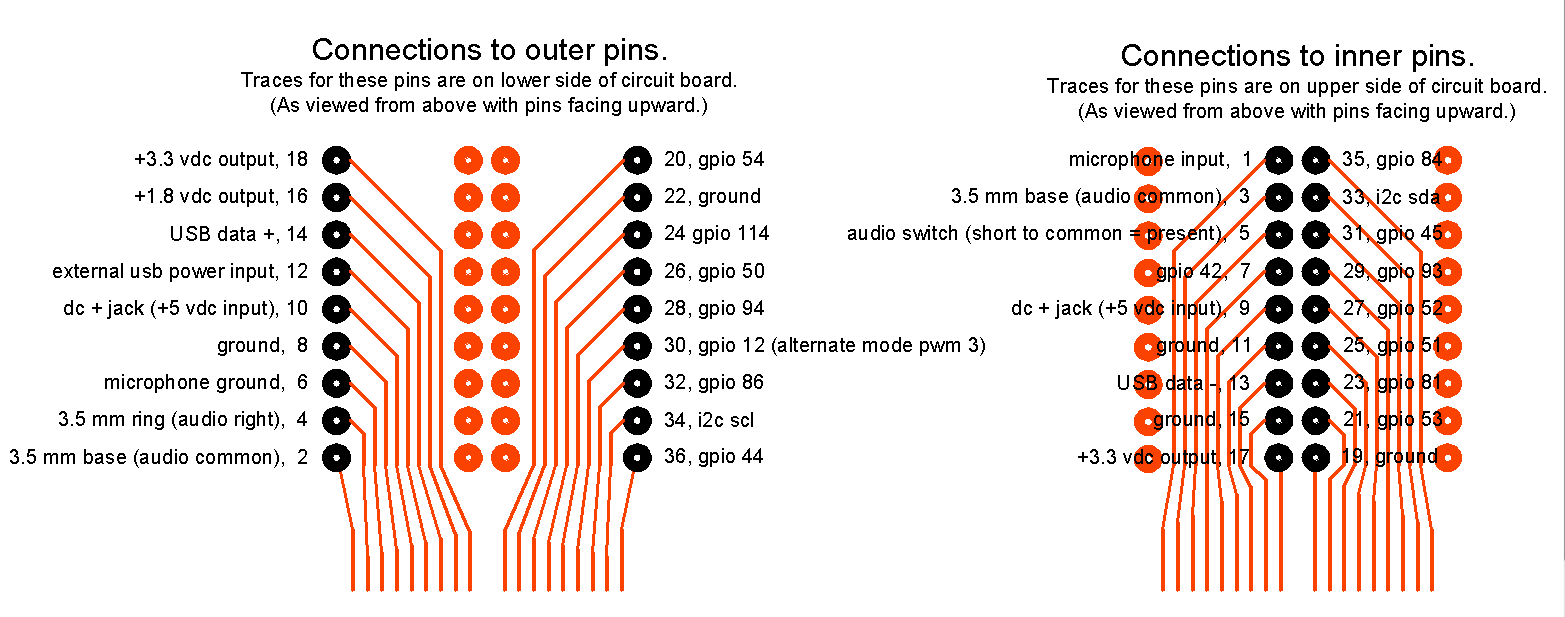

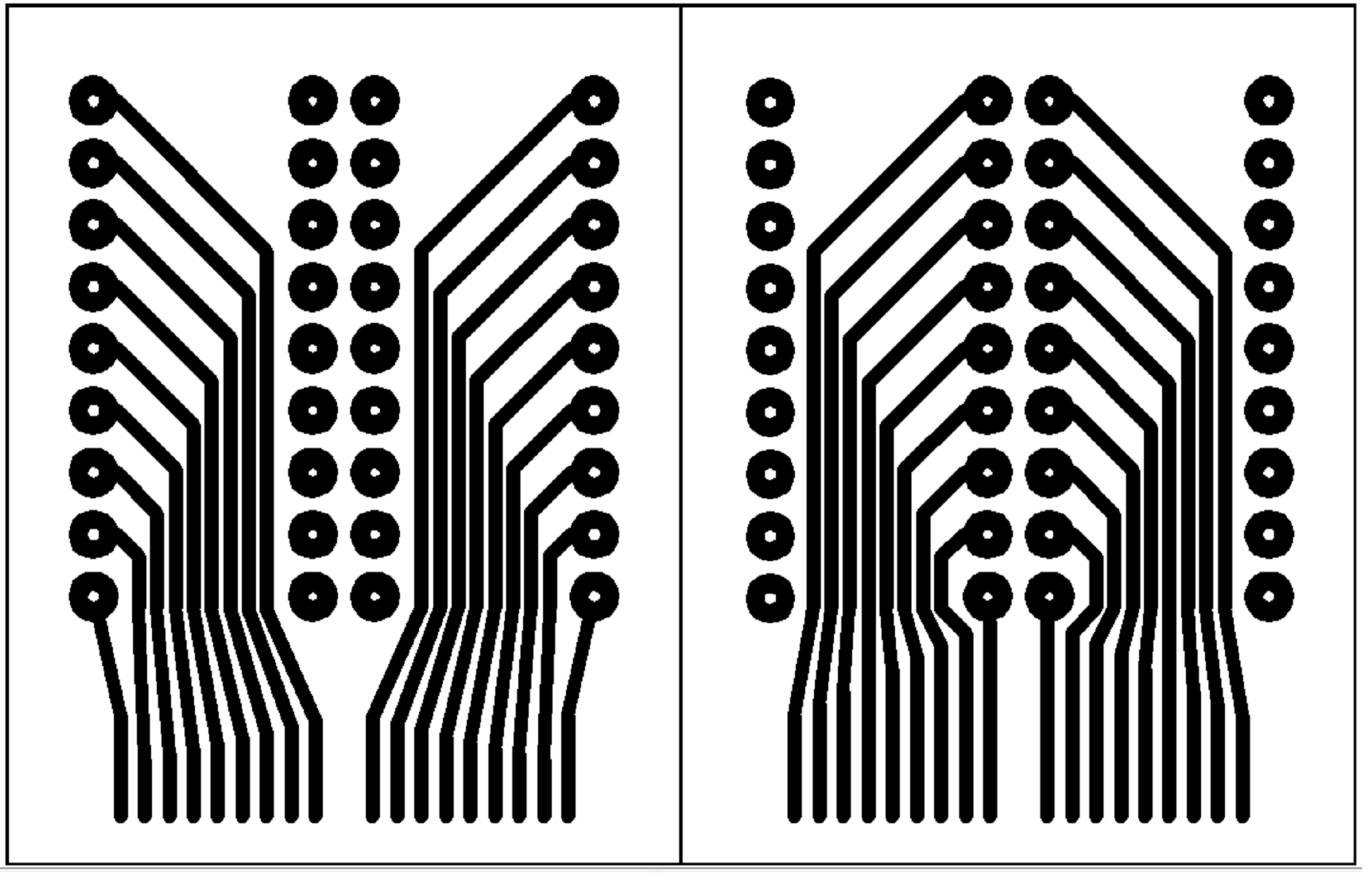

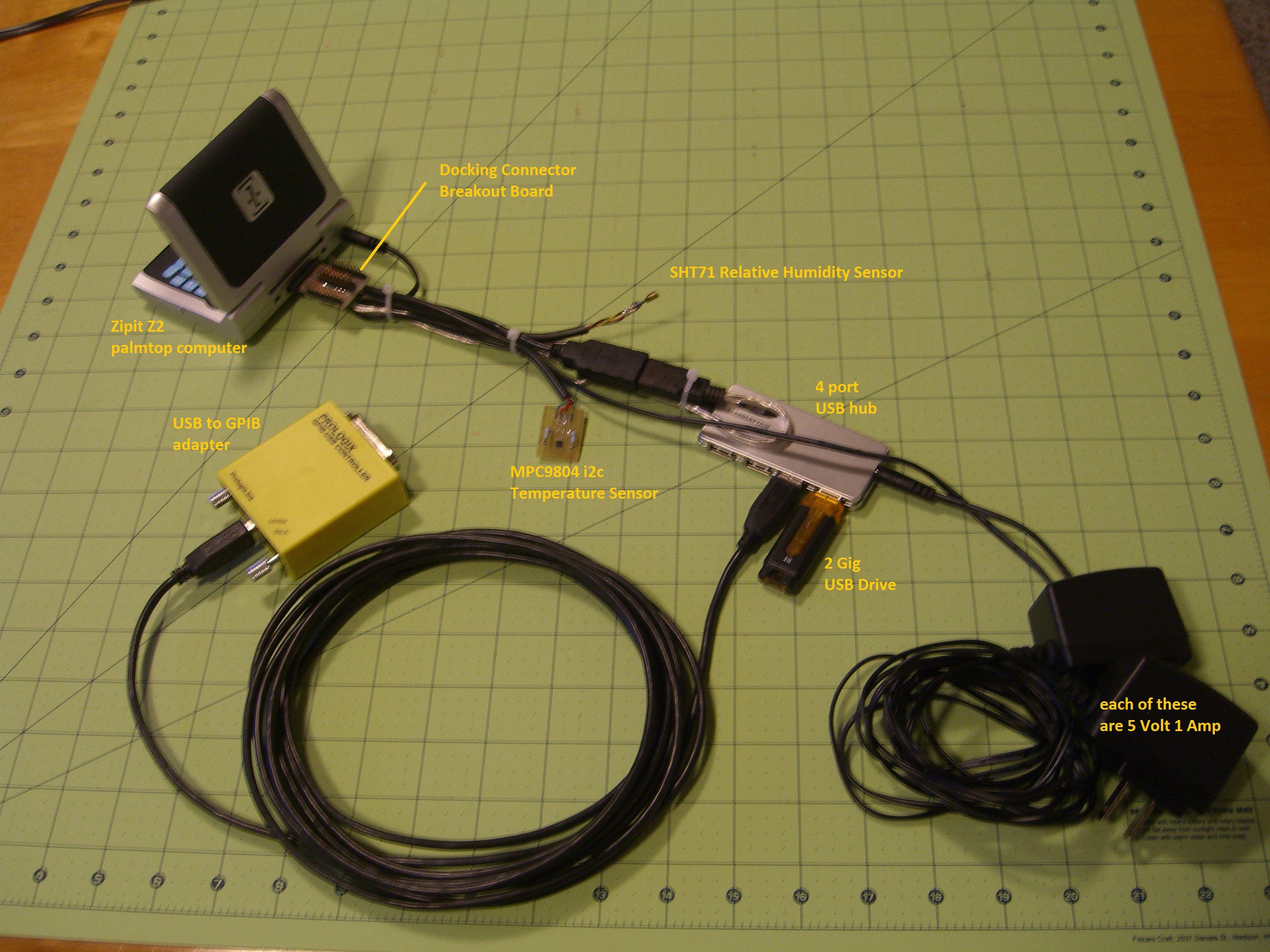

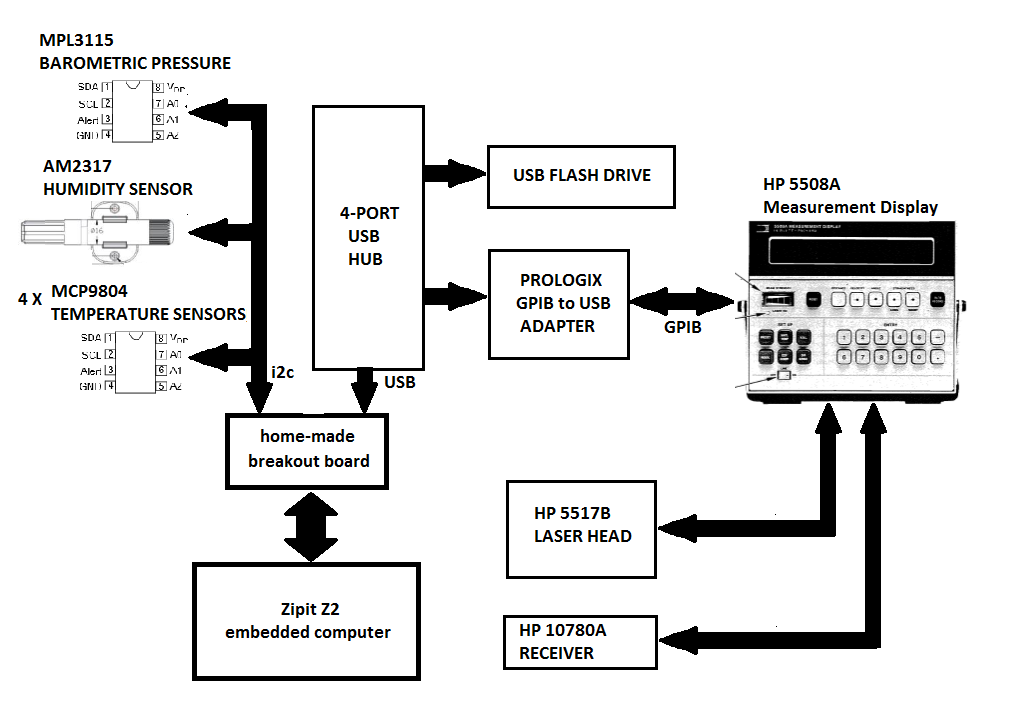

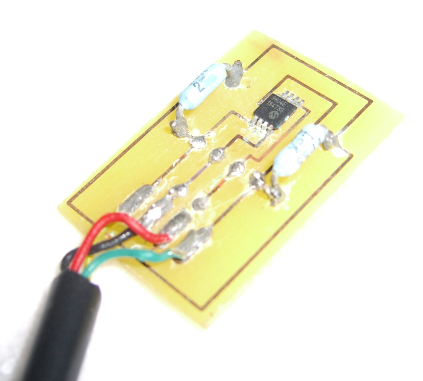

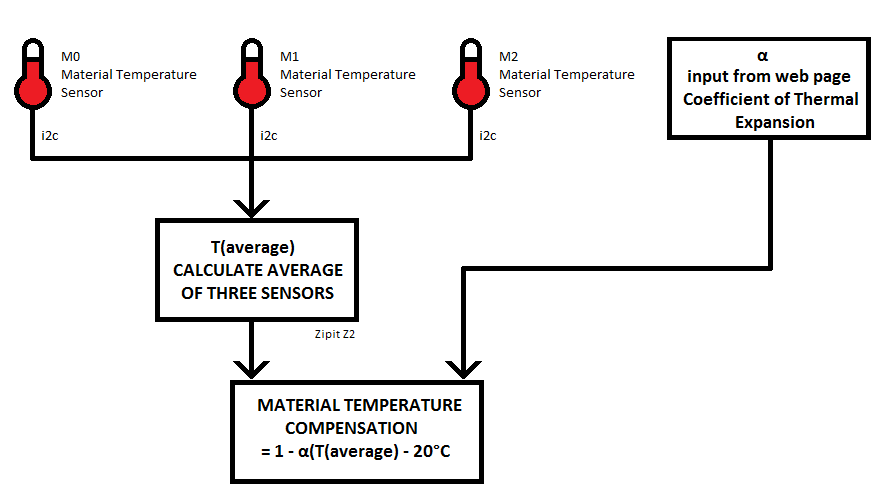

over the last few years, i've build up a functional laser interferometer. now i want to use it to accurately measure distance.

Beaglebreath

Beaglebreath

Lithium ION

Lithium ION

Leonardo Gomes

Leonardo Gomes

Juan Albanell

Juan Albanell