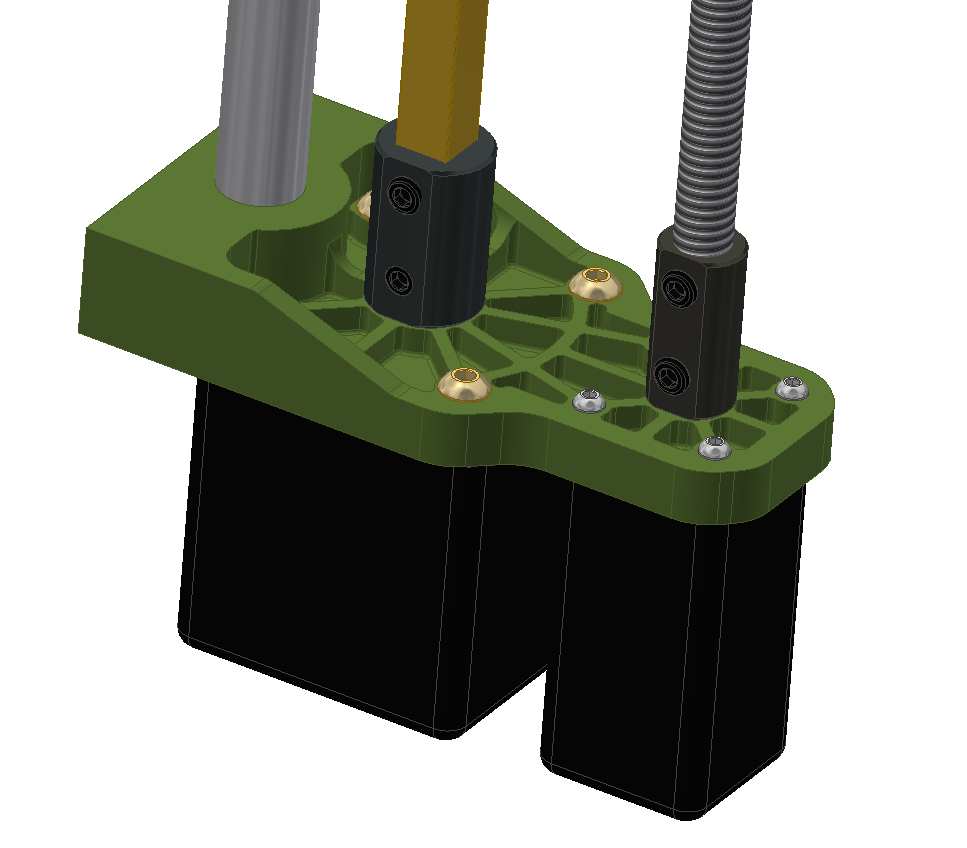

Finally had time to sit down and redesign the motor mounts, as stated earlier they will be a single piece design to minimize parts count. We are planning to 3D print the prototype through Shapeways, but eventually these brackets will be CNC machined out of 6061 T-6 Aluminum.

In this render you can see the square drive for the X axis, guide rod for the Z carriage, and the lead screw to drive the Z axis. There are 2 NEMA 8 stepper motors (one per side) that work in tandem to drive the Z-axis stage. The square drive will be much easier to understand once more of the drive mechanism has been modeled.

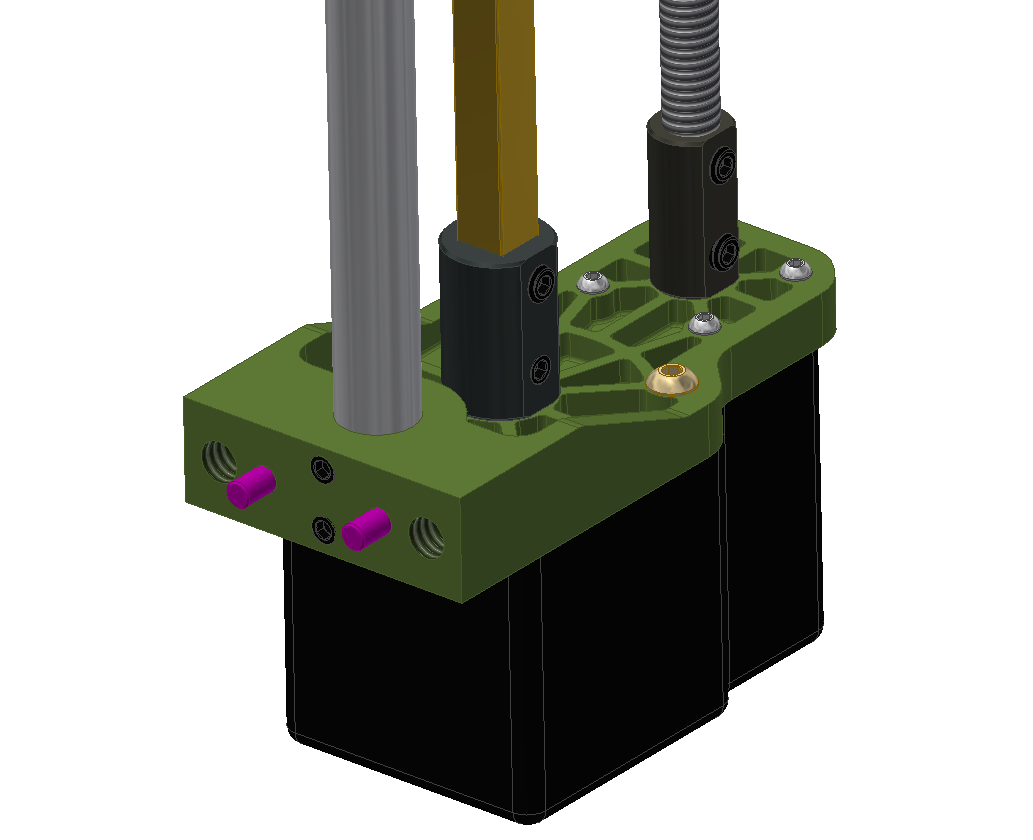

Here on the back end you can see how this carriage attaches to the main back plate. The back plate will be machined out of 6061-T6 aluminum, the TOME derives most of the rigidity from this plate. Both couplers will change slightly in order to 3D print them with sufficient strength to run the prototype.

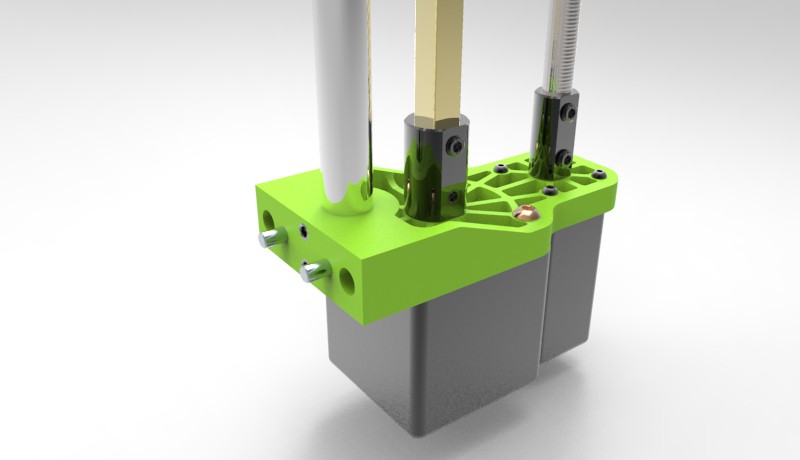

And because I know everyone love shiny things, here is a photo-realistic render....

I have to attend an open house at work tomorrow, for anyone in the PHX area come stop by Local Motors for some fun! (6/15/14 Starting at 10:00Am). I plan to have the preliminary Z and X Axis stages finished by this weekend. Stay tuned!

Philip Ian Haasnoot

Philip Ian Haasnoot

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.