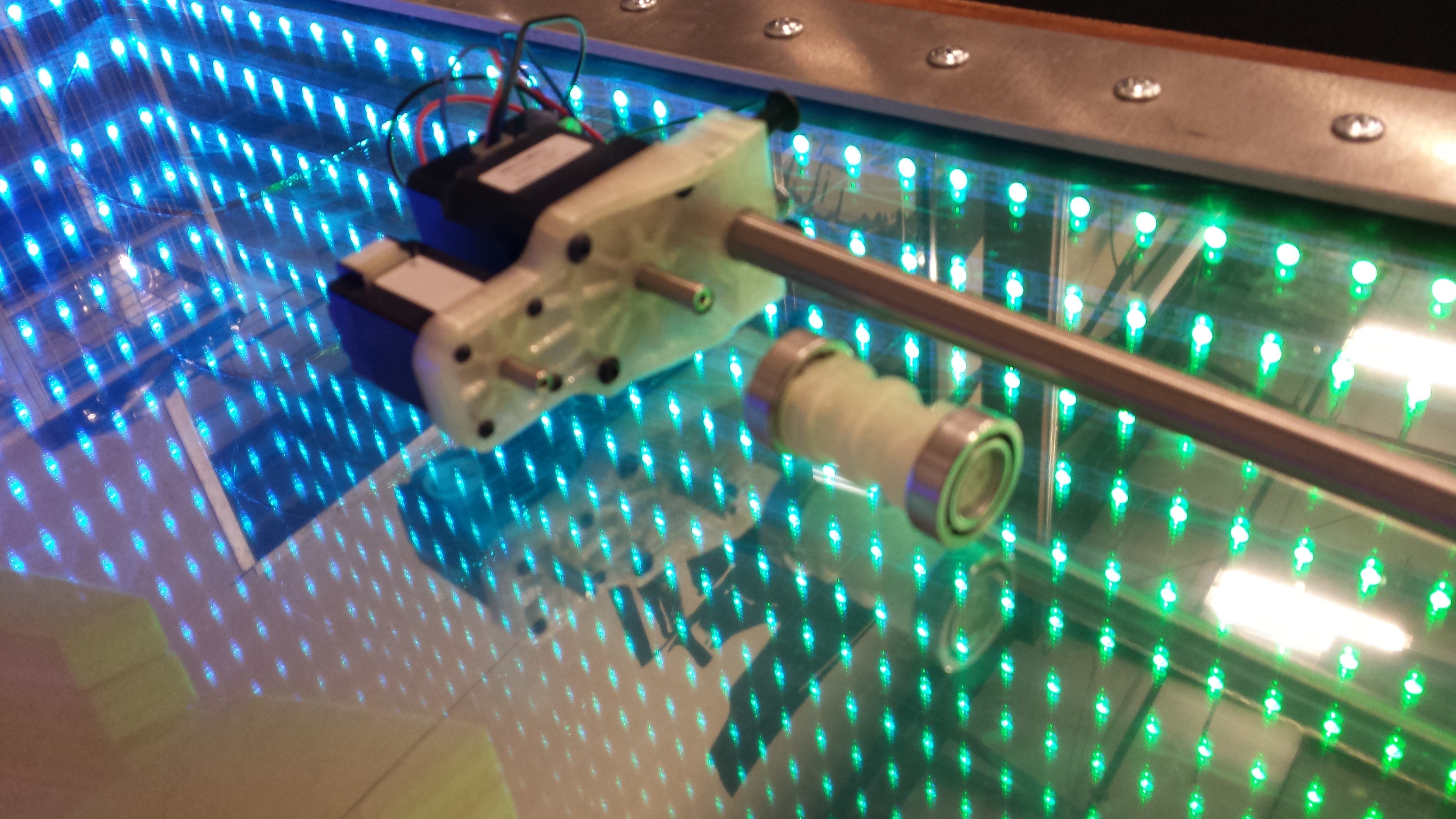

Today we received the first prototype part order, which contained enough of the components to start assembling the prototype to check for errors in the design. As stated before the clear PLA parts shown in the images will be replaced with 3D printed parts from Shapeways for the prototype. The spool in the center will need new bearings as the ones purchased from McMaster were of terrible quality, and the linear bushings were not the size we had ordered. Once we have the correct bushings and better bearings we will machine the first spindle.

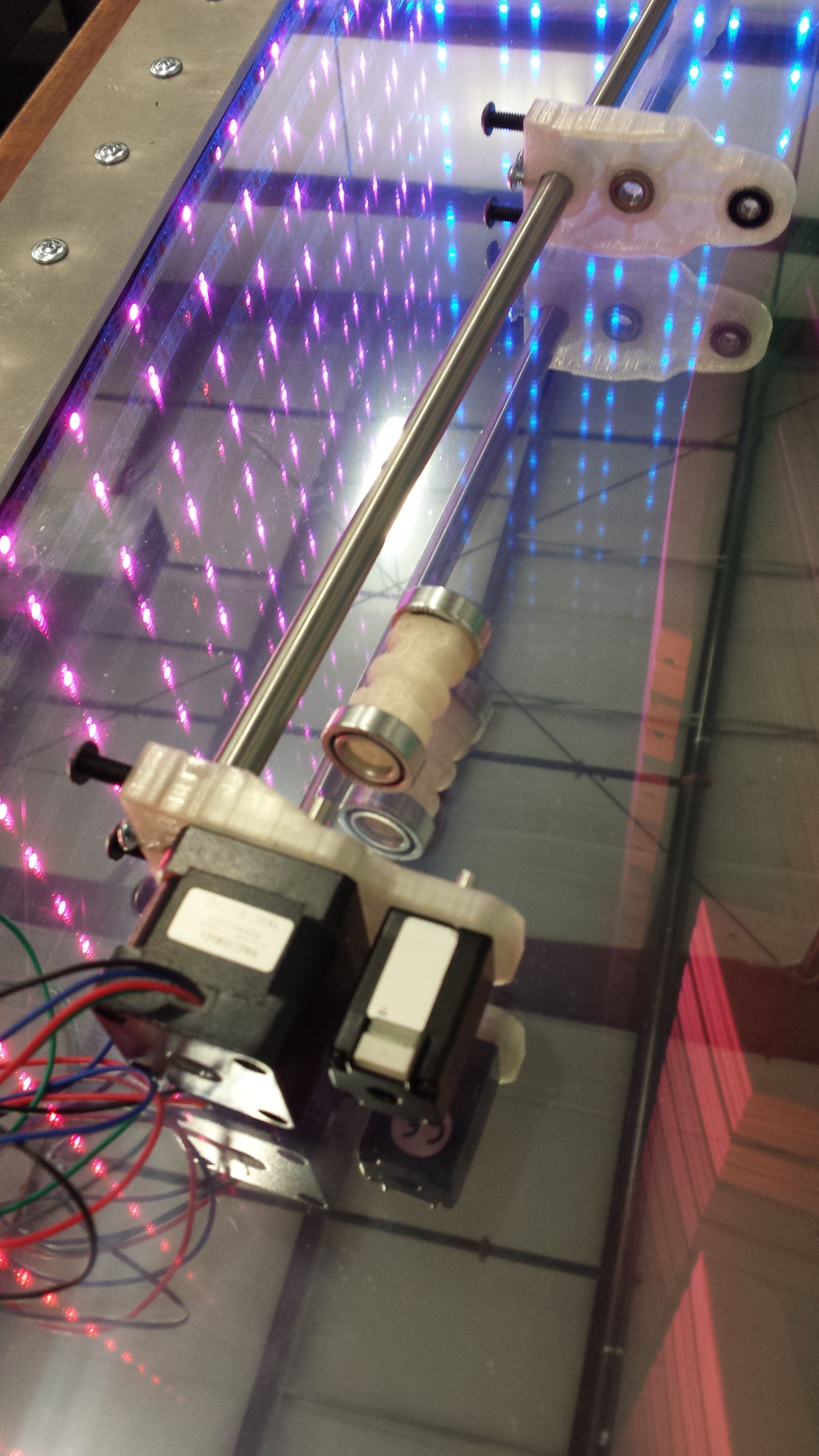

I plan to waterjet a prototype aluminum backplate tomorrow to mount this to, as well as cut the drill rod to the correct length. Here you can see the overall assembly clamped to the drill rod.

Here is a close up of the bottom motor mount and X axis spindle. As with most FDM prints there was some finishing required to get everything to fit due to excessive support material adhesion in the stepper motor counterbores. However this will not be an issue with the SLS parts from Shapeways. The spindle was printed to mock up the Z-axis which I plan on printing early next week.

The top bearing mount did not require any additional finishing, both bearing pressed in without hassle. The threaded rod will be arriving tomorrow, and will be machined this weekend along with the z axis coupler to get that component installed.

The plan is to having a functional printing prototype by July 12th, with most of the work after that going to building the battery pack, filiment cartridge, and overall aesthetics.

Philip Ian Haasnoot

Philip Ian Haasnoot

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.