One of the causes of slop in my printer linkages was the Traxxis ball joints. They have quite a lot of play unless they are pre-loaded. I worked around this by using elastic to pull the two arms together. This worked surprisingly well but showed slight movement at higher speeds.

Linkage arm pre-loading

As with most of my printer upgrades, I usually see some cool idea somewhere on the internet and think “That would be great on my printer”.

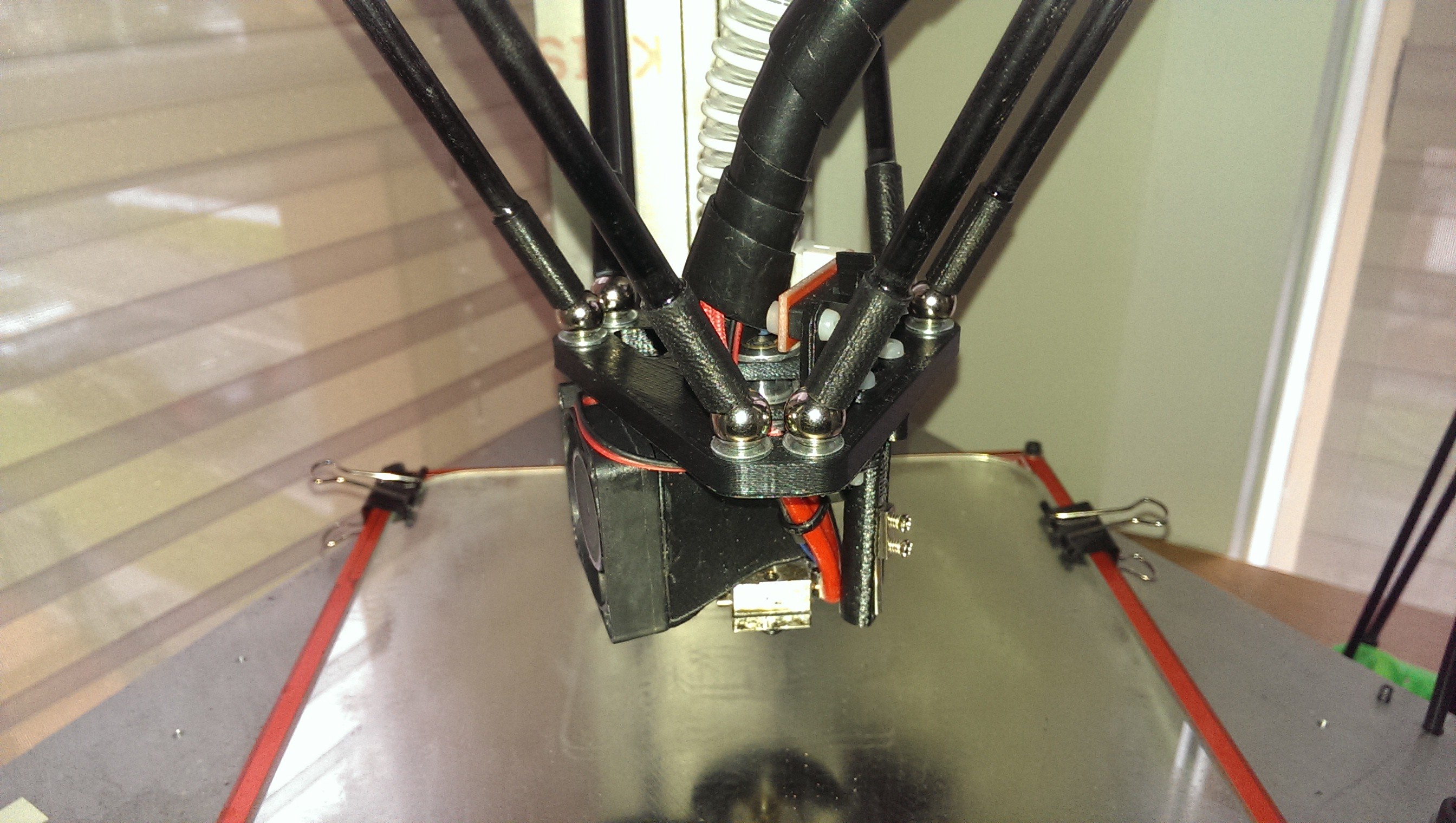

Magnetic ball joints have zero backlash. The magnet keeps tension on the ball and pre-loads automatically. I really liked the idea and thought it would be a good challenge to manufacture accurately. It would also fulfil another idea that I had in the back of my mind - easy interchangeable end-effectors! I could quickly swap out the print head for an engraver, laser or pen plotter.

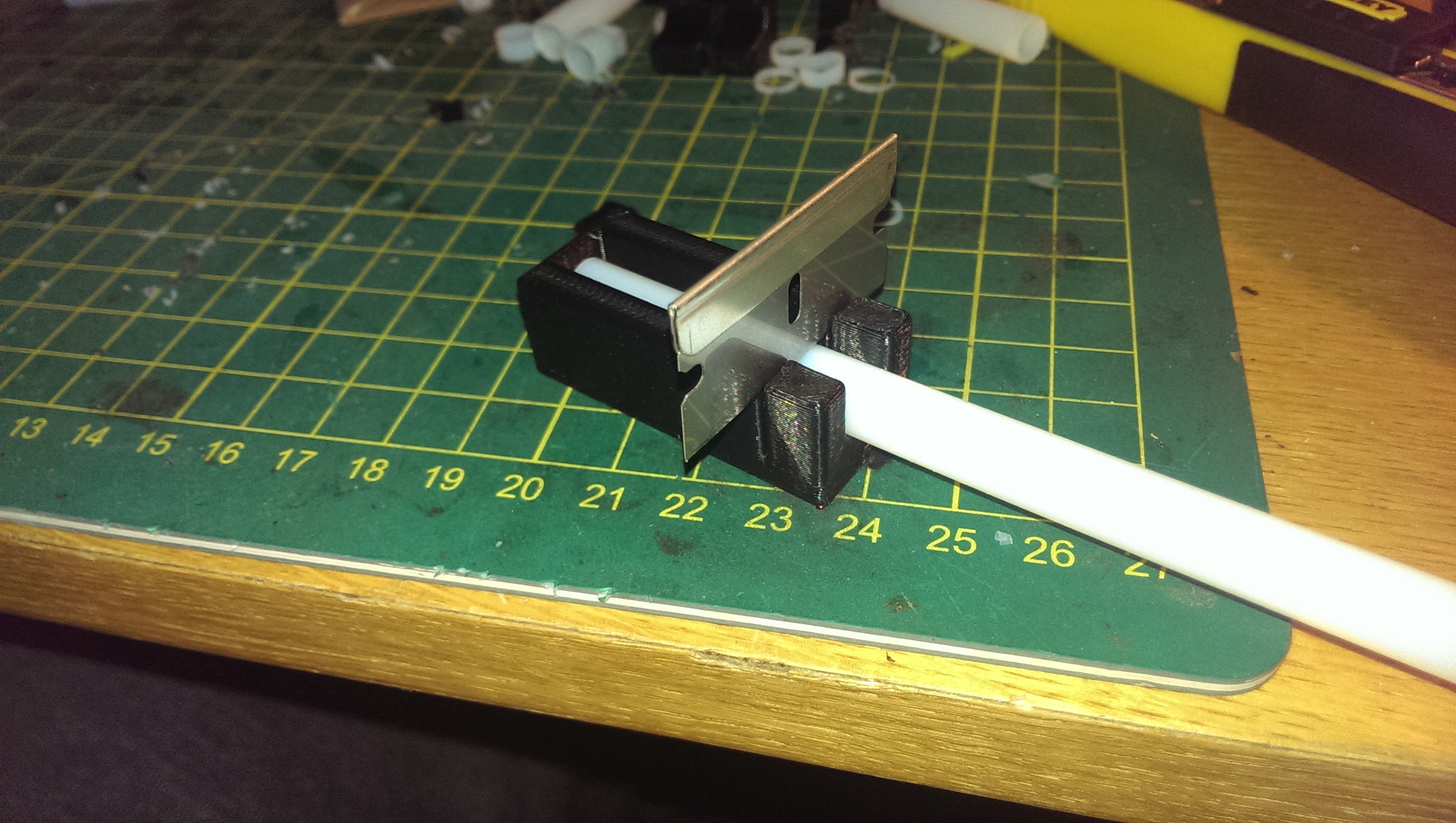

I started with some 6mm x 10mm cylindrical Neodymium magnets and 6mm carbon fiber tube. I printed some small tubes with an inner diameter of 6mm. These were slipped over the magnet and tube to hold them aligned. I sliced some PTFE washers from an old 6mm bowden tube. A printed jig ensured an accurate cut.

Printed mitre box

The PTFE washers were epoxied in the end of the printed tube between the magnet and ball. PTFE washers provide a low friction interface and prevent the magnet from touching the ball.

PTFE washer, magnet and tube

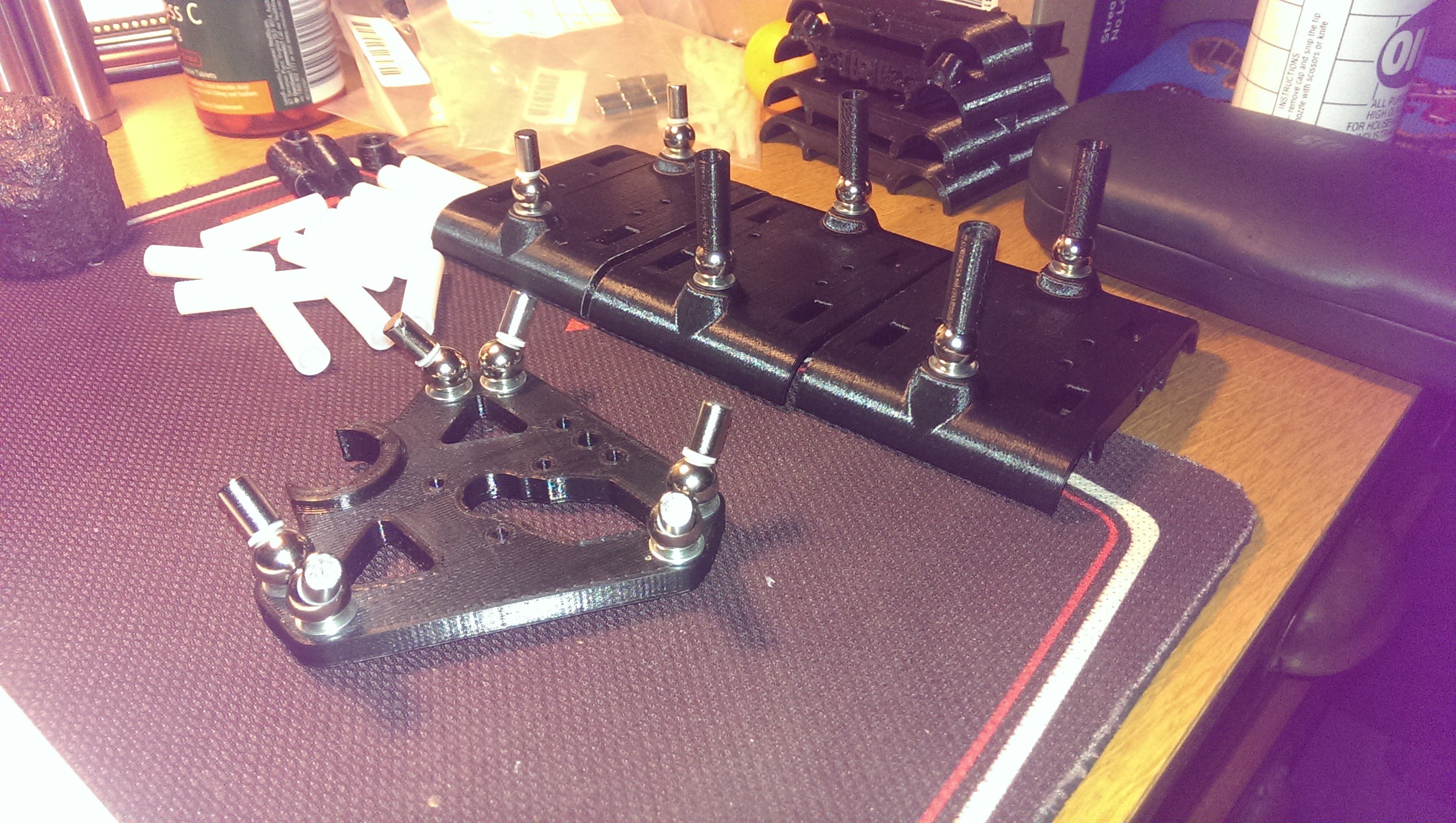

I had to print a new end-end effector and vertical sliders to incorporate 10mm threaded steel balls.

Testing PTFE washers

I assembled only one end of six arms and allowed the epoxy to harden. I then printed a jig to ensure that the other end of each arm would be glued at the same length.

Precision jig

The rods turned out well and the delta mechanics were extremely rigid. There was no backlash at all. The main issue that arose from the upgrade was when the magnets let go. The printer wouldn’t know if a ball link released and the end effector would be flopping around making a mess. This was soon to be rectified with another upgrade…

The power of magnets!

New vertical slider

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.