WHO: We're a handful of engineers, artists, and makers from San Francisco, working in security, hardware, software, gaming, and embedded systems.

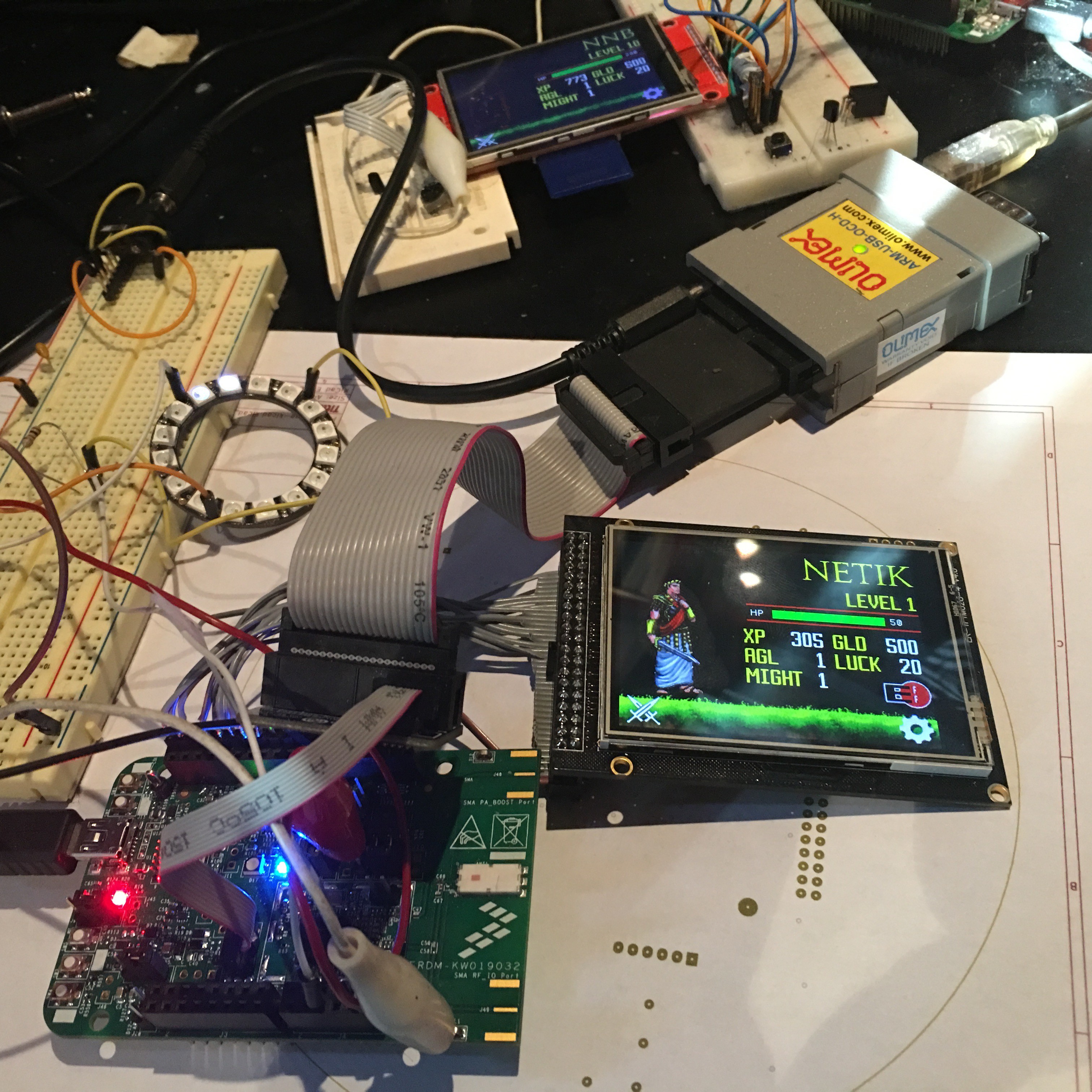

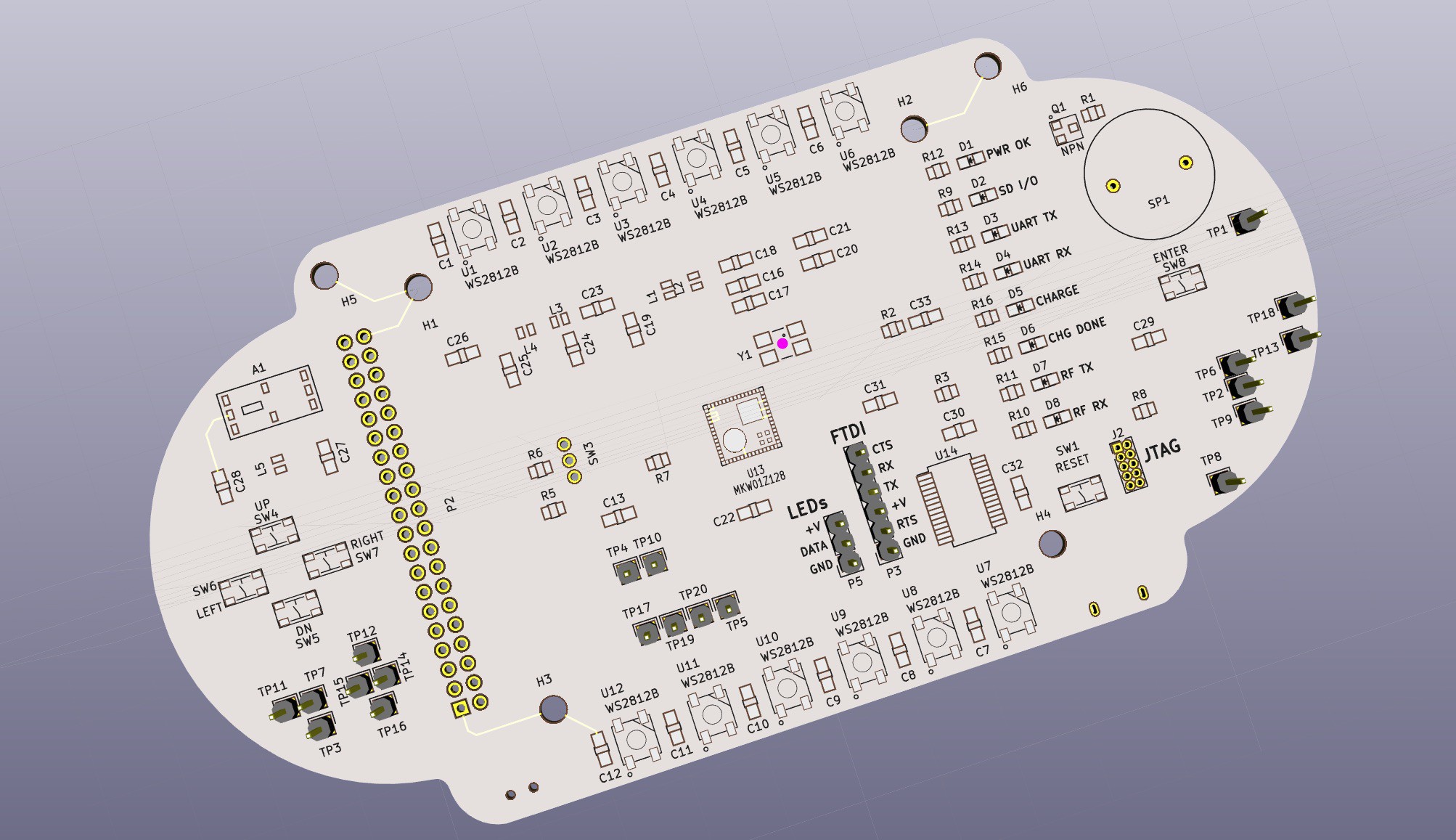

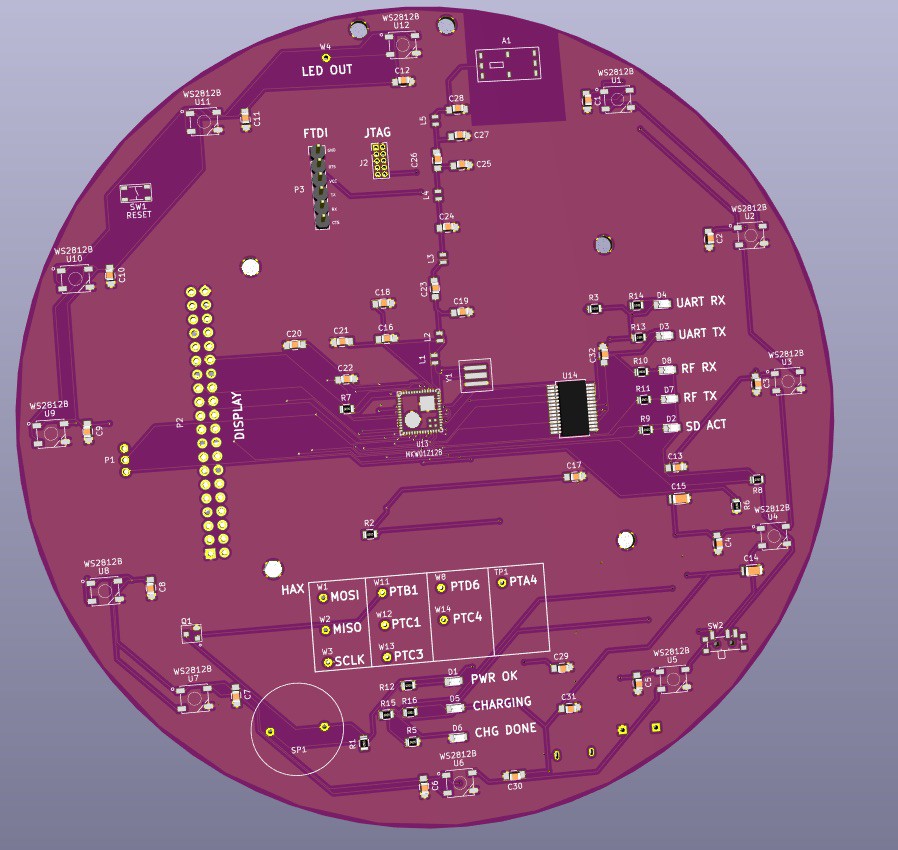

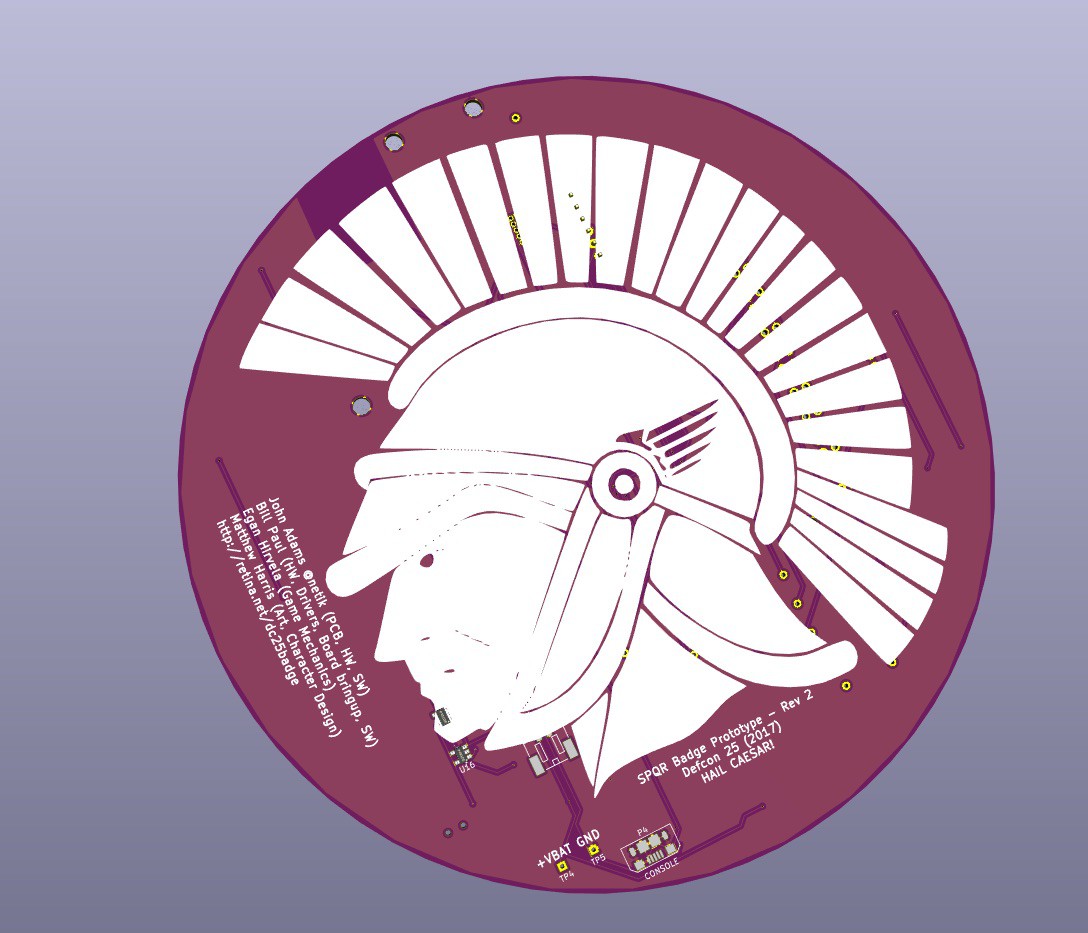

WHAT: We are building a hackable, open electronic badge for use at DEFCON 25 in Las Vegas. We want to showcase the Freescale platform + ChibiOS, experiment with wireless technologies, and make a fun game for people to play.

WHY: Because we've never done an embedded hardware project in this quantity on our own, and want to learn electronics manufacturing and work more on MCUs.

WHERE: Caseser's Palace, Las Vegas. DEFCON25.

WHEN: July 2017

EXTRAS: We're spending our own time and money to develop this.

We are definitely open and encourage feedback, suggestions, and features.

If you like what we're building and/or have suggestions, let us know.

All of the software, PCB design, and schematics will be open sourced during DEFCON25.

John Adams

John Adams

Piotr Esden-Tempski

Piotr Esden-Tempski

Dylan Brophy

Dylan Brophy

Casual Cyborg

Casual Cyborg

Hi there, it is probably "dead", but is there any chance to grab one?

Missed the campaign unfortunately :( Thanks!