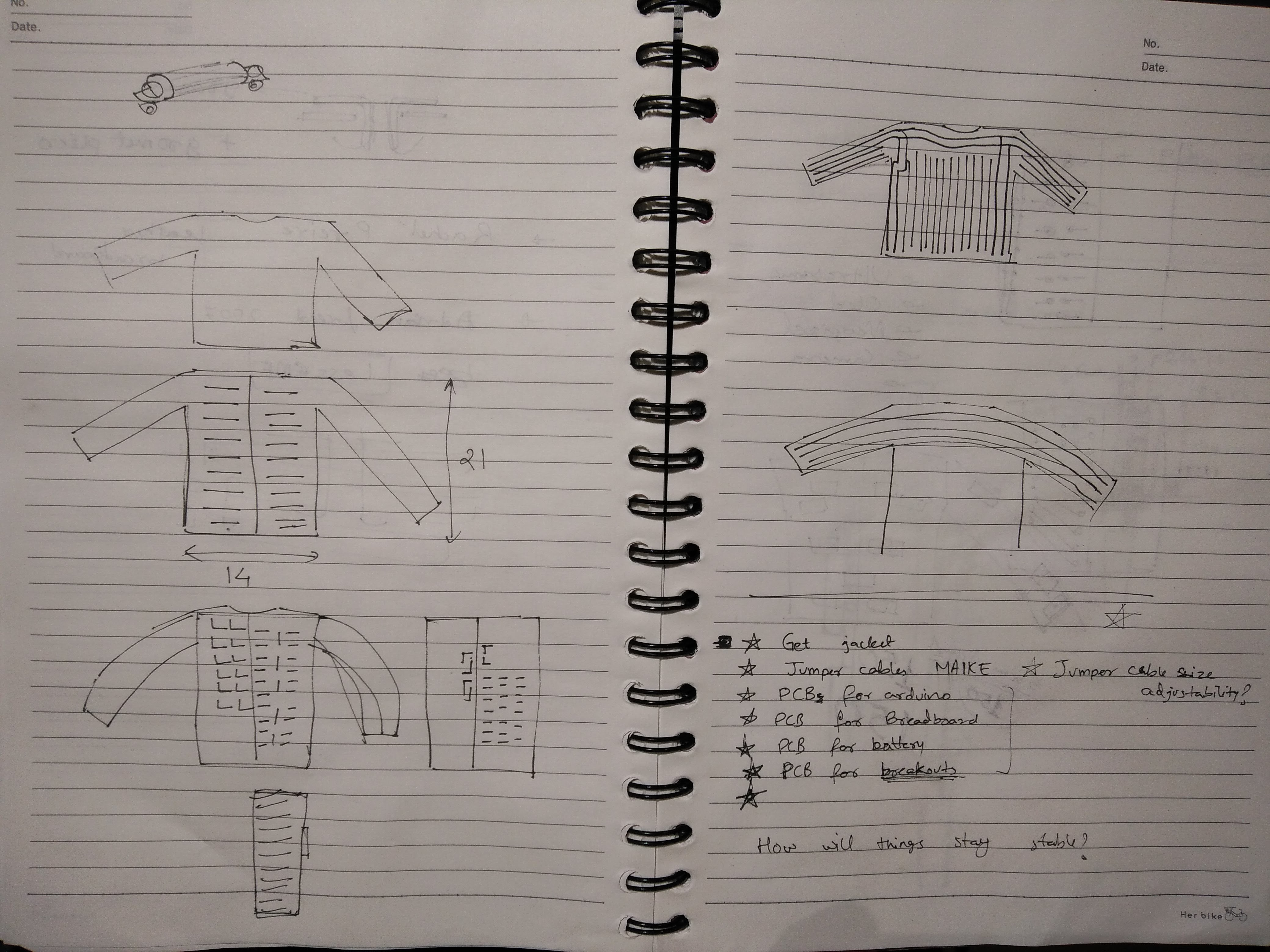

IDEATION:

The project has evolved over the past two months through the Wearables class at Tandon, NYU (DM-GY 9103-I). It started out as a wearable breadboard, with the aim to allow quick and dirty wearable prototyping. After much design and redesign, I realized that a robust and easy to use solution is not possible. So I altered the idea to be a wearable prototyping platform.

I wanted the jacket itself to be very robust against wear and tear, even with rough use. So I opted against sewing conductive thread. I researched a lot for a suitable conductive material, testing dozens of metal ribbons. I finally settled on steel ribbon from Adafruit. But the ribbon is prohibitively expensive at 25$ per meter. In true ITP fashion, I hit the junk shelf instead and realized that the steel sheathing for display cables is an ideal replacement. I stripped around 10 meters of the stuff and was on my way to fabrication!

Amitabh Shrivastava

Amitabh Shrivastava

Nikodem Bartnik

Nikodem Bartnik

Tyler Johnson

Tyler Johnson

Niek

Niek

Gabriel D'Espindula

Gabriel D'Espindula