It always takes a few hours to program the pick & place. Here I am using a bunch of components on cut tape, so I just stick them to a board and use the vision system to set the location of the first and last part. That's the first part of project setup for the placer, and takes an hour or so unless you bump a strip of 0603 LEDs and have half of them jump out into a scattered pile. Then, it takes longer. :)

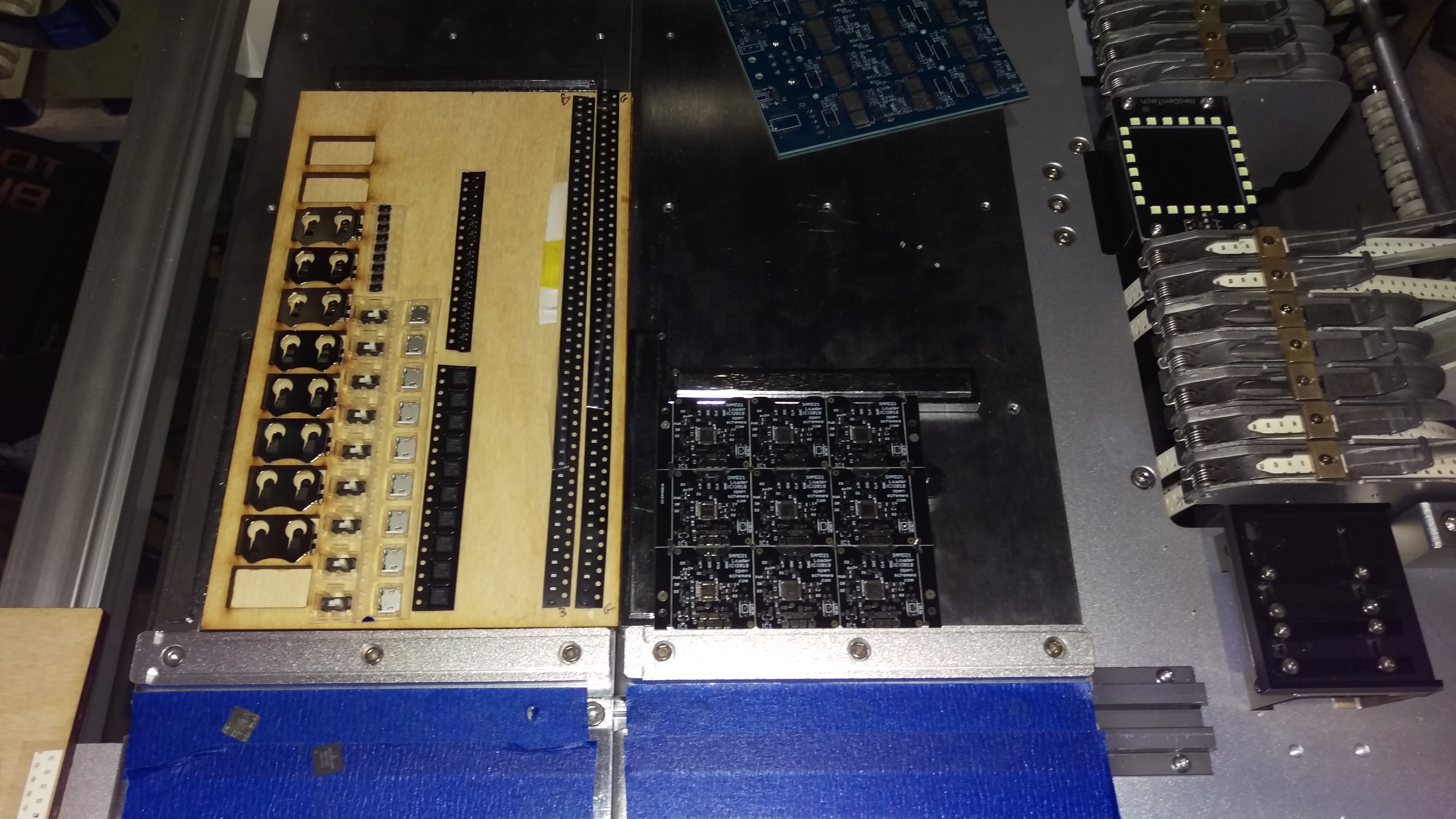

Here you see the PCB panel on the right, and components stuck to a wooden plank on the left. From left, it's Battery Clip, Switch and Reset Button above it, USB socket, SAMD and LDO above that, then two rows of LEDs - blue and green.

Some components like caps are already mounted in reels on the side of the machine, but there are always a handful of custom components (or ones that are too expensive to buy a full reel!!) that I use cut tape for.

The next part of setup is verifying the placement and orientation by running a placing cycle (usually for one component only) with double face tape on the PCB. The machine grabs the part, checks it, and sticks it where Eagle said it should go. It's usually perfect, but a few oddball devices like the USB port had a center location different from what Eagle outputs and need editing.

It's tedious, but if you're making a bunch of boards it is much easier to take the pain now in exchange for MUCH faster assembly than doing it by hand.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.