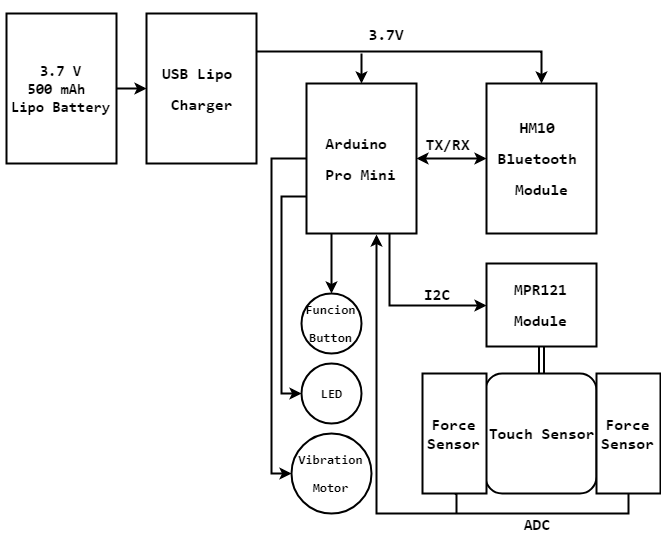

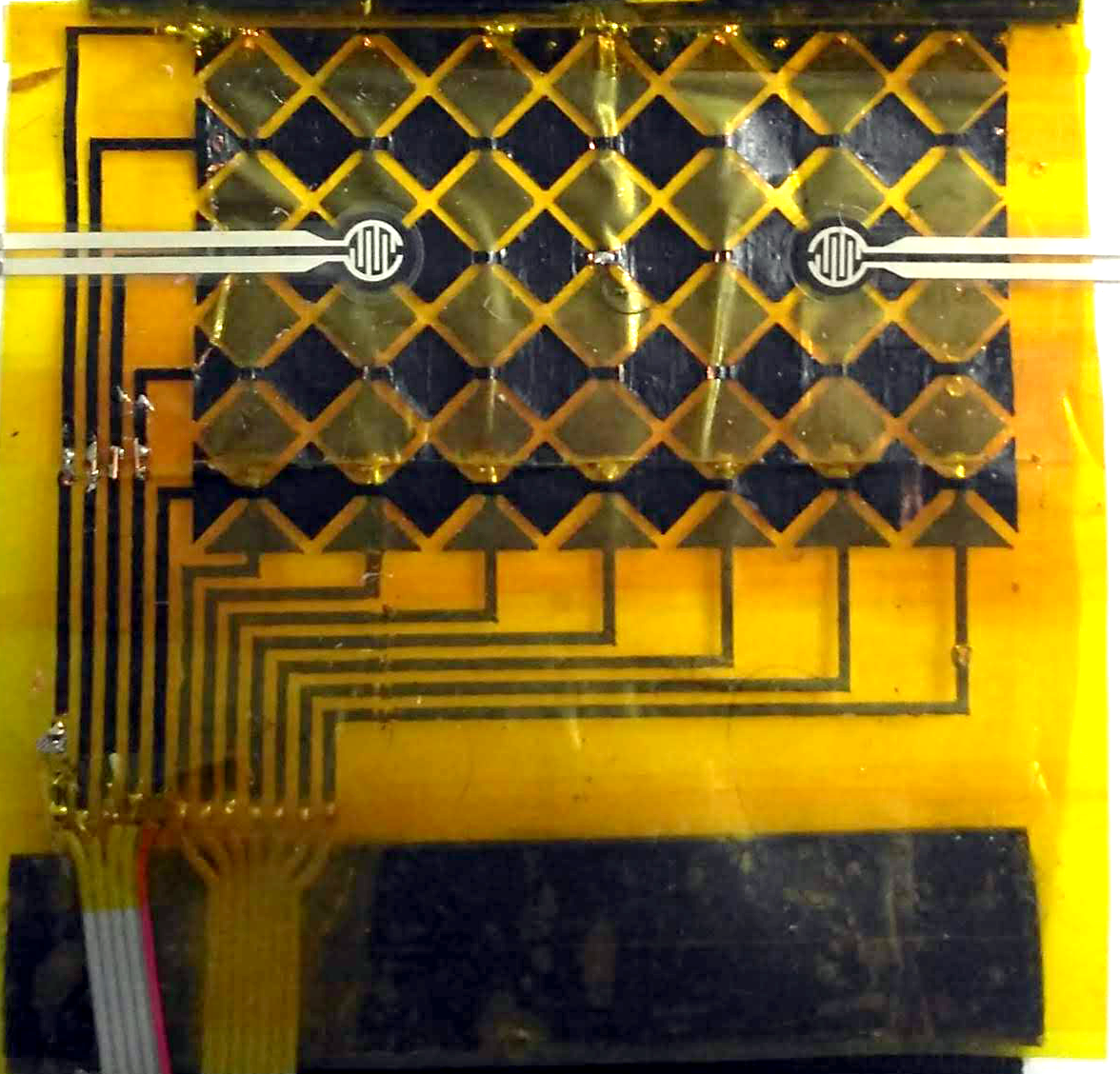

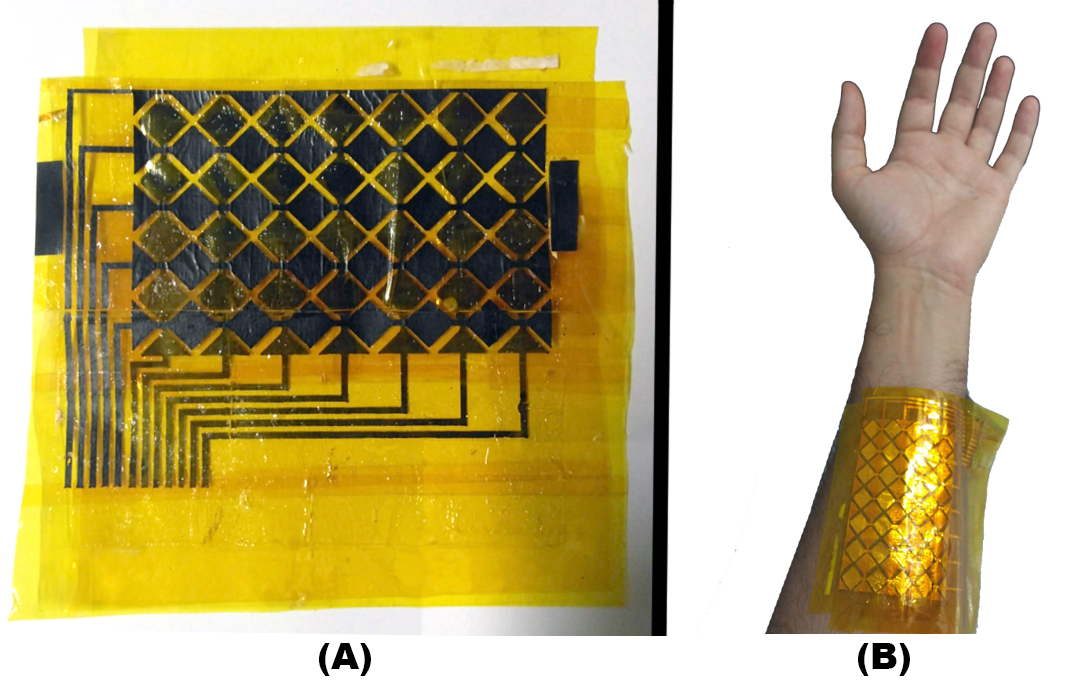

The TouchYou is a pair of touch sensitive and stimulation interfaces for detecting the touch and simulating it in a long distance. The primary use is for transmitting the touch for couples in a long distance relationship, but the touch interface can be used as a smart skin for sex robots and sex toys, besides the possibility of the couple using their own bodies for stimulating their partner remotely during the virtual sex. The TouchYou presents as a good option to overcome the problem of lack of physical contact for couples and relatives that are living apart, and its technology is promising in the field of human-computer interaction.

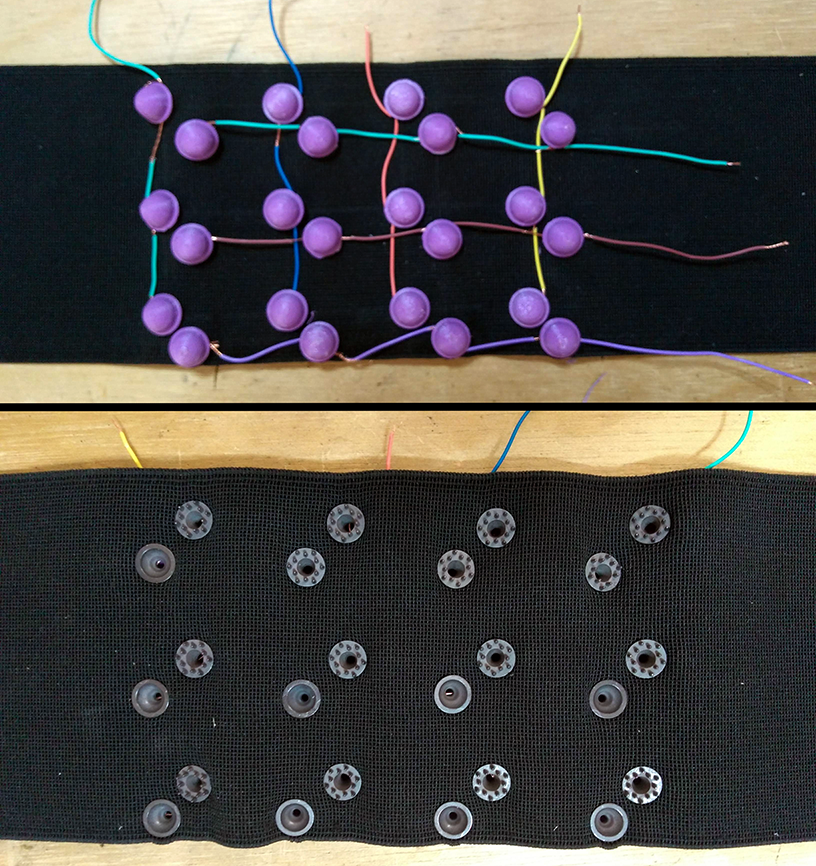

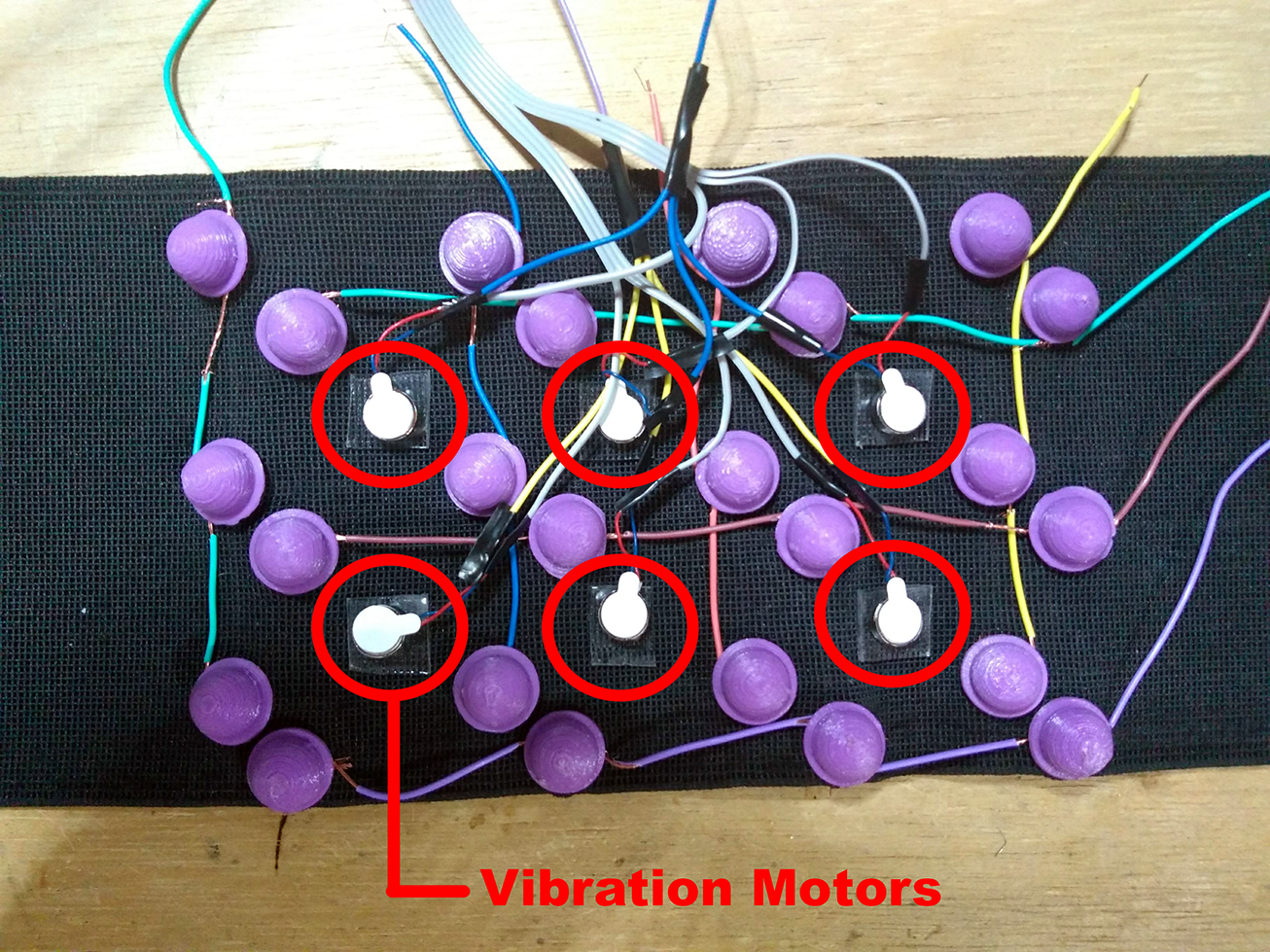

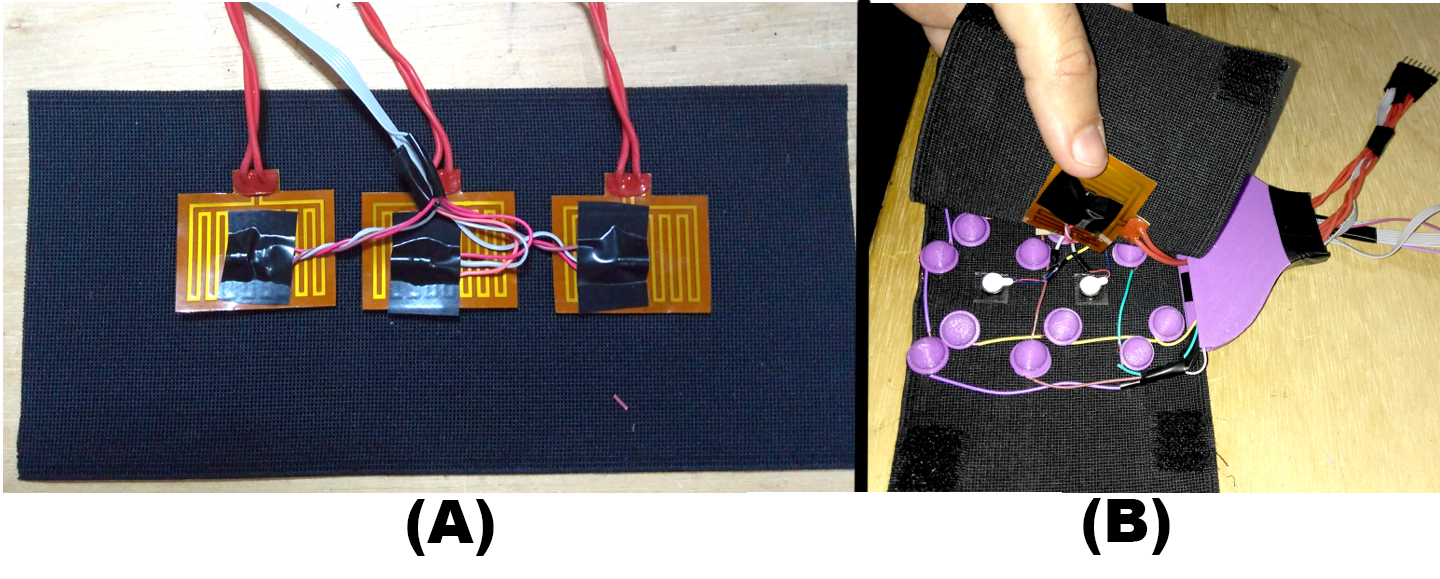

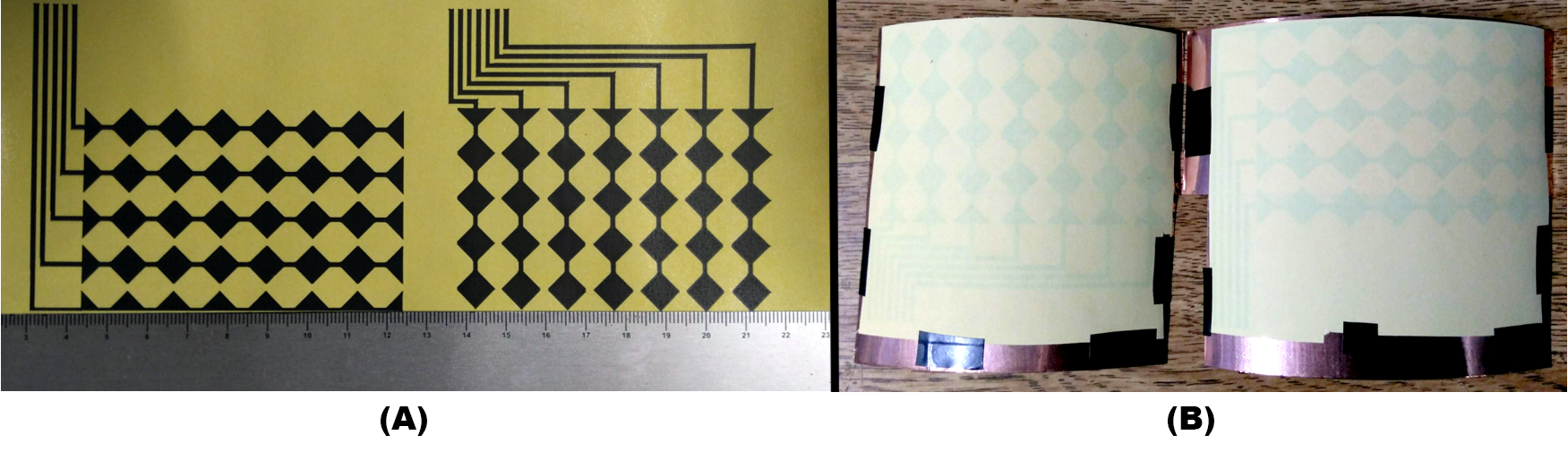

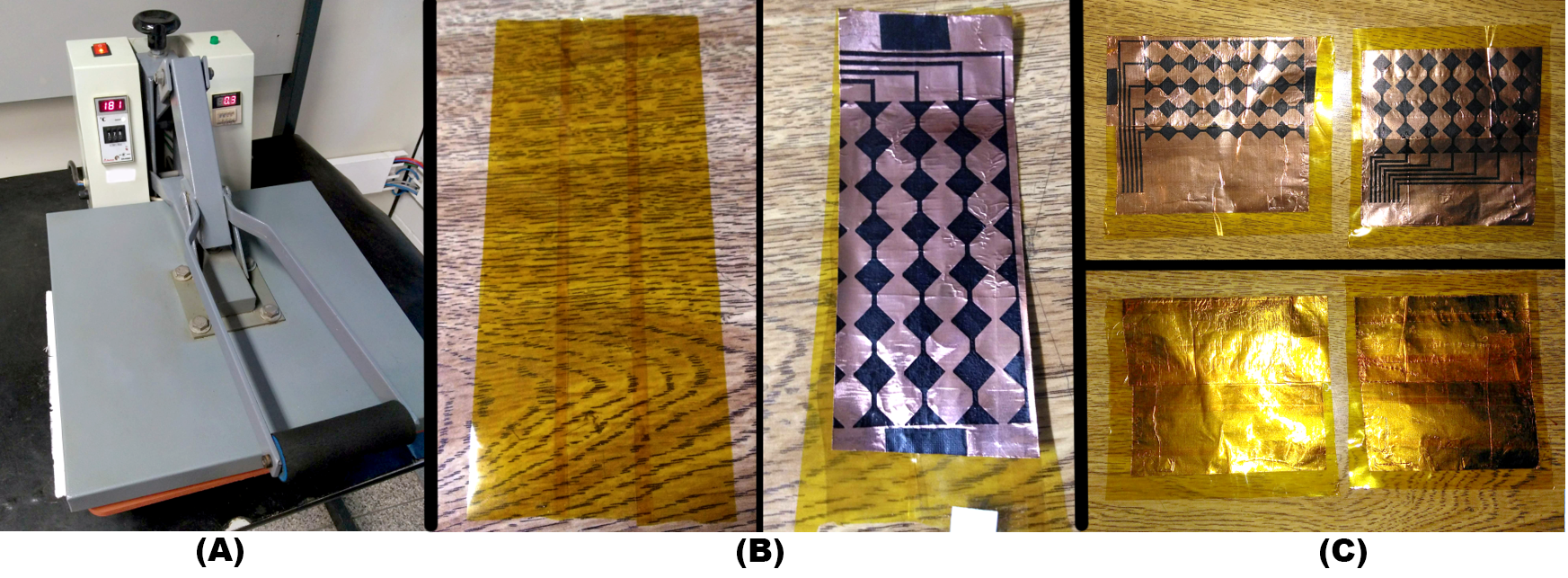

One of the outputs of this project was developing a low cost method for building a flexible and wareable capactive touch interface, which can be done at home.

This is an ongoing project. The touch sensor is already developed, and it is able of measuring the position of the touch and the force applied. Its interface also can transmit the touch data to a computer by bluetooth.

The next step is to improve and test the touch stimulator interface.

Leonardo Gomes

Leonardo Gomes

Varun Suresh

Varun Suresh

Keerat Singh

Keerat Singh

Vignesh Ravichandran

Vignesh Ravichandran

Naveen Sridharan

Naveen Sridharan

Hi Leonardo, https://www.facebook.com/energyoverlords Please contact me !

I've been developing technology like this for over a year right now - let's start an IndieGoGo campaign together.

https://www.linkedin.com/in/piotrslupski << here's my LI - feel free to get in touch as I'm right now acquiring funding to develop the tech further . A cooperation with your usecase would be extremely beneficial for us both.

Kind Regards, Piotr