I really like smaller contests on Hackaday, like The Return of square inch contest.

The rules for this one are stating:

The total printed circuit boards required for a single copy of an entry must fit completely within a 1 inch by 1 inch square. (It may also be smaller.)

Should such a copy of an entry require multiple separate circuit boards, they must be panelized by the entrant to fit within the aforementioned dimensions.

OK, got it. One piece of given project has to fit single PCB no larger than 25,4x25,4mm and if needed, I can cut it to smaller pieces, but all the pieces has to fit 25,4x25,4mm of PCB area. Say no more.

Inception

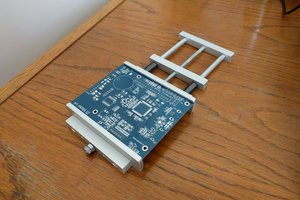

The first project that comes to mind is SMD breakout board, with module of 2,54mm and two rows of pins. This is thing of many uses and really helpful when breadboarding/protobarding with SMD components. Dimensions constraints of the contest are limiting me to 9 pins per side; disregarding diagonal placement of pins, that would limit me to 18 pins at most. That is not much. What about more than 18 pins? Perhaps I can have more than 18 pins, if the PCB would be cut in creative way.

There are kids-parties ways of gaining apparent dimensions of sheet with given dimensions, but those will not help me much, especially considering those - and in fact most of thinking around PCB design - are happening in two dimensional space, ignoring height of the PCB. One I stop limiting myself with cutting perpendicularly to front/back side of PCB, I can gain twice as much of PCB real estate.

Implementation

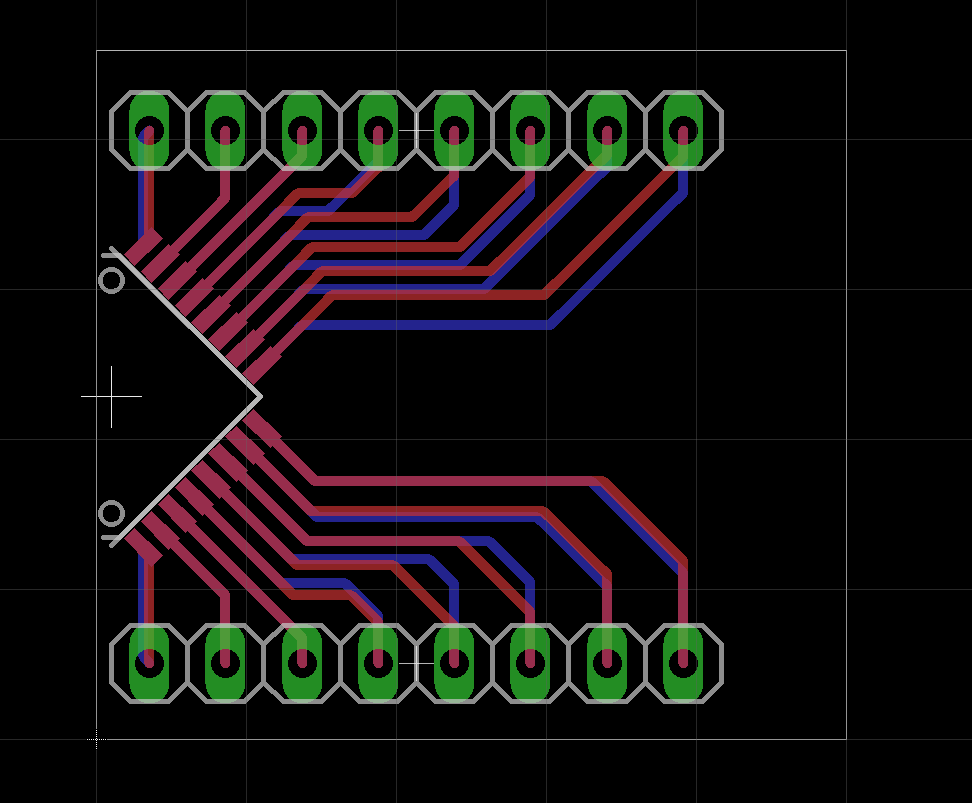

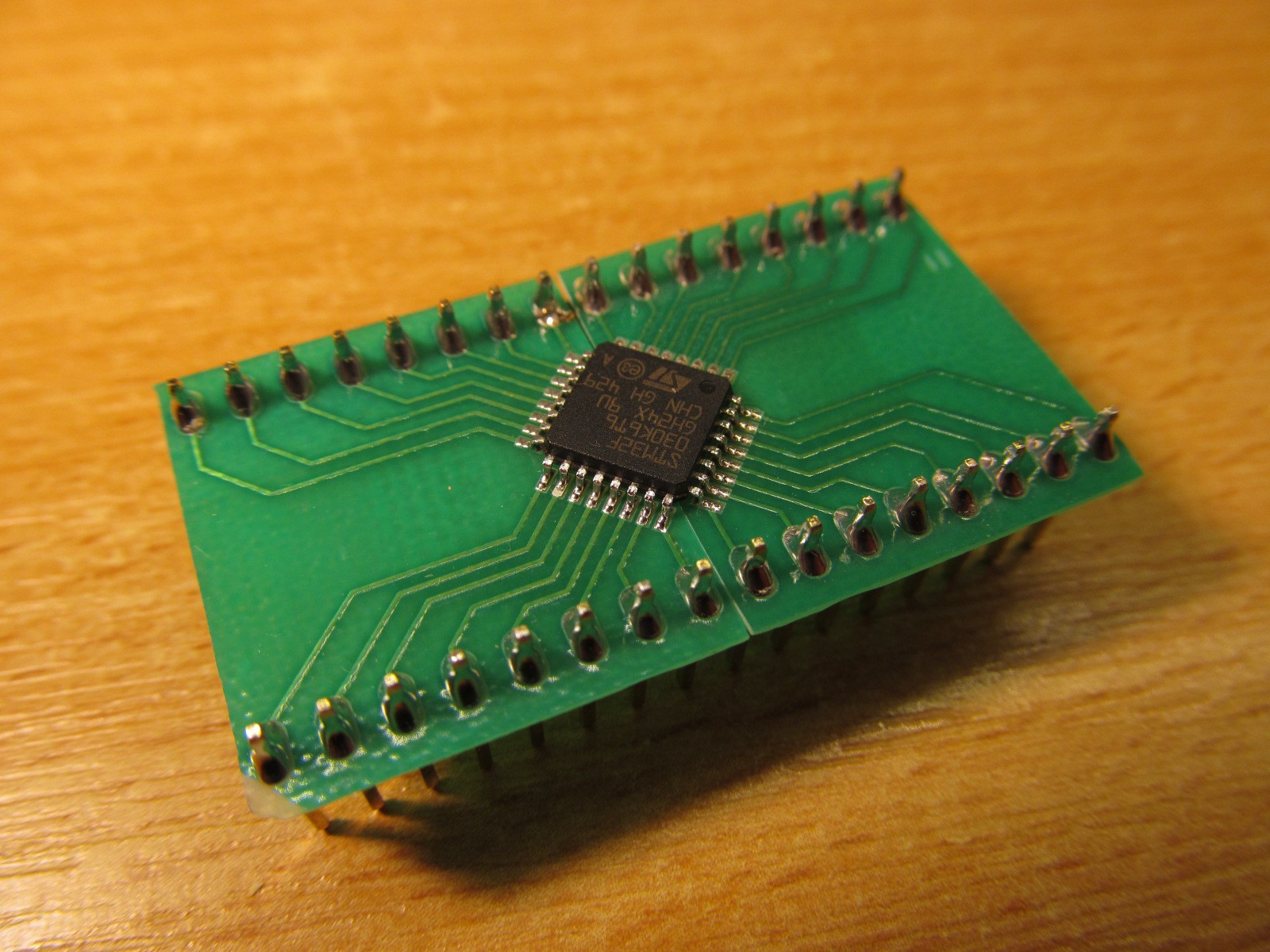

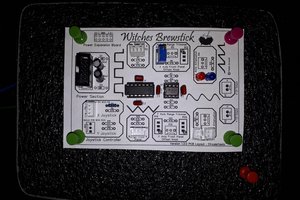

I hastily designed sloppy double-sided PCB like this:

Notice the PCB is indeed smaller than 25,4x25,4mm. The grid has 5mm spacing per division.

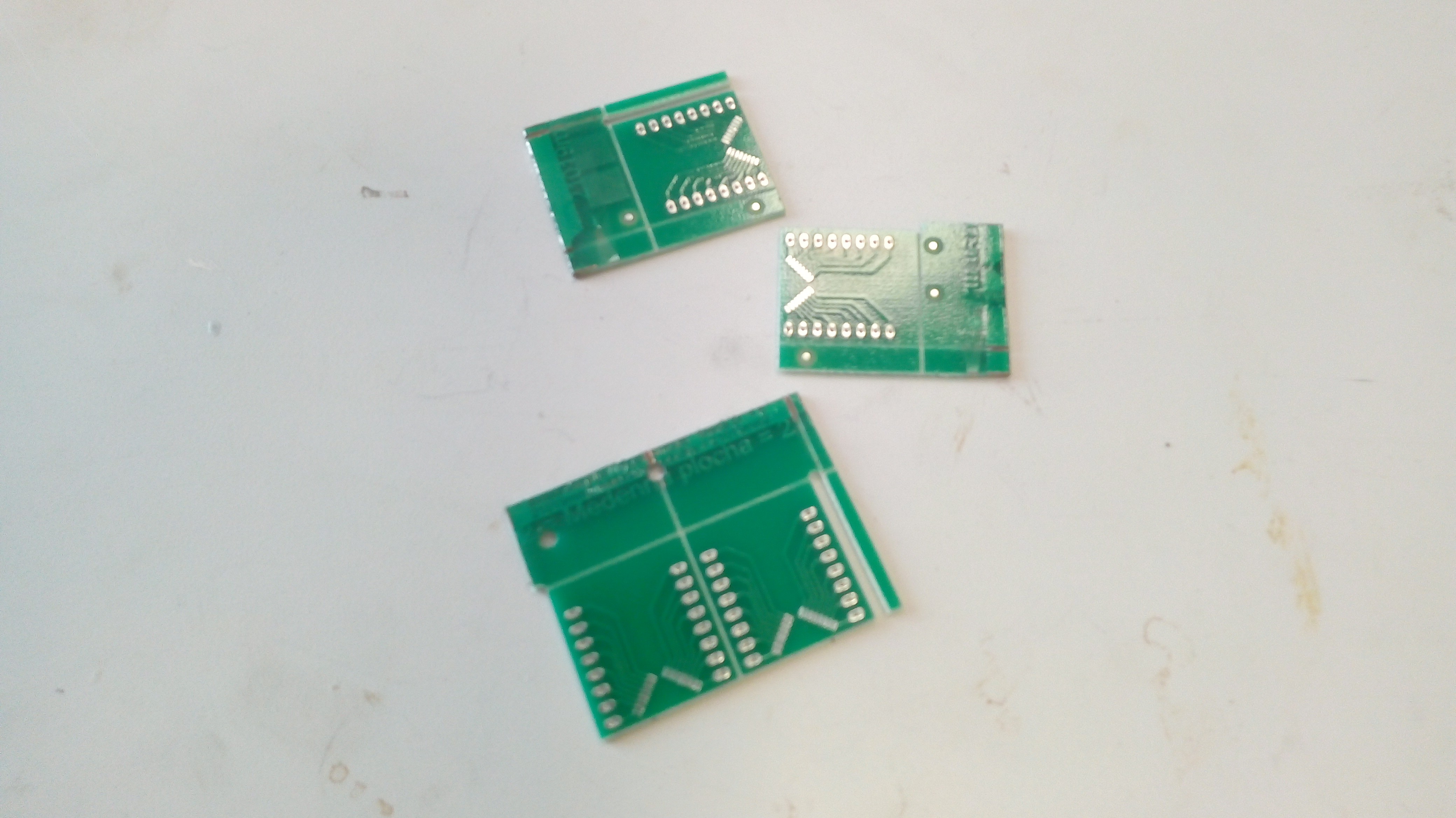

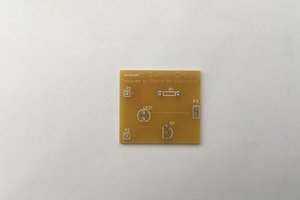

And got it manufactured in a few pieces, as I felt like there will be losses

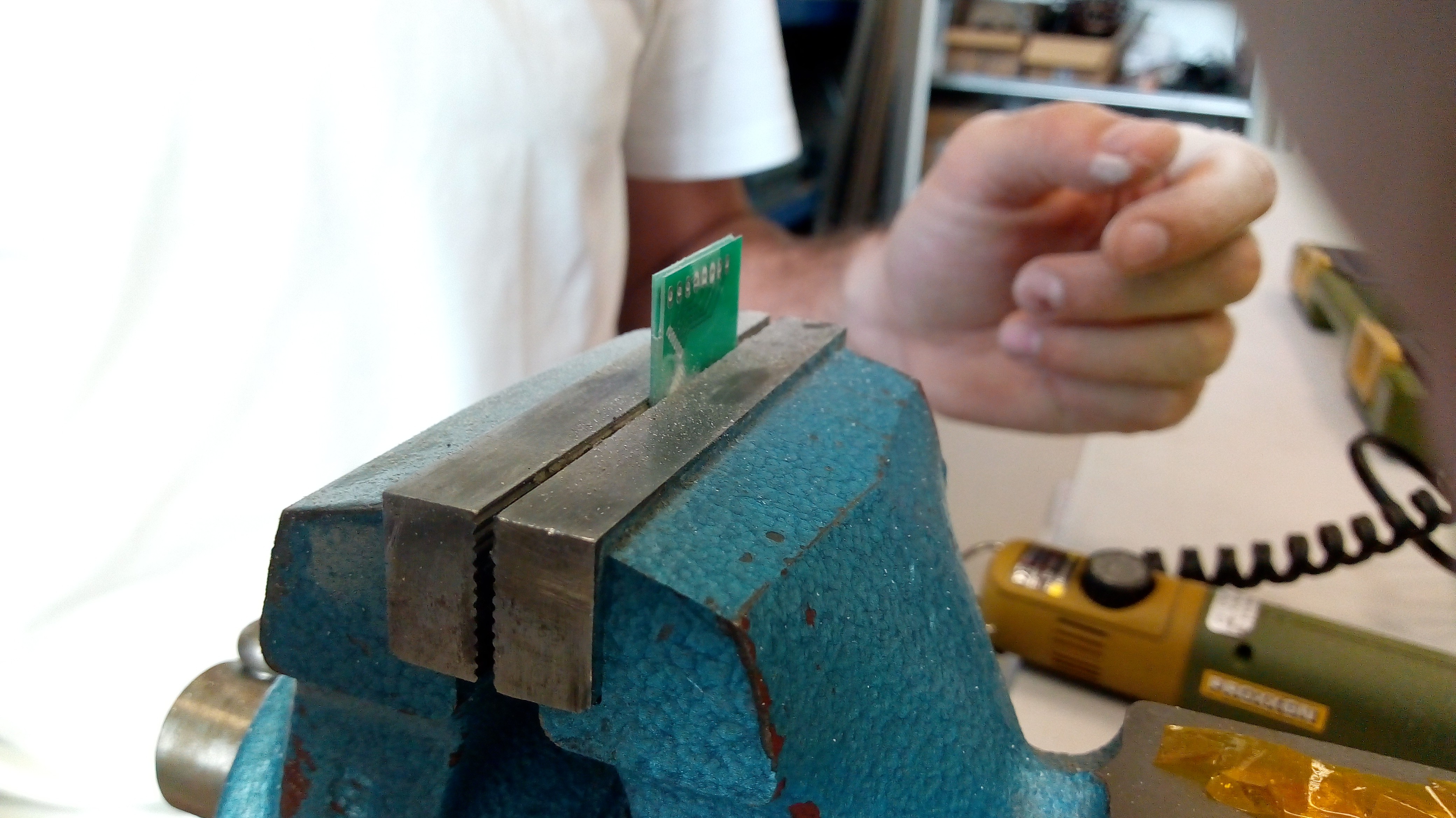

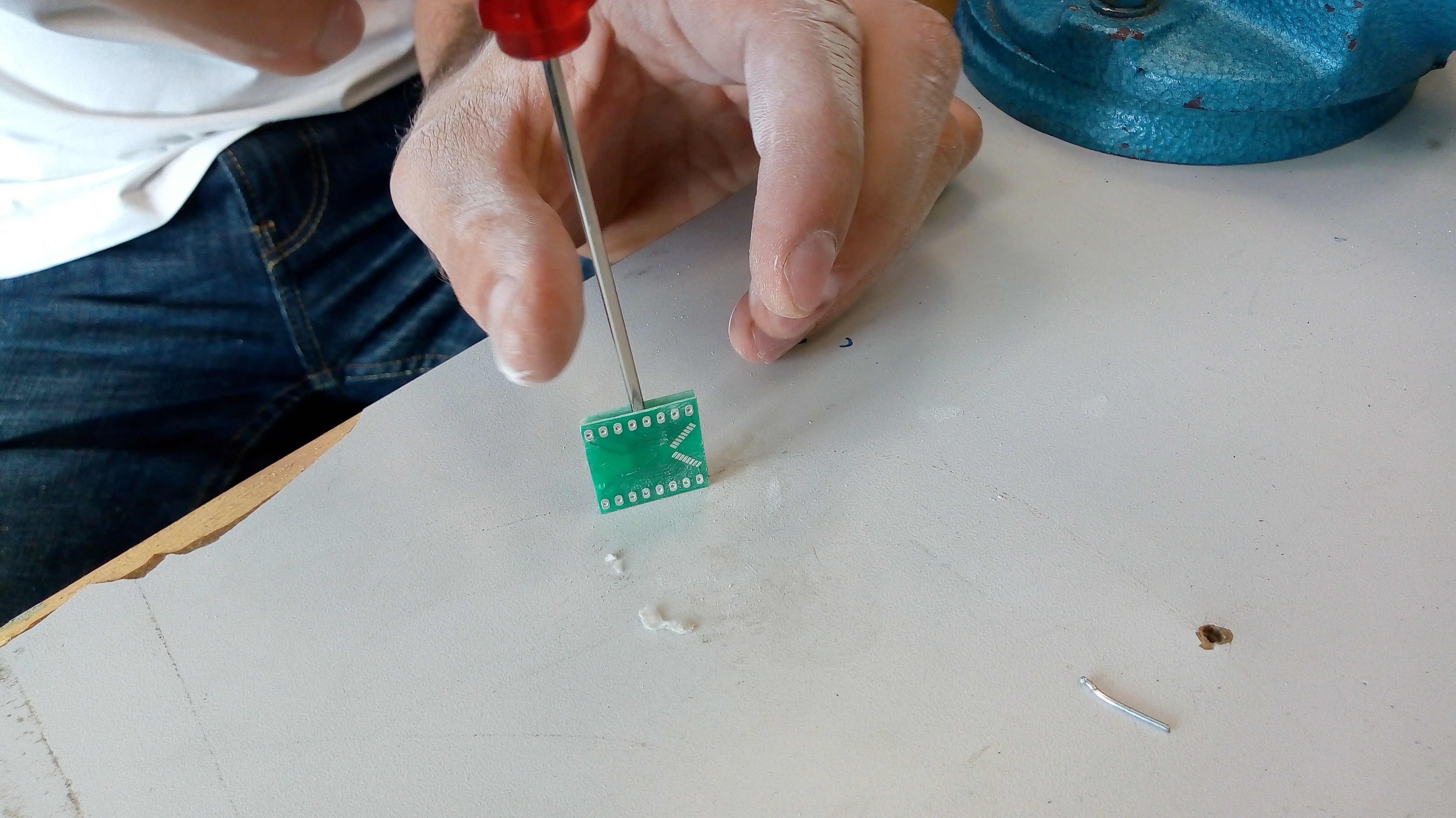

Single PCB secured in vice, ready to be cut in two

First side cut

That dust is really nasty

I had only access to cutter able to cut 7mm deep, so I had island of PCB material untouched in the middle of PCB.

I exploited the laminated structure of PCB to get the two halves apart. Putting flat screwdriver and applying a bit of unreasonable force

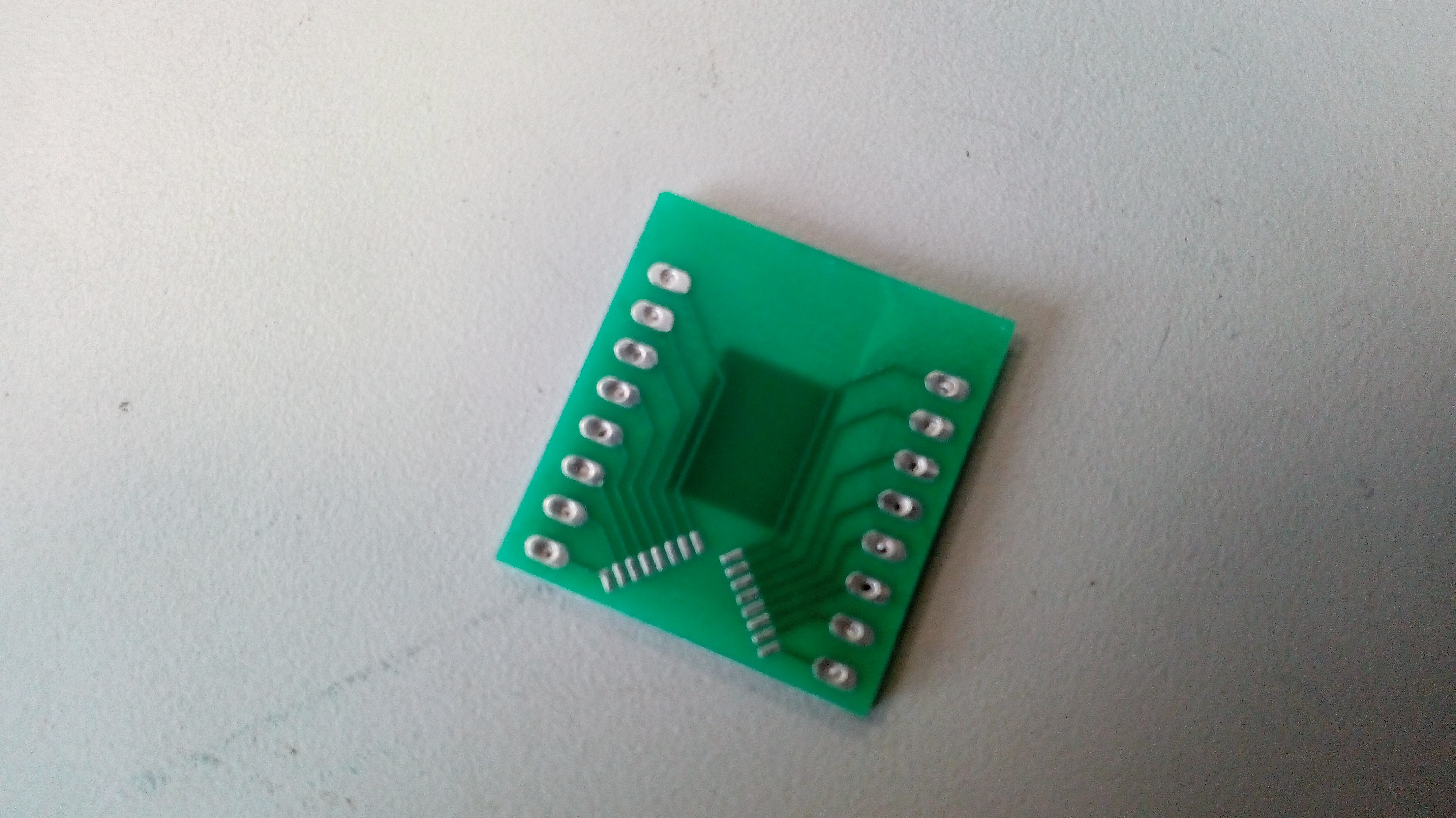

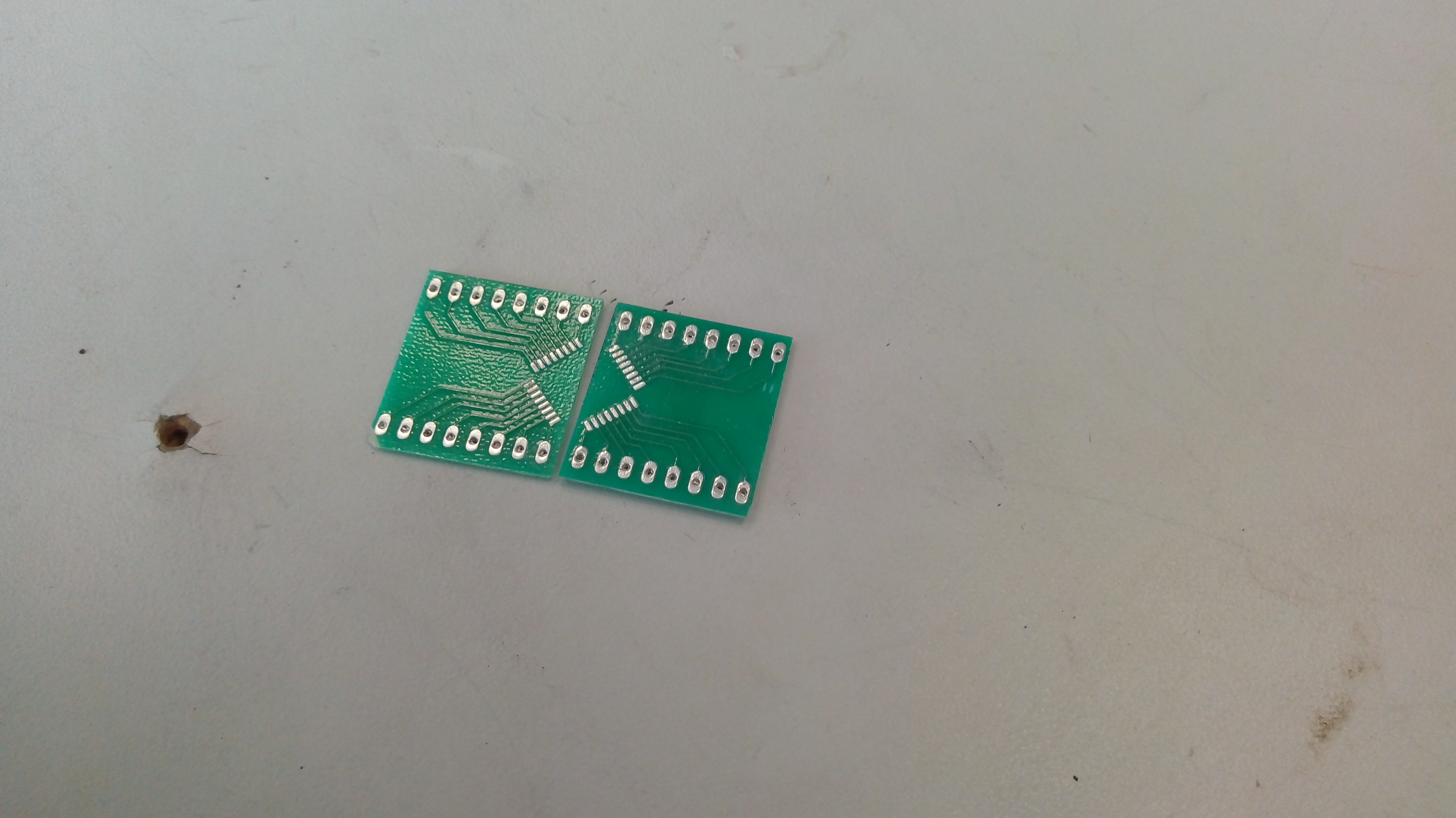

got me to two beautiful halves of single PCB.

The PCB halves are now ready to be soldered and used as breakout board

With final result looking like this

jaromir.sukuba

jaromir.sukuba

Saimon

Saimon

Neil Mundt

Neil Mundt

Elecrow

Elecrow

Doing all this without technically breaking the rules is such a fantastic hack that I hope this wins for that alone.