I saw this Hackaday Article based on this project and decided to build my own version for my kids. I've made a couple changes from the design that was show in that project and wanted to share those along with my thoughts.

Summary of Changes / DIfferences

- Used scrap plywood for top and body (see post about top)

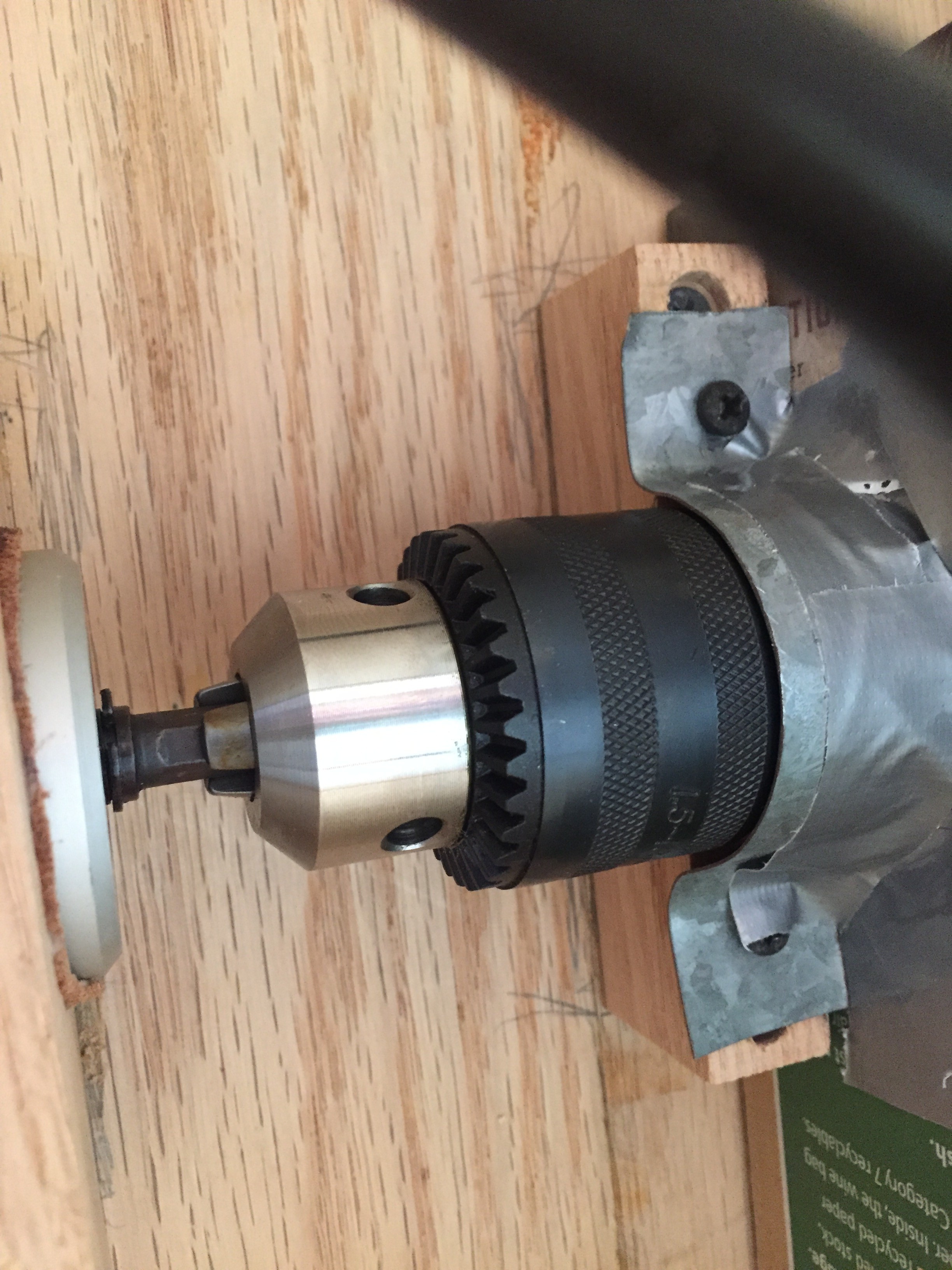

- Ground Out nibbler discharge port

- Variable Speed adjustment knob

- Hot Air discharge port

Nathan Brown

Nathan Brown

David Hopkins

David Hopkins

I am just about to finish a similar saw for my kids. I hit the same road block with the discharge port. I will try to grind it.

Is your saw still running well? Any changes made since initial construction?