Today I want to talk about the ratchet system that controls the 4th and 5th digits of the hand. The ratchet system is loosely based upon the commercial "Boa Closure" system that is commonly found in a variety of outdoor gear and, indeed, some traditional prosthetic devices.

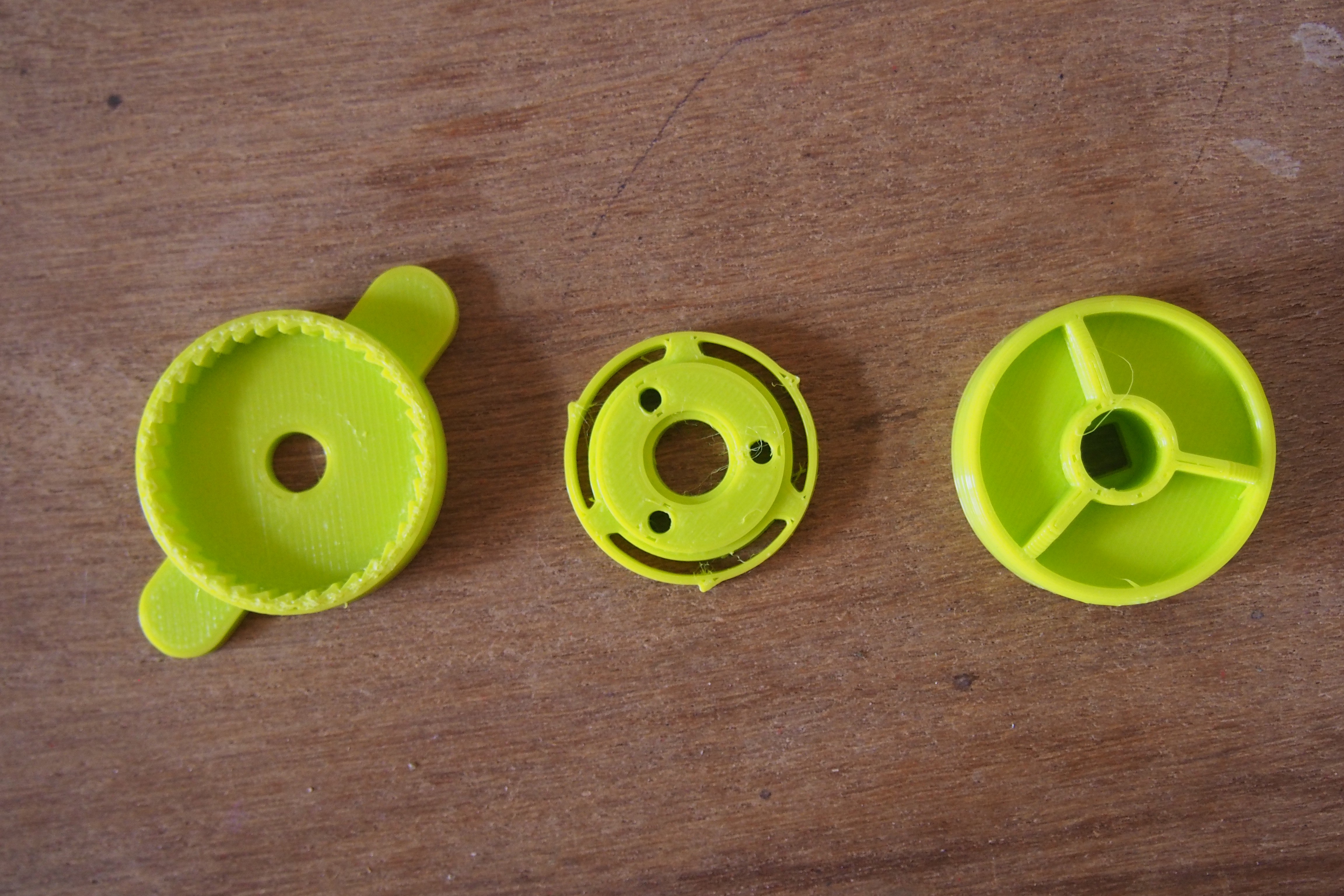

The ratchet system is based on the Pocket Ratchet Wrench by Cleven, the most popular ratchet design on Thingiverse--which the addition of a "servo arm" type part which pulls on the cable, and a push-button release mechanism. This initial design fit together as a six-piece assembly in the back of the hand:

While the design worked well enough to show off in the prototype testing video, I was underwhelmed with its overall performance. First was the resultant precision available to the user. In the initial design, it only takes 5-6 "clicks" to move between fully open and fully closed, which made it very different to get precise finger positions or to clamp down effectively on items being grabbed. Secondly, the design tended to bind under high tension, making it difficult to release the tension on the fingers and the item being held.

In order to improve the design, the ratchet for v0.2 will be inverted, such that the ratchet gear is on the outside and the pawl is moved internal, allowing for a larger-tooth ratchet gear to be used--creating more "clicks" per degree which should improve the resolution:

Secondly, the radius of the "servo arm" or pulling arm will be significantly reduced, thus reducing the amount of cable pull per click (increasing precision) and reducing the amount of torque on the ratchet system, which will hopefully control the binding.

To be honest, the 3D-printed ratchet began as a placeholder for a commercial Boa-like device, but for the cost and function, I am interested to see if the 3D-printed version will be solid enough for the economical "standard" version, saving more robust commercial devices for the higher-cost "heavy-duty" version of the hand.

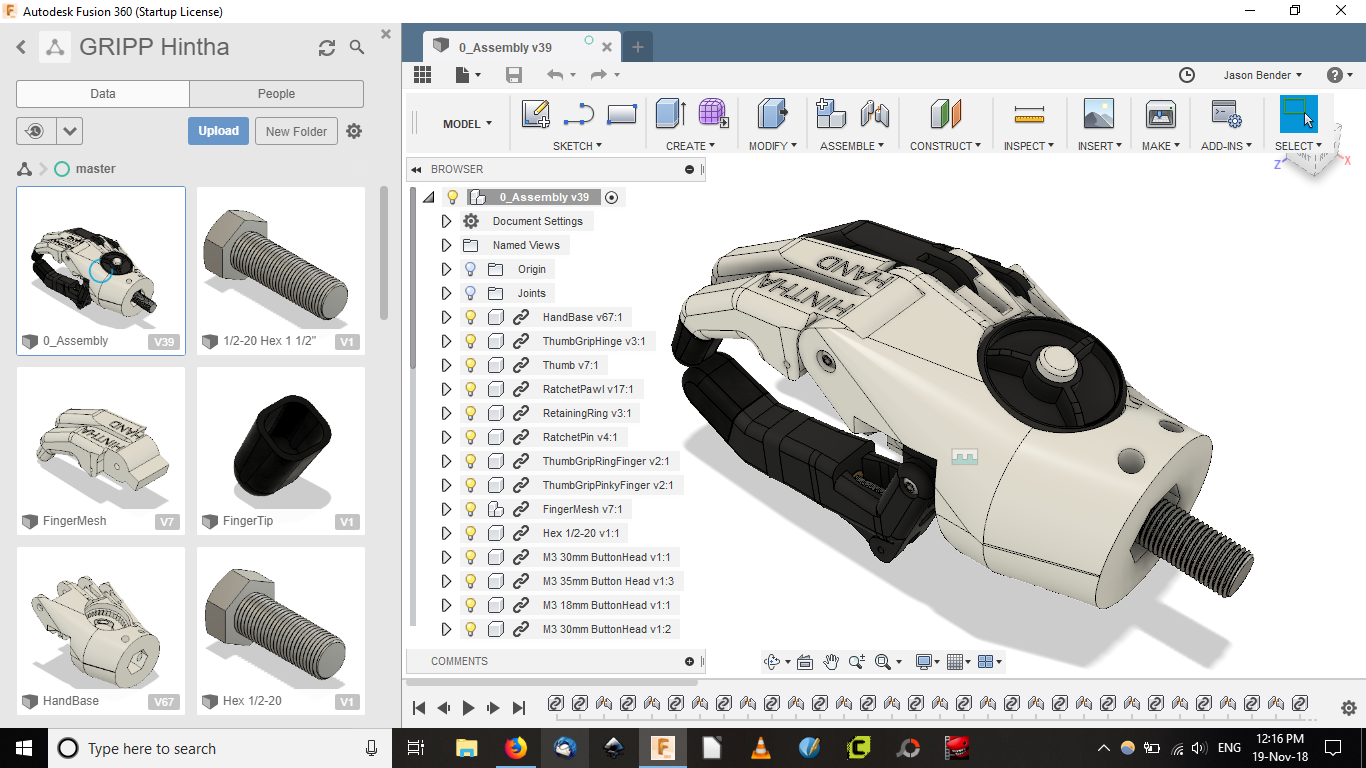

Version 0.2 is almost ready for printing, incorporating the new thumb joint location and improved ratchet design, along with a few small tweaks such as heat-set inserts and more simple design processes:

Hopefully much more coming soon!

Jason

Jason Bender

Jason Bender

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Hi Jason...

I am a father of a 3 year old who needs a prosthetic solution.. i am an engineer and already started working on 3D printing, socket design, elbow and other pieces design.. how do i get hold of the step files so that i can print it out and improve on it? I can share what i have done so far.. please let me know.. thx

Are you sure? yes | no

Your work is brilliant Jason! Please continue doing what you are doing and sharing with other e-NABLE designers. You have so much to offer us!

Are you sure? yes | no