For the first concept, designed with the ATSAMD21G18A, I ordered 150 boards and started putting these with a soldering iron. Soon I found out that this was going to take way too long, and so I moved to a reflow oven soon after.

Placing the components on the paste, and moving it into an oven to do the soldering did speed up the process. Unfortunately supplying the paste, even with the stencil, was messy, complicated and still took a long time.

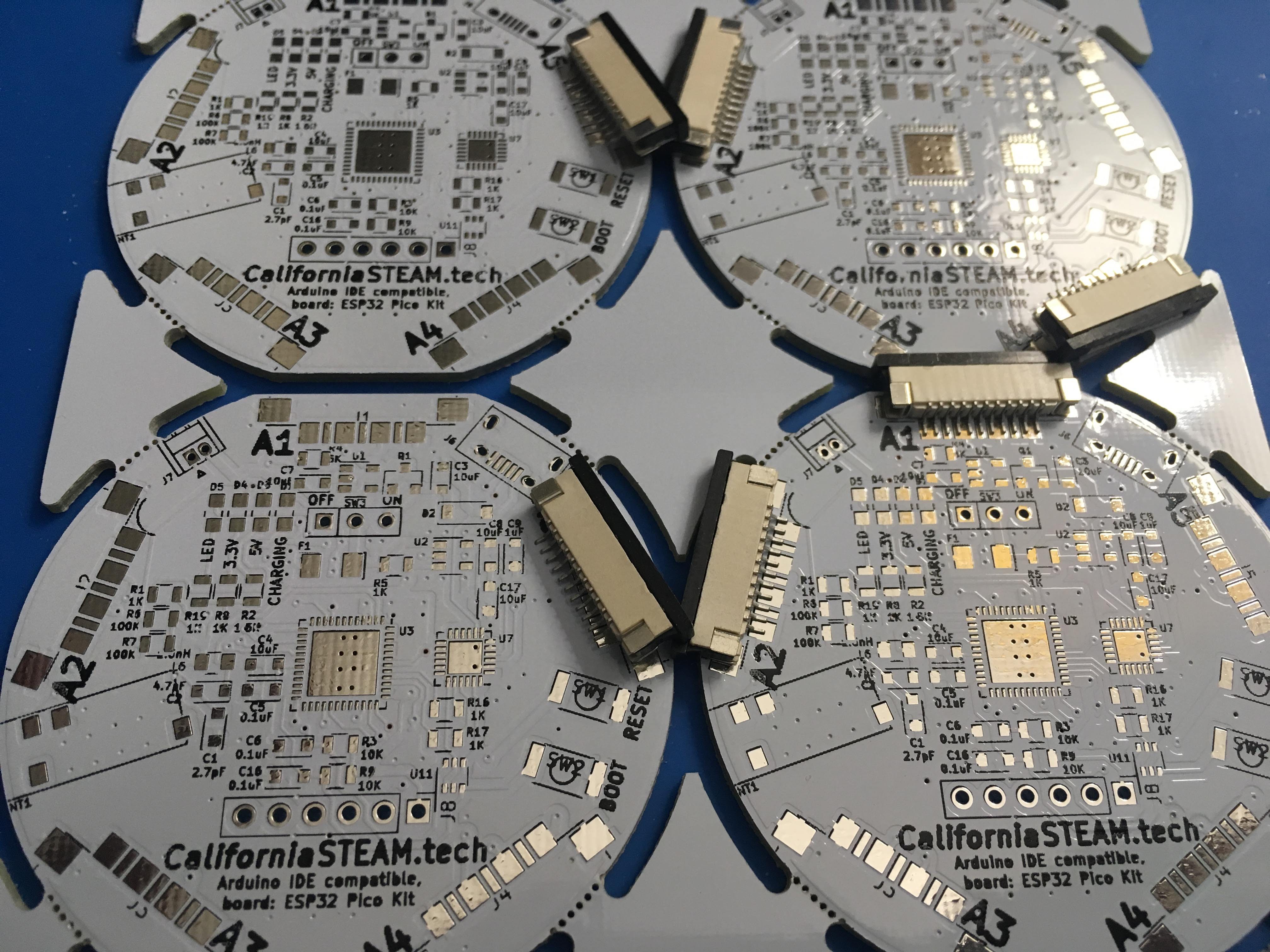

With the second concept, designed with the ESP32, I decided to order a panel instead. Since I never designed a panel before, I asked the board manufacturer to design me one. They did a great job, and it did make it so much easier to apply the paste. You actually do 4 boards at the same time, and the larger surface makes it easier to align the stencil. There was just one problem, most of the components are sticking out on this board, and these were interfering with each other.

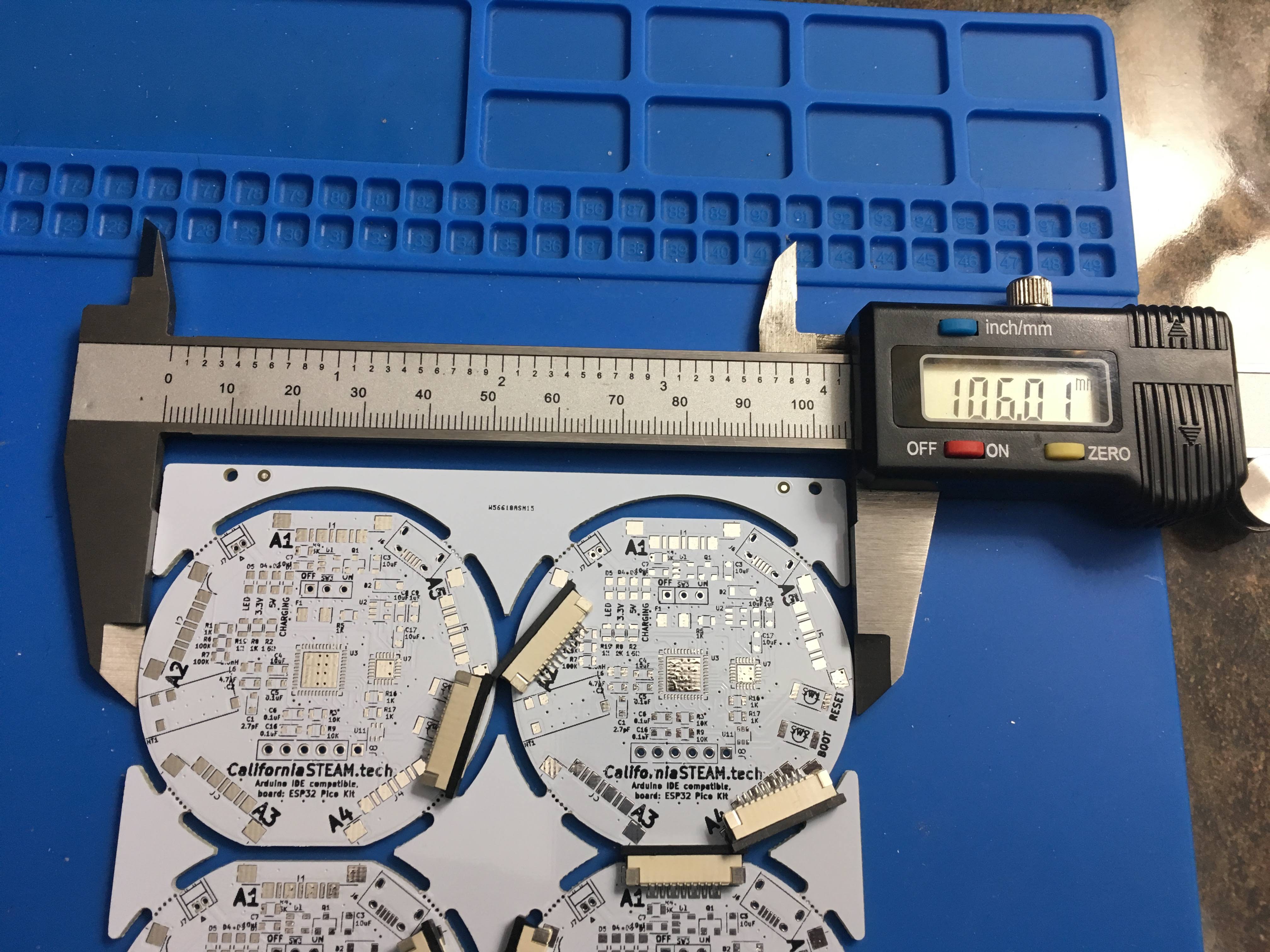

There are some very good deals for PCB manufacturing out there, as long as you stay within a 100mm square panel. The panel shown above was just a couple millimeter over, but doubled the price.

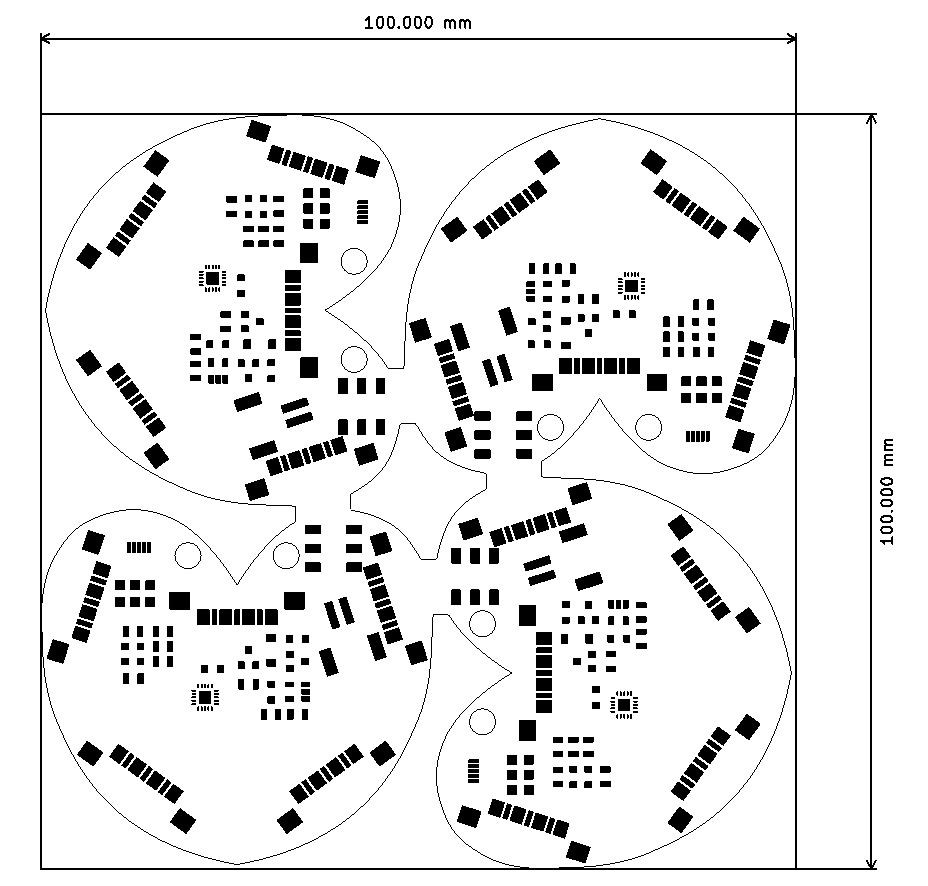

![]() kiCAD panel design

kiCAD panel design

Using KiCAD to design the panel not only avoids the interference mistake shown above, it also allows you to stay within the 100mm square window, and you can even combine different designs. Depending on the manufacturer you might have to pay more for a panel, so please check carefully if a panel fee is added before placing the order.

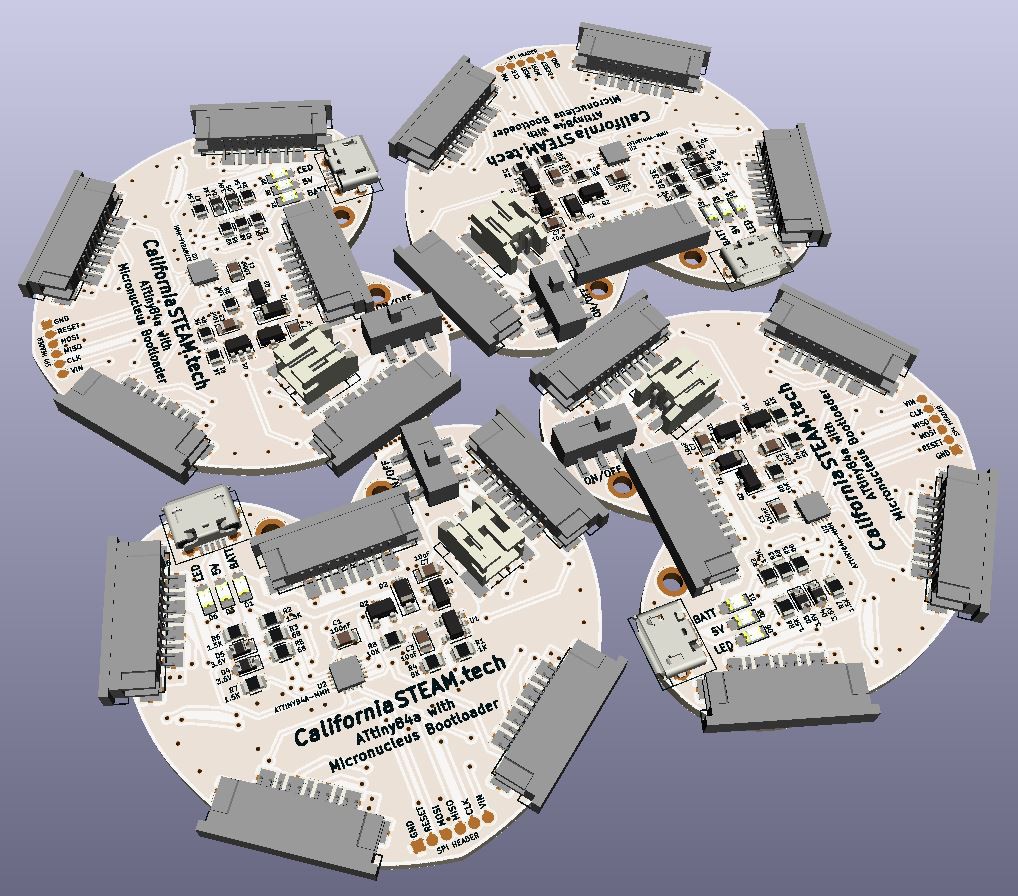

The latest board design, with the ATtiny84a, is just a little over 50mm wide. The board cannot be redesigned for a smaller footprint since the location of the FFC connectors determine the actual size. The location of FFC is important to get about 16.7mm between the LED's (60 LED's per meter).

Fortunately the new 'hearth' design allows these boards to stack inside each other, and there was only one solution to eliminate parts from interfering with each other.

And the panel is just within the 100mm square limit:

The design is accepted by the board manufacturer, and on order. I am expecting these to finish just before the Holidays.

Sander van de Bor

Sander van de Bor kiCAD panel design

kiCAD panel design

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.