How does it work?

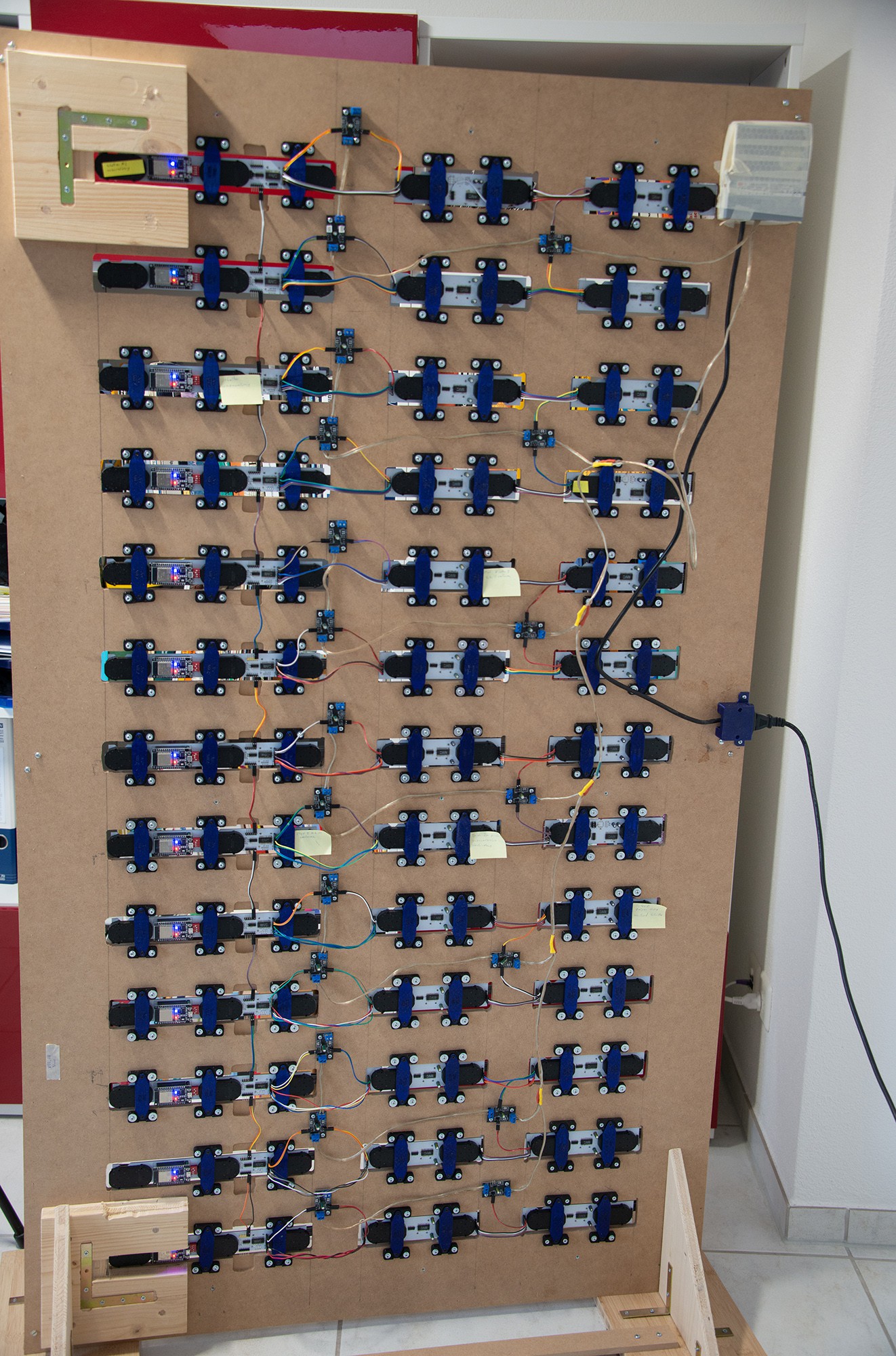

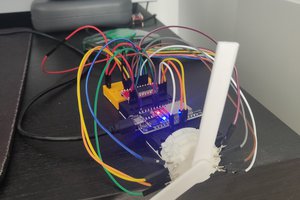

I have one master controller (ESP32) which has all the moves and forms saved in the code.

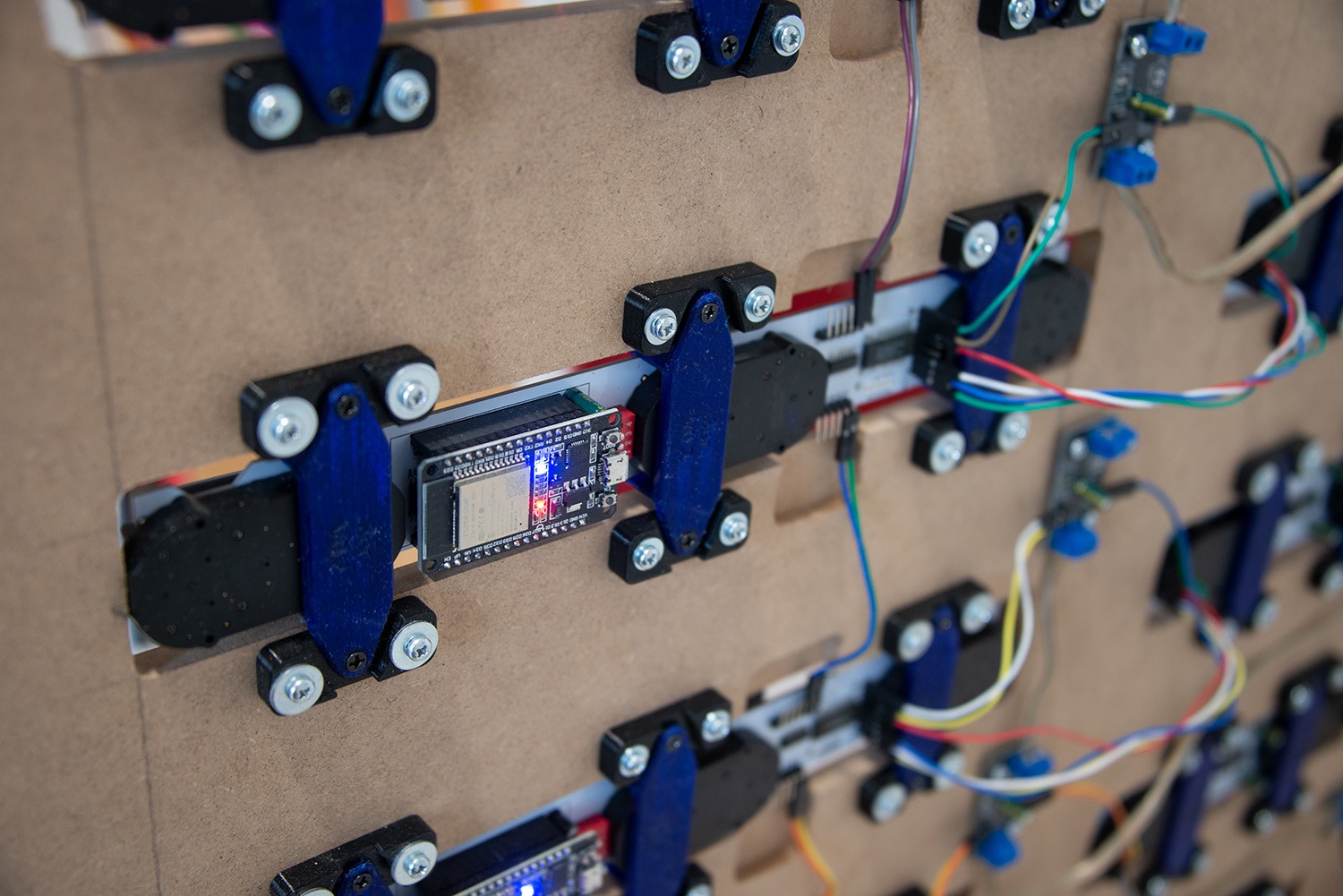

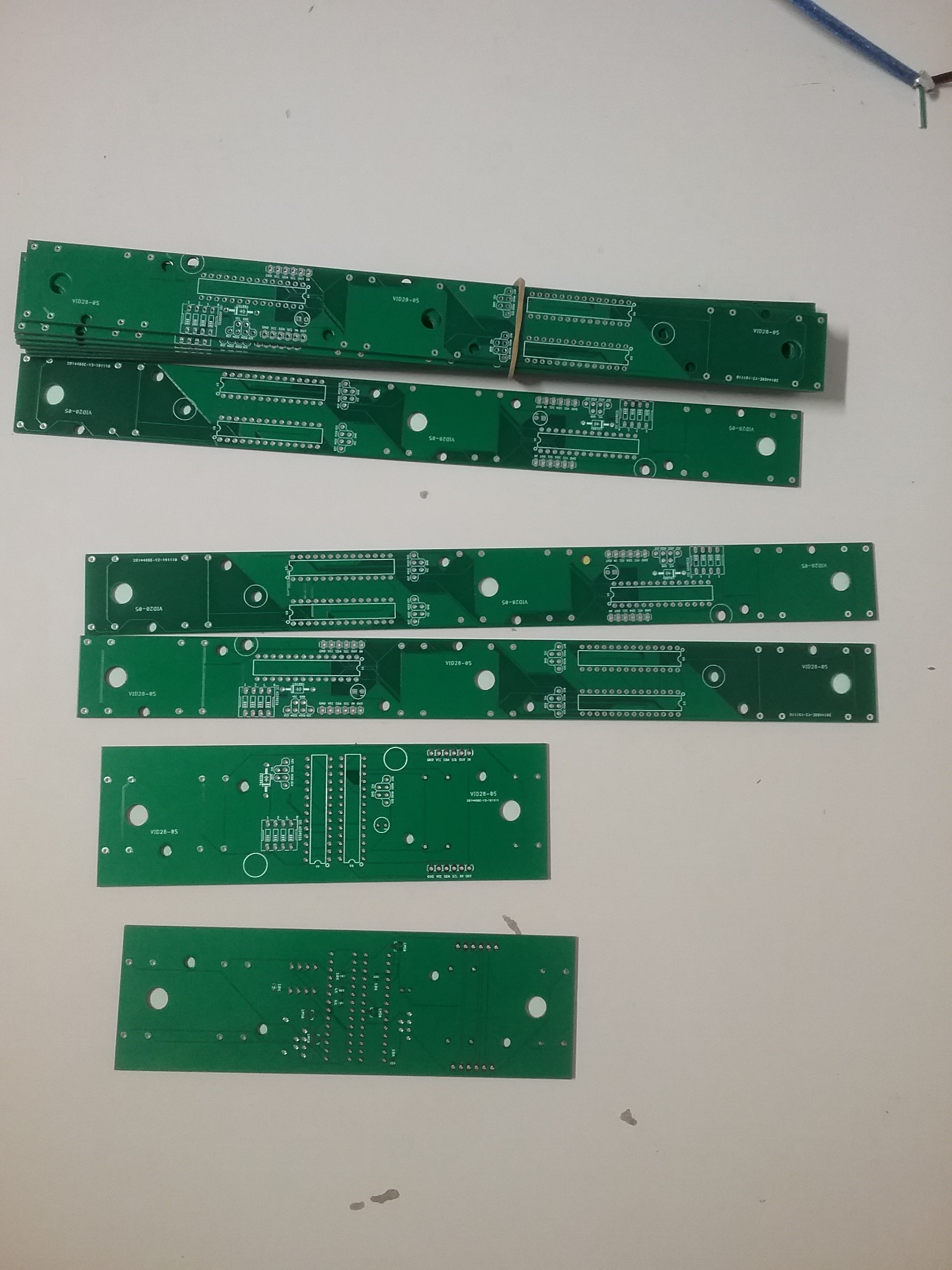

Every Motor (VID28-05) has one ATMEGA328P Microcontroler which is a slave on the I2C bus. Every Slave has his own address on the bus.

With an IR control I can start the movements. For this, the ESP32 (Master) sends out the target positions for each handle via I2C. As soon as this is done, he sets a pin to HIGH so that all slaves start to move. As soon as all slaves reached their position, the master sends out the next etc.

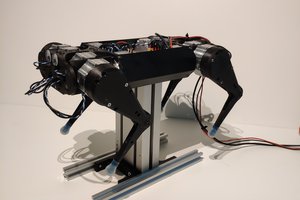

The flaws of this approach is clearly the noise and the precission of the VID28-05 steppers. So now I try to build the same with the X40 steppers.

The code ist very simple and offers a lot of freedom. However it has to be improved to be more "user friendly" :)

Peter Wasilewski

Peter Wasilewski

Daren Schwenke

Daren Schwenke

flamefire

flamefire

Very impressive project, i don't understand how are you controlling each hand of the clock with one motor?