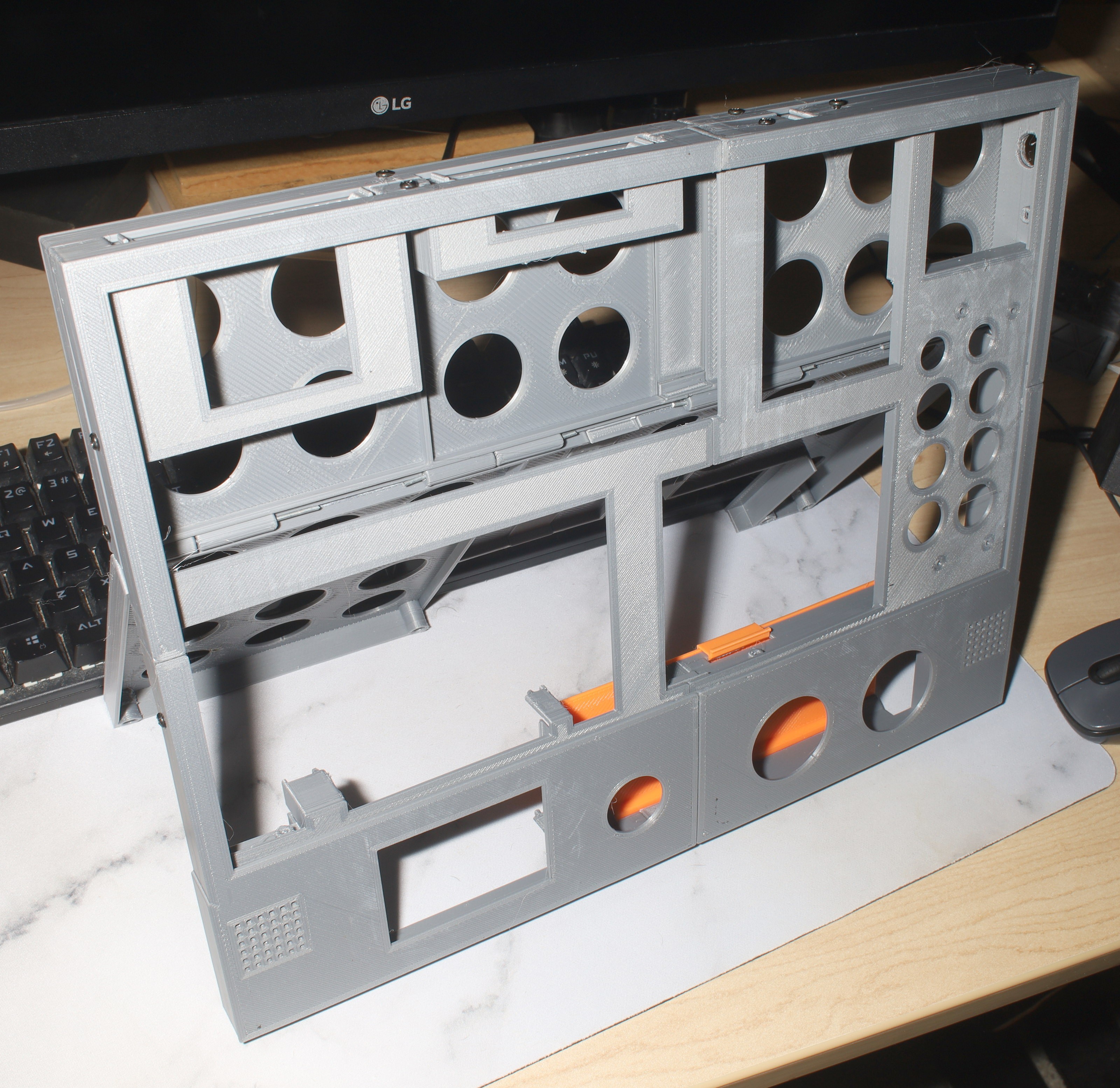

The enclosure took 3 days to print & burned 3/4 of a roll of filament despite all the holes. It ended up needing 24 joiners to fit on the print bed. The enclosure had to be split into 10 sections. Tolerances with the many joined segments are horrendous.

That was brutal, but there are good reasons why print beds aren't getting bigger than 220x220. The mane problems are electronic bed leveling is really slow & not really good enough, it costs a lot to heat the mostly unused space of a larger bed, it costs a lot to make a flat enough piece of metal since bed leveling can't fix everything. Larger format printers continue to have short lifetimes on the gootubes before the reviewers are back to good old 220x220.

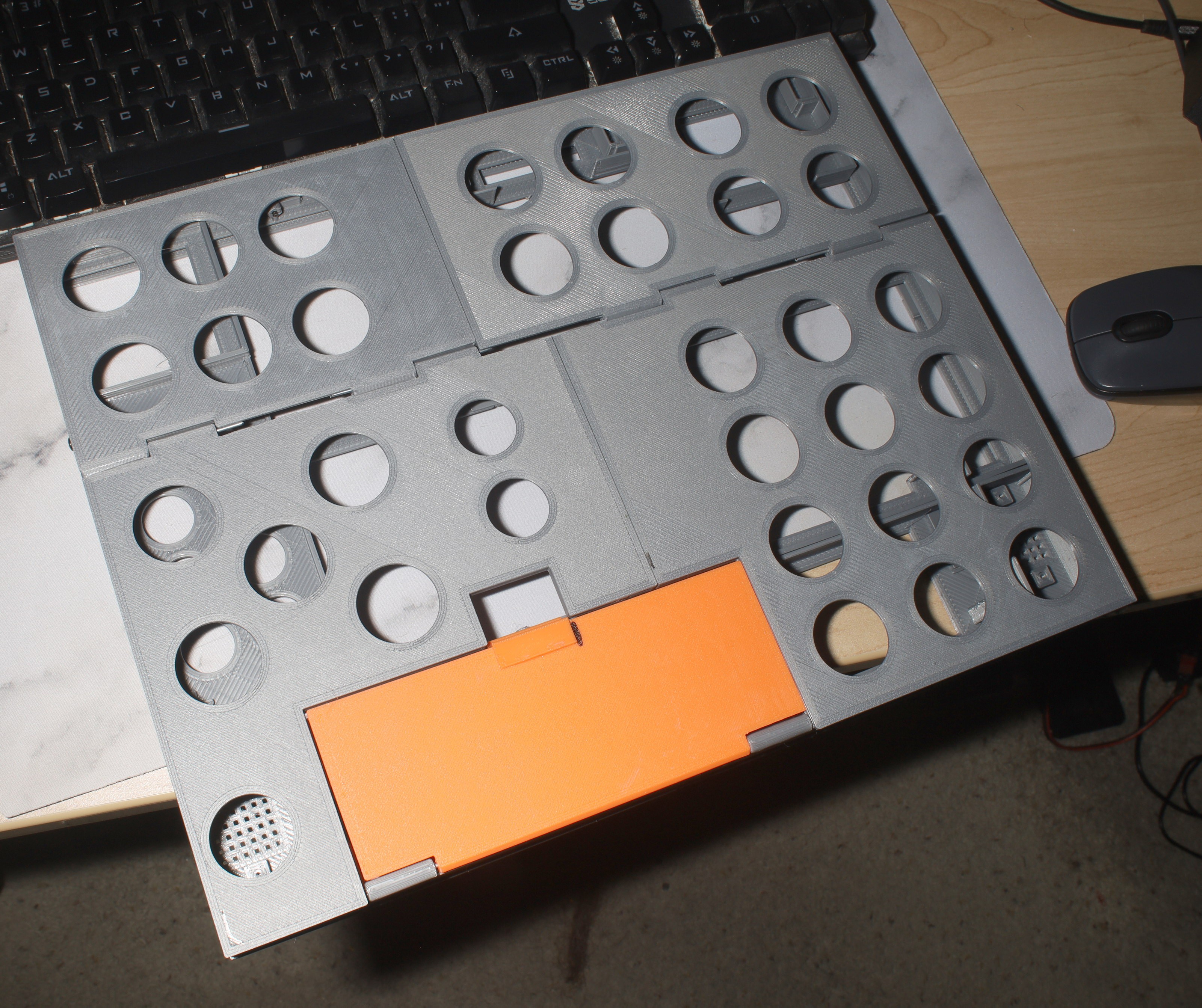

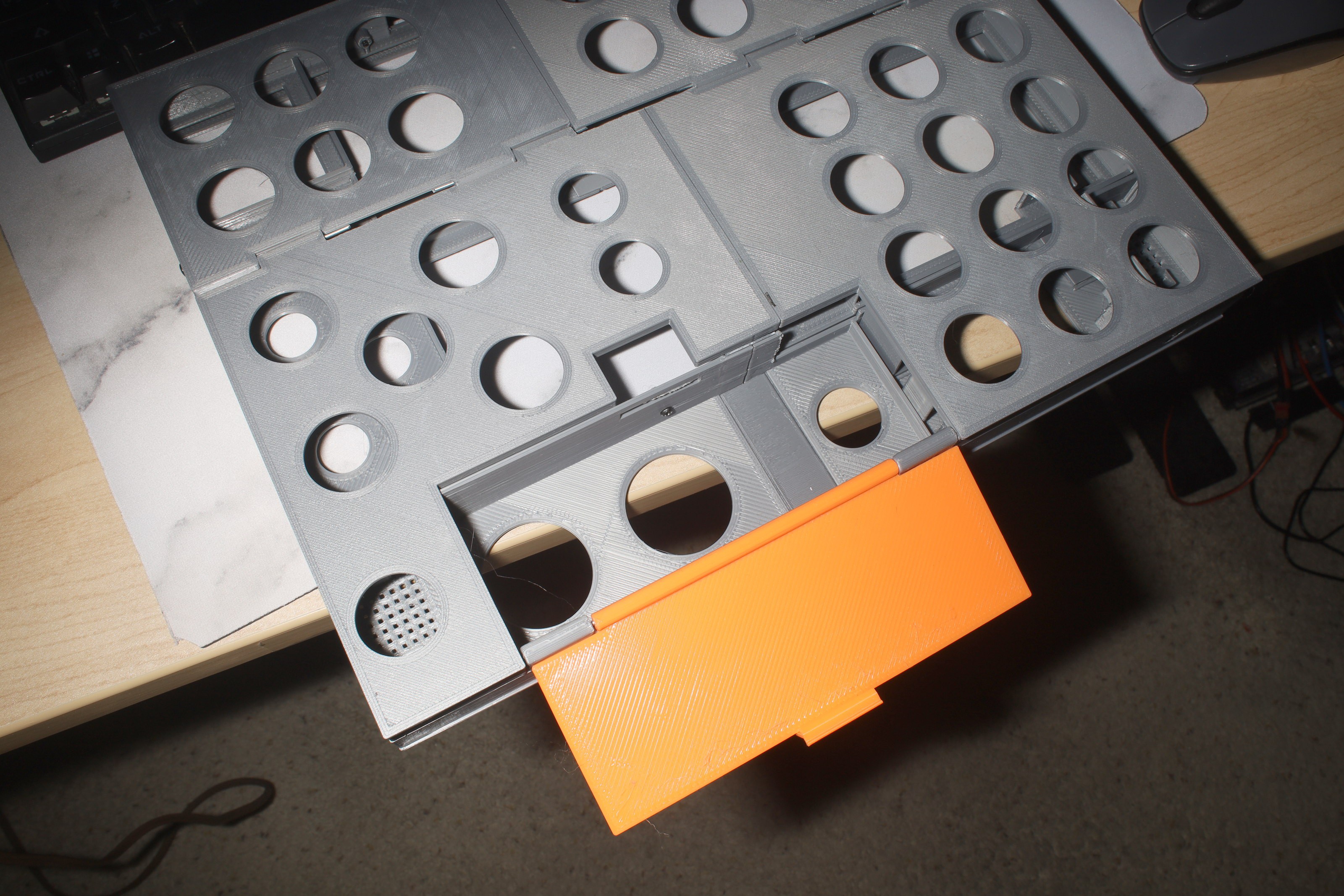

The battery compartment can't be opened with the stand closed. The separate battery door is still necessary to strap the battery in when the stand is open. The easiest solution is having the hinge on the top, maybe inset to keep clearance for the wires.

It needs a track to stand up on a wood floor.

The filmsy bits for the jetson & the daughter cards shouldn't be permanently part of the case.

The trick with hinges is to PLA weld the rods in place.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.