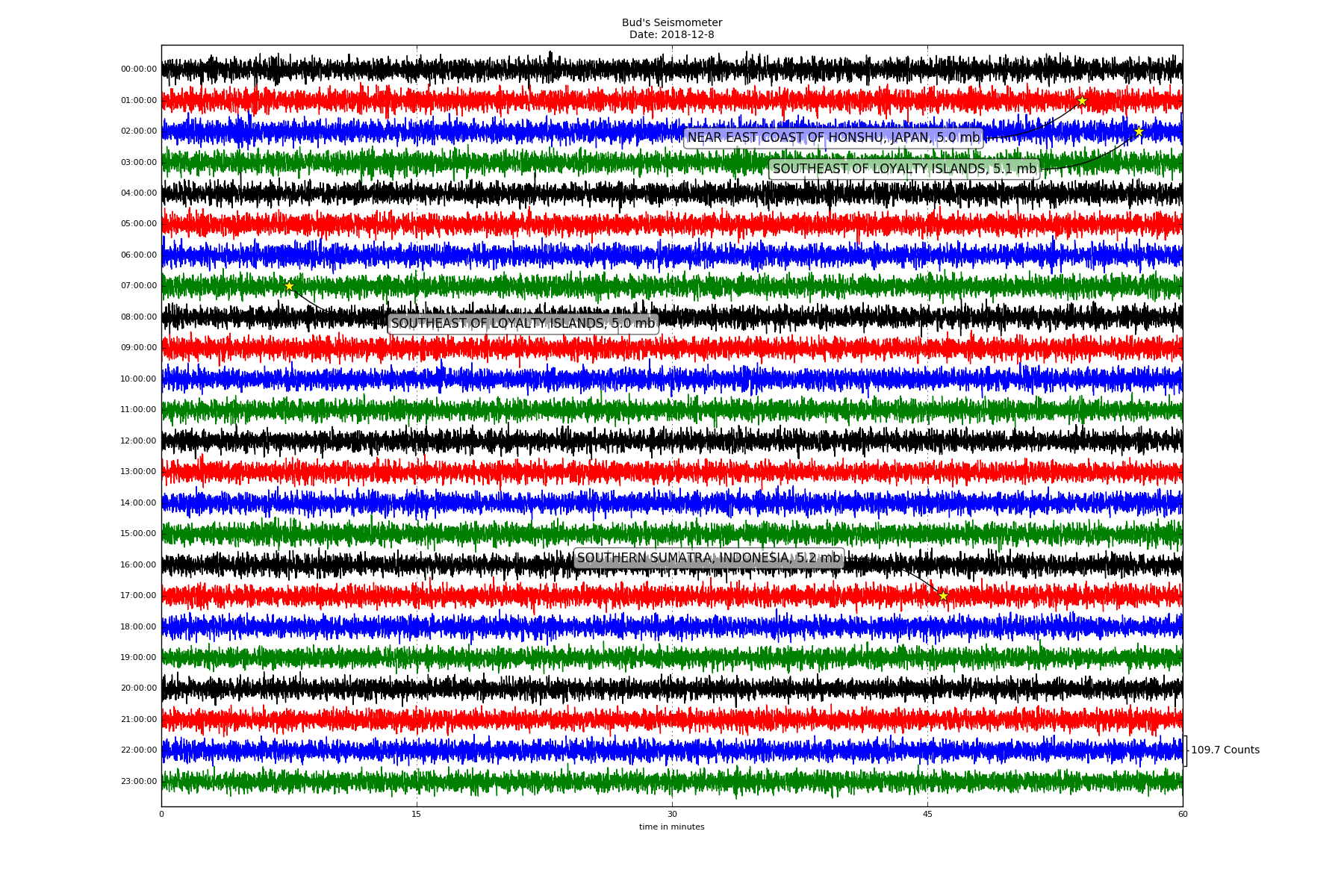

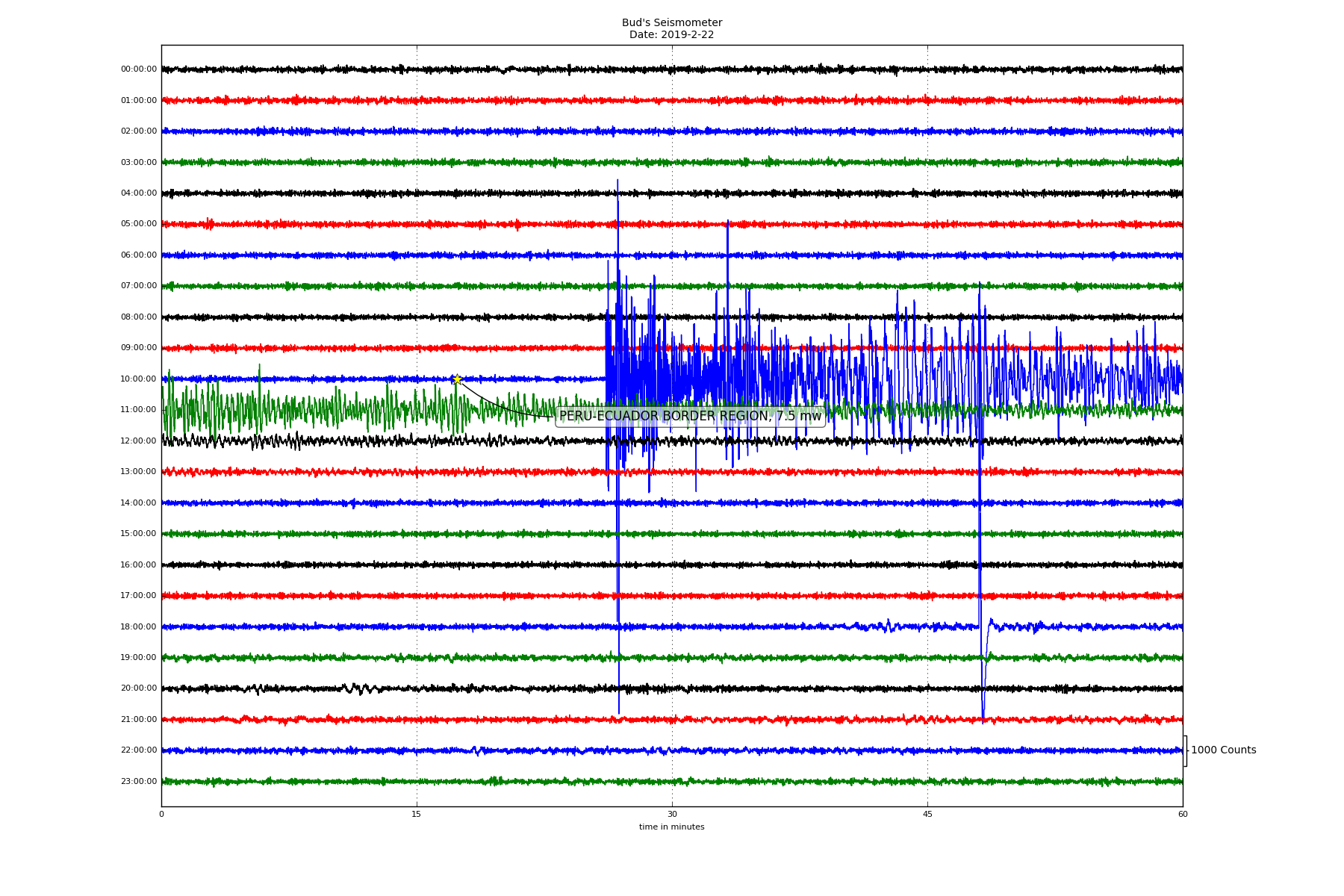

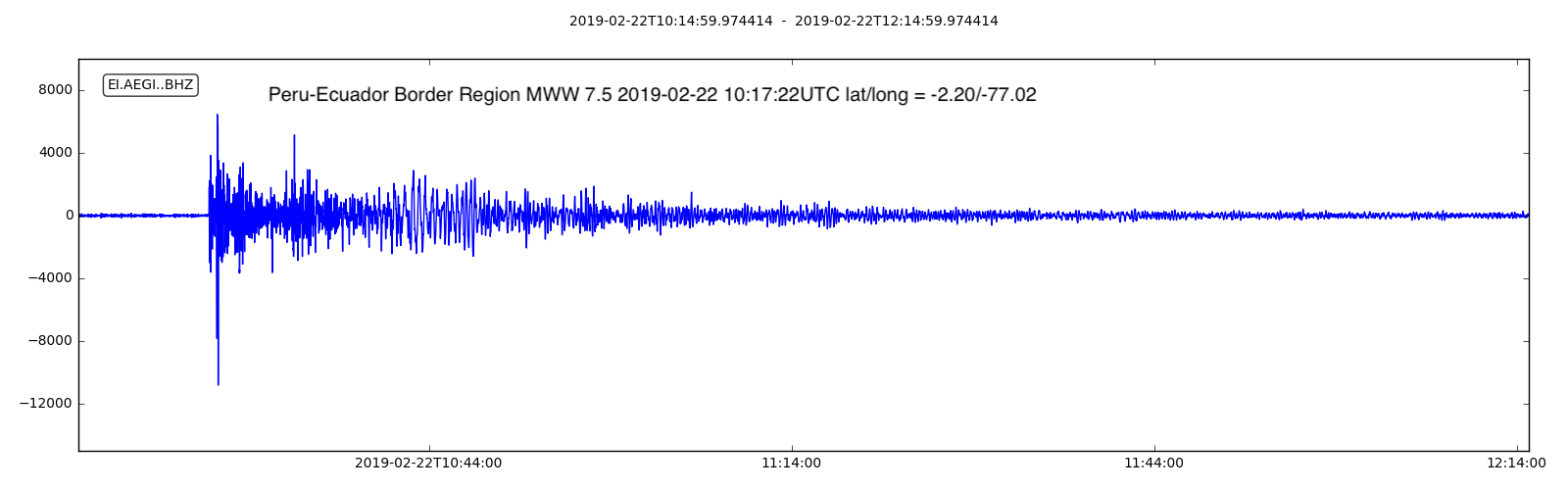

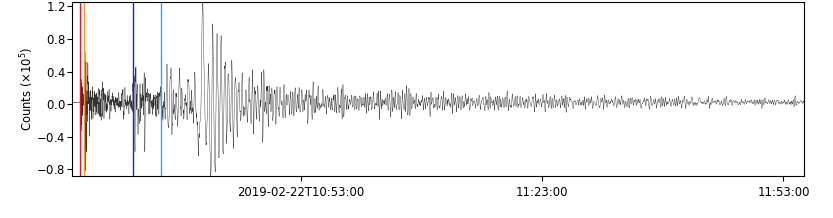

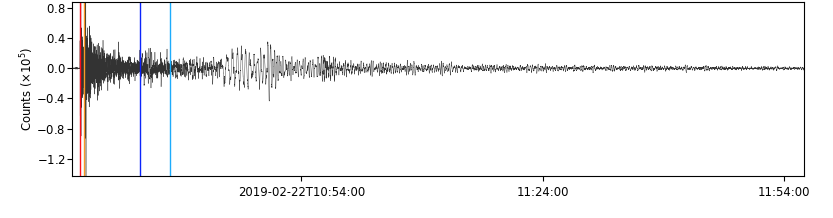

This seismometer has been running 24/7 for the past 3.5 years. It's time to document it and also upgrade the sensor to a professional-level PCB instead of a chicken scratched monstrosity. This space will slowly accumulate all of the information necessary to build one.

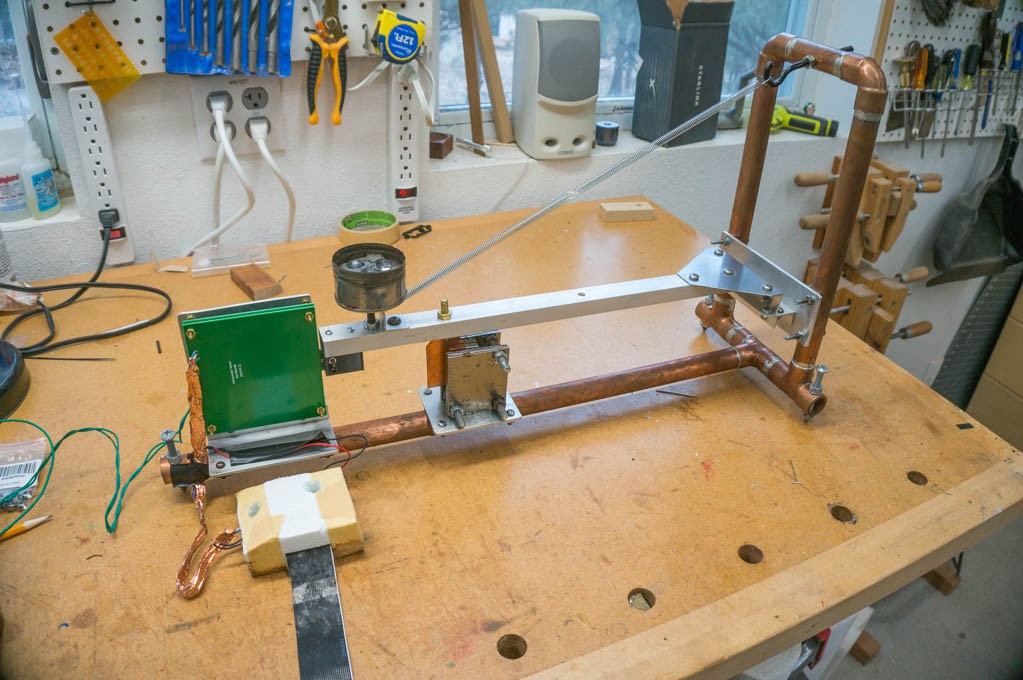

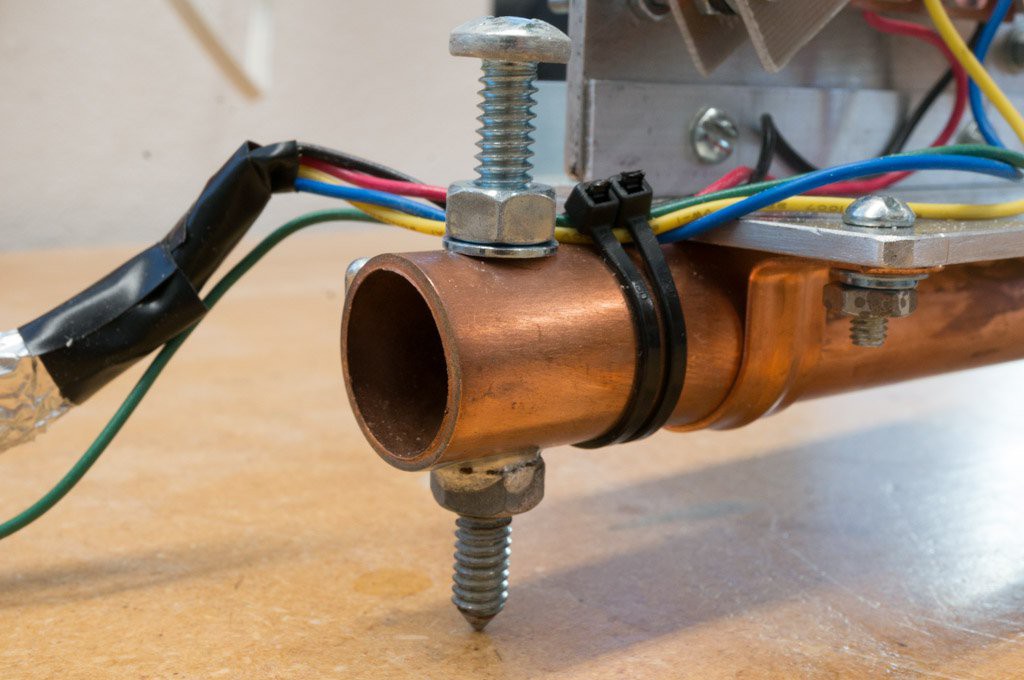

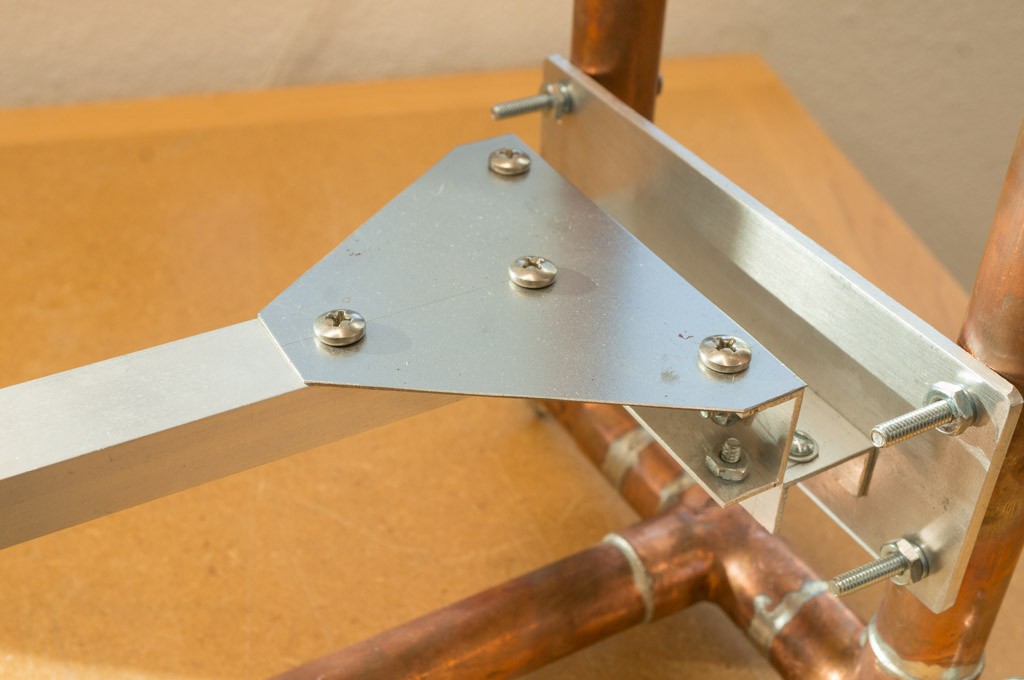

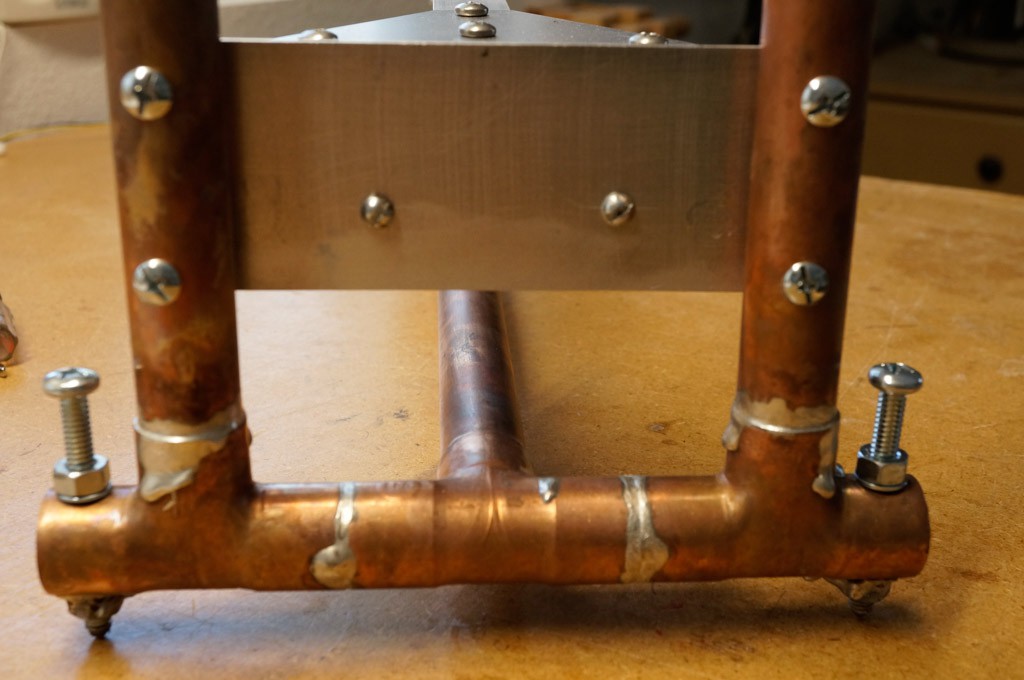

It started out as a wooden prototype, to keep the cost low, but morphed into a relatively easy to build frame made from copper tubing from the plumbing section of the local hardware store.

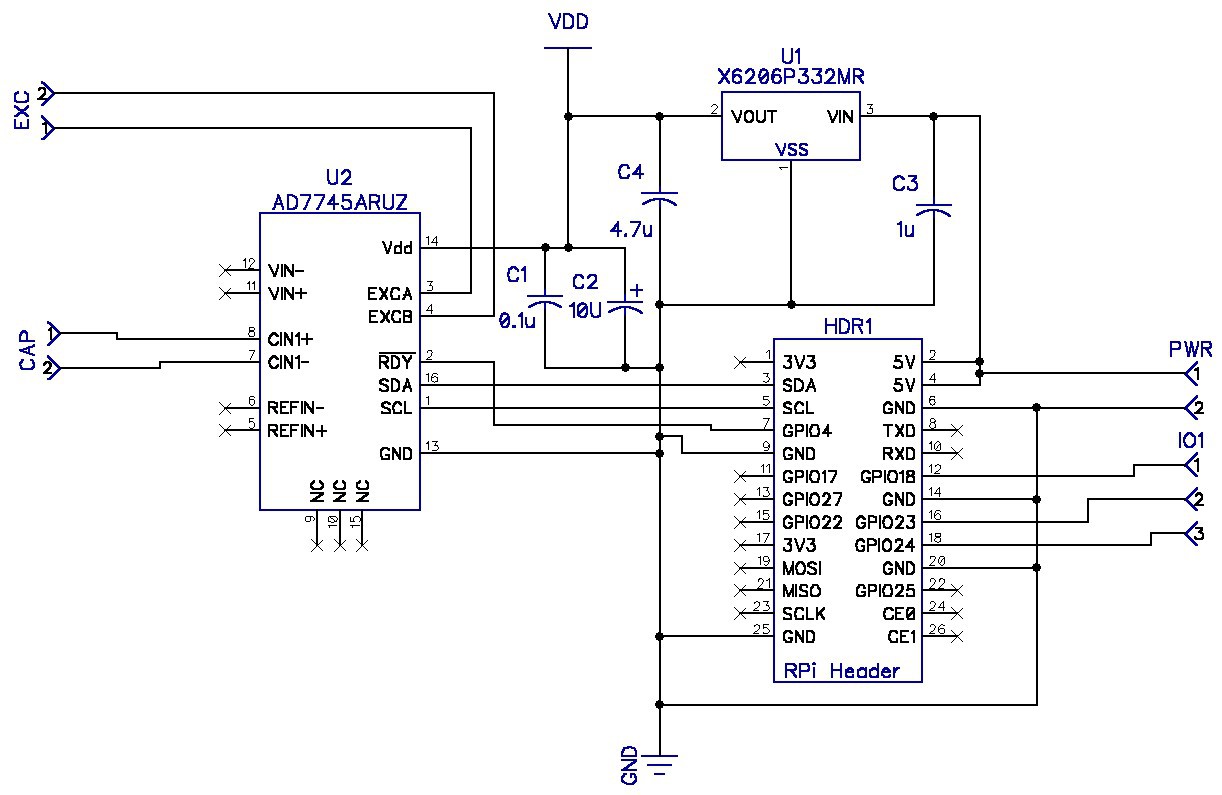

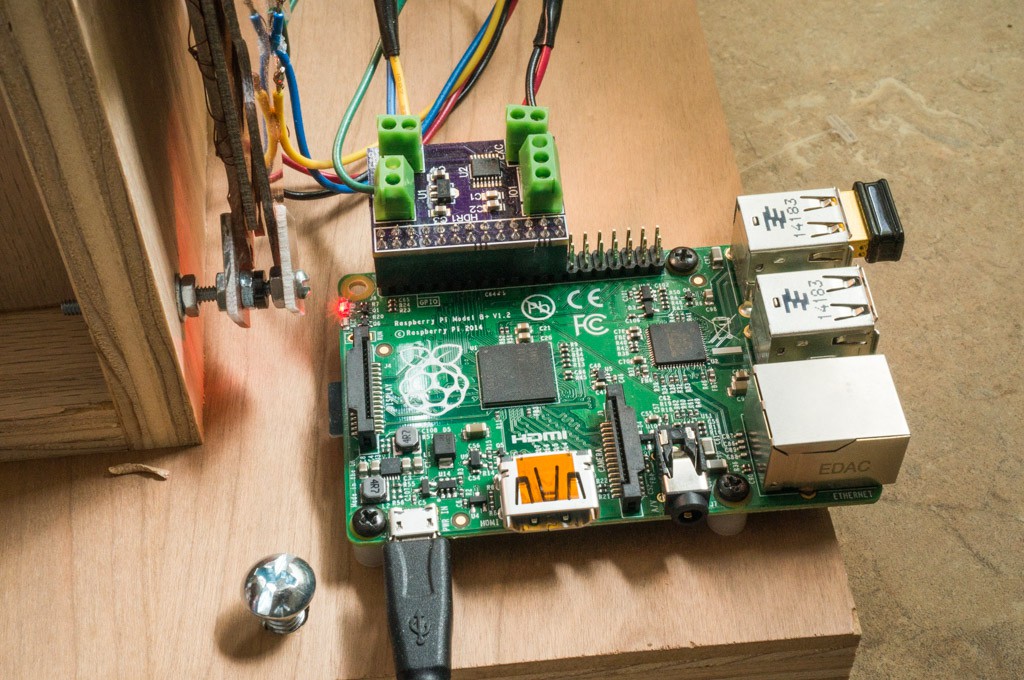

It uses a home-made capacitance displacement sensor to sense the movement of the pendulum. The electronics employ a 24-bit capacitance-to-digital converter and a basic Raspberry Pi single-board computer.

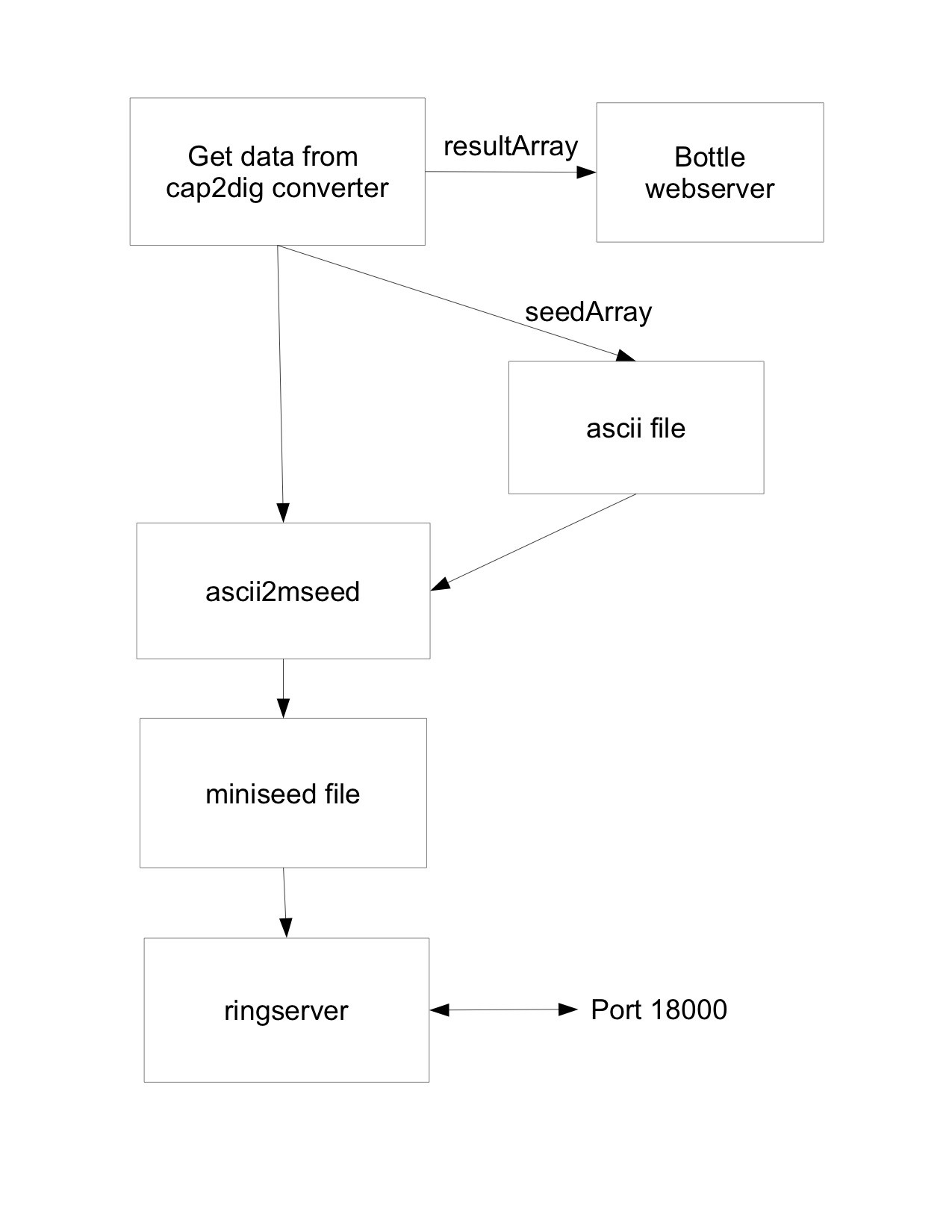

The Raspberry Pi provides a ringserver function on an ethernet port so the seismometer data is available to any computer running standard seismic data collection software.

This is a hobbyist-level seismometer. Professional grade units start at $1500 and usually must be buried at least 15 meters (40 feet) underground to avoid temperature swings and surface disturbances (like wind through the trees.)

Some Background Information:

An excellent overview is presented in this paper: Havskov, J., "Instrumentation in Earthquake Seismology", June 2002. (Available in the files section of this project.)

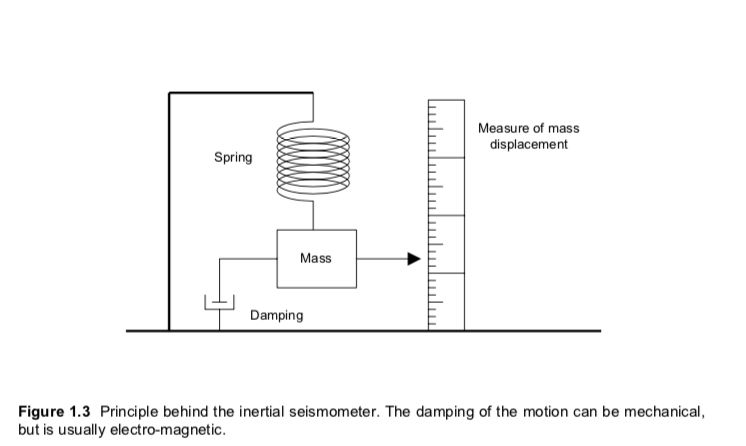

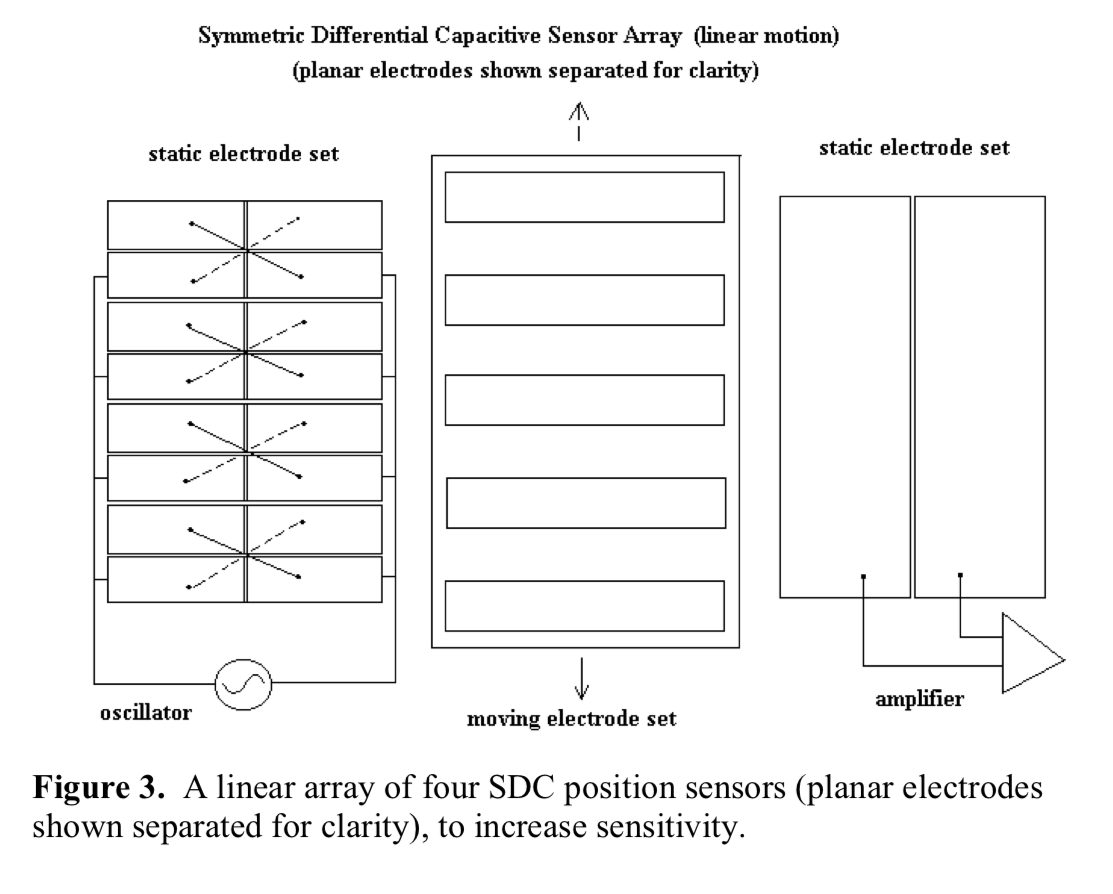

The basic concept is a mass suspended from a spring, with some method of measuring the displacement caused when the ground moves relative to the mass, which is supposed to remain stationary. All of the diagrams below are from Havskov paper.

The system must be damped to remove the resonance at the natural frequency of the pendulum. Otherwise, the response tends to "ring" at the natural frequency when perturbed. The seismometer above measures movement in the vertical axis (the z-axis). Many hobbyist level seismometers only measure movement in the x or y direction, and require two seismometers to get both dimensions. Most professional seismometers measure movement in 3 dimensions, x-y-z. My preference was to detect vertical movement for two reasons: it can be less sensitive to certain noise components, and it has no preference to east-west or north-south orientation.

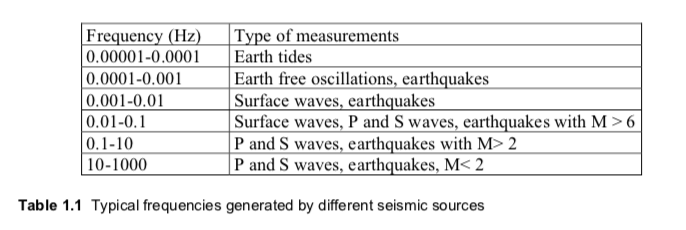

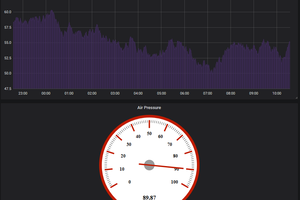

These are the frequencies of interest to seismology:

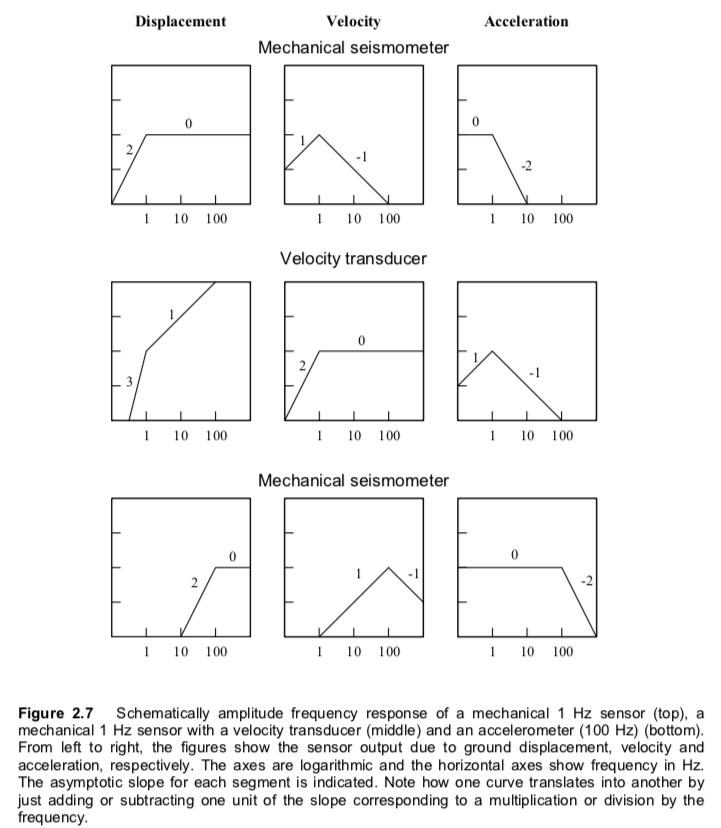

It would be nice if the seismometer could measure frequencies over the range 0.001 Hz to 10 Hz -- a 4 decade range. The problem is that the pendulum system has to have a very low natural frequency in order to be sensitive to very low frequencies. Long period seismometers are difficult to make stable -- a 30 second period is usually the limit of what can be obtained easily, with a reasonably long pendulum. Here's a series of plots showing frequency response of various sensor types coupled with the natural frequency of the pendulum.

A velocity sensor response falls off at the rate of 60dB/decade below the seismometer's natural frequency. A displacement sensor is a bit better -- only 40dB/decade. All things being equal...using a displacement sensor to measure movement should result in a seismometer with a decade lower frequency sensitivity.

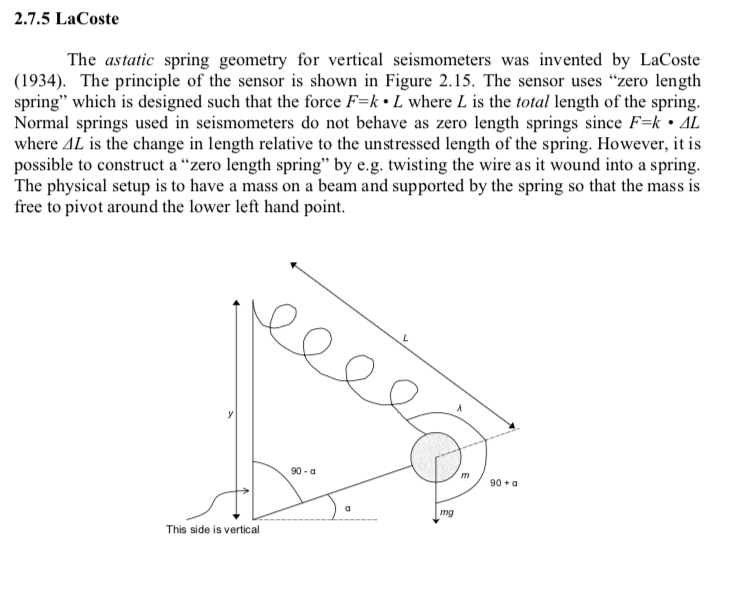

Lacoste Pendulum:

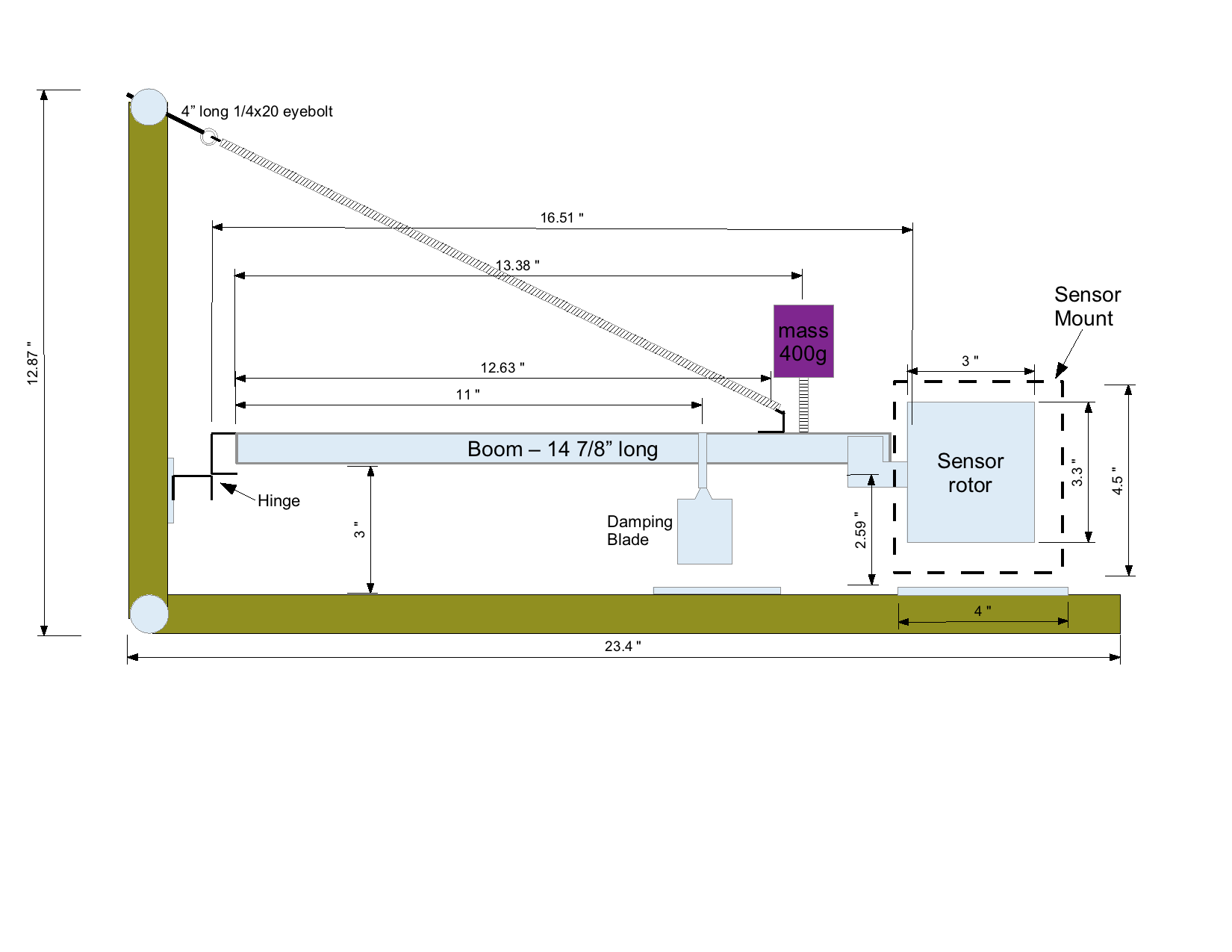

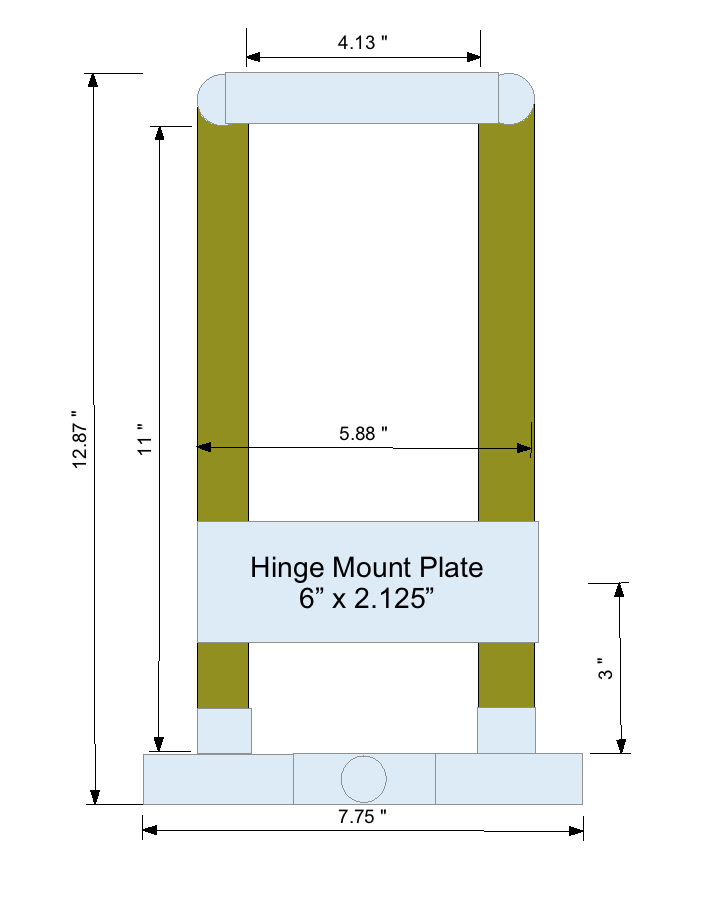

I chose a Lacoste type system, which uses a horizontal pendulum suspended by a spring as shown below (the figure is also from the Havskov paper.) Theoretically this setup can have a natural frequency close to zero.

But a "zero length spring" is hard to get. With reasonably small dimensions, 12" high by 24" long, the natural period is around 2 seconds. If I coupled this pendulum with a displacement sensor instead of the usual velocity sensor, then the effective sensitivity would be as good as a 20 second period pendulum. That's the fundamental mechanical approach of this seismometer.

Bud Bennett

Bud Bennett

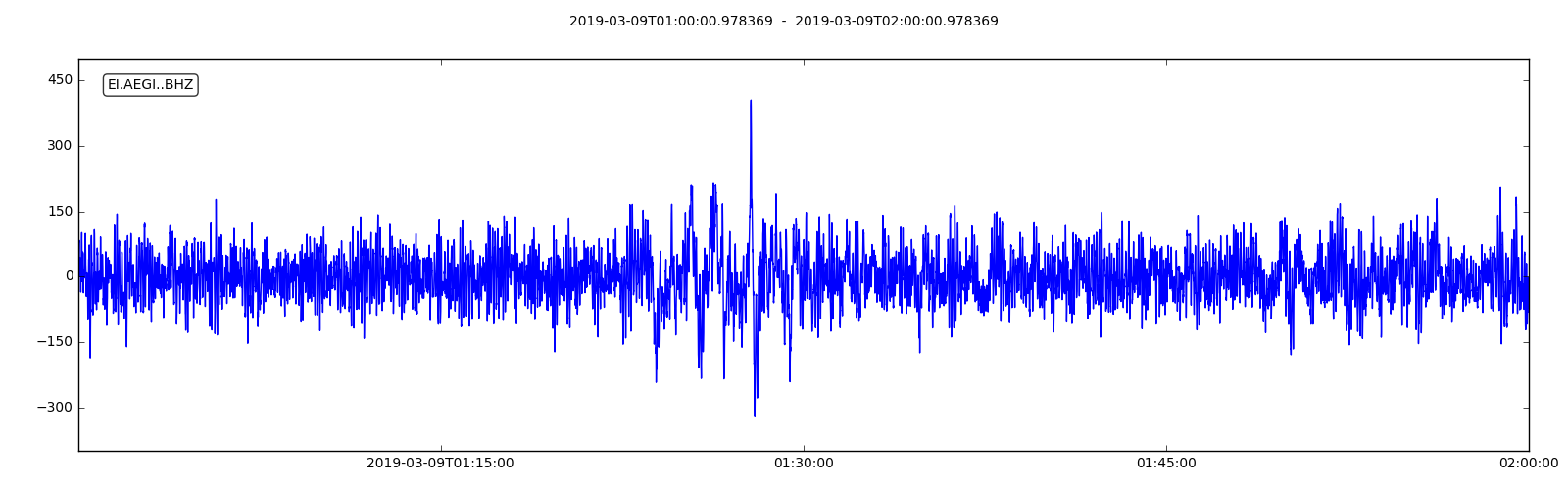

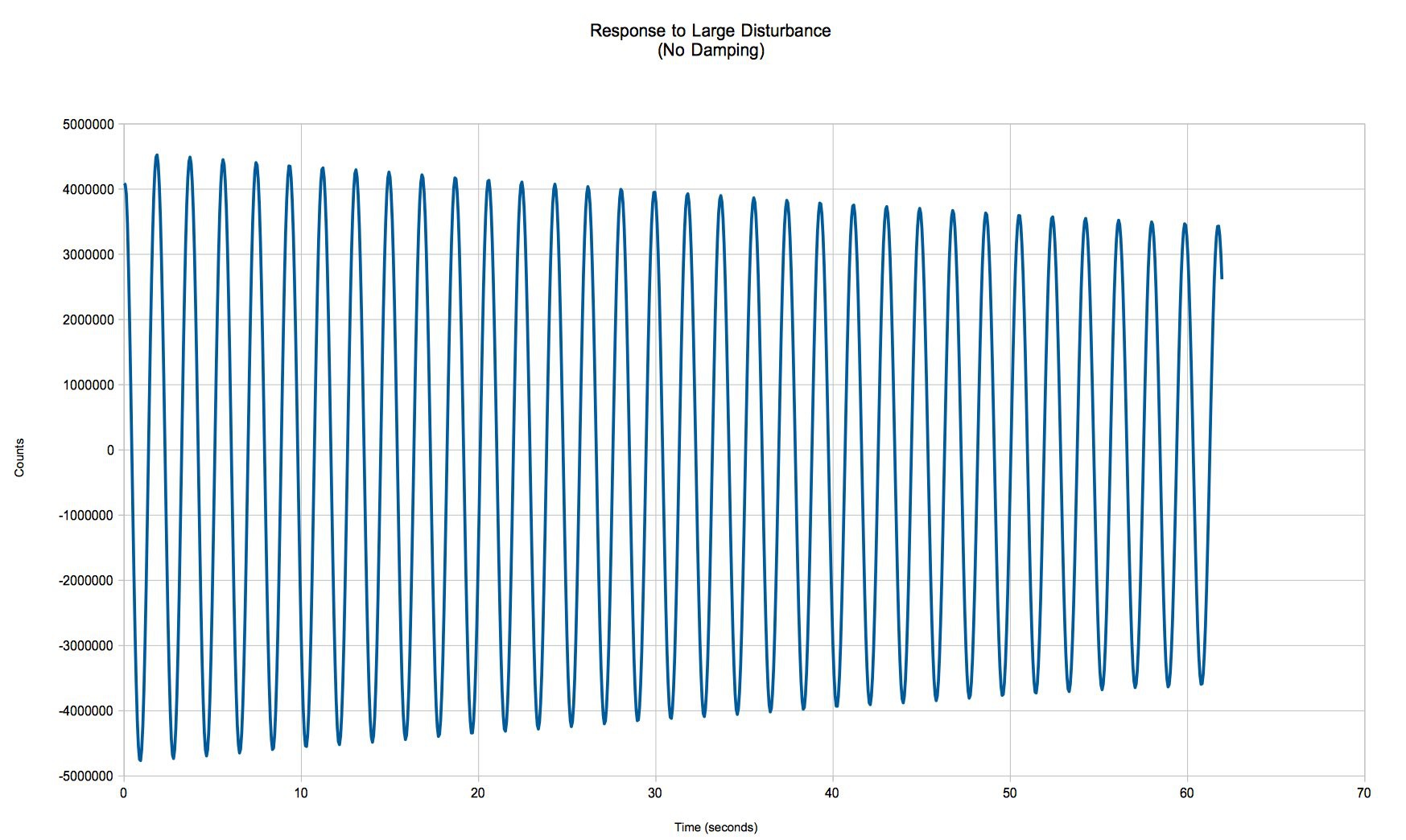

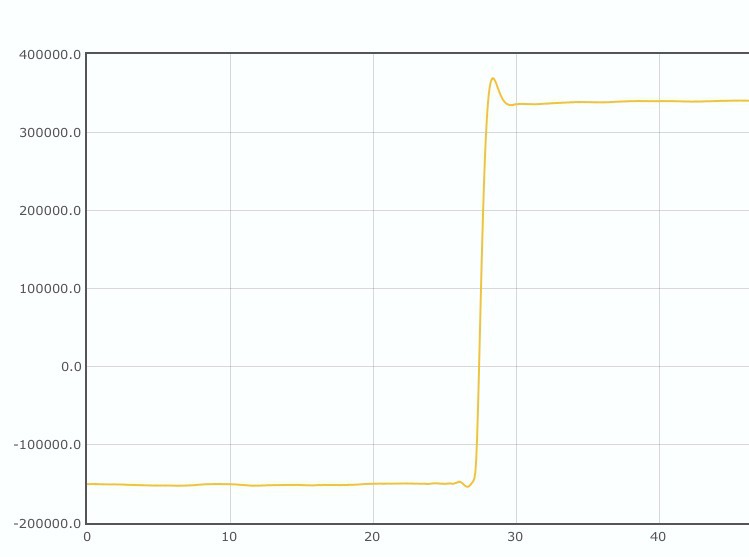

From the above plot, the natural period of my seismometer is 1.875 seconds. The amount of decay over the 60 second measurement is indicative of frictional forces at work.

From the above plot, the natural period of my seismometer is 1.875 seconds. The amount of decay over the 60 second measurement is indicative of frictional forces at work.

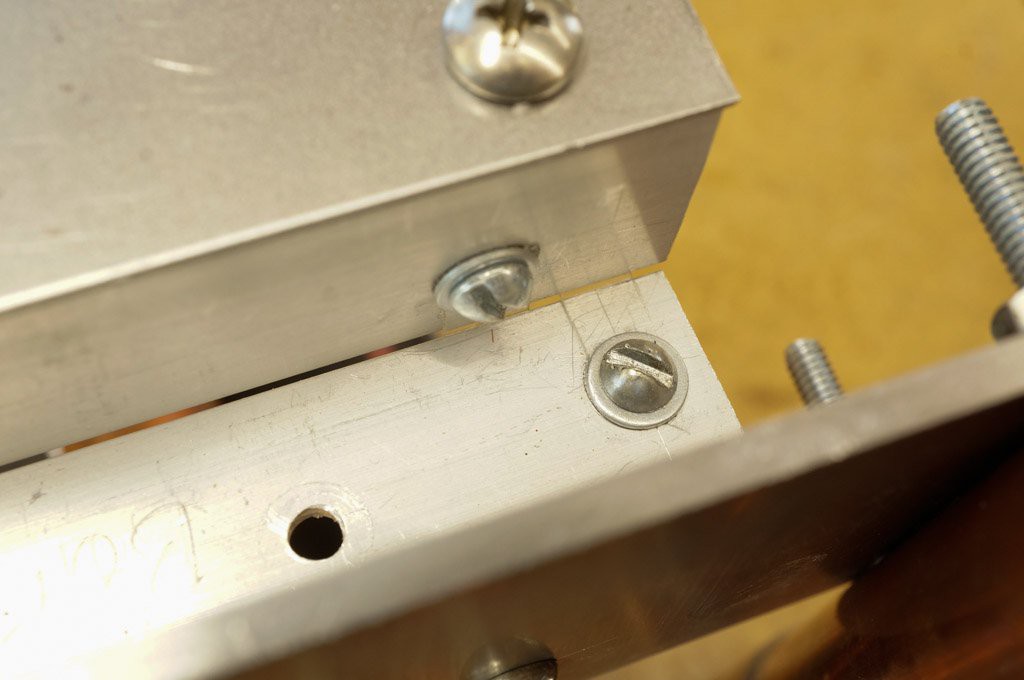

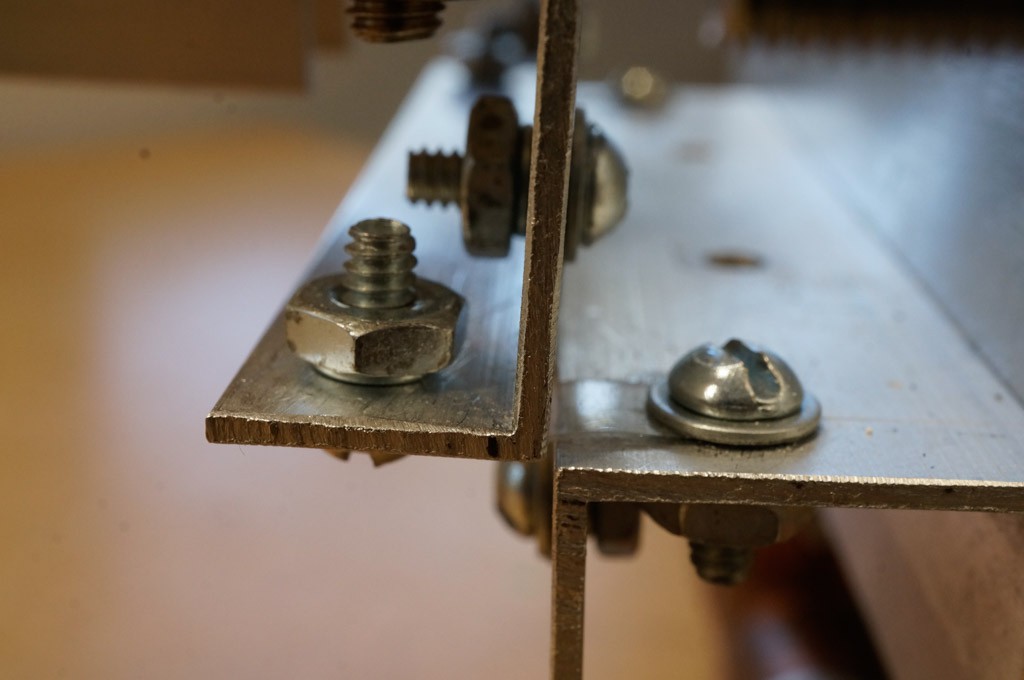

Cut the last bit of the eye to form a hook instead. The spring has a small loop at the end so you may have to grind the point of attachment at the hook to fit. I also filed a groove on the inside of the hook for the spring to sit so that it would not move and create unwanted artifacts. It is desired to have the spring only touching that groove. You can do all of this later, when the position of the spring will be more easily determined.

Cut the last bit of the eye to form a hook instead. The spring has a small loop at the end so you may have to grind the point of attachment at the hook to fit. I also filed a groove on the inside of the hook for the spring to sit so that it would not move and create unwanted artifacts. It is desired to have the spring only touching that groove. You can do all of this later, when the position of the spring will be more easily determined.

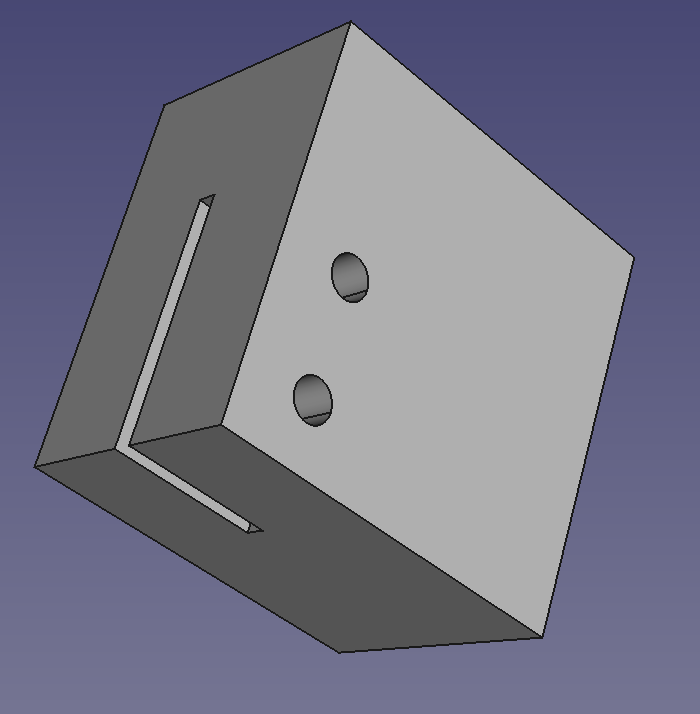

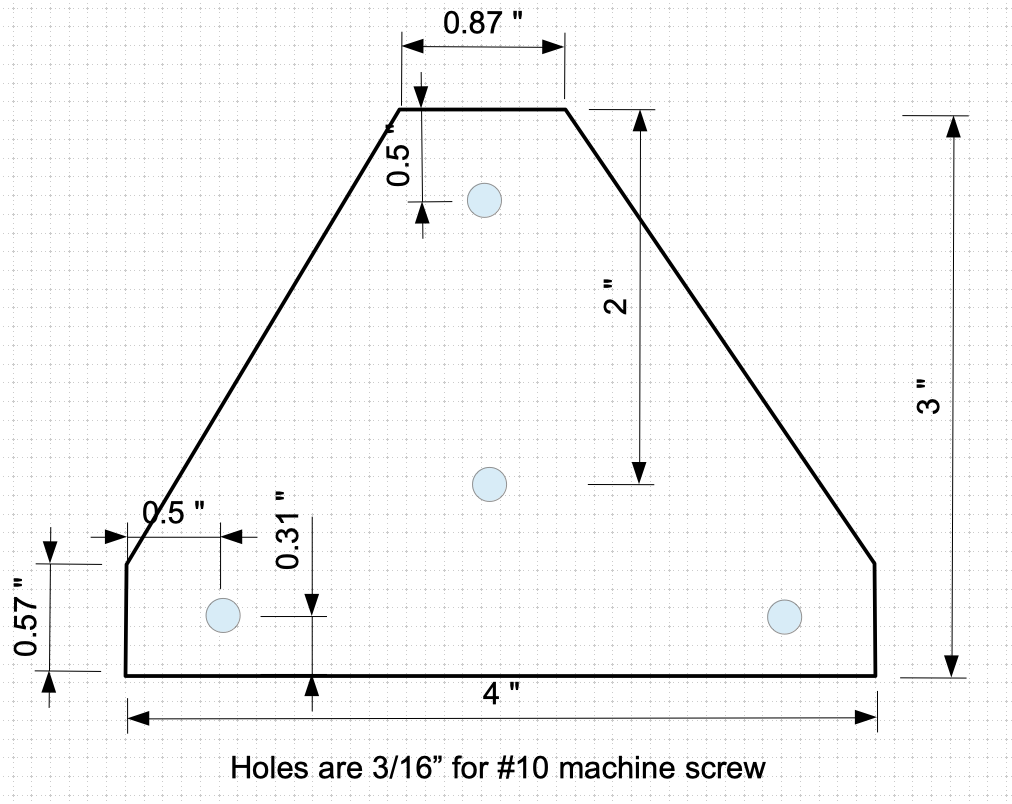

My drawing software can't make fractional dimensions. The 0.87" translates to 7/8", 0.57" is 9/16" and 0.31" is 5/16".

My drawing software can't make fractional dimensions. The 0.87" translates to 7/8", 0.57" is 9/16" and 0.31" is 5/16".

staticdet5

staticdet5

Manoj kumar

Manoj kumar

Brenda Armour

Brenda Armour

Nice writeup, thanks!