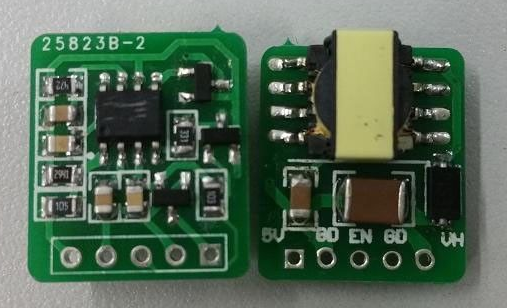

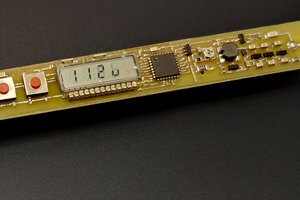

I've made a number of Nixie and VFD tube clocks over the past few years, often using professionally manufactured PCBs I designed.

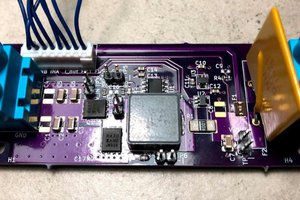

For 2019, I thought I'd go back to basics, and make a PCB design I could fab at home, using easy to source components (such as high voltage NPN and PNP transistors, and shift registers).

That limits me to a single sided board, which I can etch at home using photolithography.

David Pye

David Pye

Jenny List

Jenny List

Tijl Schepens

Tijl Schepens

BleakyTex

BleakyTex