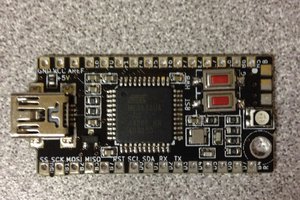

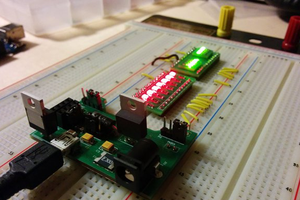

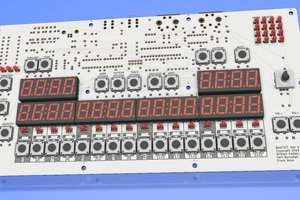

I often find myself needing a combination of SMD and trough hole parts for a project. If I want to make a quick prototype I would like them to be on the same prototype board. Therefore I am developing the prototype board of my dreams starting with basic stripboard with some power connectors and eventually moving up to a combined SMD/trough hole prototype board with various connector footprints.

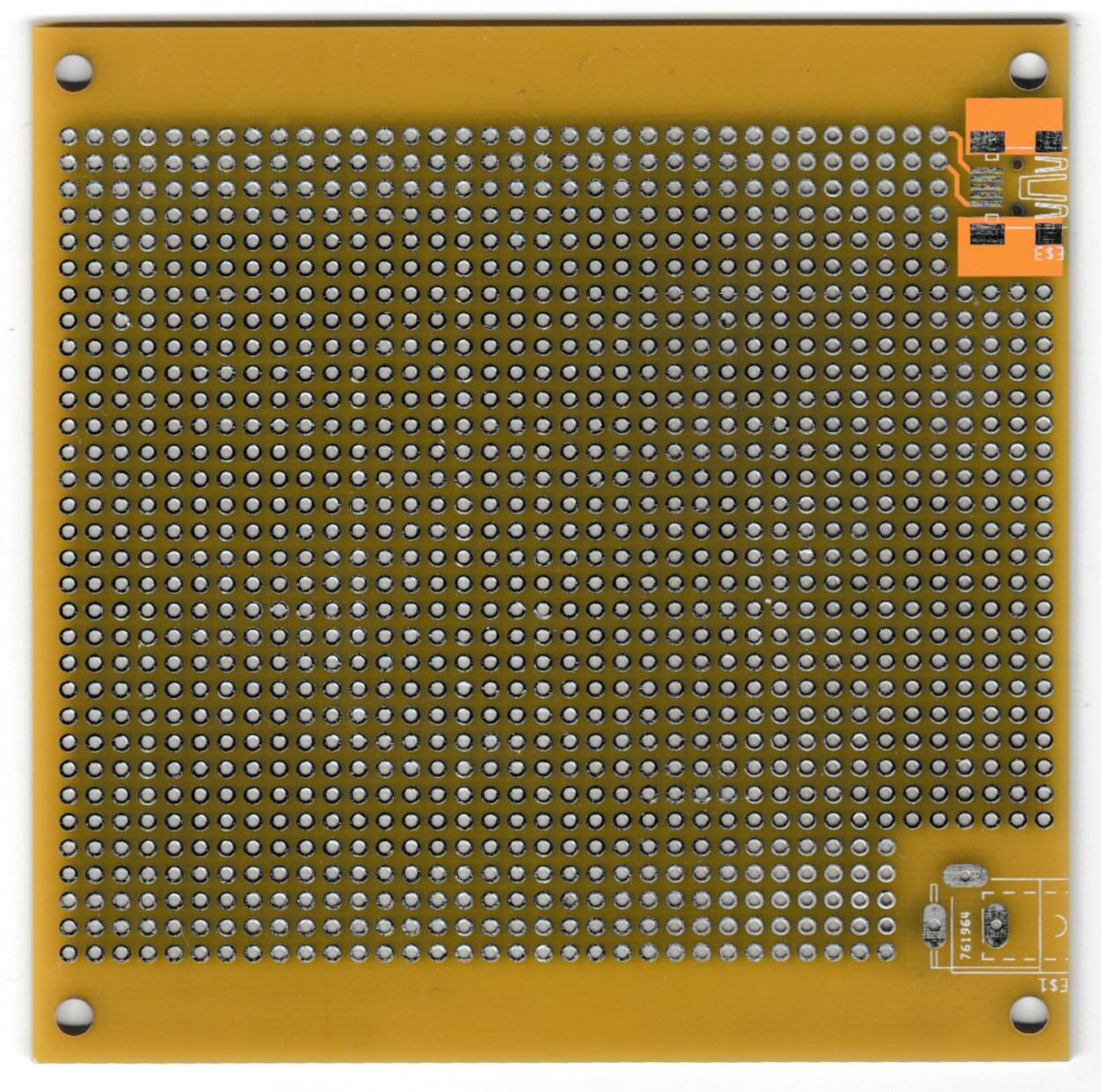

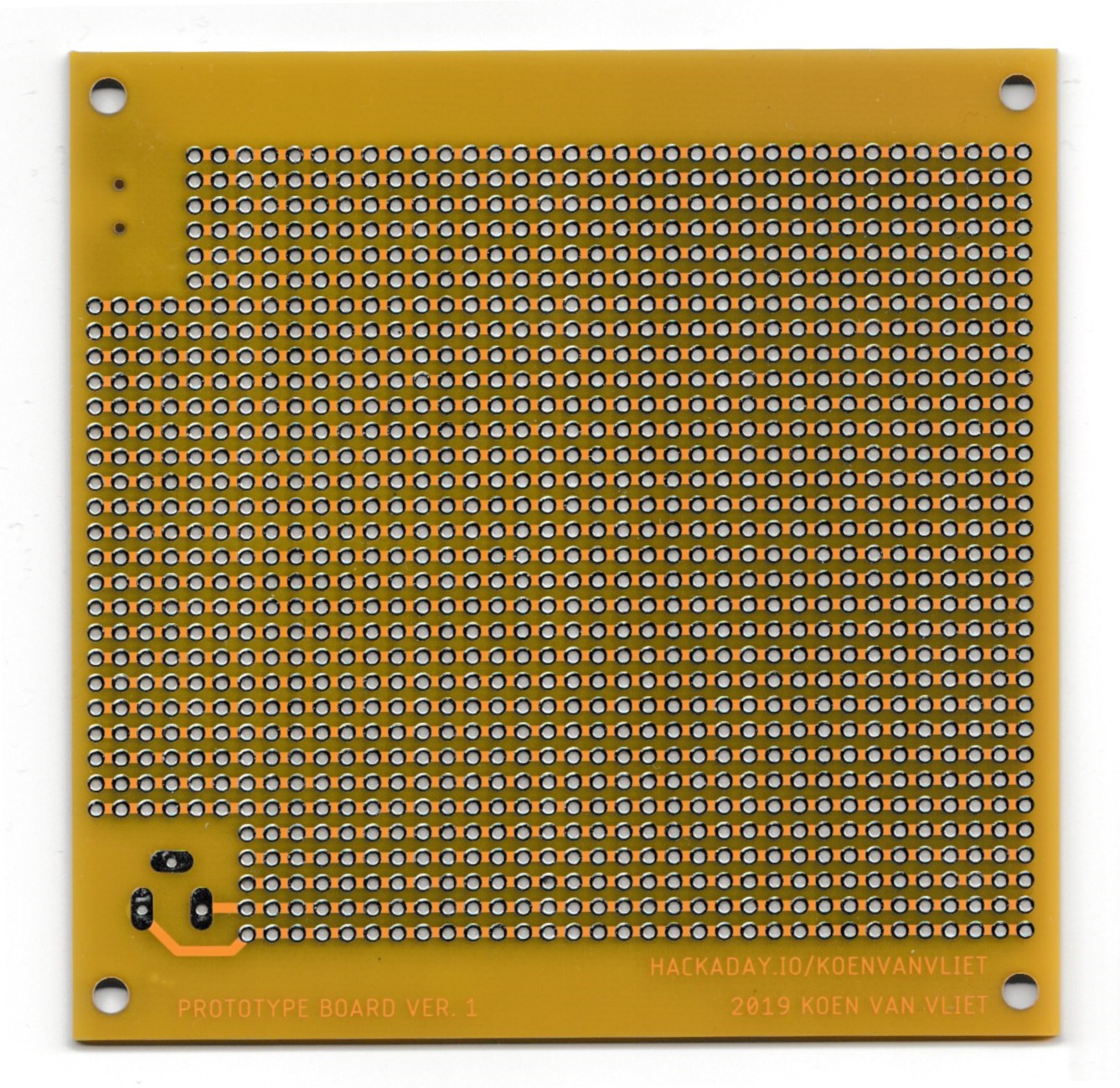

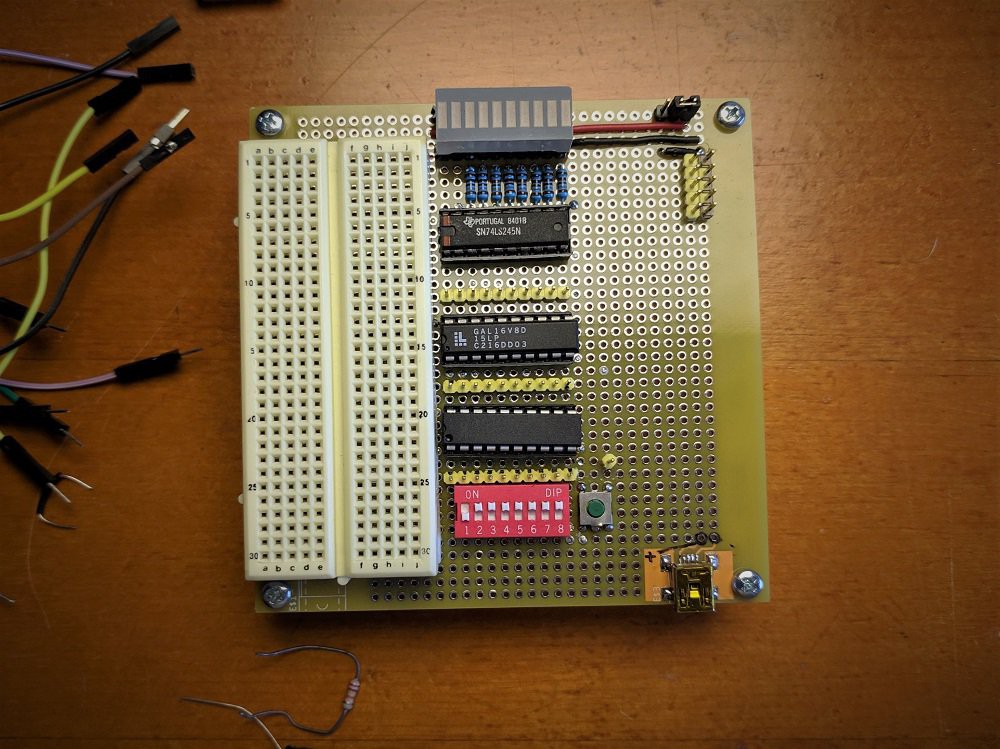

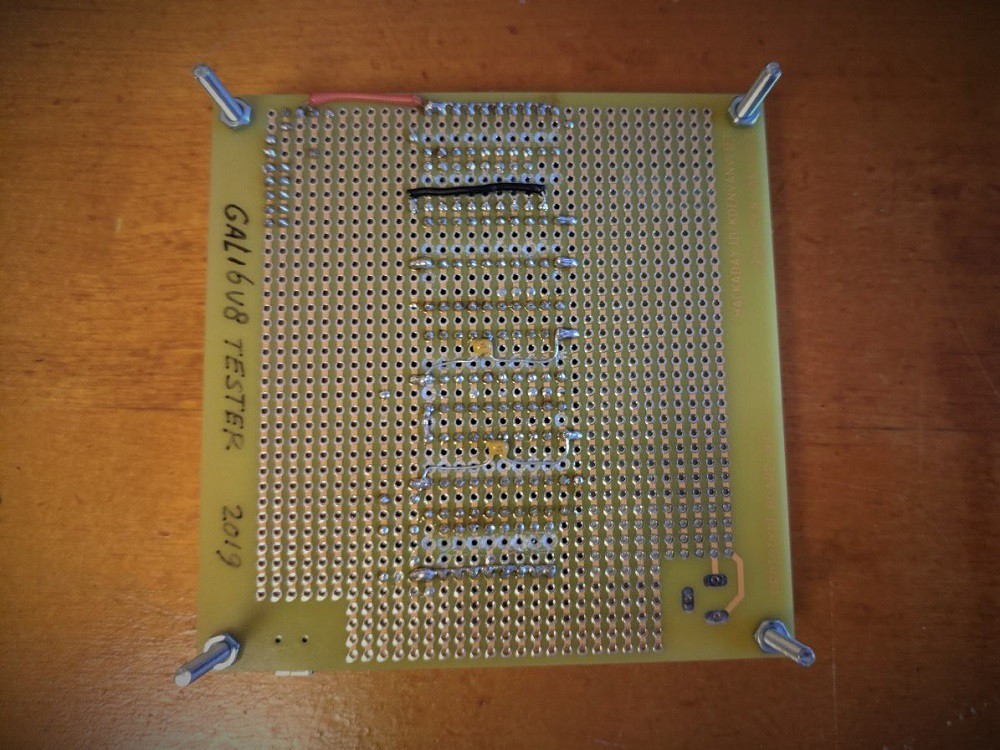

Getting my own perfboard manufactured

Prototype PCBs for conventional and SMD components

Koen van Vliet

Koen van Vliet

The Big One

The Big One

technolomaniac

technolomaniac

danjovic

danjovic

Frank Buss

Frank Buss