Built this out in Fusion360. Now I'm going to put the power supplies in the main LED cabinet.

This will be hidden inside, will have three 120v fans, to move air over the power supplies. Will have panels to route the air across the power supplies. This will make it easier to move it around, will be all one unit.

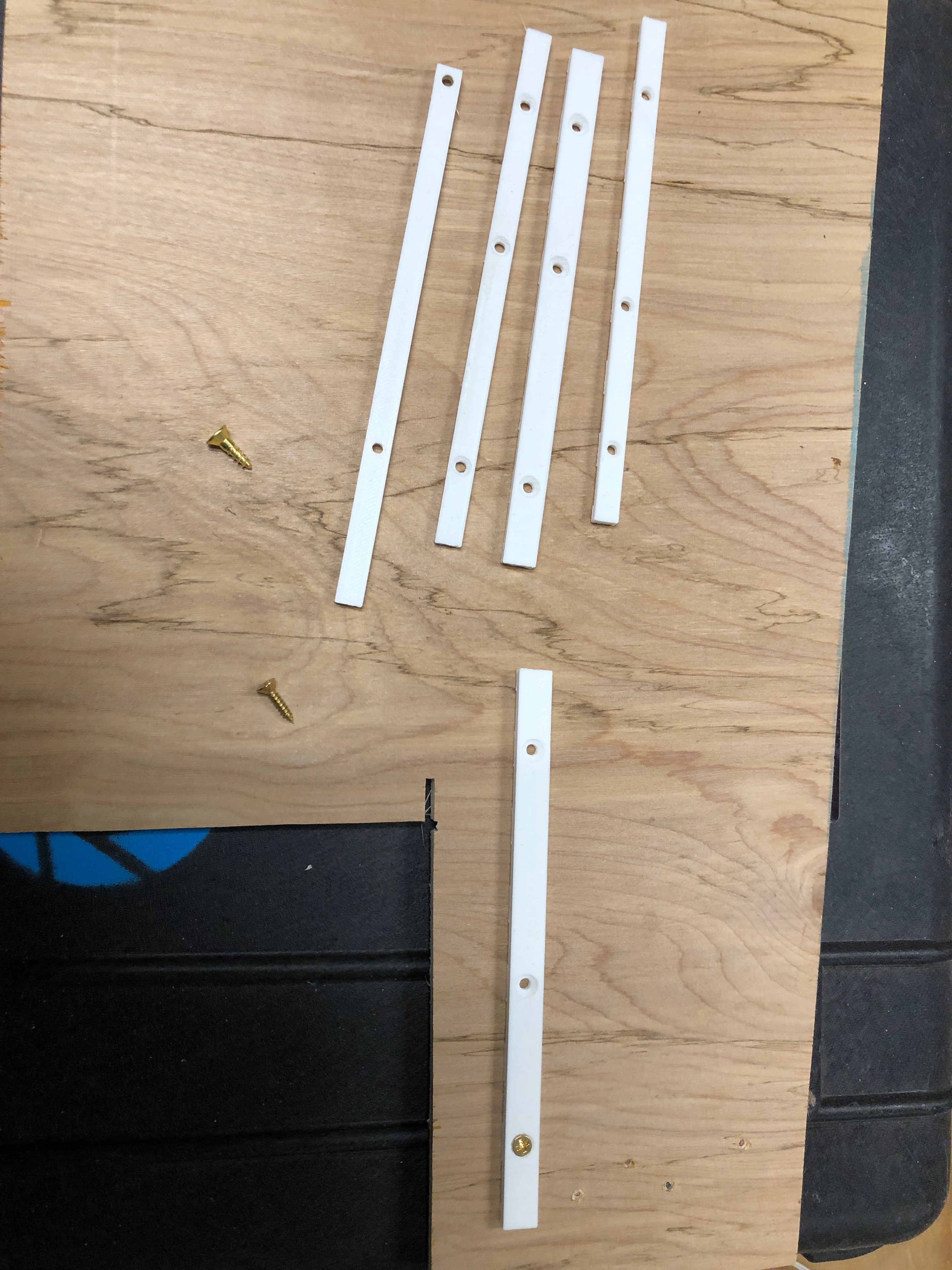

( picture showing several test prints of the strap, we tweaked the hole size and inset. It's hard to see in this picture but there 1/2mm slots that the LED strip will be held in place with. Also experimented with different screw sizes, this is scrap 1/4 plywood. I will be using 1/4 plywood to mount the LEDs on)

My son designed straps to hold the LED strips down. I will have everything marked and I can have the kids screw the strips down. It is critical that the LEDs be positioned in the correct location, I'm going to drill small pilot holes for the straps. I will also draws lines showing where everything is to be located. Also, I will make sure the LEDs are positioned in the correct direction, I will be using a Z pattern. We made several prints, and tested the screws. I tried #6 x 1/2 then #4 x1/2 and lastly #4 x 3/8s. It took 7 minor tweaks and prints but we have a nice strap design that works well with #4 x 3/8 screws. I will pick up 2 boxes of 100 of these. Did first print, need to tweak the design and reprint. These will be screwed into the hard board that the LEDs are mounted too. I do not think hot glue will work in the environment, it tends to not hold if in a hot area. I've had problems with hot glue before, so going to avoid it and go with solid screw down holders. I'm trying to keep the cost down, originally I expected it to be ~150-200, now looking more like $350. I'm going to look around Home Depot tomorrow, I need wood for the box, get an idea of what's available.

Some test pieces of acrylic arrives today, one was 1/8 white, the other 1/4 semi transparent. I tested these with my small test LED board, 20x15 at 150 brightness. The 1/8 looks the best, it did a good job defusing/blending the LEDs. Also it had the nice feature of when the LEDs are off you can not see the LEDs. The bad part is its sort of expensive. I'm going to call around to some local places. Another concern I have is cutting the acrylic cleanly. I've had very bad luck with this in the past. I have some ideas how to do it better this time, and can use the small test pieces to test cutting with. I'm hoping if I find a local place they can cut it for me. I was going to hold off on the defuser until phase 2 (next year), but I'm changing my mind. The location where this will be mounted, Fair Animal Barn, will have a lot of debris in the air. It will be very very hard to get this out of the LEDs, this clings to most things.

Next I need to 3D print 14 of the straps, I can print 4 at one time.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.