The design for this curing chamber was inspired by the Wanhao Boxman I chamber. It is a commercially available chamber that uses four 30W UV LEDs as light sources.

Another additional use for this chamber is found in UV glue curing, a function in which this chamber offers great performance because of the high total LED power (150W total). Very short curing times can be achieved. This is what motivated the entry of this project to the Hackaday Prize 2020, in the Field Ready open challenge. This curing chamber design allows for a very economical build of a high power UV glue curing device, made from readily available components and low-cost manufacturing methods.

In the following video I summarize the project:

The idea with my curing box was to surpass the light power of the Boxman I, while keeping it under the price of Boxman I.

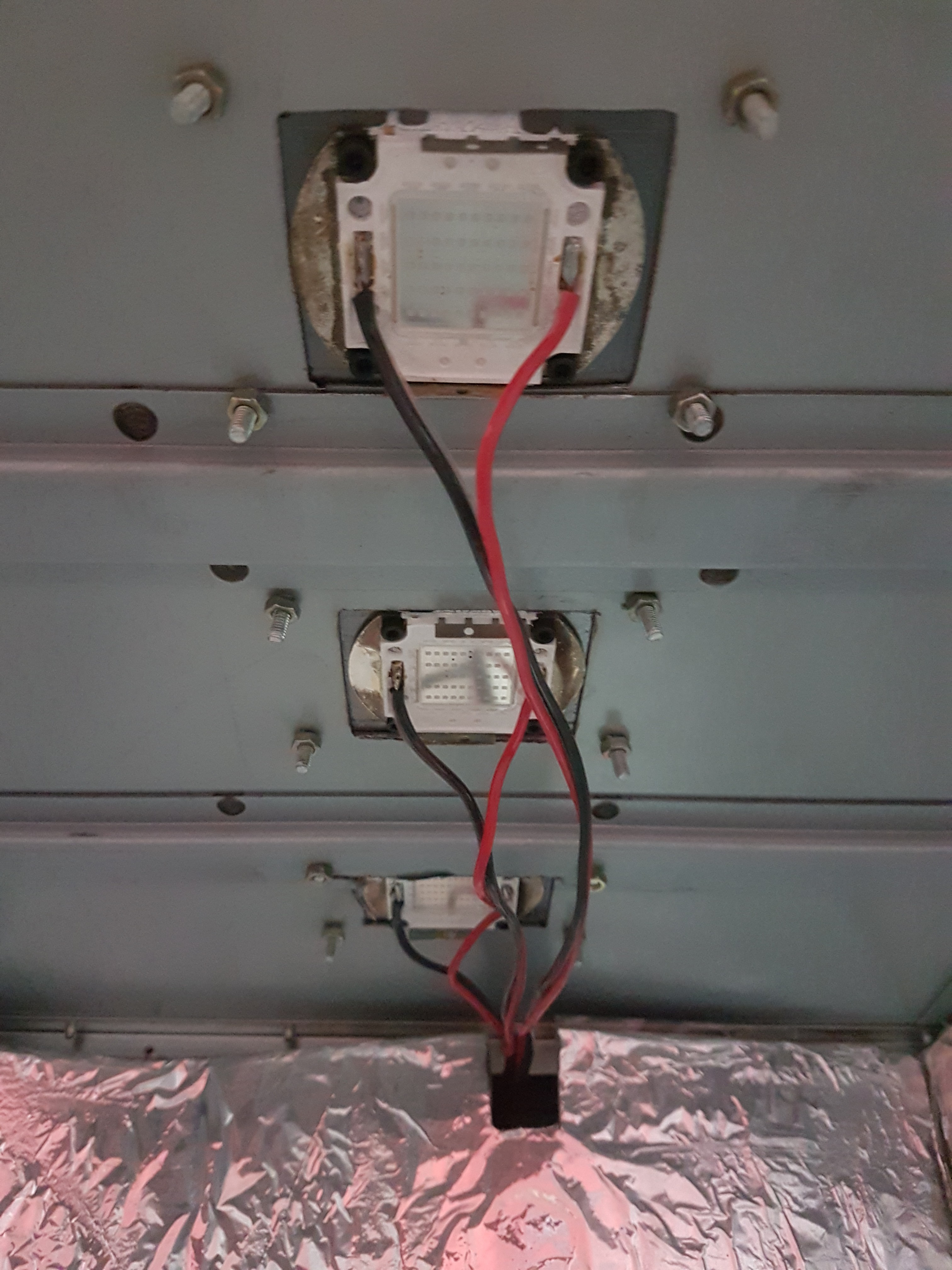

For the structure of the chamber, I used an old Cisco Catalyst 8500 rack that I salvaged from the dumpster at my university. Without the equipment, the rack is just a very nice and sturdy box. The inner walls need to be reflective in order to get the most uniform curing possible. Regular mirrors are a poor choice, since the glass in front of the reflective material absorbs UV light. A better solution (and a lot cheaper) was to cover the inner walls with cardboard sheets with aluminum foil glued on. This reflects almost all the incident UV light.

|  |

The light sources are three 50W, 405nm UV LEDs. These need to be attached to a heat sink because they dissipate a substantial amount of heat. To drive them, I used three 55.6W LED drivers (one for each LED). Three holes were cut on the top of the chamber with an angle grinder to accommodate the LEDs.

|  |

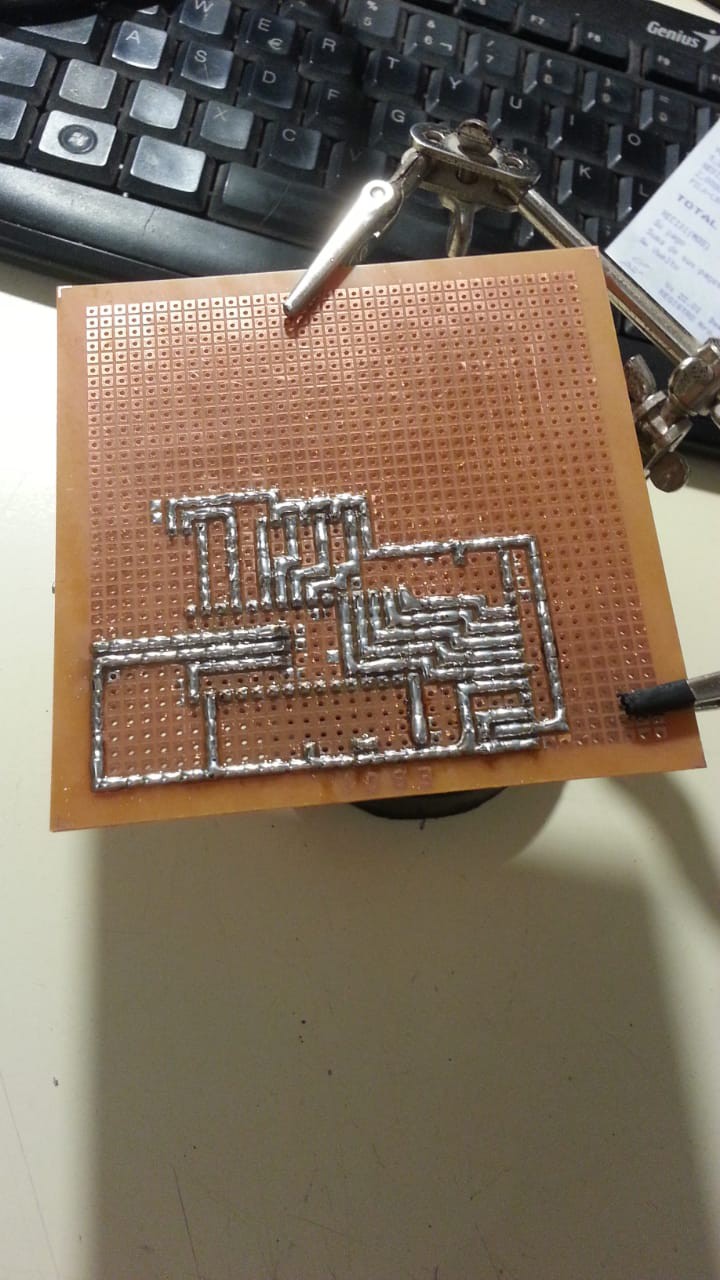

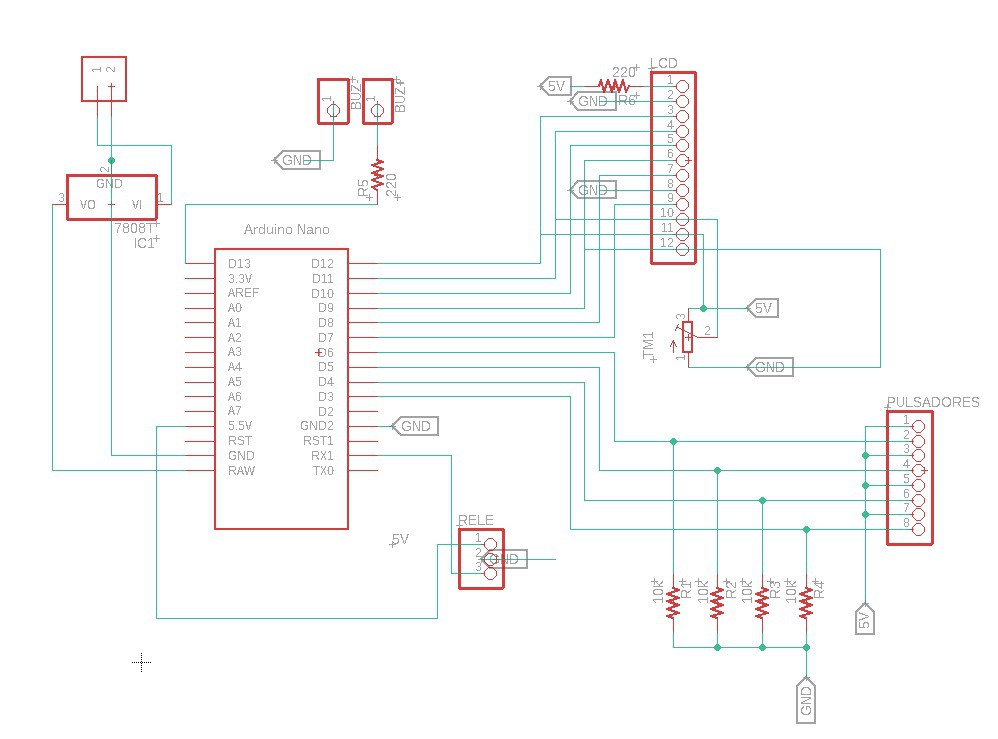

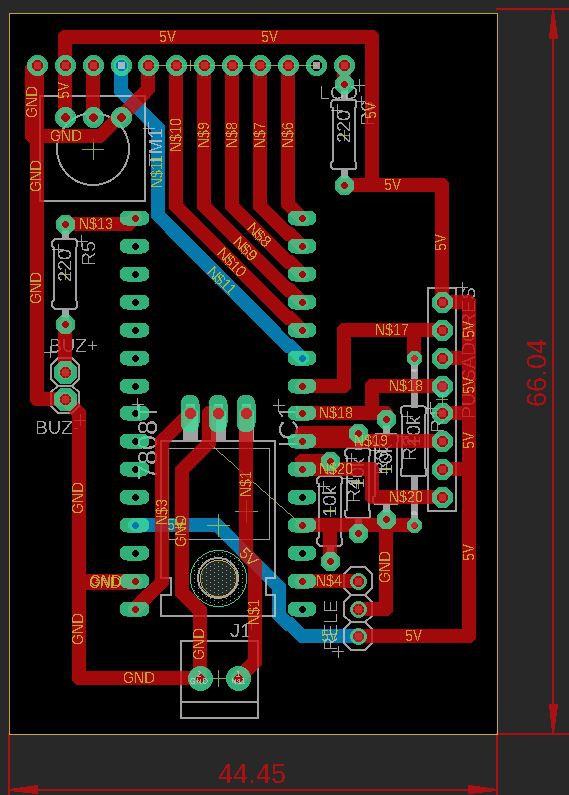

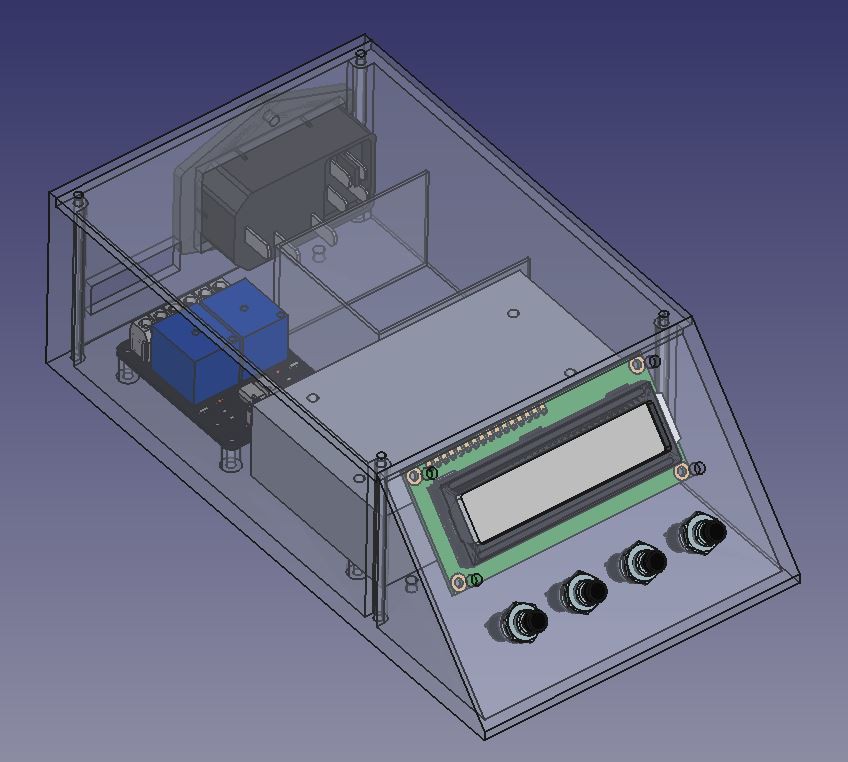

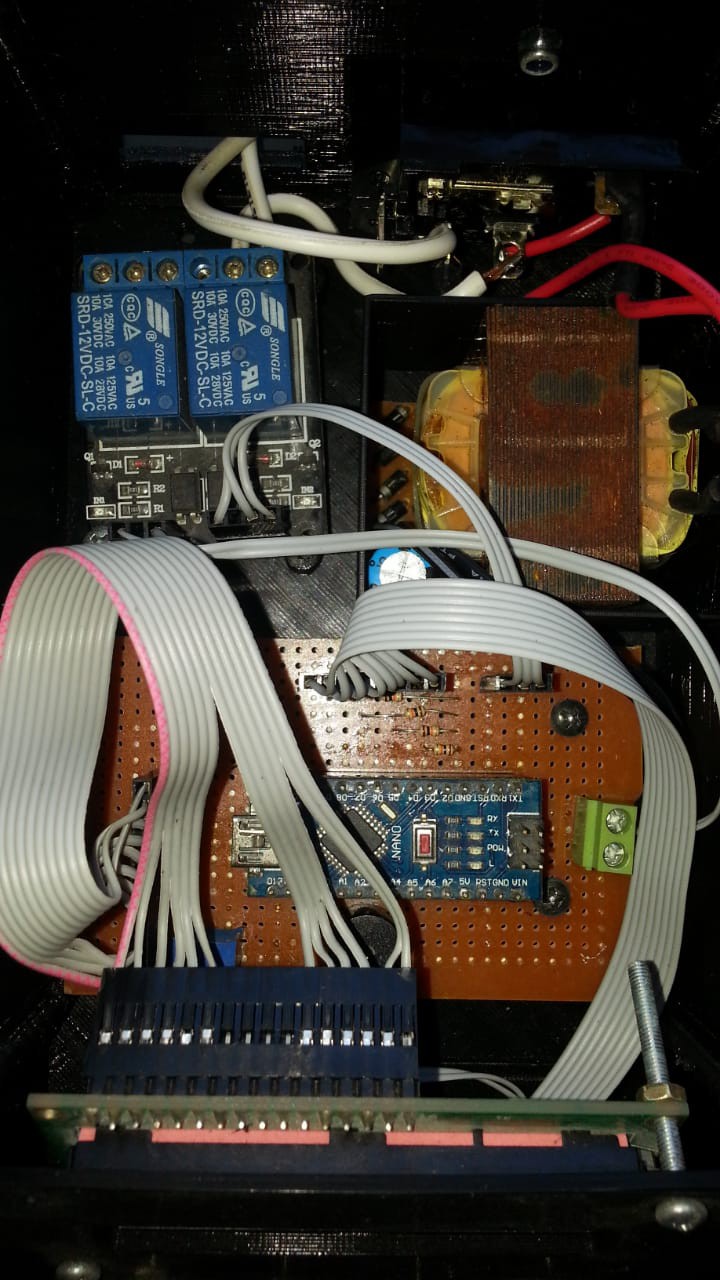

I needed a timer to control the exposure time, that turned on the LEDs and turned them off after the programmed time had passed. For this, I used an Arduino Nano, a relay module, some pushbuttons and a 16x2 LCD display. The code for the Arduino (included down below) is based on the very nice Kitchen Timer project, adding some lines of code to control the relay (which in turn switches mains voltage to the LED drivers), and a greeting screen on the display when the system is turned on. The circuit schematic is very similar to the aforementioned project.

The circuit is designed to be easily built with perfboard. The board layout included was used to predesign the circuit with the perfboard construction in mind, but the same files are useful if etching a copper clad board. Power is provided using a 220/12V transformer with a full bridge rectifier that I salvaged from an old wall wart. This is further regulated with a 7809 linear reg on the board, which in turn powers the Arduino.

An enclosure for the electronics was designed and 3D printed in PLA using a conventional FDM 3D printer. The STL files are included in this project page.

Inside the chamber, the printed parts are submerged in a big flask full of water, since contact with Oxygen inhibits the polymerization reaction and thereby requires longer curing times.

Further development may include adding fans to the heatsinks, since after 3 minutes of operation the LED's get really hot. The water in which the parts are submerged could be heated with an electric heater to a preset temperature, to further accelerate the curing reaction.

Andrés Lopez Pulzovan

Andrés Lopez Pulzovan