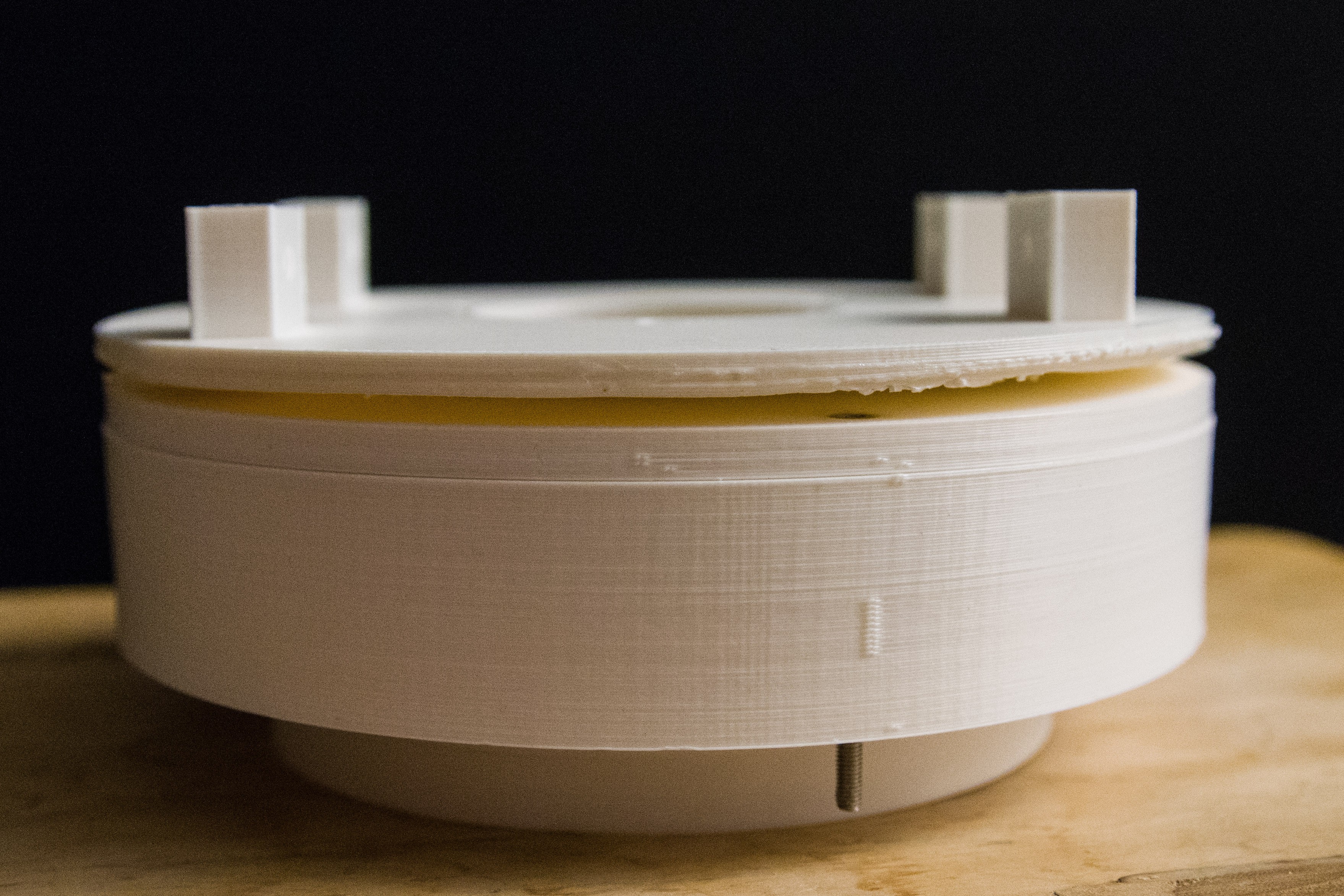

Art1Top did not print without a fight. The job was an 8h30 3D print job because it had a lot of support structures that on my Prussa tends to start warping and ends up with a failed print 6 hours into the print.

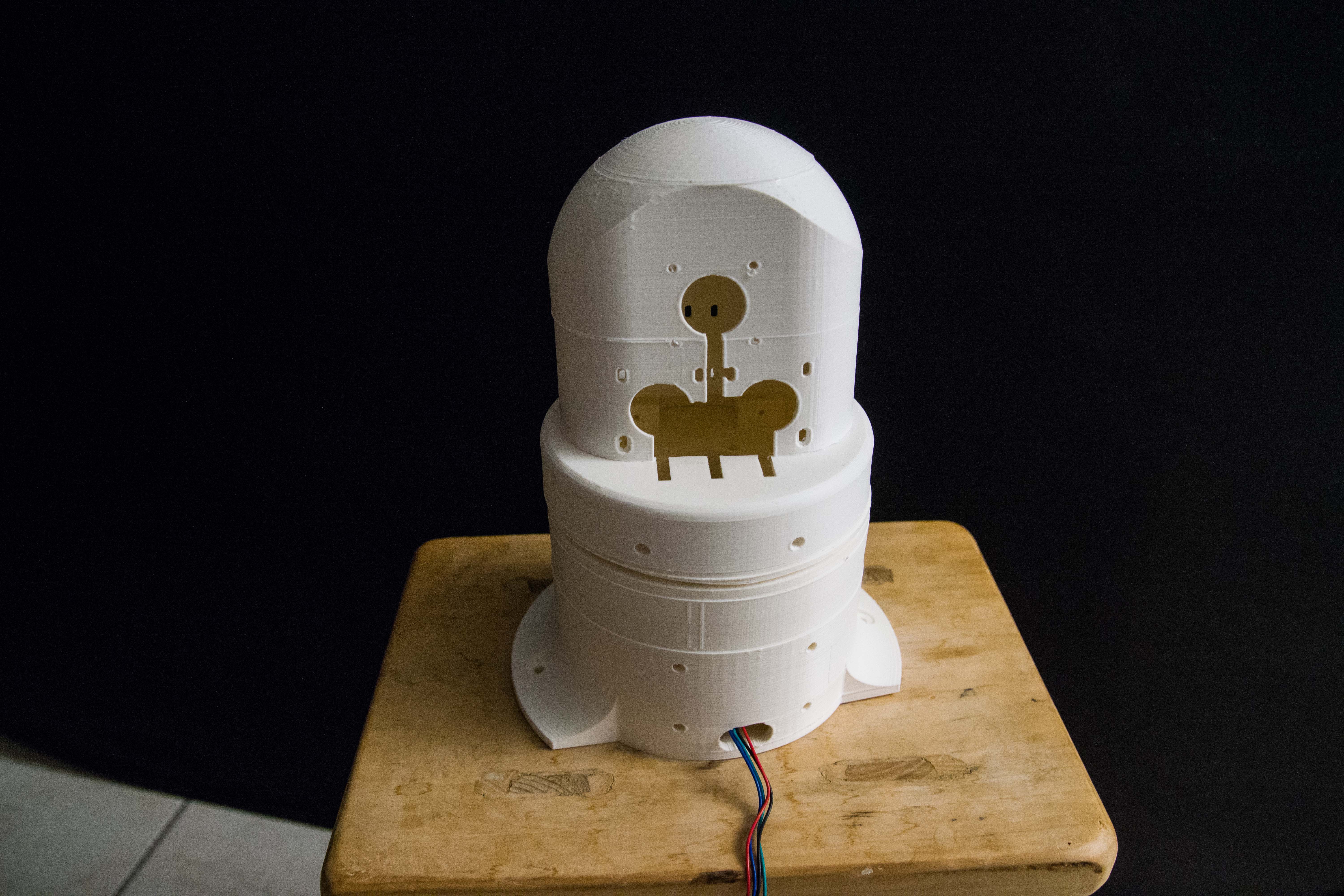

Art1Top is the upper part that rotates the base. It is screwed down with3 bolts to the lower cog.

I had to print the rest of it in a second trial and then glue the 2 parts together.

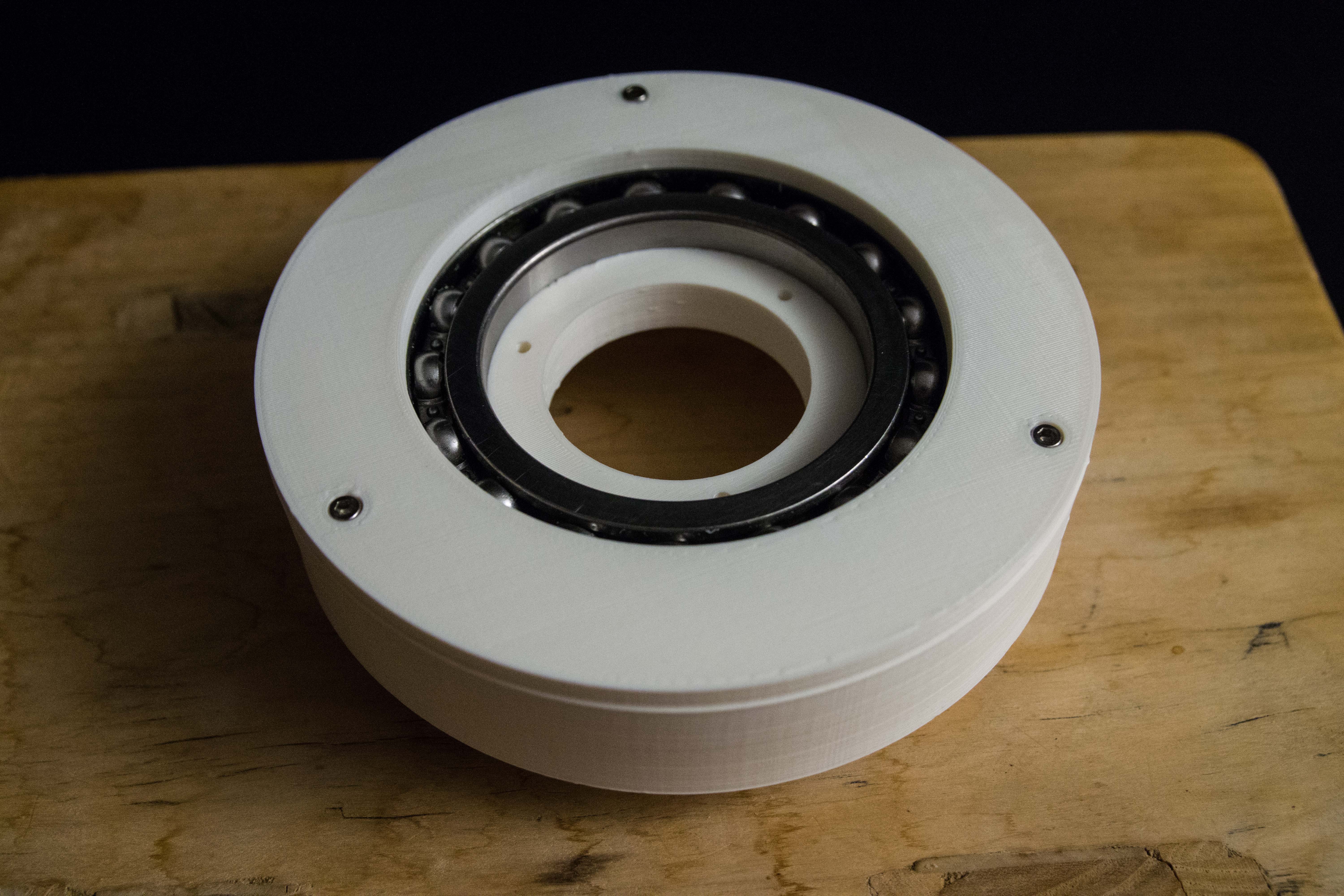

First glance when I assemble it, it rotates normally and without offset.

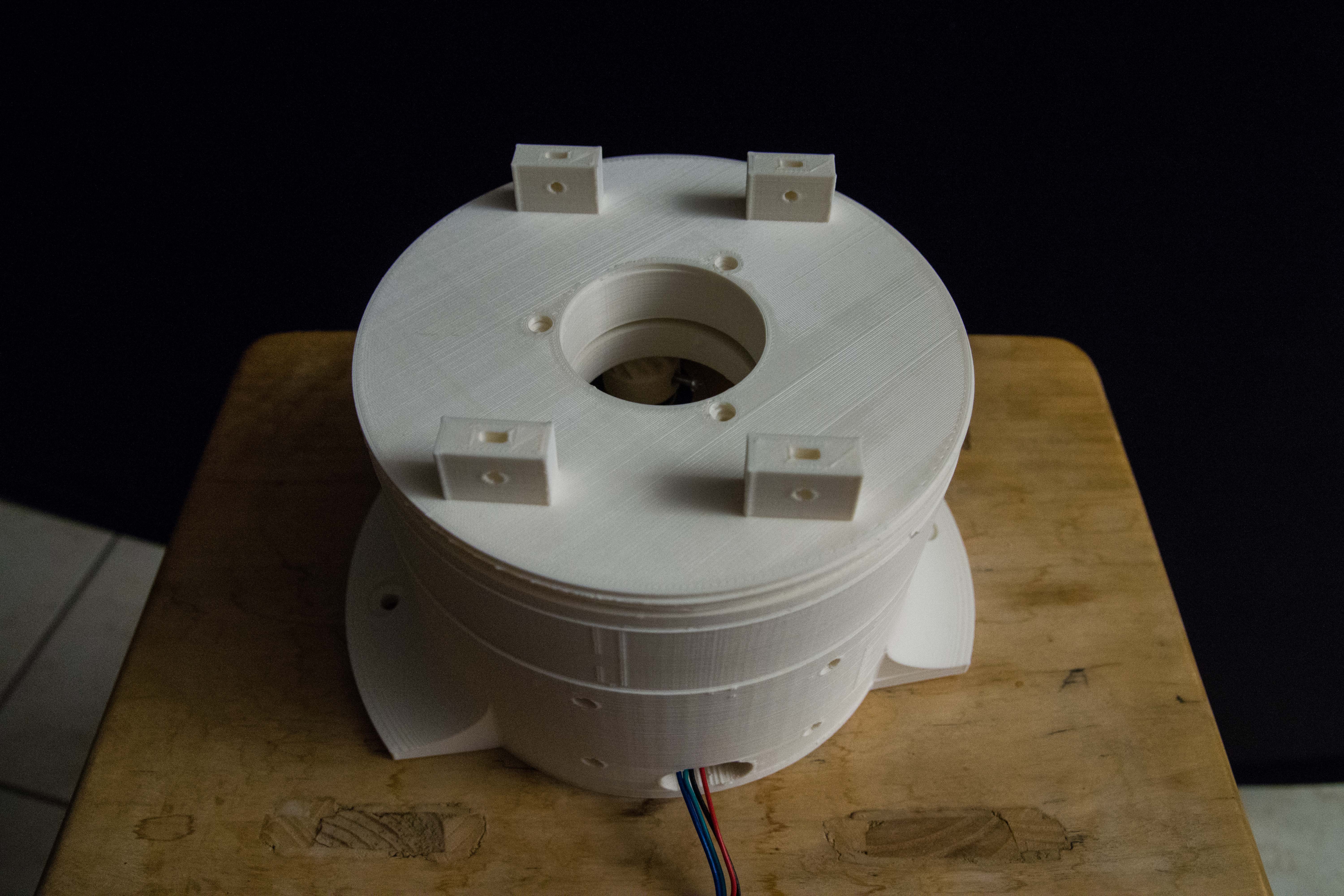

Fully assembled rotation plateau. Upside down on this image to show the inner cog that drives the upper base. And the 3 nuts that squeezes the upper part to the ball bearing inner ring. The plastic wall with the split is intended for a homing photo detector, but in this 3D print it also came lose. Again the gluing method was required.

Maybe that part could have some slope to prevent this from breaking off.

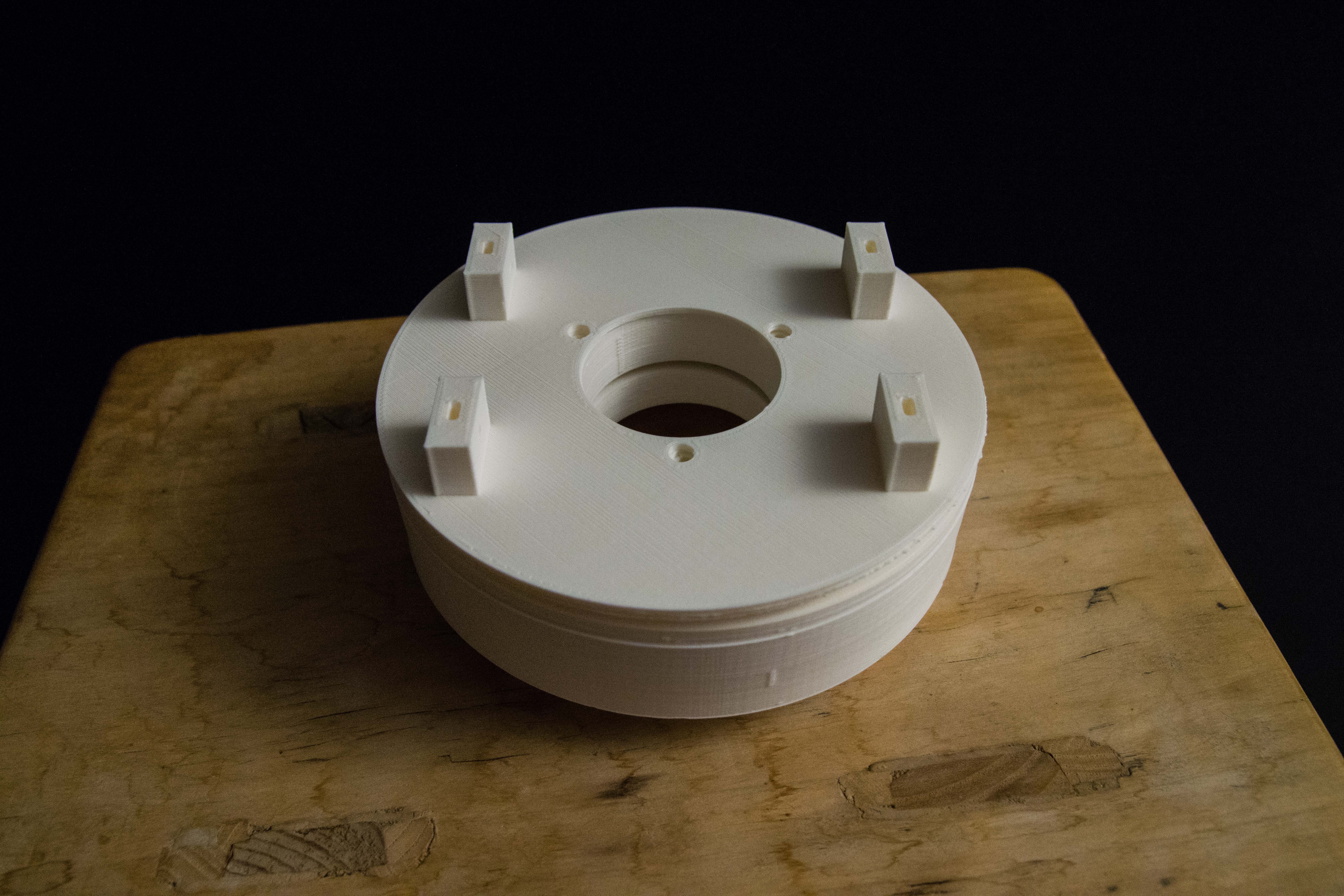

We have a big opening in the middle for wiring and 4 nut holders to screw on the upper part.

This assembly goes onto the base.

This assembly goes onto the base.

Yes the upper part has also issue with broken off plastic. The walls are maybe too thin.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.