Cake pan + mains powered heated bed = stronger, harder nylon parts.

This works for basically all 3D printable plastics, but nylon has a nice wide 85C range between its glass transition temperature and melting temperature so this is easier to do.

The parts tend to shrink in XY and expand in Z between 2-4%, so plan accordingly. If your parts need to interface with the real world or other non-annealed parts you'll need to make them wider, and shorter to start.

Clean your print bed well, so your parts don't end up sticking to leftover build plate adhesion material.

Setup your parts so they don't touch each other in the center of the bed.

If your prints have been out in the air for more than a day (since you printed them), they have likely absorbed some moisture. Too much moisture and fast heating can actually cause the parts to come apart. If this is the case, you will need to also ramp up to your target temperature. Cover your parts, set the bed temperature to 100C, and leave it there for an hour. You can avoid this step by just storing them in a brand new ziplock freezer bag right off the printer (for a while).

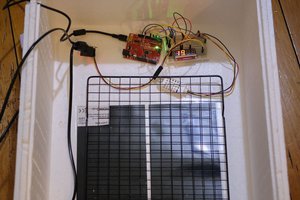

Cover your parts with a cake pan, and heat your bed to 145C. This is a little above half way between nylon's glass transition temperature of 95C and it's melting temperature of 180C. Depending on your heated bed wattage, you will probably need to cover the parts just to have enough thermal insulation to get up to this temperature.

The parts won't get quite this hot all the way through. You are shooting for holding at least a 130C part temperature for the duration of annealing. Check it.

Maintain the target temperature for about 2 hours.

Ramp down the temperature at the end of the time. Allow at least 30 min for the parts to return to room temperature. If you have a lot of thermal mass in your heated bed like I do, just shutting the heat off is probably fine. If not, ramp the bed temperature down yourself.

The resulting parts will be slightly yellow in color, and a lot stronger than they were before.

In the files section you'll find a simple gcode file which will remove moisture, anneal, and ramp down at the end for you.

Daren Schwenke

Daren Schwenke

randyarchy

randyarchy

nfk

nfk

Michael

Michael

This is looking very impressive pan cake you can visit cake delivery sydney I hope you can buy the best cup cakes from here.