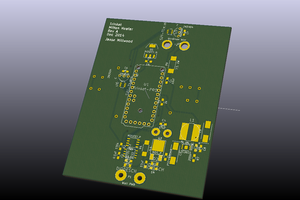

The question "What can make out printed circuit boards?" struck me. PCBWay and many other board producers sell prototype friendly 2 sided printed circuit boards for 5 dollars or less (plus shipping). Armed with the fact that it is 5 dollars whether I order 1 or 10 boards, my question became "What can I make out of 10 circuit boards?"

Since I play Dungeons and Dragons, the handy shape of a 10 sided die came to mind. I set about designing a circuit board that could serve as all 10 sides of my desired decahedron.

The first phase of this project with attempt to answer the following questions:

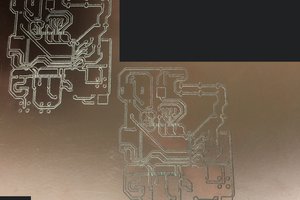

- How do I design plated edges or castellated holes so PCBWay (Current Fab house of choice) understands what I want?

- How well does lead free (SAC, leftover from another project) solder hold up as "weld" between PCBs?

The second phase, if this project is continued, will attempt to put a microcontroller and IMU into the decahedron, and recess the LEDs so I can roll the LED like a normal die. If this fails, then the decahedron will just need to be relegated to babble or desk ornament for my dungeon master.

Ian Shannon Weber

Ian Shannon Weber

TRAN.VINH.QUANG

TRAN.VINH.QUANG

Jesse Millwood

Jesse Millwood

alpha_ninja

alpha_ninja

Jon Thomasson

Jon Thomasson