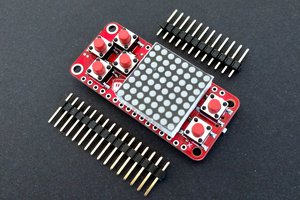

The basic BOM

- (1) ATSAMD21G18A

- (4) 2x3 Female PIN Headers (Keyed preferred)

- (12) SUNLED LED 2PLCC SMD (XZM2CYK45WT)

- (6) BC817 NPN Transistor

- (1) Micro-USB 10118194-0001LF

- (1) Polulo 3.3V Step-Up Voltage Regulator U1V11F3

- (1) PhotoResistor

- (2) AA Batteries

Corey Benn

Corey Benn

blinkingthing

blinkingthing

deʃhipu

deʃhipu

Christian Walther

Christian Walther