Keyword: LoRa, IoT solutions, smart meter, freeRTOS, technology solutions, SCADA solutions, Network monitoring, Engineering solutions referral program, embedded C++, embedded C, LTE modem, Engineering solutions, structural monitoring, Network management.

INTRODUCTION

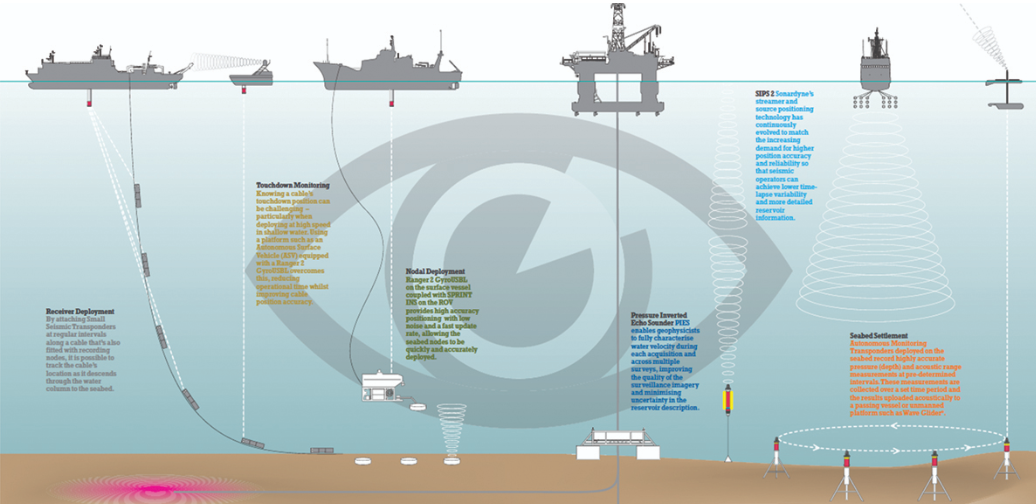

A standalone data logger is a data-capturing device that, once initialized, can automatically log data and store it in its on-board memory. After a data logging session is completed, data stored in memory can be downloaded into a computer for analysis to provide information on the history of parameters or events. Typically, a standalone data logger consists of a central processor unit (CPU), analogue to digital converter, data memories and other support electronics. It can accept signal from various sensors such as accelerometers, strain gauges, displacement sensors, inclinometers and pressure gauges etc. One example of standalone data logging in the offshore oil production industry is to record riser displacements as the result of vortex induced vibration (VIV) or drilling process. Standalone motion loggers are attached to risers over a lengthy period to record motion. This can provide vital information on the fatigue life of the riser. Standalone data logging is not real-time data logging. Data can only be viewed and analyzed after the data is downloaded into a computer. However, it can provide economical and rapid instrumentation deployment, with simple interfaces and minimal impact on platform equipment.

Drilling and workover operations

During both drilling and workover operations, it is important to ensure that tension, bending moment and movement is kept at a bare minimum, accurate monitoring of these factors, either continuously or as a part of an assessment. For drilling operations, we arrange our sensors strategically in order to detect relevant loads, such as movement or VIV (vortex induced vibrations), but also motion, tension and bending moment. During workover operations, we arrange sensor on the tension point and on the lower tapered stress joint and, if required, on the LRP (lower riser package) or EDP (emergency disconnect package).

Wellhead structural monitoring

To determine the tension and bending moment at the wellhead, we place sensors as far down as possible on the BOP connector, on the BOP, and on the flex joint. This provides an accurate measurement that allows us to assess the fatigue and remaining service life of the wellhead.

Vibration subsea and EEx Zone

ELB-REV4 iSCADA based development board provides systems for monitoring high frequency vibrations (>1Hz), both subsea and topside, based on strain measurements and accelerations. Subsea monitoring may be combined with hydrophones, and is ROV/diver installable. Topside may include EEx Zone requirements.

Displacement

We use LVDT (linear variable differential transformer) and hydro acoustic sensors attached with ELB-REV4 iSCADA to measure displacement from a micro meter to meter range. This may be combined with other sensor systems to provide additional information. Systems are custom built to suit the application.

SENSOR MODULES

There is a wide range of advanced sensors available in the market that can be integrated easily with the ELB-REV4 iSCADA development board. Typically, these sensors consist of a sensing element and integrated amplifier & conditioning circuits. The sensor requires a single rail power supply and the output from the sensors is simply an electrical voltage or current. The sensors utilize latest sensor technologies to achieve low power consumption and high performance.

- Micro-electronic machined (MEMS) accelerometers

- Inclinometers

- Angular velocity sensors (MEMS Gyroscopes)

- Linear displacement gauges (LVDTs)

- Pressure sensors (silicon sensors)

- Temperature sensors

- Load sensors for tension and compression

- Current waves and position

Features:

- I. The logger provides massive memory space by using a Smart Media memory disk as its data storage.

- II. Connect to a computer for initialization using special software. Users can choose logging frequencies, logging modes and logging start time etc.

- III. After initialization, the logger can be dispatched to designated locations.

- IV. Data logger will automatically start the data logging session and data will be logged and stored in the mode specified by the users.

- V. After the data logging session, the data logger can be retrieved and data on the Smart Media memory disk is downloaded into a computer.

- VI. Data is analyzed.

- VII. Send to Sensor data to remote location.

Data Logger Hardware Implementation

The ELB-REV4 iSCADA is a start-of-the-art standalone monitoring device we can integrates sensors, logger, batteries and memory disk into a compact package. It is a cost-effective solution for standalone data monitoring applications.

The ELB-REV4 iSCADA an be contained in a rugged pressure casing and used for the harshest environment and the most demanding applications. They can also be integrated into customized casings.

It consists of the following functional parts:

- 1 GHz cortex-A8 processor, SGX530 Graphics, 512 MB DDR3 RAM

- Smart Media memory card to achieve massive data storage

- Networking: Ethernet, Wi-Fi, LoRa, LTE modem for various regions

- Serial Interface RS232, RS485, CAN, SPI GPIO (25)

Lithium Batteries The logger has some unique features. Ultra low power consumption is one of the important features of this logger. It uses the latest low-power electronic components (including memory) and adopts an intelligent power management scheme. When no data is logged, the data logger can go to sleep mode and switch off the power supply to all sensors to minimize power consumption. The data logger itself has a typical sleep mode current consumption of 2 mA and a wake-up current consumption of 5 mA. Before a data logging session, the data logger wakes up and supplies the power to the sensors. The makes the logger most suitable for battery operations.

CONCLUSION

The standalone data logger is a state-of-the-art and cost-effective data capture device, featuring a massive on-board memory, low power consumption and compactness. Integrated with various modern sensors available in the market, the logger can send data various remote location. In the offshore oil and gas industry, for which the logger was primarily designed, this facility has already assisted in providing empirical data to prove equipment fit-for purpose, and to improve and streamline design for subsequent engineering projects.

ssla-couk

ssla-couk