The idea of the Macrofab competition is to design and build a useless machine. This build has exactly zero uses, as all it does is unplug itself.

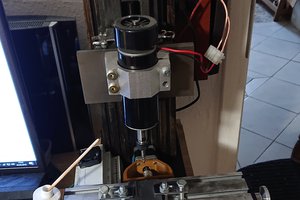

It consists of an arduino, a motor, and some 3d printed gears. The arduino flashes its LED a few times, then uses PWM to soft-start the motor. The motor turns a few gears, retracting the carriage holding the socket. The plug is restricted by the outer case, therefore is unplugged from the internal carriage.

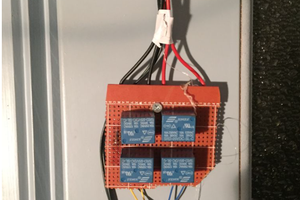

There were some issues on the border of plugged and unplugged, where the arduino would essentially just have a boot loop due to intermittent power supply. This has been fixed by a few capacitors, holding the power on for just long enough to fully unplug.

SirDan

SirDan

Li

Li

Luke J. Barker

Luke J. Barker

Matthew Potter

Matthew Potter

Electroniclovers123

Electroniclovers123