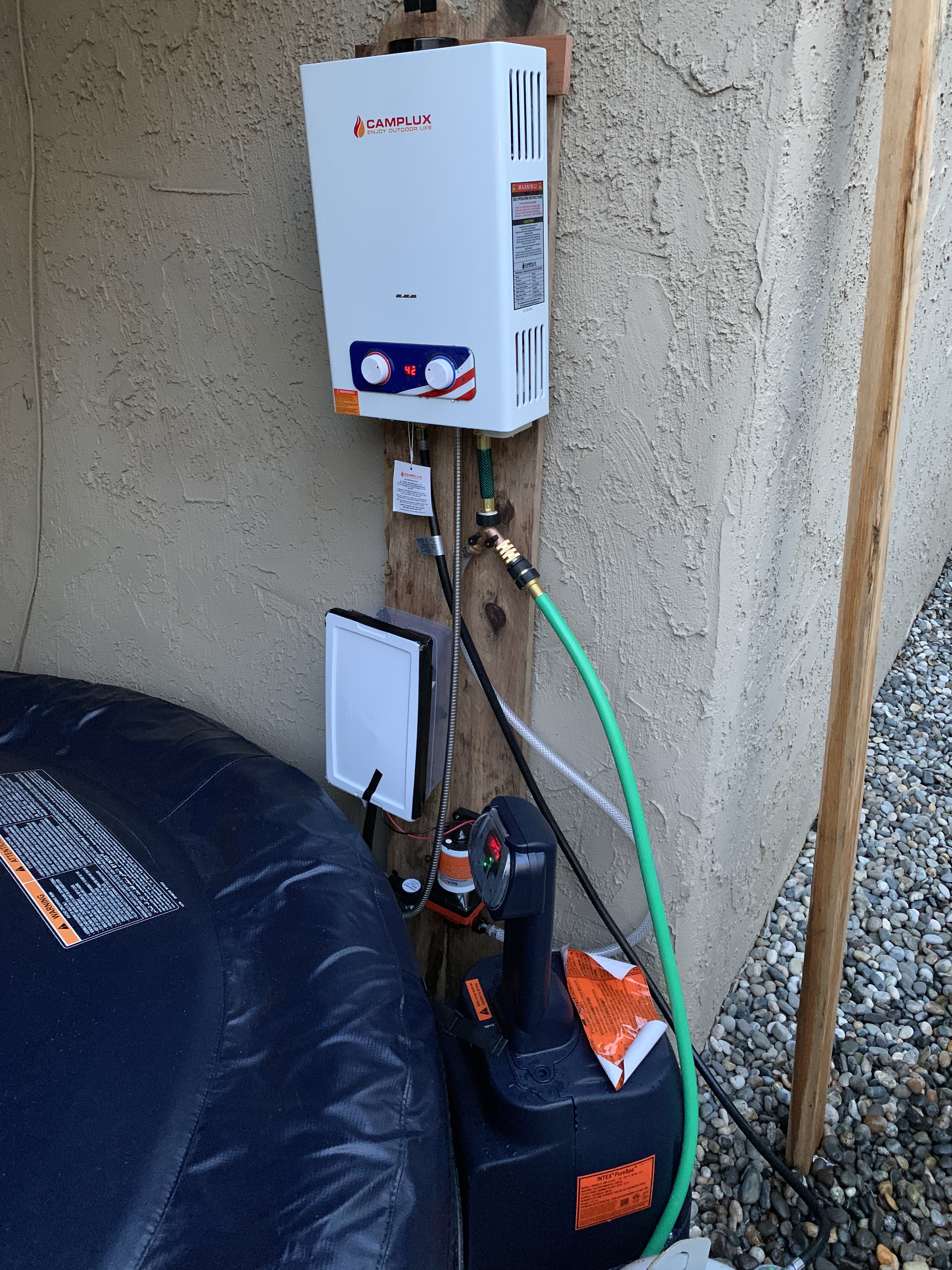

Hot tubs are very fun, a huge quality of life improvement, and also much more expensive than you might think at first blush. If you're like me, you searched "hot tub" on craigslist and thought, man, there are a lot of free hot tubs in this world! Or maybe the first place you searched was a hot tub store and thought "$5000 for the cheapest, yeah, nah." Even a free hot tub isn't cheap.

Luckily for the cheapskate, the world of plastics has just absolutely EVERYTHING to offer these days, including durable, enjoyable, affordable hot tubs!

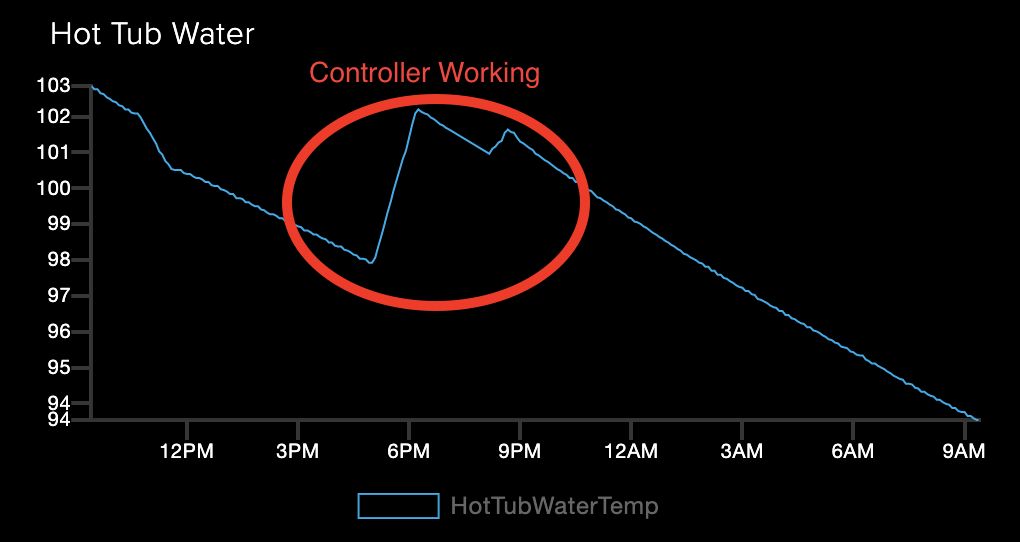

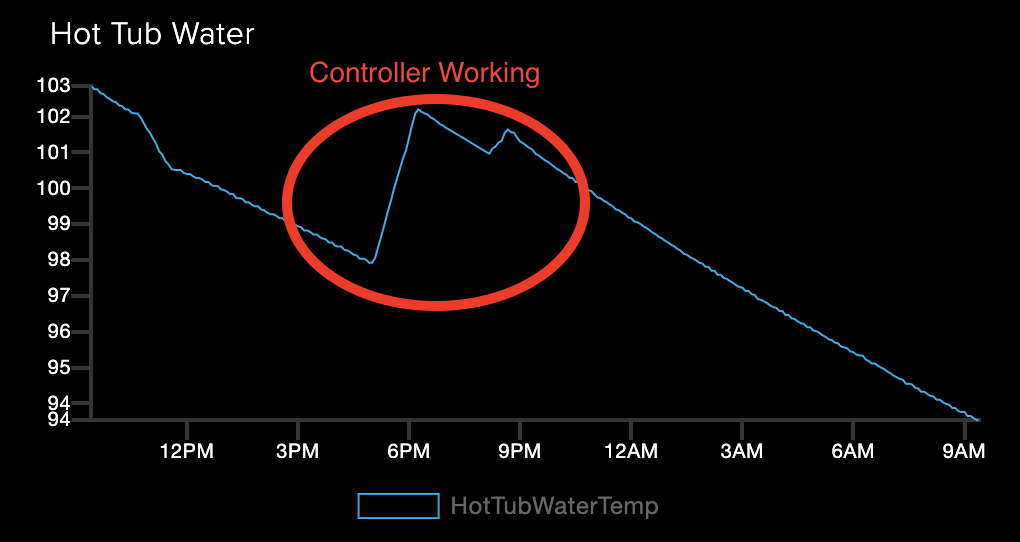

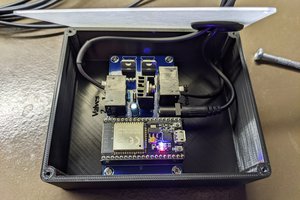

SmartSoak is an extended review of and indeed improvement upon just such a product, taking things two or three steps too far at each turn.

Check out the project logs for all the details. You probably want to read them start to finish, so scroll down to "Log 1" first.

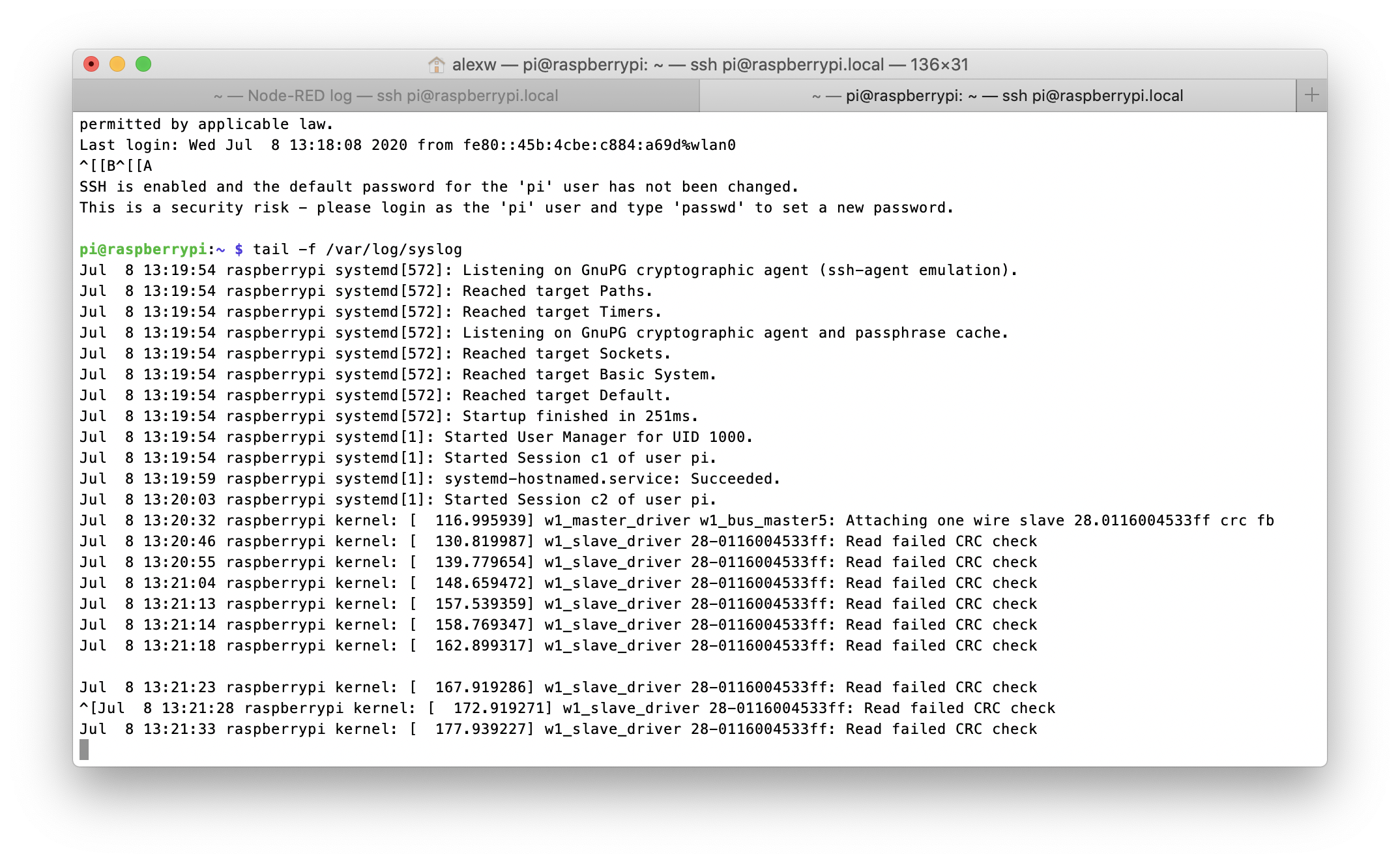

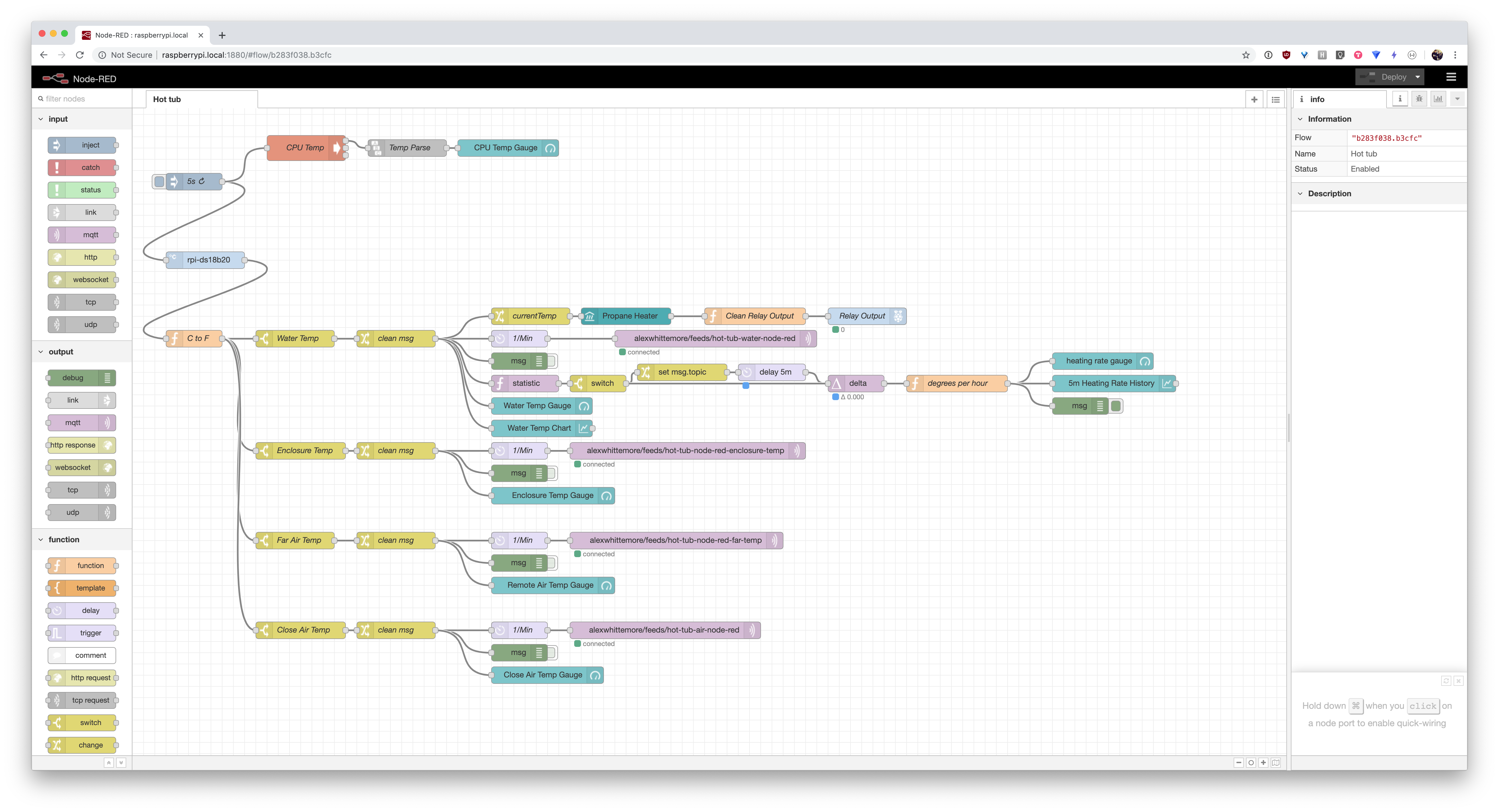

Github repo with node-red flow, though no documentation to reproduce: https://github.com/alexwhittemore/HotTubPi

alexwhittemore

alexwhittemore

JanoHak

JanoHak

Pauli Salmenrinne

Pauli Salmenrinne

Ben Brooks

Ben Brooks

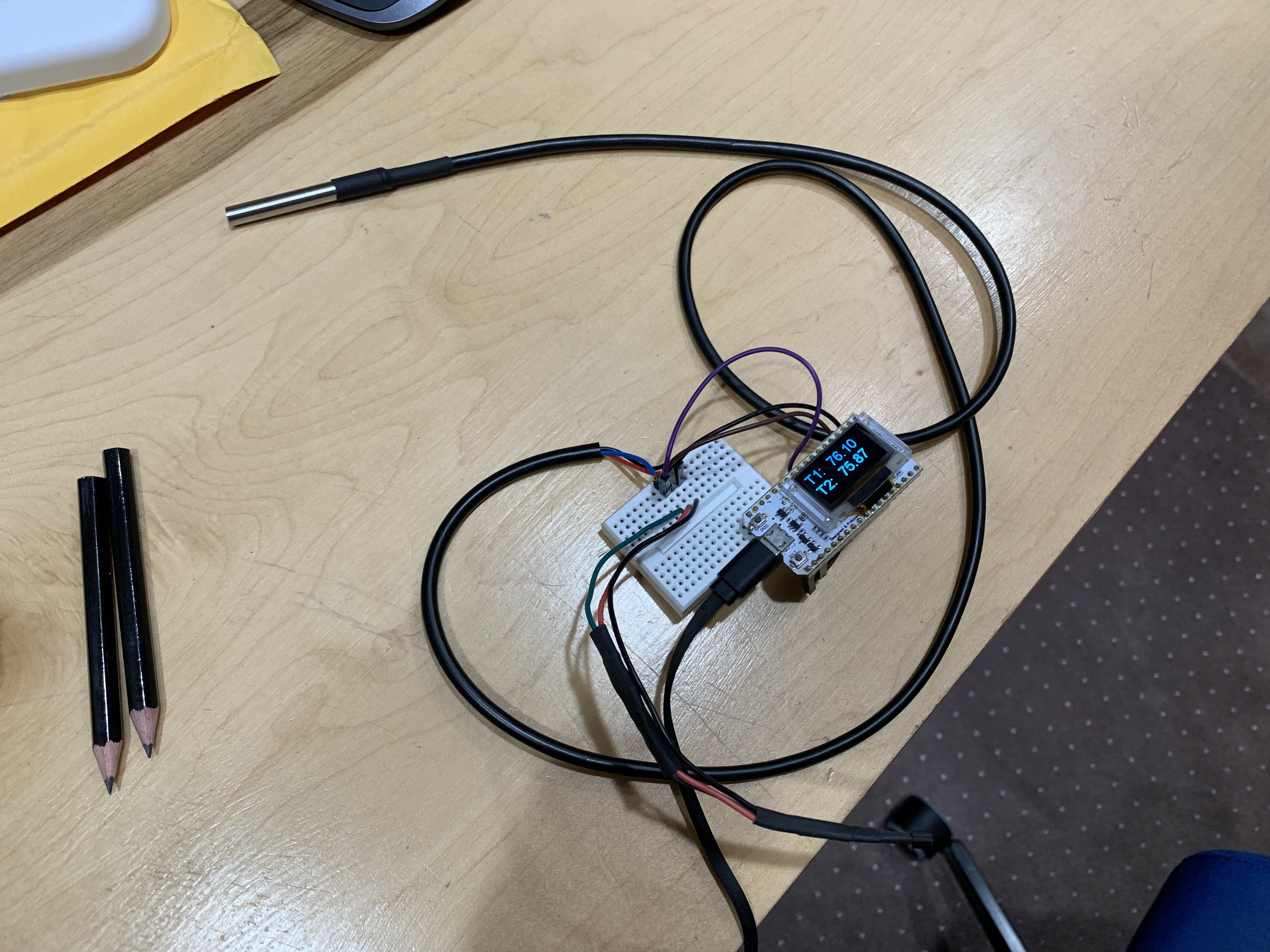

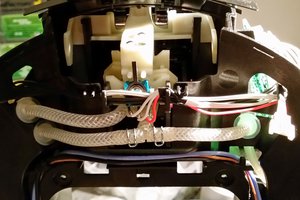

I use many DS18B20s with 6 NodeMCU devices for over 3 years with no issues including controlling the waterbed temp. 3 DS18B20 on one input in some cases. Programs include error checking. Web pages hosted on the device are used to monitor and control instead of an app. Data is sent to a cloud spreadsheet. Also monitor and control from anywhere using MQTT. Upload programs wirelessly.

https://sites.google.com/site/nodemcu12e/