Via in PAD

Connect via in solder pads is a big trouble in pcb assembly process.

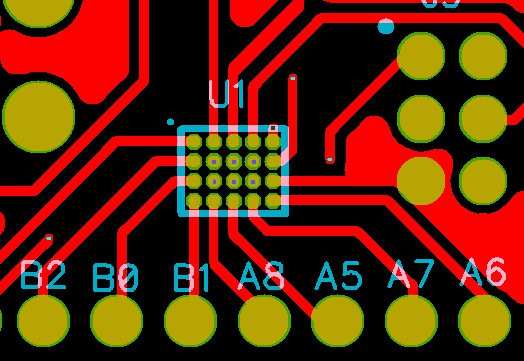

Especially,when the via in BGA pads,

But the designer often based on its design can not achieved.

In face,the electronic products is getting smaller,

printed circuit board going to smaller, high density and more layers,so,many CAD Engineers( PCB Layout engineers) design the via in pads.In particular,small BGA ball space of BGA Pads,there is no enough place

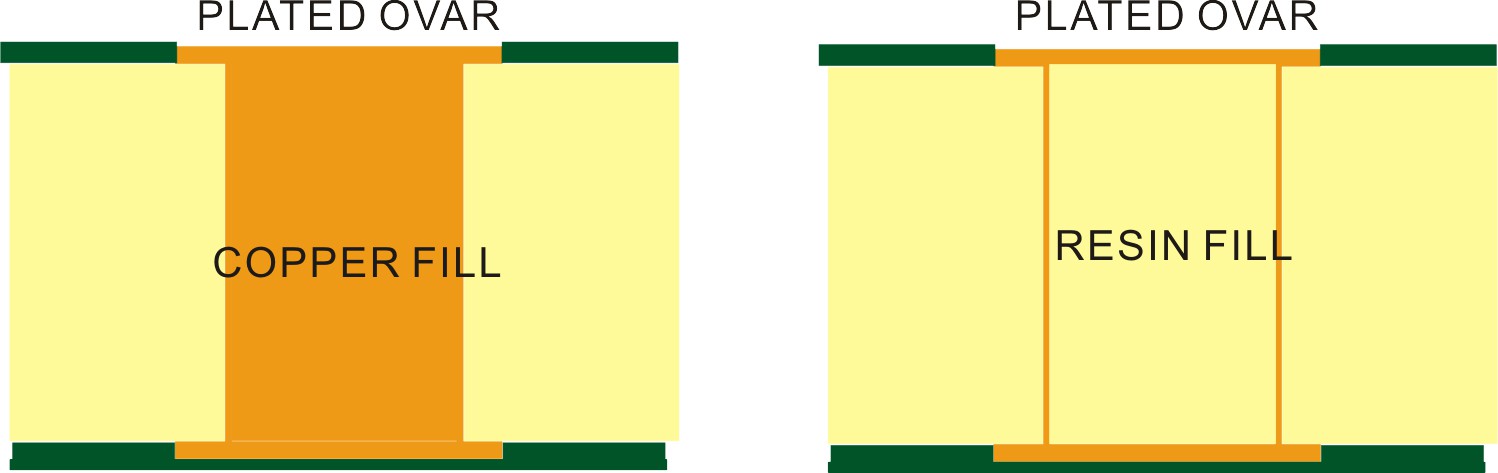

Could place the via holes.It is disaster for SMT engineers.With the improvemet of via in pad technology,The solder problem can be solved.

Capabilities

Capabilities

Smallest Hole:4Mil(Laser) 6Mil(Machine)

Smallest BGA: Holes+6Mil

Aspect Ratio:1:1(4Mil) 12:1(other)

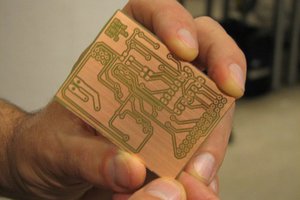

Product

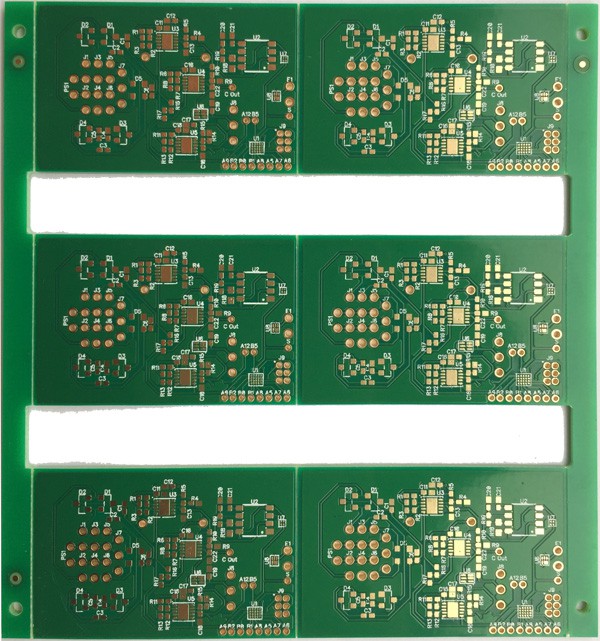

SPECIFICATION:

Material:FR4

Thickness:1.6mm Copper:1OZ

Surface Finished:ENIG

Layer Count:2Layer

DIFFICULTY:

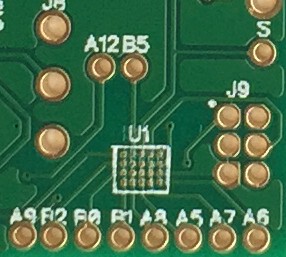

Via in BGA

Holes:4Mil BGA:10Mil

Finished Board Thickness:62Mil

Aspect Ratio:16:1

PCB designer

PCB designer

Michael Delaney

Michael Delaney

Ray Olsen

Ray Olsen