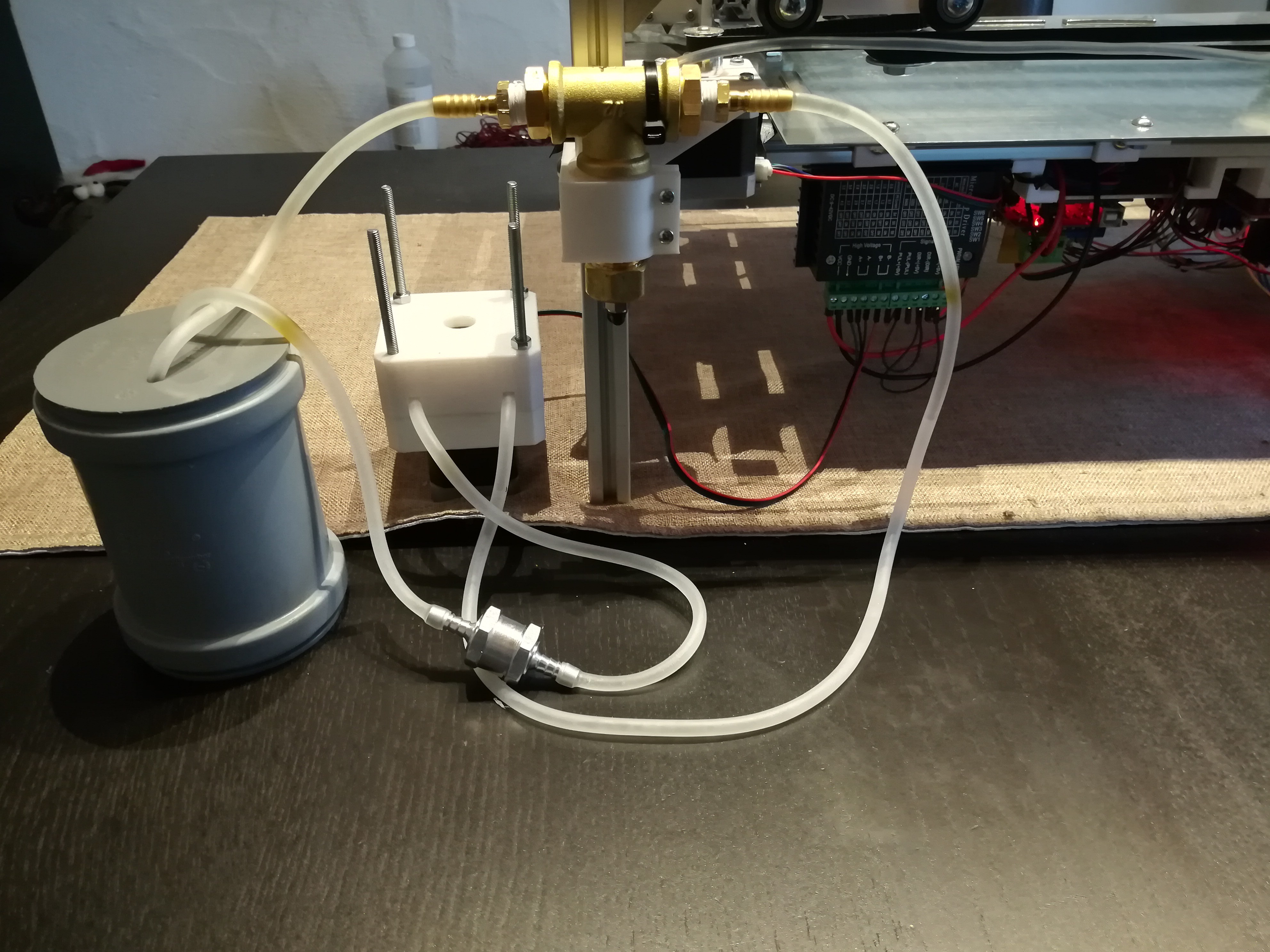

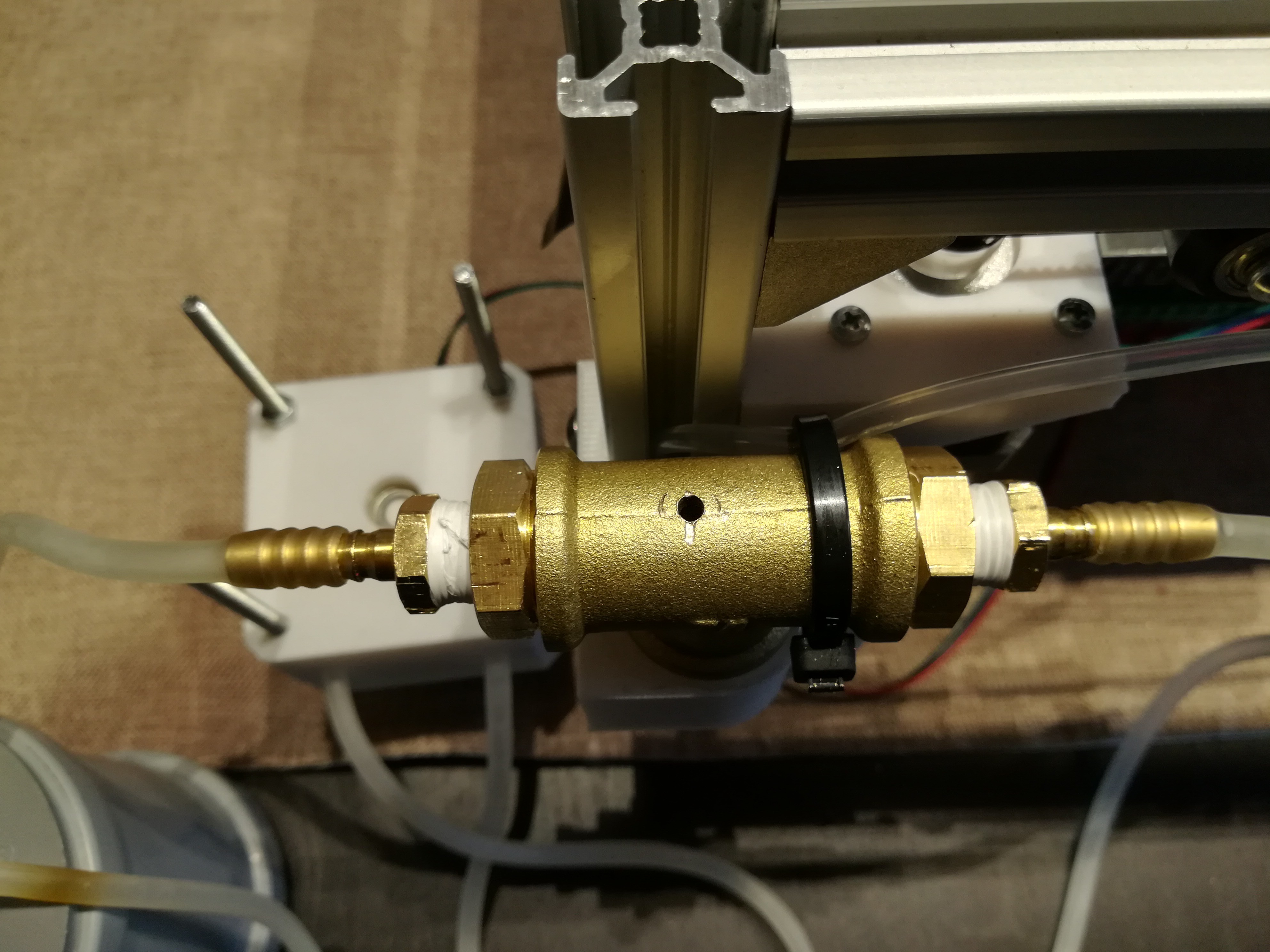

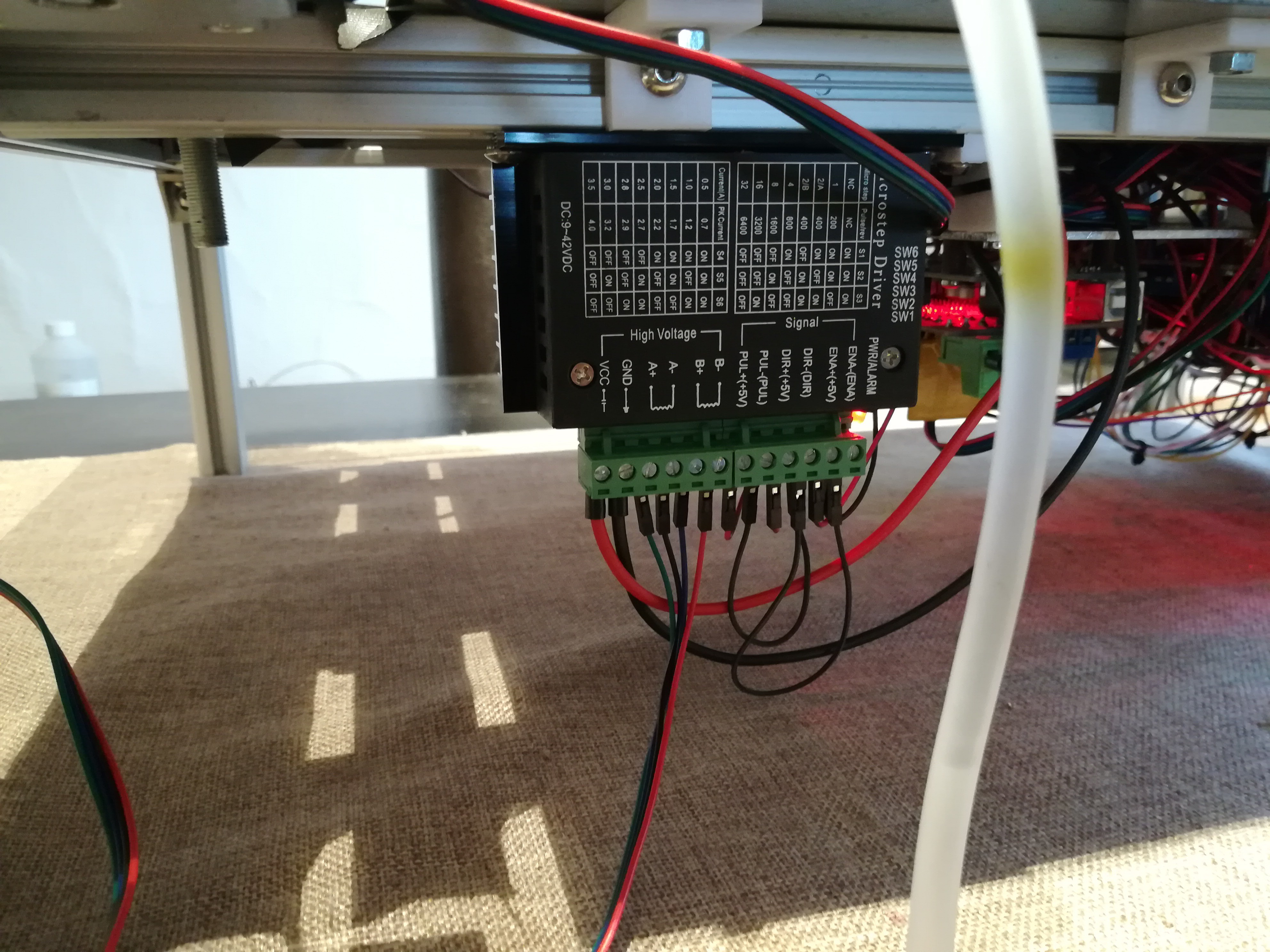

I've added a Closed Cycle Material Supply System in form of a T fitting with some hose connectors, a Nema 17 stepper motor driven peristaltic pump, an extern stepper driver, a check valve and some silicon tubes to solve the problem of continuous material supply.

The pump pumps the material to the T fitting, which is mounted in the correct hight, so that the printhead neither leaks nor runs dry. In the top of the T fitting is a hole drilled, so that the pump not influences the pressure between the T fitting and the printhead. A small amount of the material is used for printing, but the majority of it flows back to the tank.

This way there is always enough material in the T fitting to print until the tank is empty and besides of once setting up the right hight of the T fitting and refilling the tank when it's empty there is no additional maintenance needed.

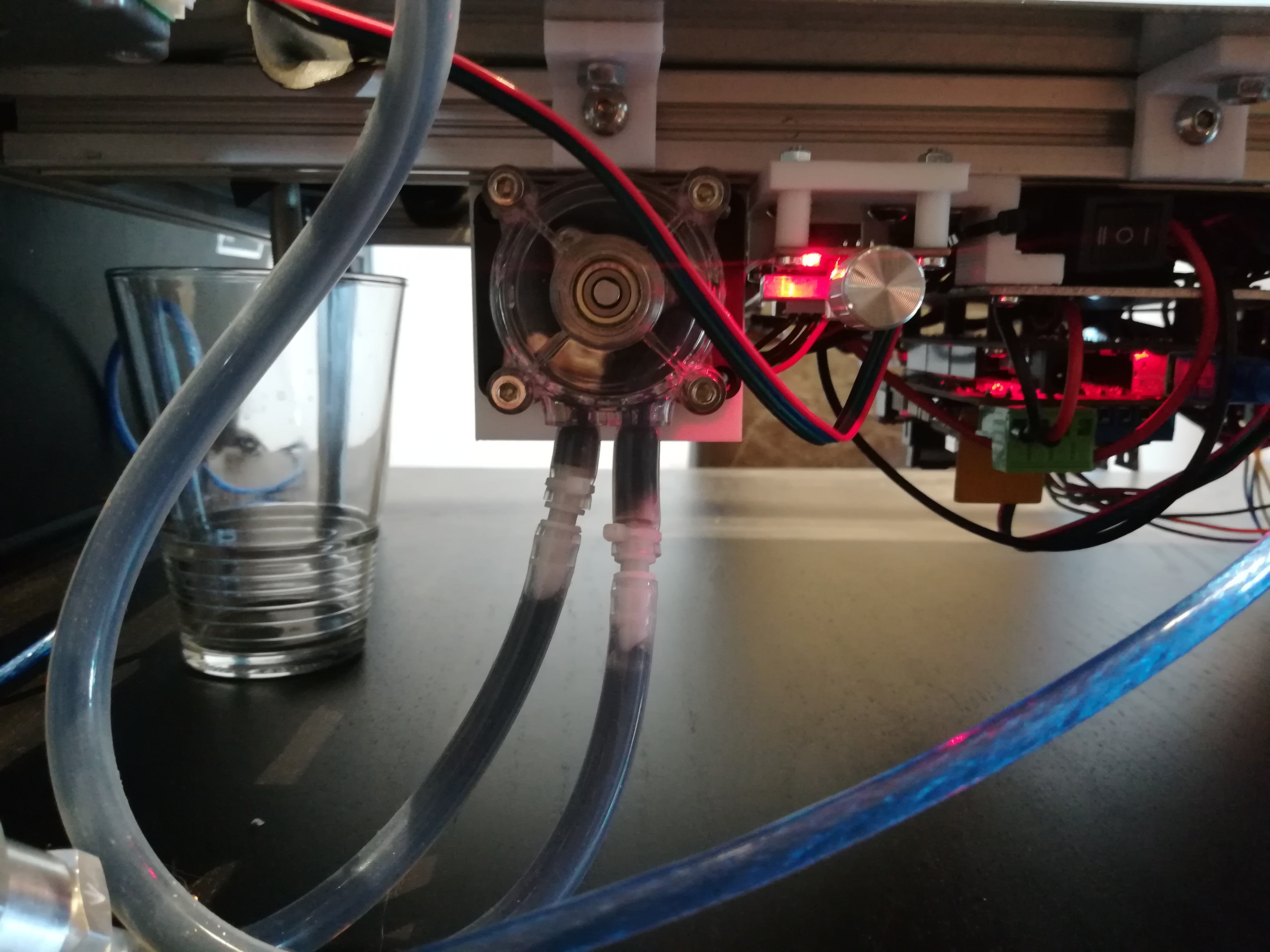

I use a peristaltic pump, because that way the pump has no direct contact with the material which maybe could damage the pump or contaminate the material.

I changed the stepper motor pump to a 12V DC motor pump & speed controller from amazon because a stepper motor is not necessary for just pumping the fluid continuous through the system.

Dominik Meffert

Dominik Meffert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Wow, ingenious way of supplying ink.

Are you sure? yes | no

Thank you. I've tried so many different approaches, but everything was either to complex or has not worked.

Wonder why I've not thought of it earlier.

Are you sure? yes | no

It's one of those ideas which looks simple in hindsight, those "eureka" moments. Ingenious IS the best word for describing this.

Are you sure? yes | no