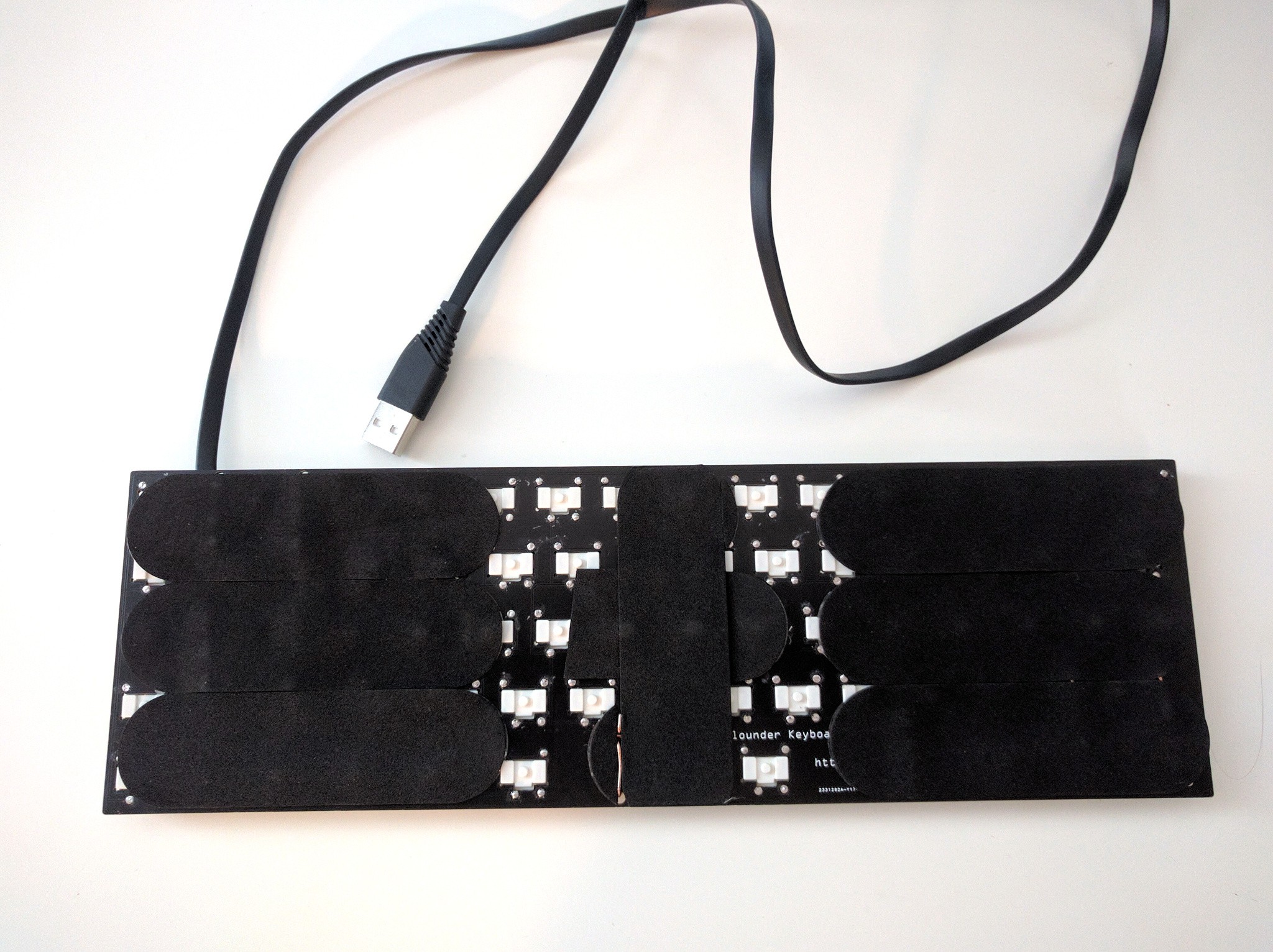

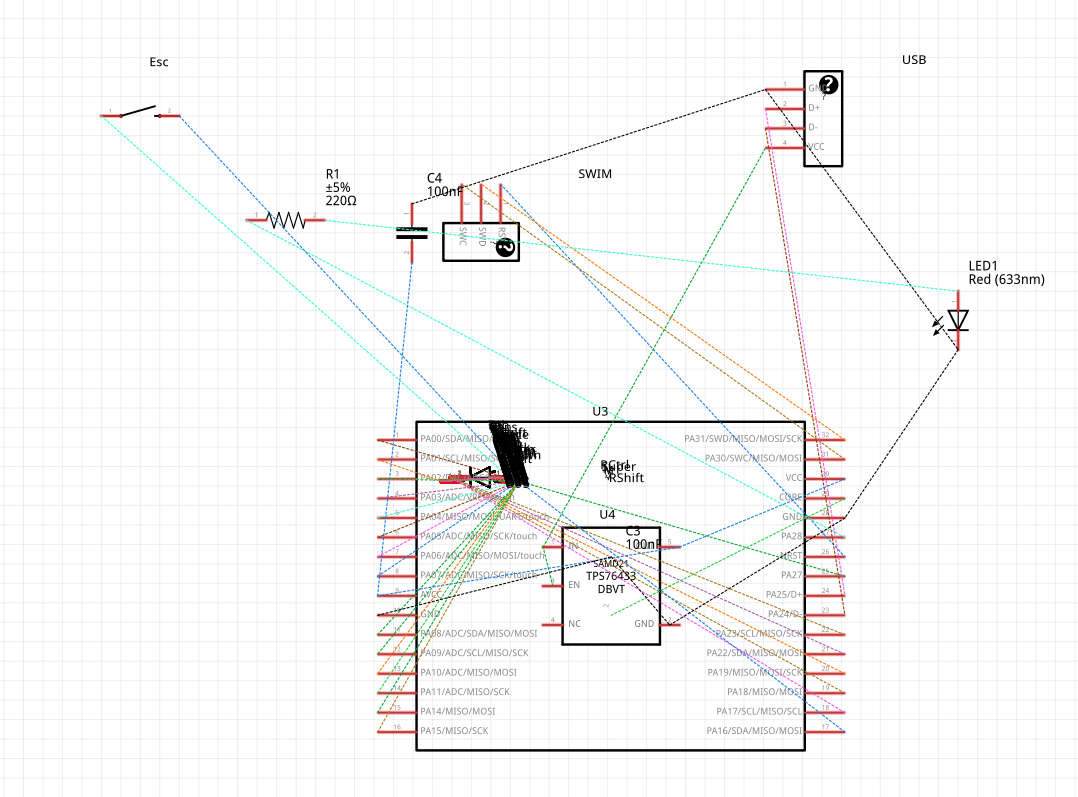

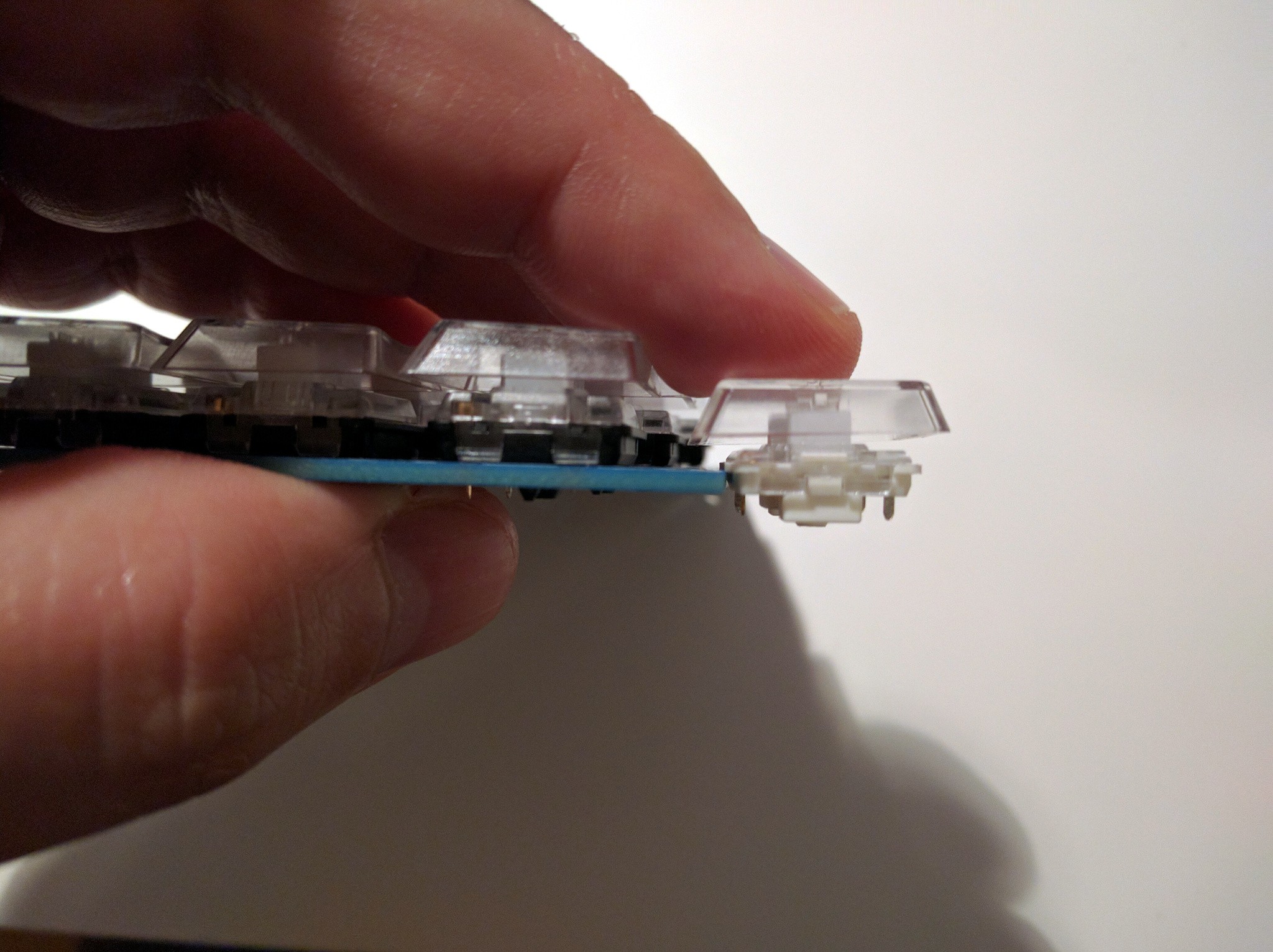

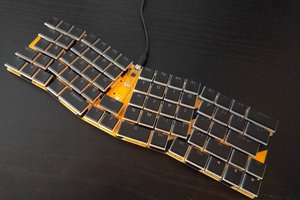

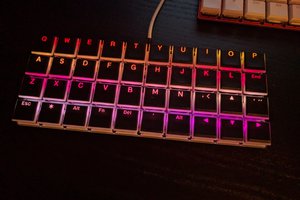

Ever since I saw the low-profile Kailh switches, I couldn't stop thinking about how thin a keyboard would be possible with them, and how it would feel. Now that I found out you can actually buy those switches in small quantities, I decided to try and design a keyboard with them.

deʃhipu

deʃhipu