This will be my first exploration into creating something for public consumption.

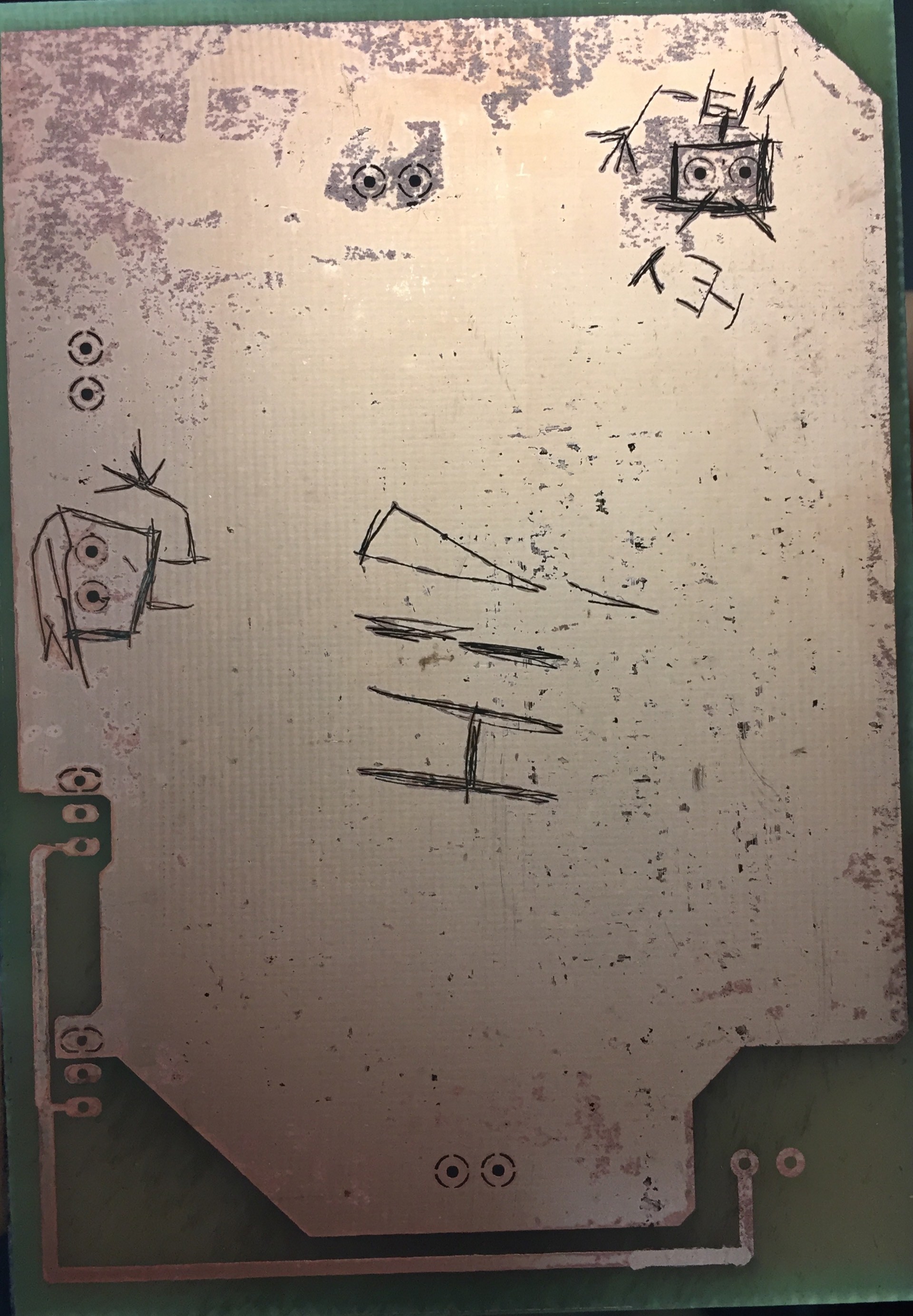

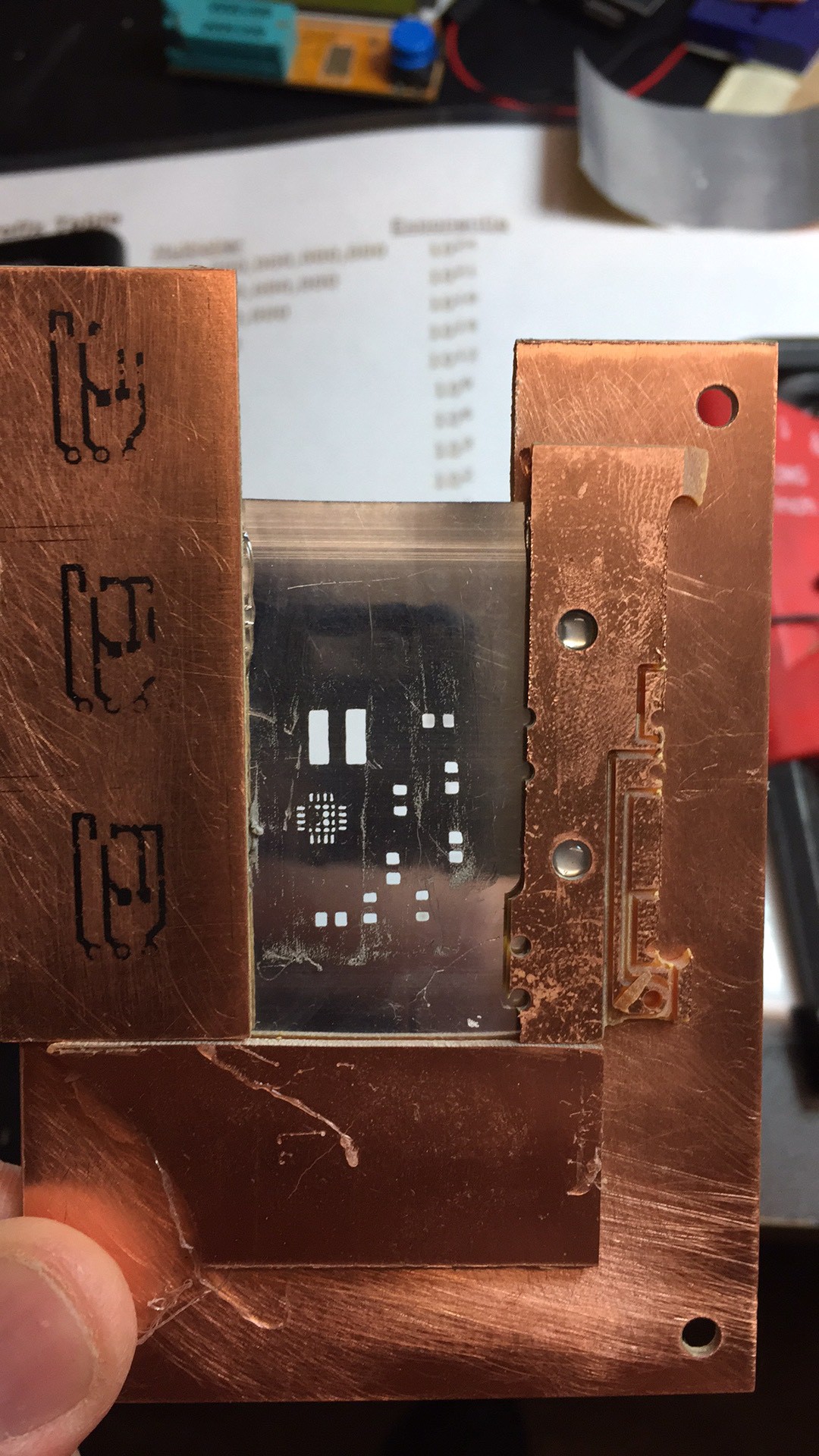

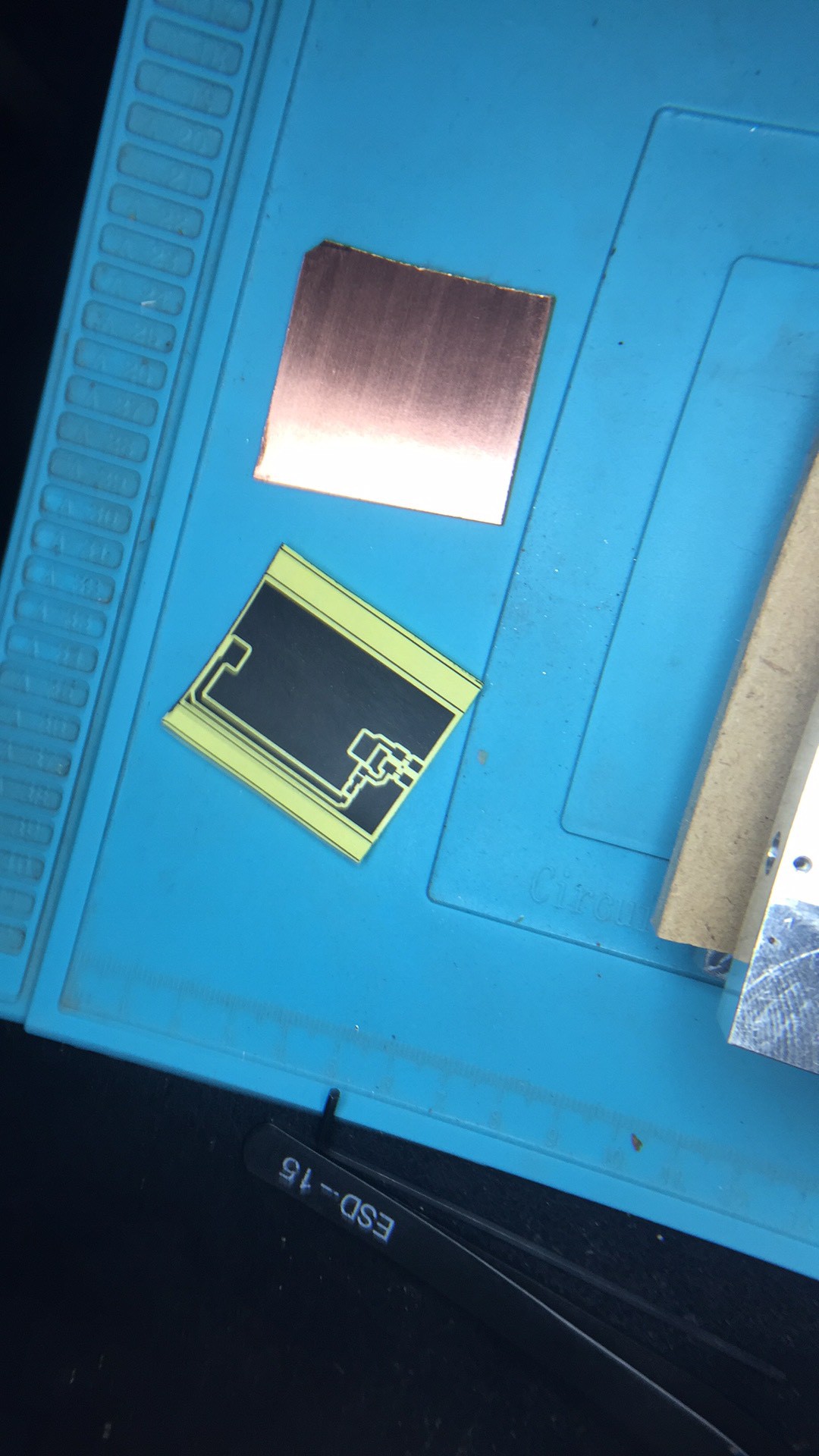

To be more specific: I make a bunch of primitive metal shapes like this, however I have never shared any thing in a public forum like this.

I usually end up making tools to solve my problems at work out of a combination of: raw materials, general problem solving, and powerful graphic design tools called CAM(Computer Assisted Machining) and CAD(Computer Assisted Design).

So it is a bit soul crushing at times because of all the miles.

I also don't mean to talk down to you I simply wish to describe in detail my story and present a sort measurement where I am at in the point of my journey.

To a lesser extent I am putting this out there for you to read, whoever you are.

Perhaps you will comment or like if you are interested, which will encourage me to share more.

Hopefully this is not irking for you.

Anyhow.

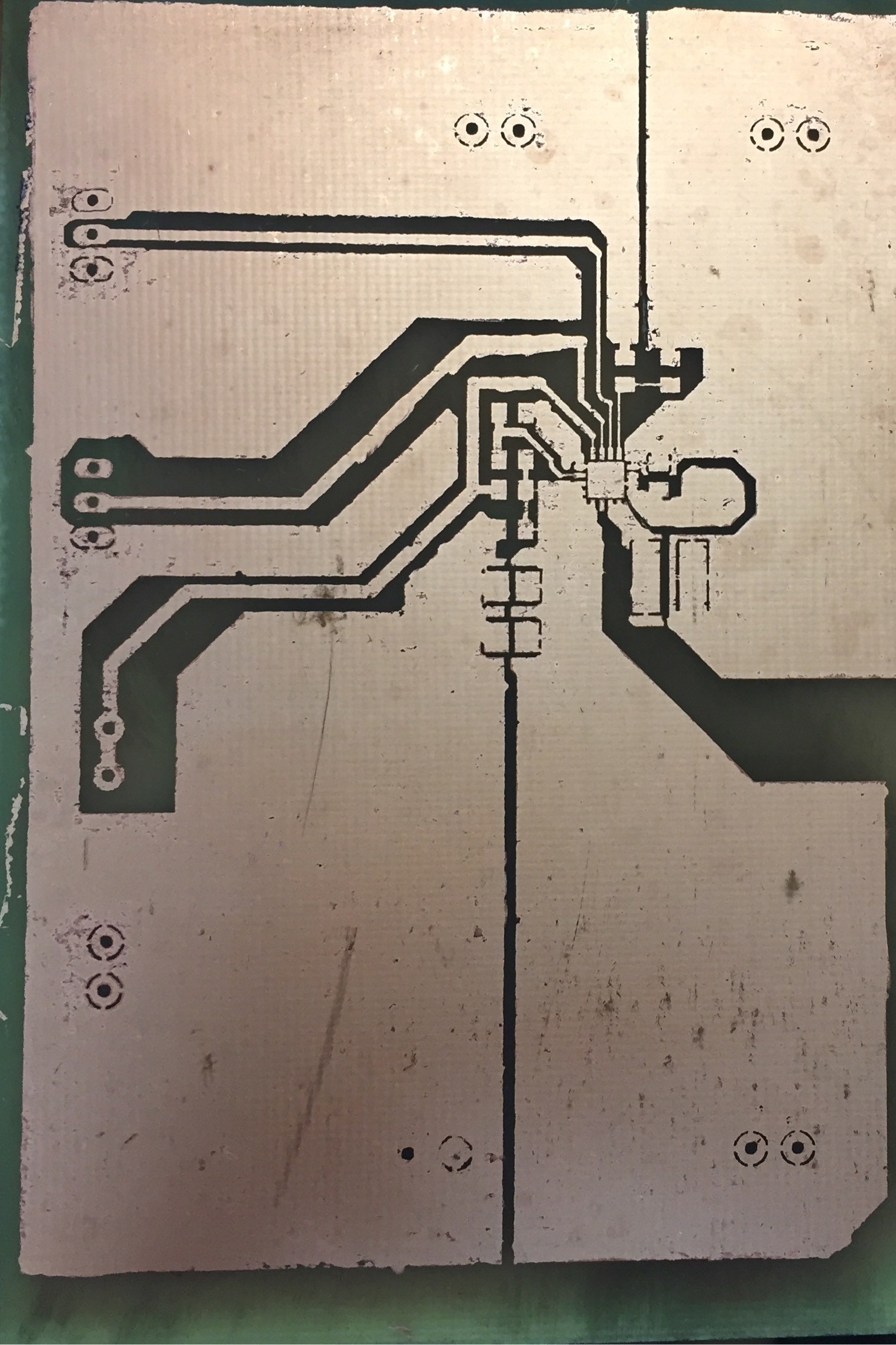

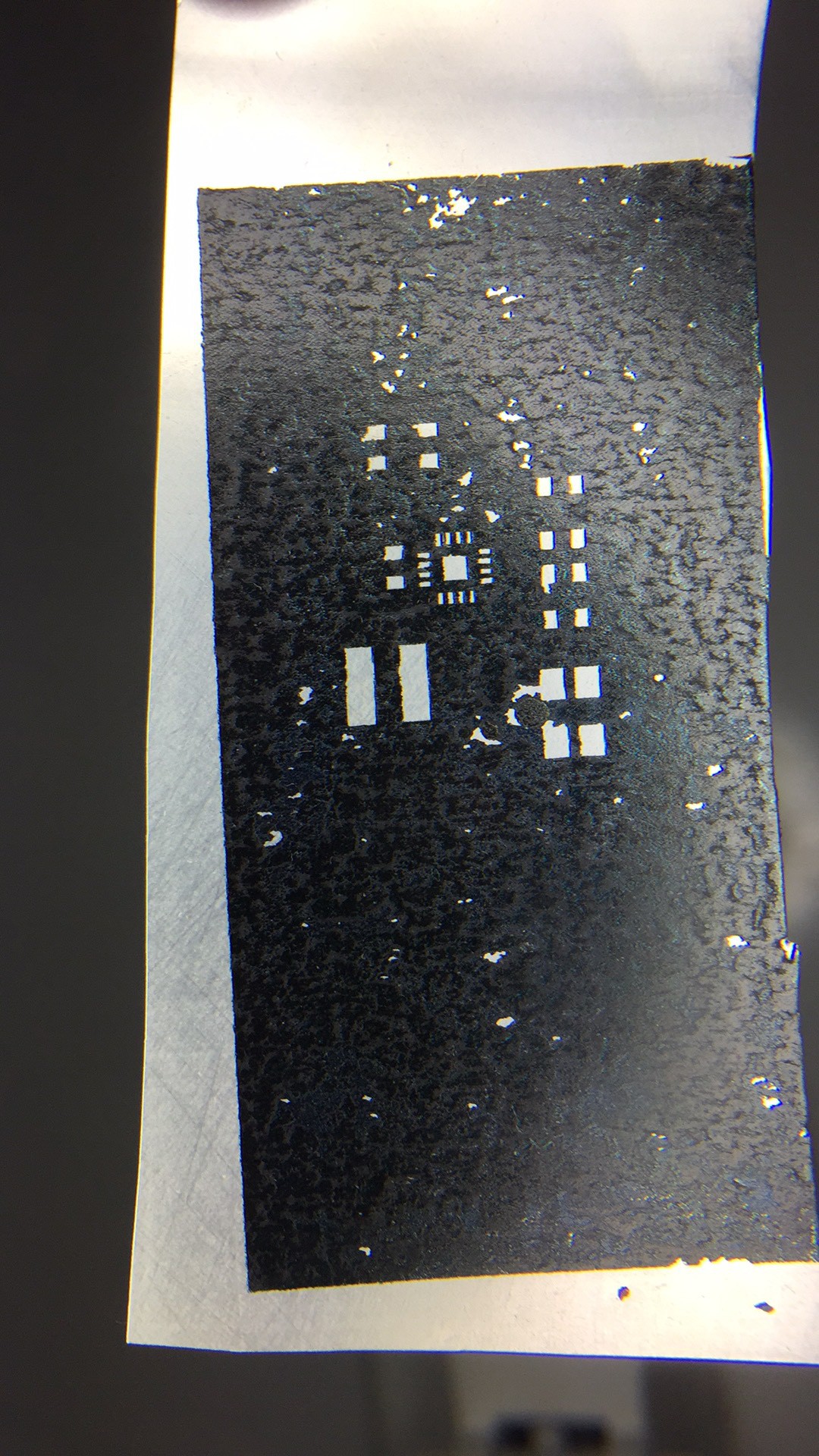

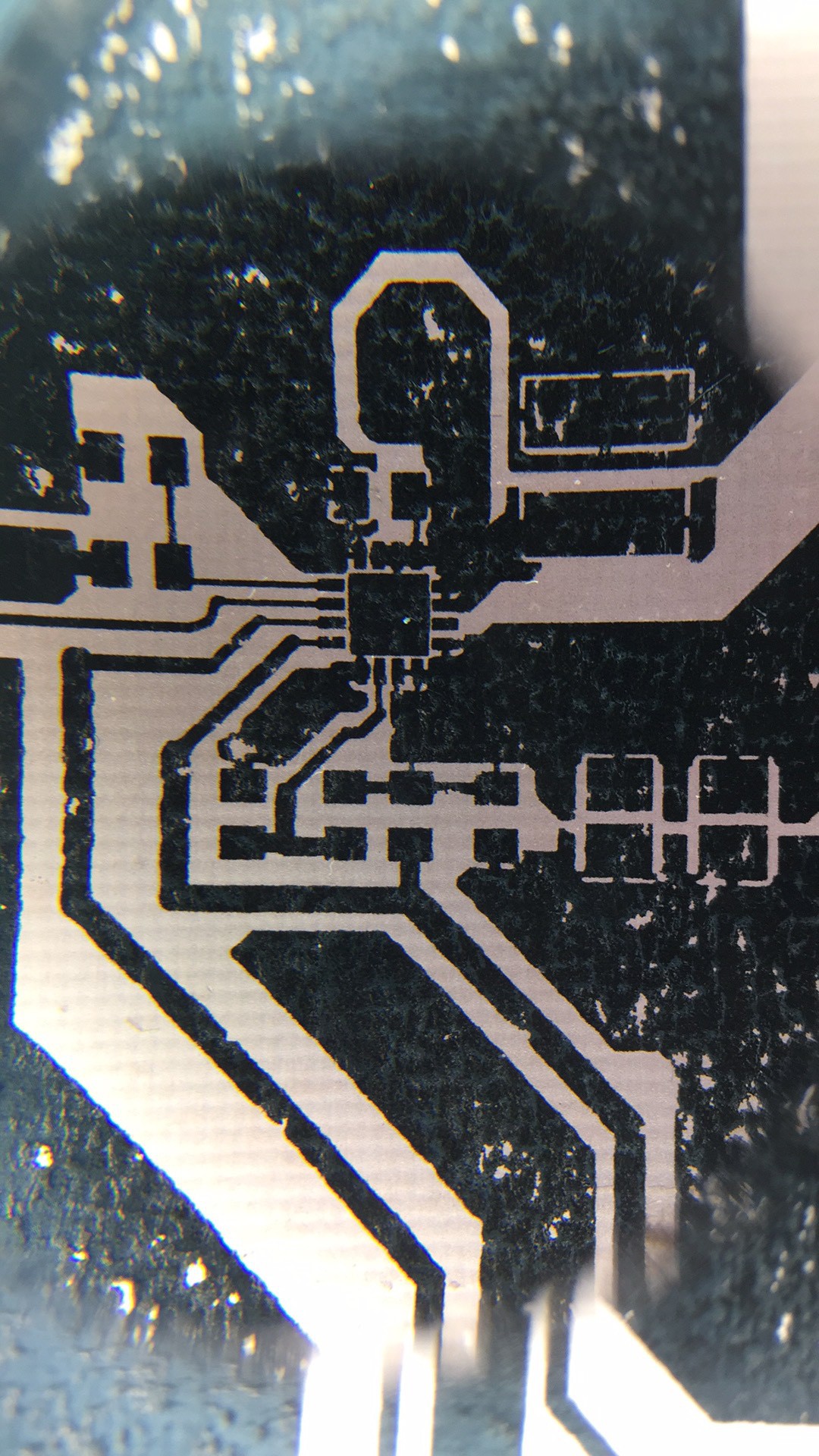

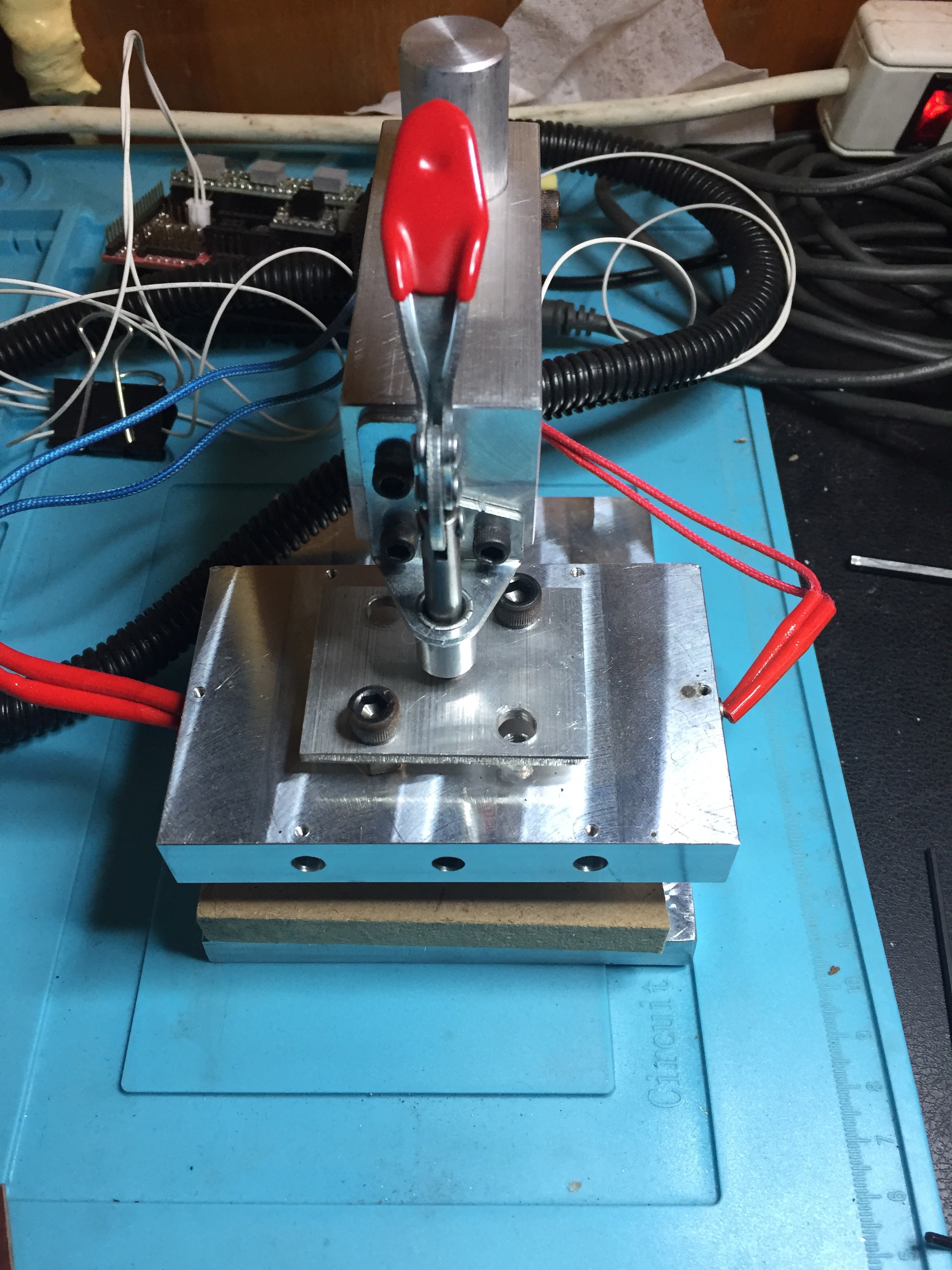

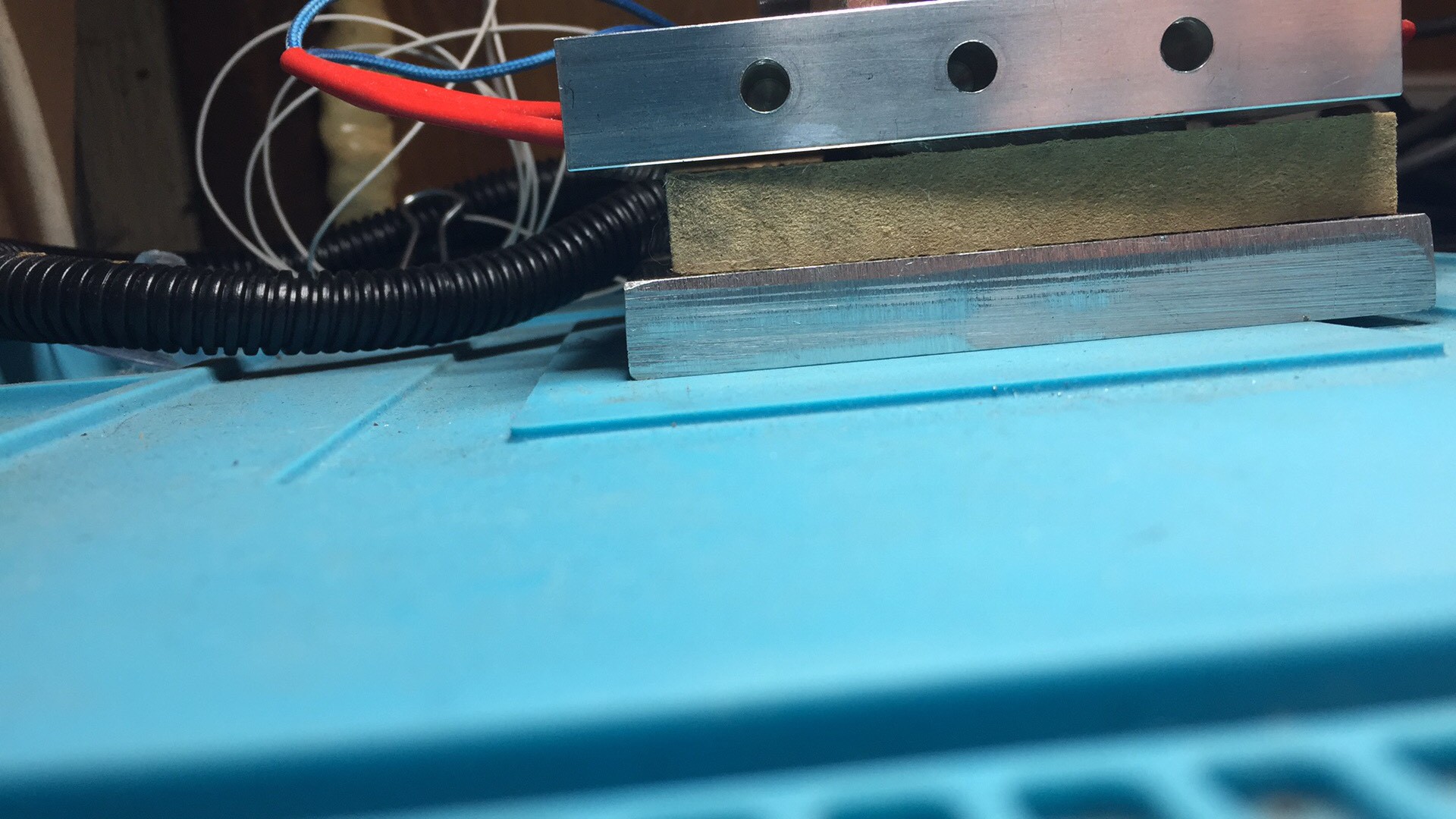

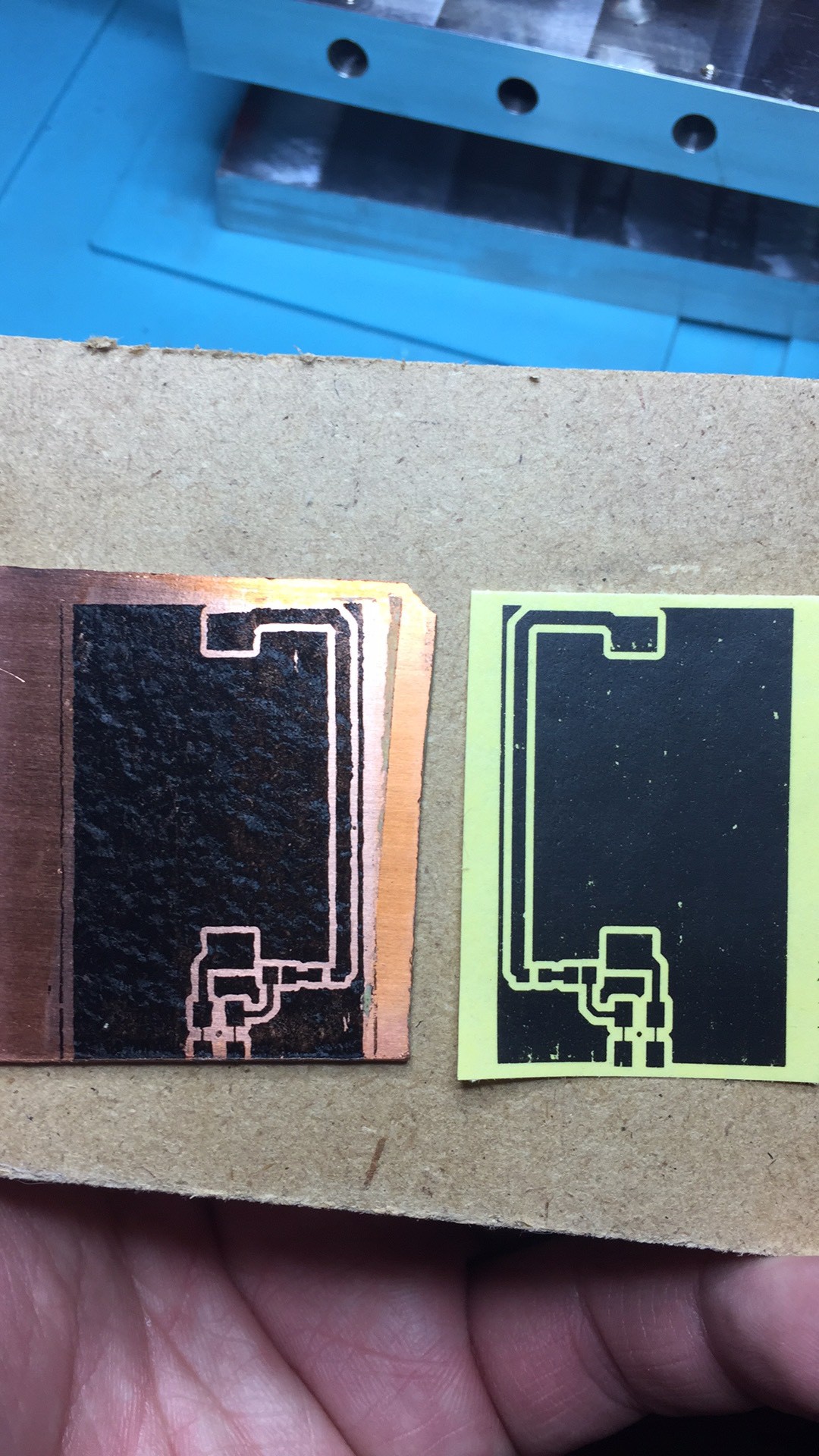

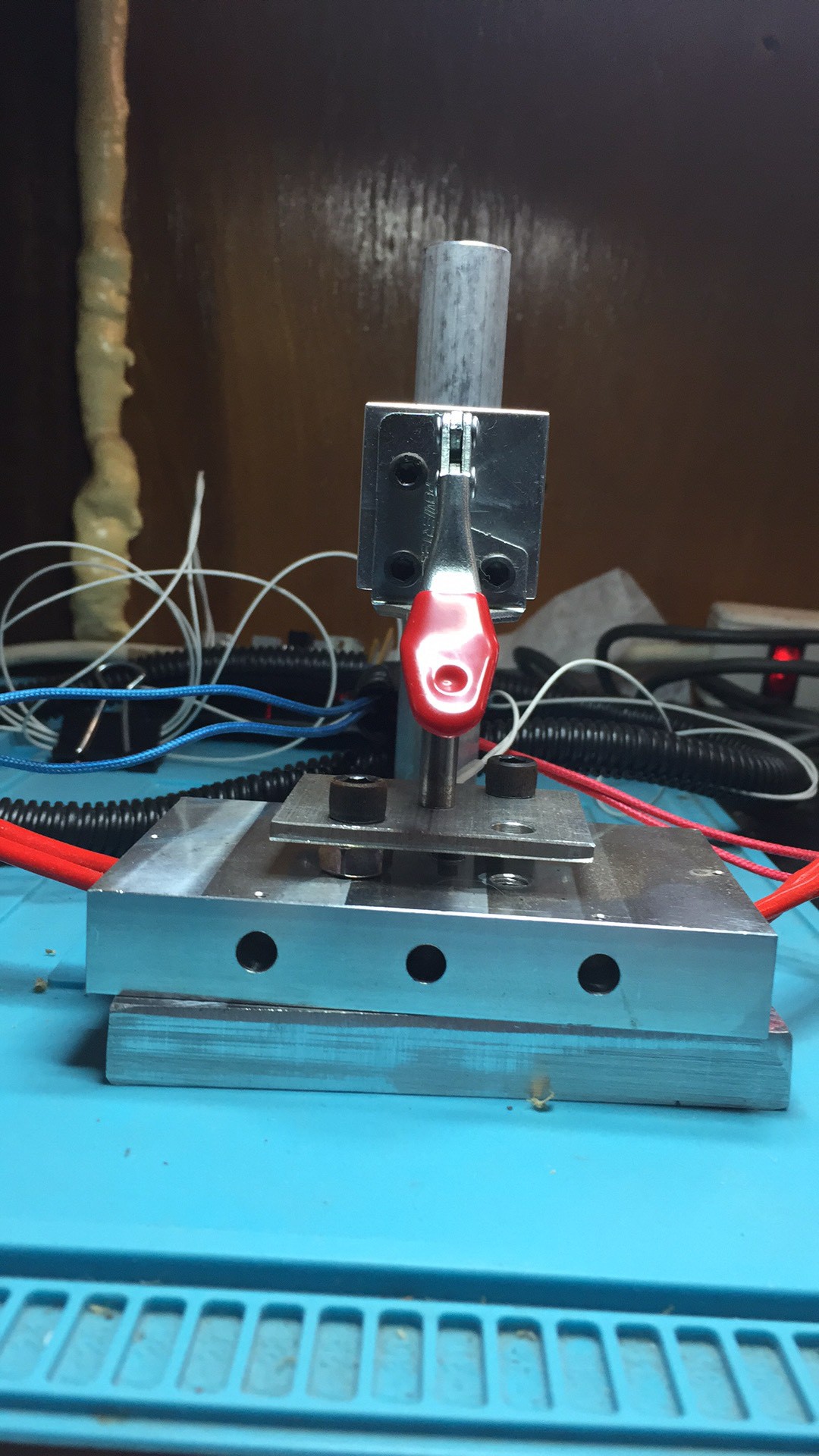

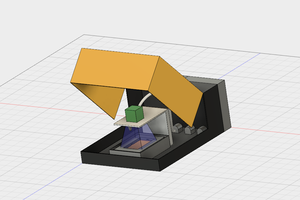

I am able to apply these combinations of skills to make a machine kit that is like a combination of two distinct processes of the toner transfer>caustic and acid etching path to printed circuit board crafting.

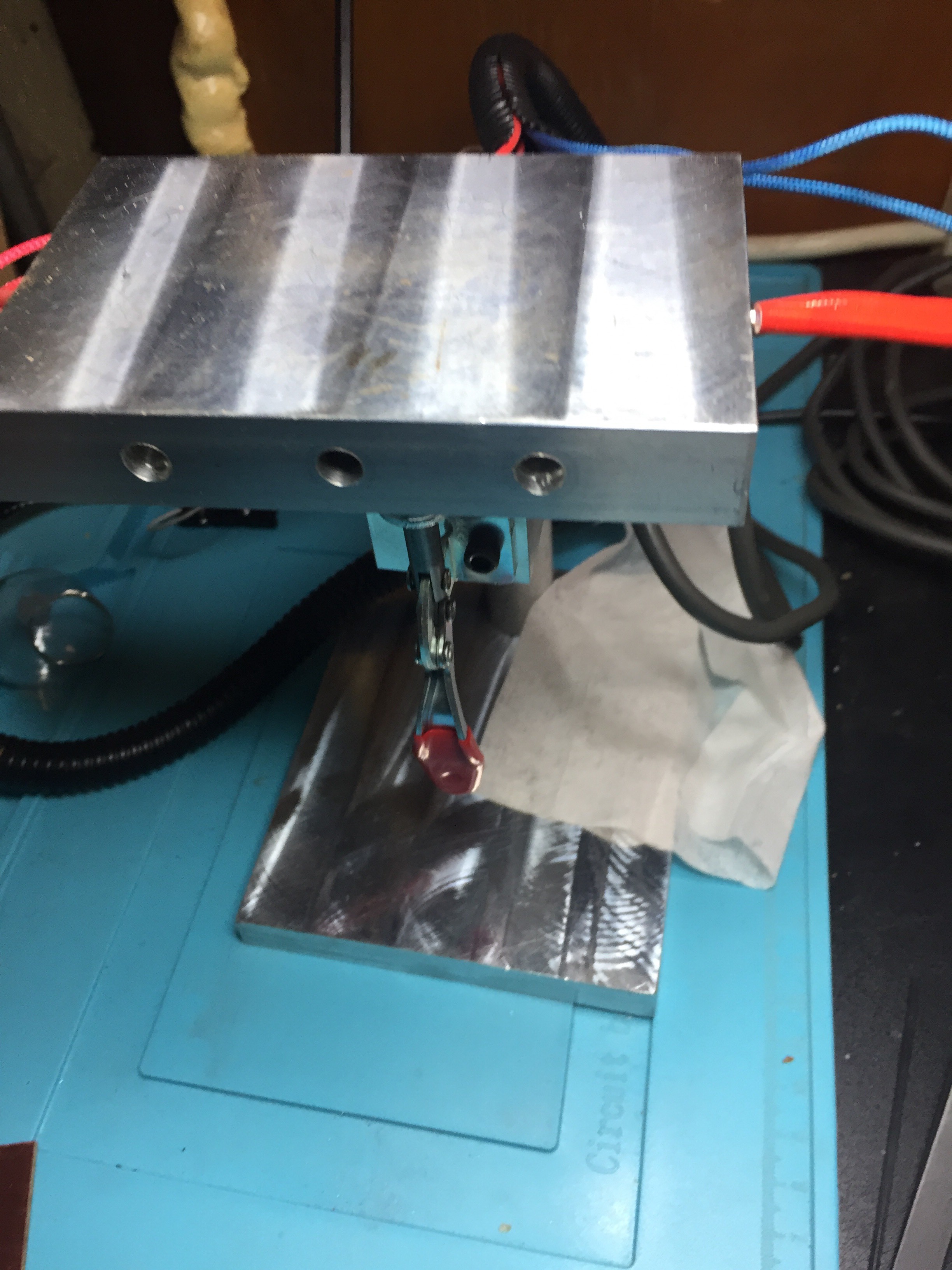

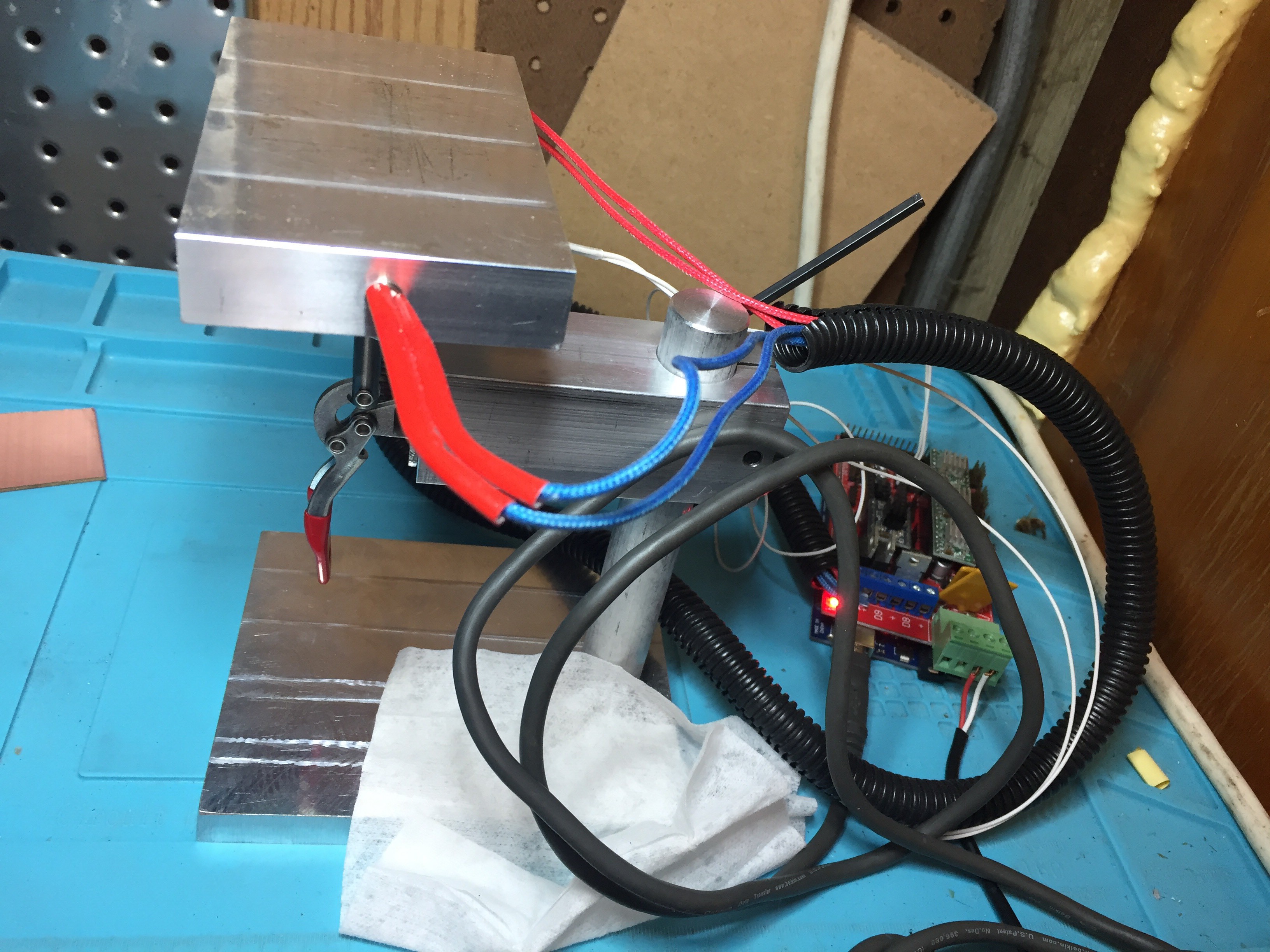

Given the general availability of the Ramps 1.4 hardware, and various soft wares available to drive, simulate, and manually control the various systems of the system in question gives you a shortcut to controlling a variety of systems, not just 3D printers.

In this case this is a quick fix to not wanting to program and design YET another thing (PID tuning machine in this case.) and it got where I needed to be: A finished homemade PCB

I think that is a pretty apt description of my journey into the making of combination systems. I wanted a thing and I thought why the hell don't I just make it?

The same reason I don't make beer.

But alas that road is many leagues behind me now.

SO--combine this kit with your ramps 1.4 and then you can heat and press the toner transfers to your copper clad, then after you've etched the PCB and you're ready to solder your SMD components you'll flip the head around heat it up then place your boards on the plate and wait a couple minutes, there-by re-flowing your solder paste and SMD components to the board. After you're feeling satisfied with where the soldering is you can remove the PCB in question and set it on a head resistant surface that will absorb the process heat.

Anyways feel free to comment.

Jayken

Jayken

Lithium ION

Lithium ION

Michael Delaney

Michael Delaney

Jarrett

Jarrett

Jonathan Beri

Jonathan Beri