The main goals of this design are:

- Design has to be cheap(ish); parts i can get for free through contacts won't be seen as costs, as is stuff like the water-jet cutter i can use for free at my university.

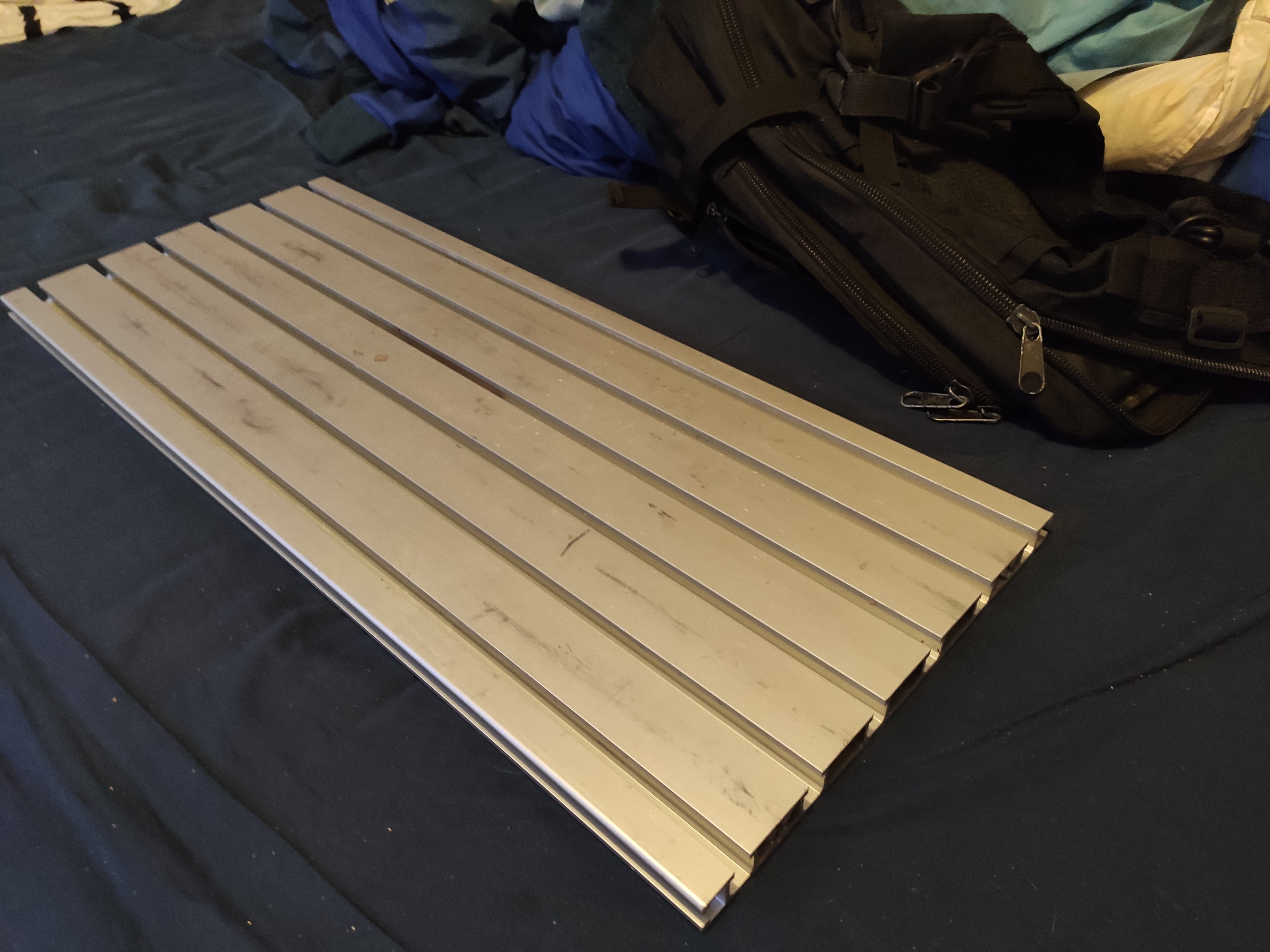

- Can fit under my bed for storage when not in use

- Minimal disassembly effort and time required for storage

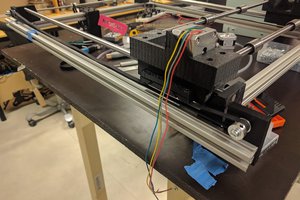

- Repair-ability and expand-ability integrated into the design

- Can machine at least aluminium parts with acceptable accuracy (0.05mm tolerances are a absolute minimum, higher precision preffered).

- 3D printed parts only used when it's right for the job, not like pretty much every other build project these days.

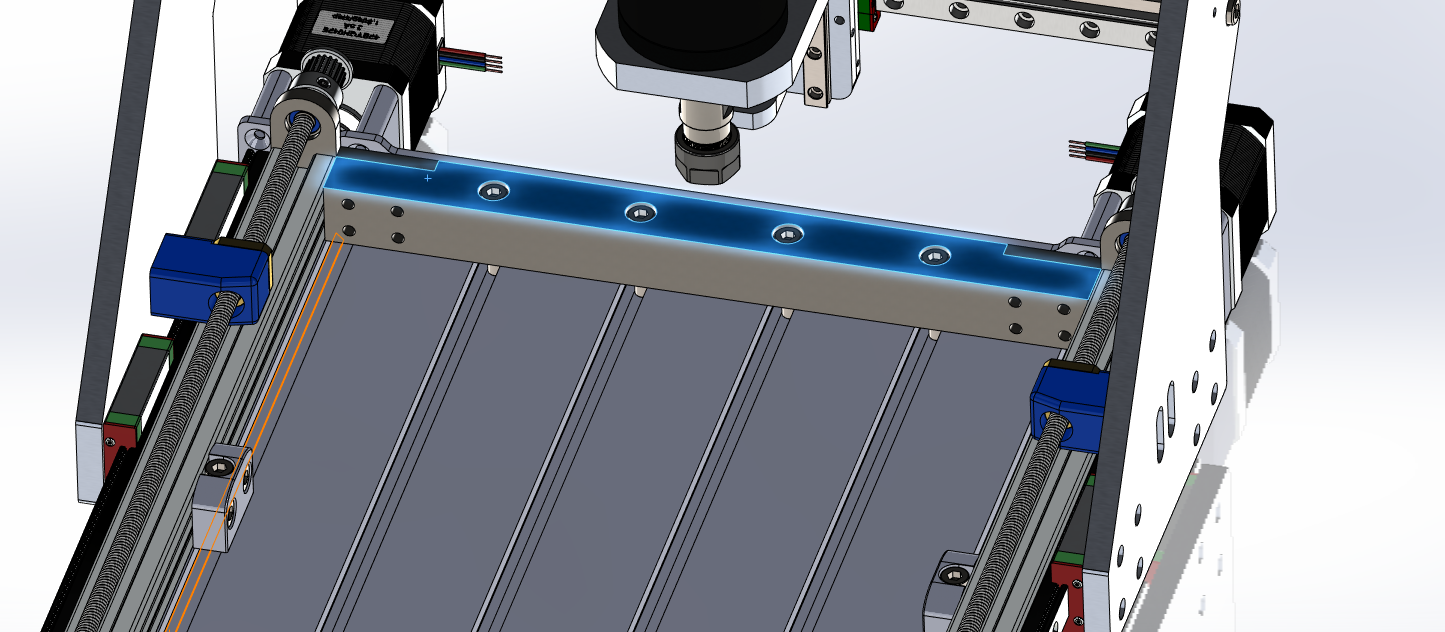

- A 3D touch probe has to be mountable for indexing and future use as a improvised CMM.

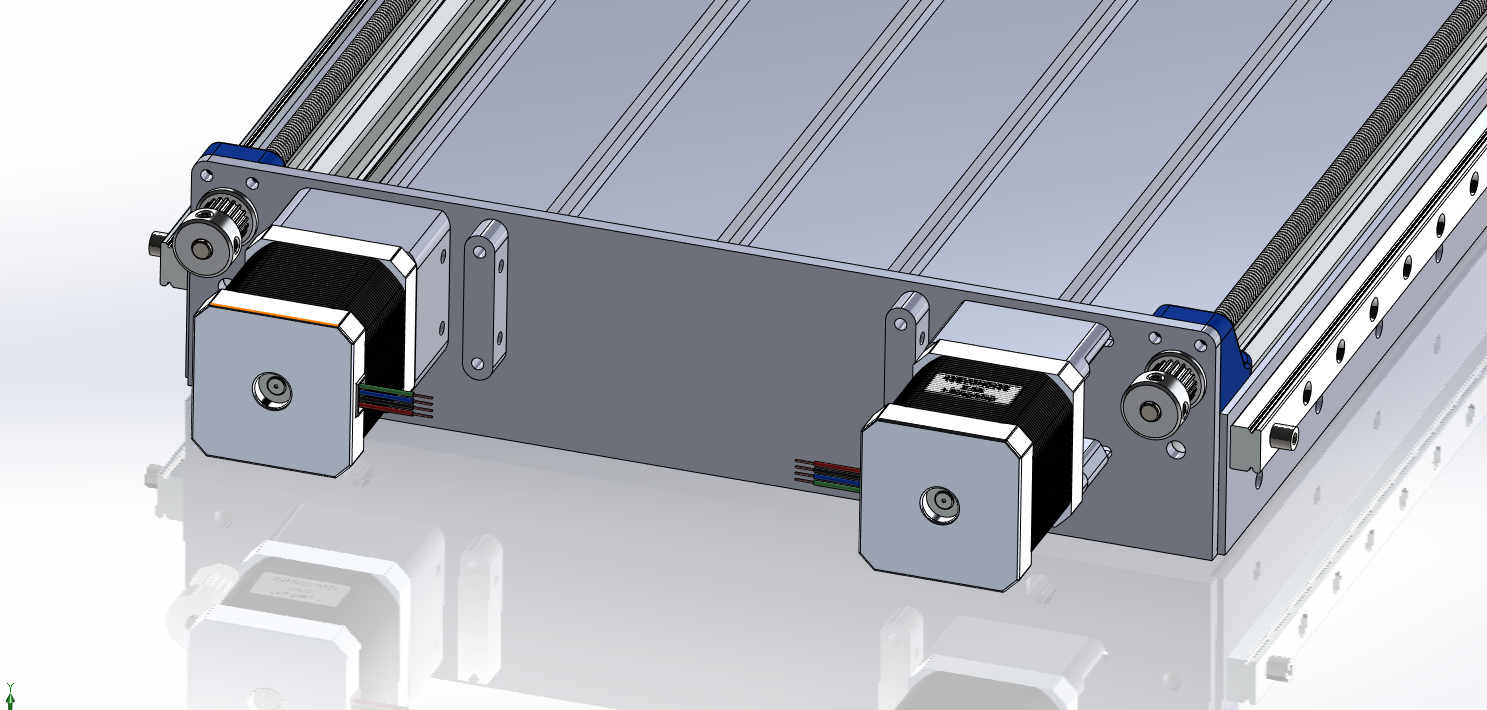

- Future upgrades may include BLDC motors for X and Y motion

Oscar S.

Oscar S.

Maximiliano Palay

Maximiliano Palay

Nikolai Ovesen

Nikolai Ovesen

Sam Baker

Sam Baker

doctek

doctek

This... is really cool. I am looking forward to hearing more about this!!!