This clock was built in 2012. I digged it up for the clock contest. Unfortunately, it is no longer working (two rubber drive belts are old and broken), but I think it is interesting enough to publish it.

This is the idea:

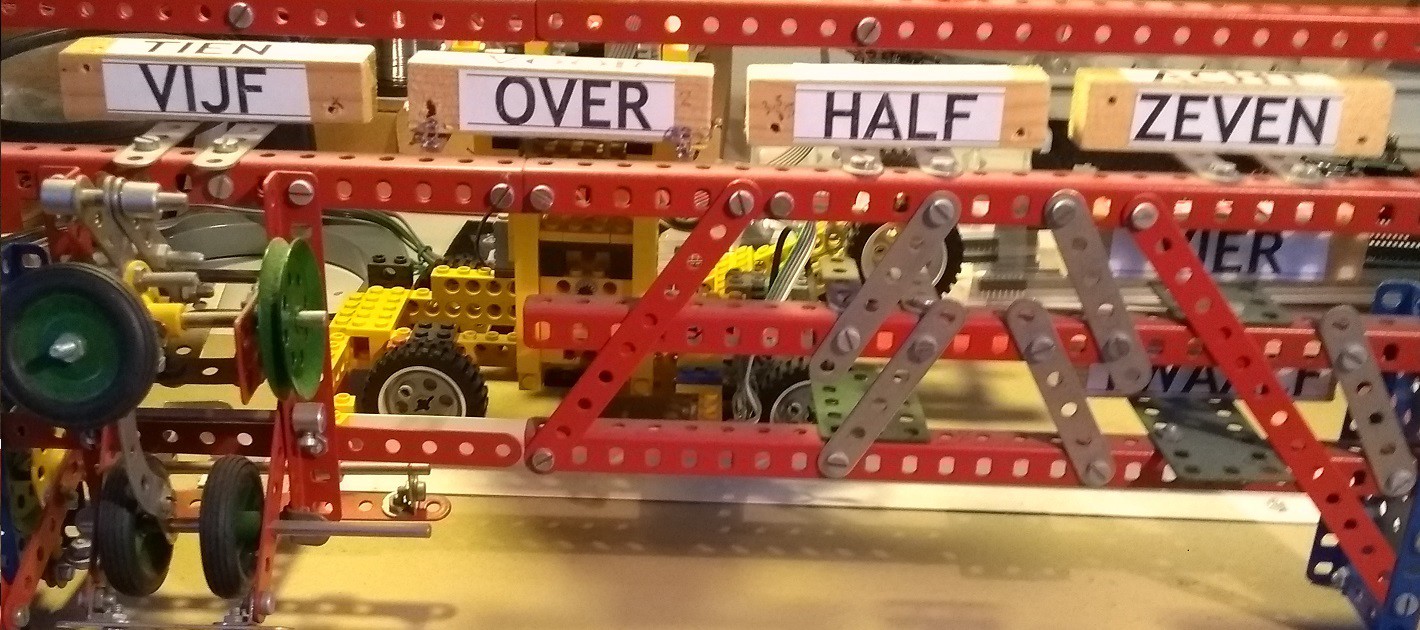

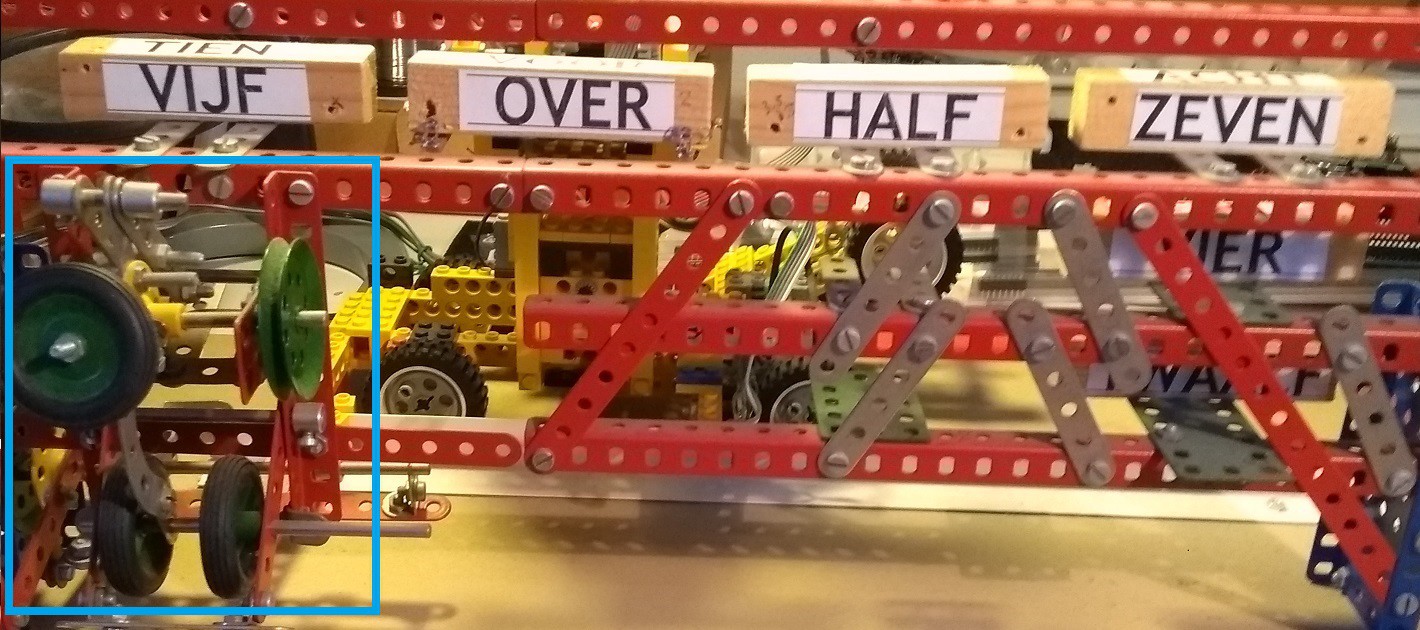

There is a storage rack, that carries 6 wooden blocks of approx. 7 cm (3 inch) length. On the highest row of the rack, three or four blocks tell the time with 5-minute precision.

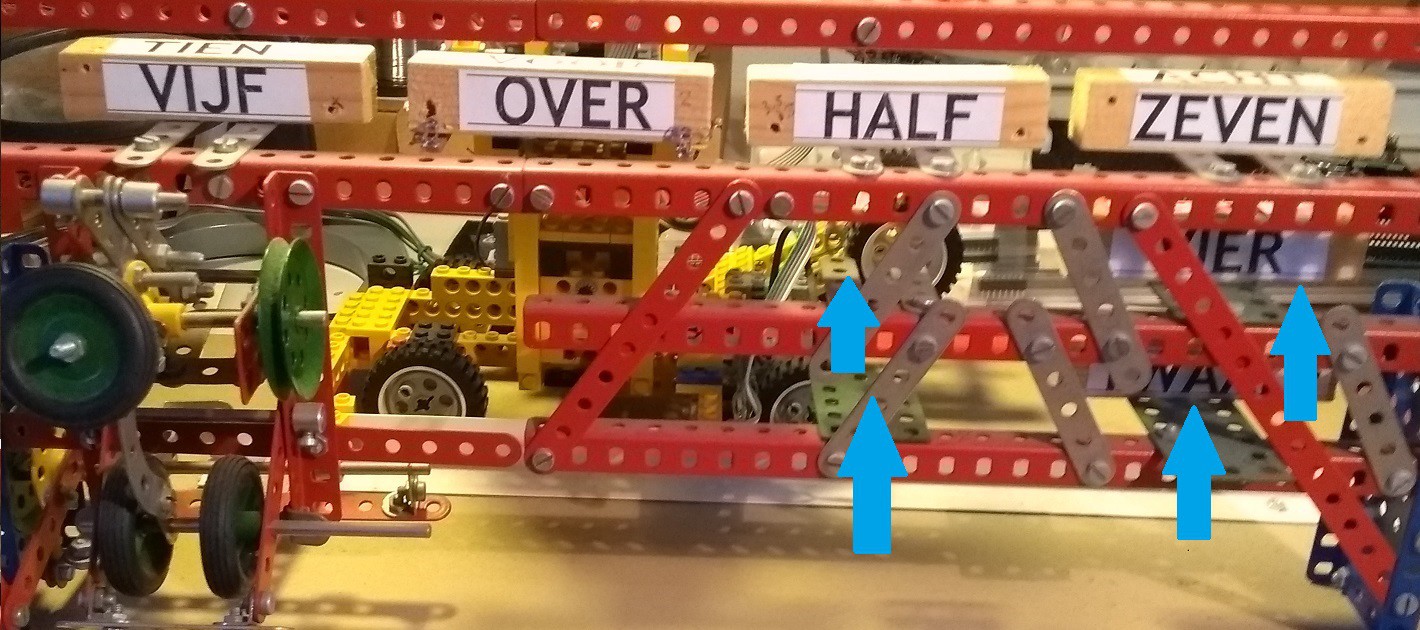

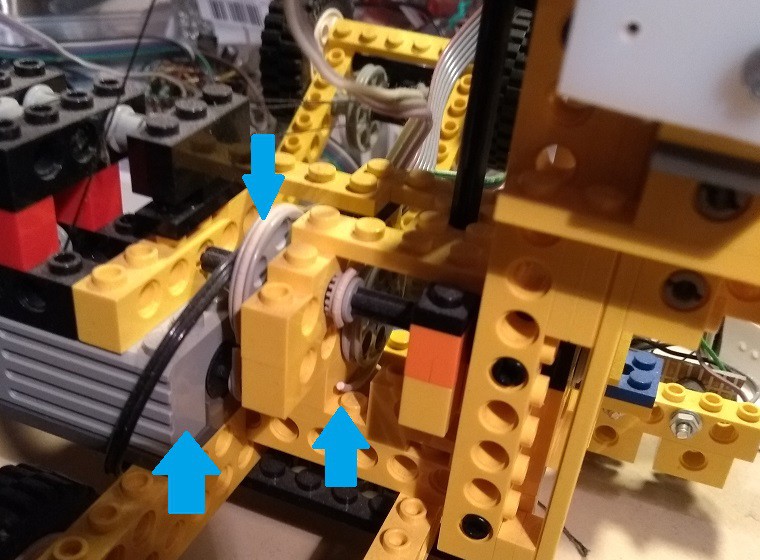

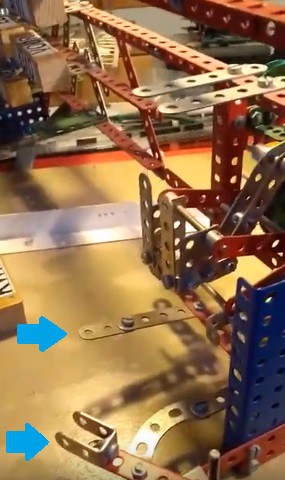

Each block has four sides, so there can be four different texts on each block. That is enough for the first three blocks. But the last block, that tells the hour, needs 12 different texts. So, there are three different blocks for the hour. The unused blocks are in storage positions below the upper row, shown with blue arrows:

This is nice. But time is always changing. So the blocks also have to change. In the pictures above, the second block ("OVER") is not on a storage position but it is carried by a LEGO forklift "truck". The truck can move the bricks up and down, and sideways. The positions below the "OVER" block are not storage positions, so the forklift can move the brick down, and then move it sideways to a storage position. It can drop the brick at a storage position, and go to another storage position on another row to get another brick.

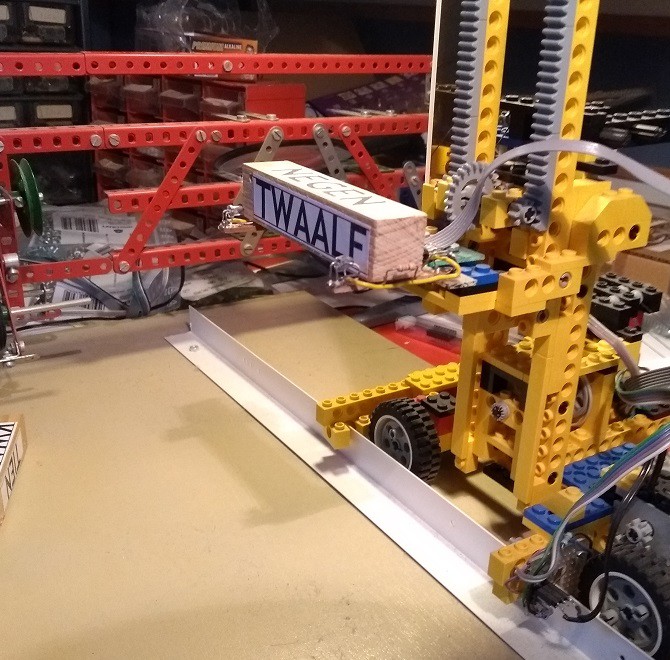

Here is a picture of the truck carrying a brick ( lift in highest position):

So, everything is in place to shuffle the bricks. It's like the Towers of Hanoi puzzle, repeating every five minutes.

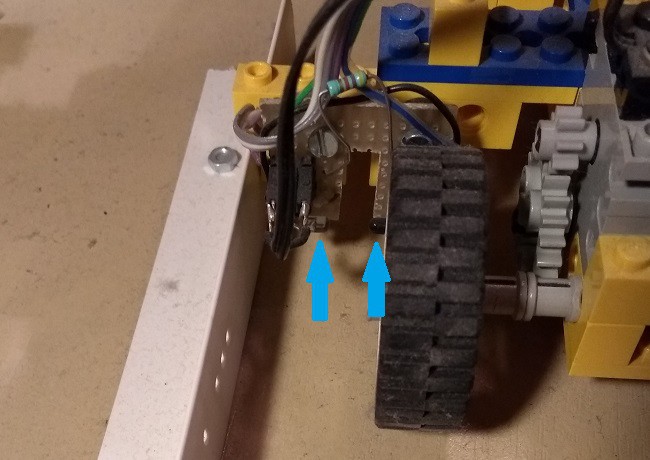

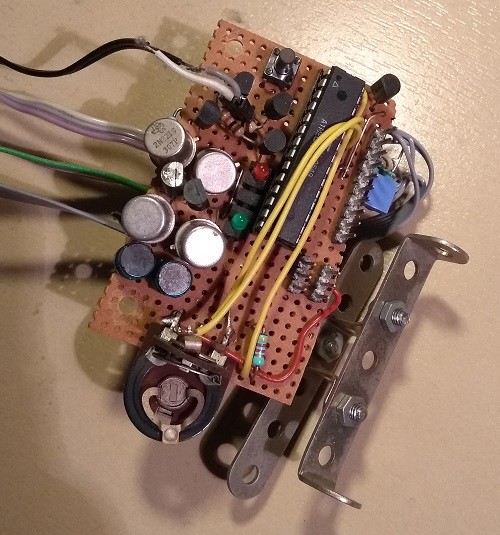

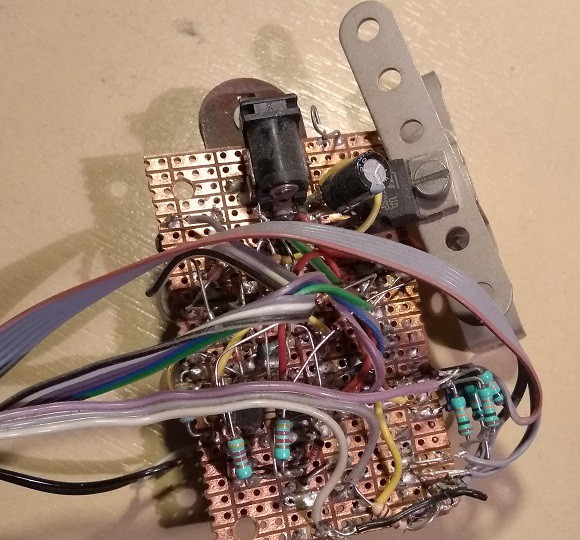

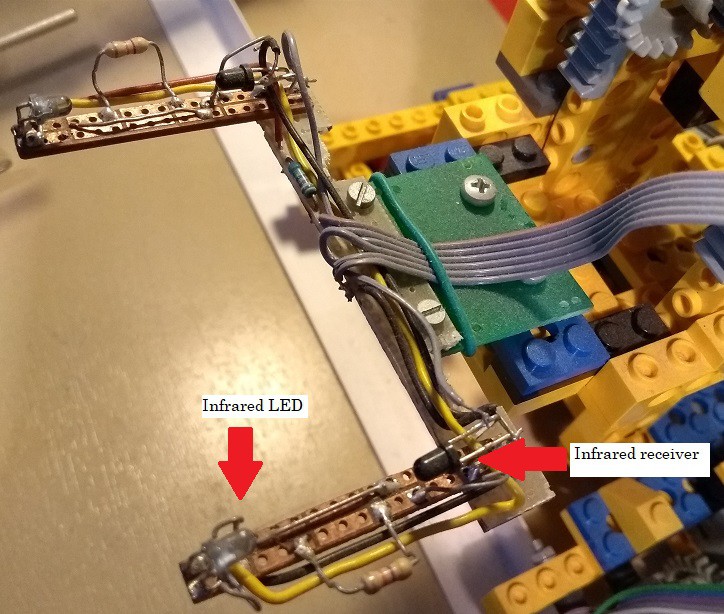

There are only two motors and a handful of infrared position sensors. The whole thing is controlled by an AVR processor. The C software for the ATMEGA168 has been placed in the file section. The program also has a RS232 output to provide information about the actions of the clock.

One more thing... the blocks have text on all four sides, so they must be turned... more things will be described in the logs.

List of logs:

[ edit: the winners of the clock contest were announced HERE. ]

alcor6502

alcor6502

mircemk

mircemk

Hahaha, very clever. One for those who like to see time in motion. 👍