Bottom Layer Material:

The last few days I was searching for the best material on which the first layer can be welded. I tried some sorts of fences, metal meshes and fly screens made of different materials and came to the conglusion, that galvanized steel fly screen could be the best bottom layer material. I also tried stainless steel mesh and I could weld the wire on it, but because of the higher resistance of stainless steel vs galvanized steel I wasn't able to weld more layers on top of each other. The greatest amount of heat was created in the stainless steel mesh instead between the wire layers. With aluminum fly screen I had the opposite problem because of the low resistance of aluminum almost no heat was created in the fly screen, only in the galvanized steel wire.

So I stayed with galvanized steel fly screen.

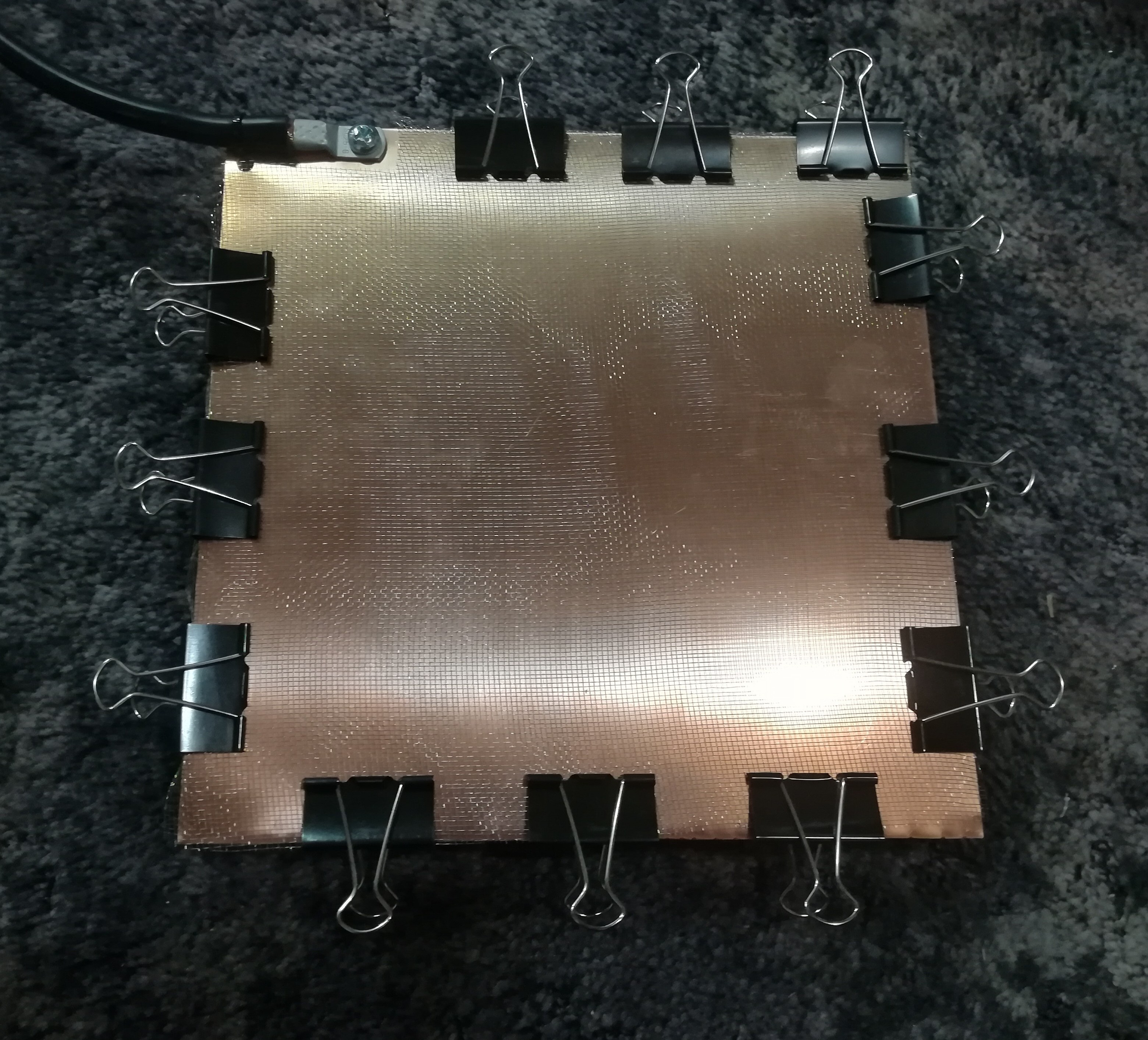

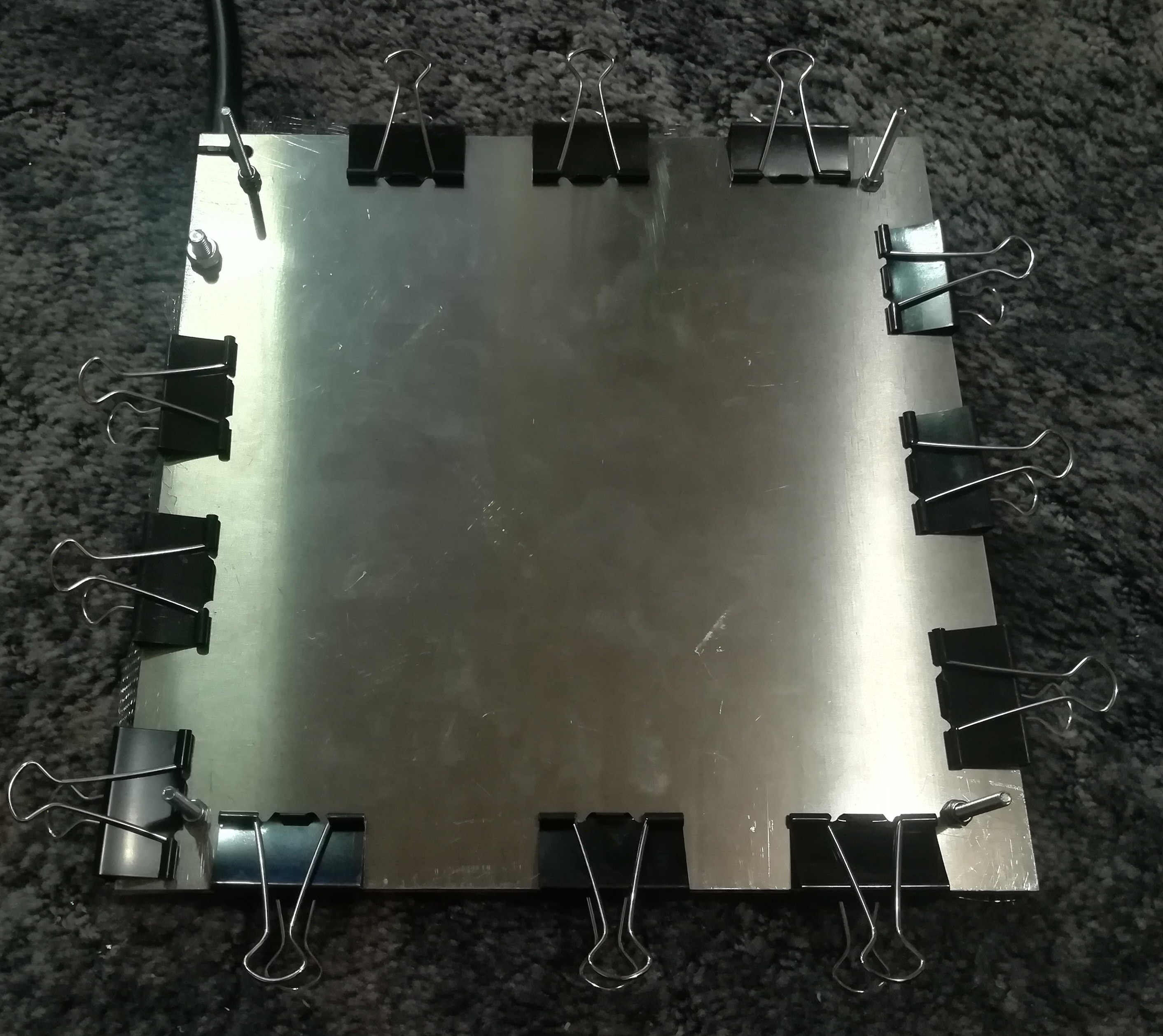

Buildplate:

The buildplate is made of an 250*250*5mm aluminum plate with a M4*40mm countersunk screws in each corner and a copper plate taped on it with double sided tape. There is also the 25mm² cable with a cable lug and a M6*20mm screw and twelve 41mm paper clips to hold the fly screen on it.

The buildplate could be mounted like in the Hypercube Evolution 3D printer and move only in the Z direction. This printer design could also be good to create a closed enclosure, so that the fumes can be kept inside and the air could be filtered before returning into the room.

Next thing could be building the toolhead.

Dominik Meffert

Dominik Meffert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.