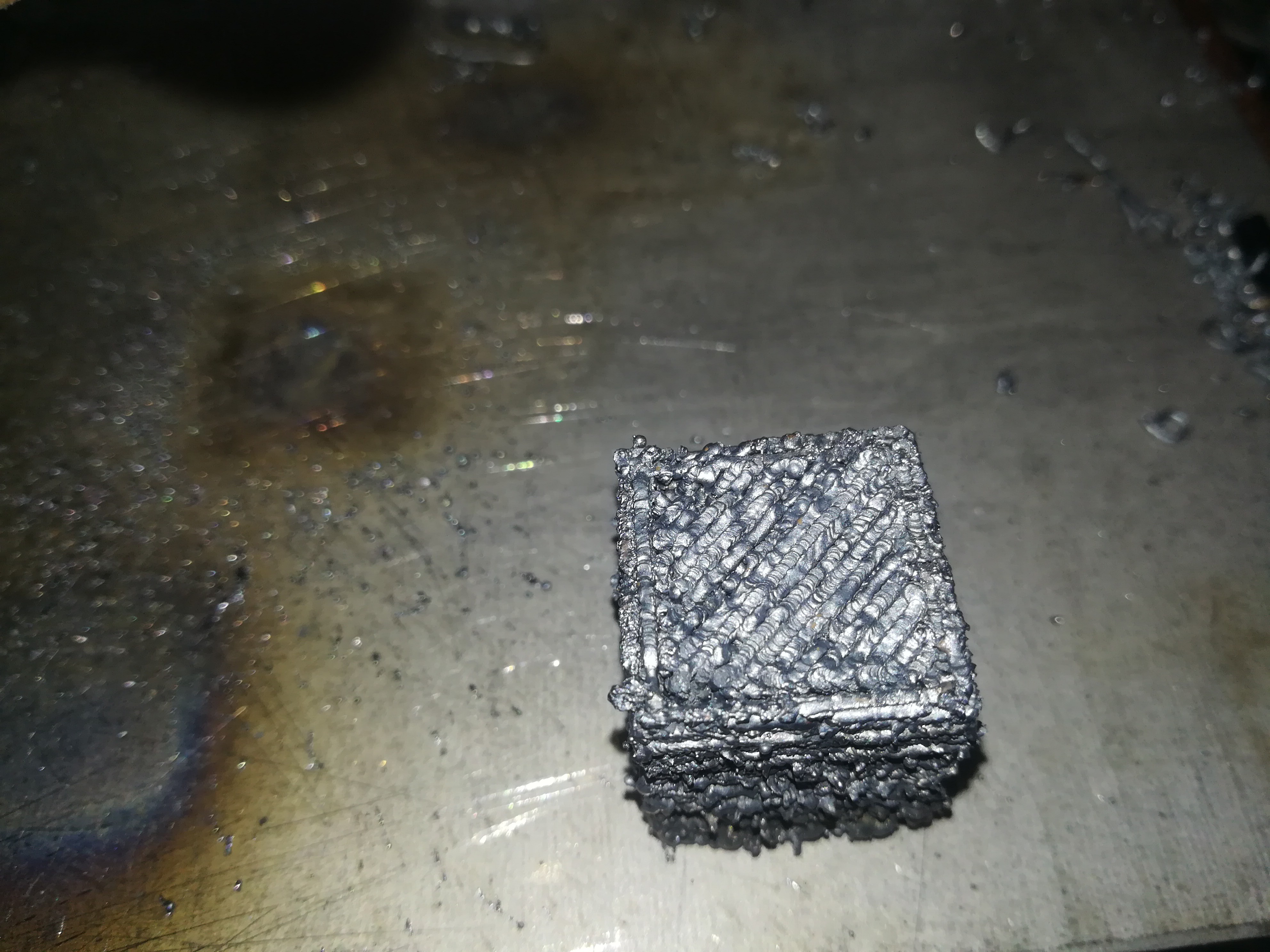

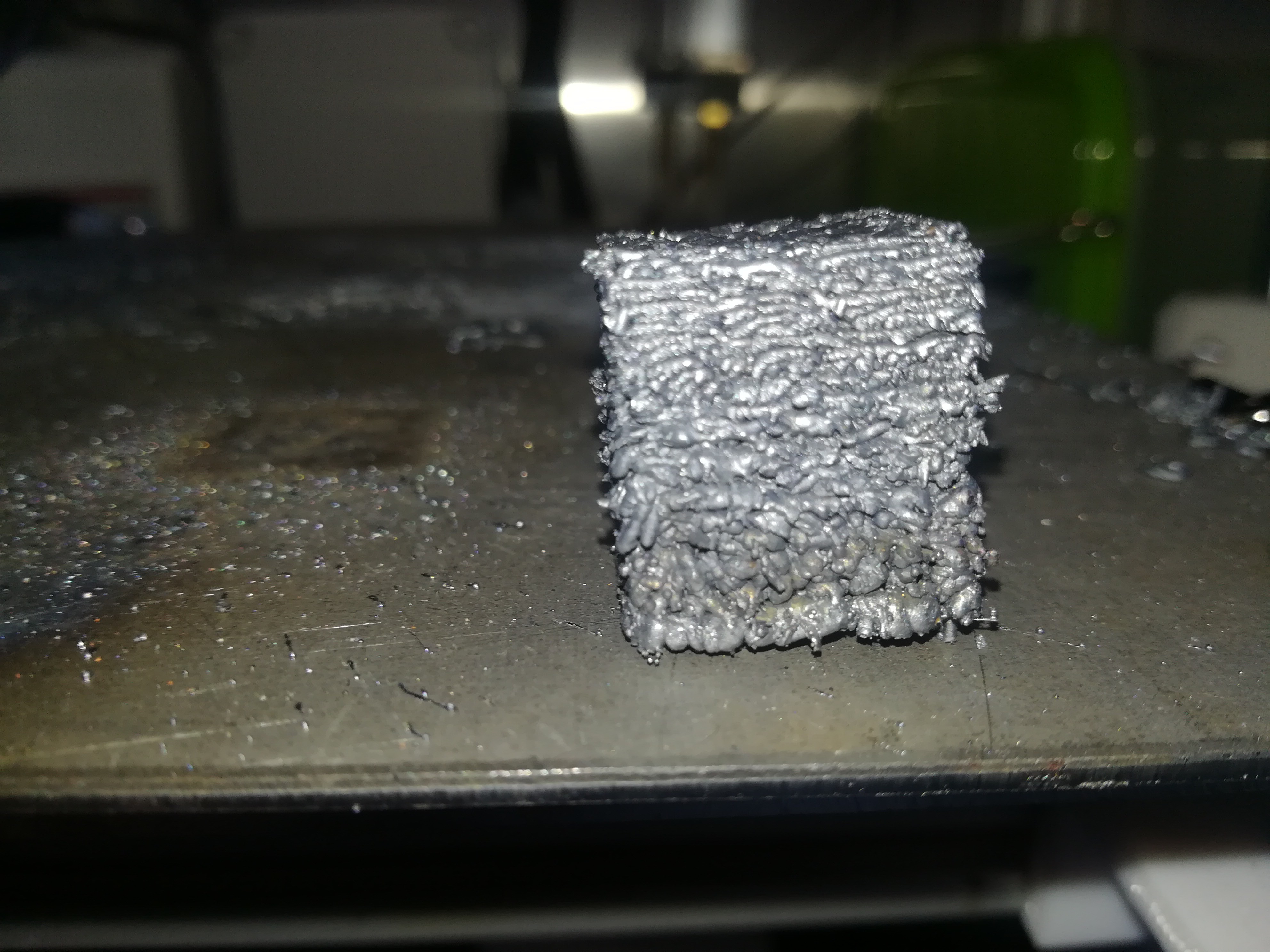

For the first time I could finish a print. It worked by reducing the extrusion rate after a few layers, so that the nozzle didn't crash in the part after some time.

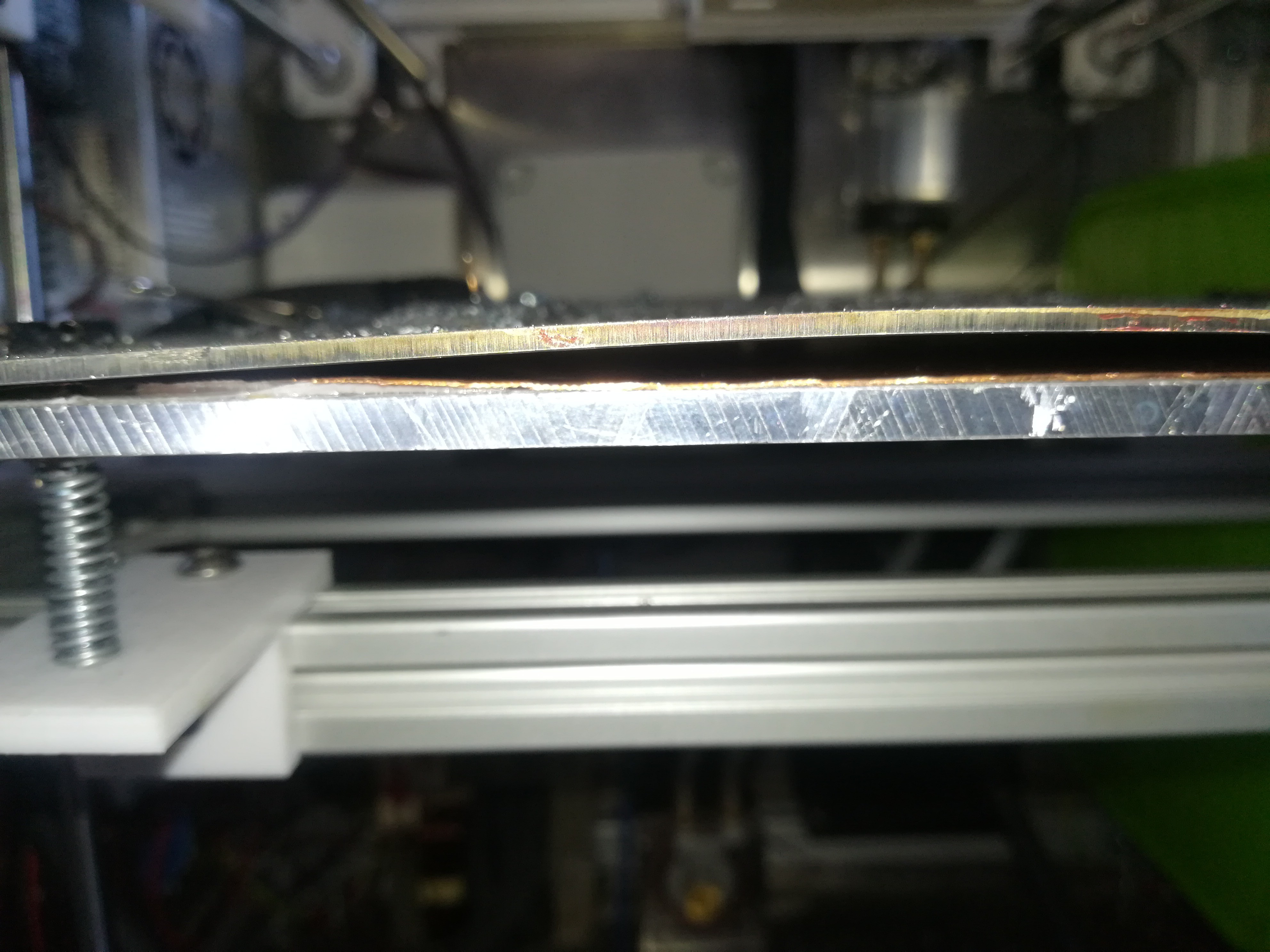

I think the problems with the first few layers came from the buildplate, which got deformed due to the heat. The melting point of steel is at around 1450°C, so there is a lot of heat on the builtplate.

I'm planning to solve this issue by automatic bed leveling with an inductive poximity sensor which should get delivered later this week or early next week.

Dominik Meffert

Dominik Meffert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

As for proximity sensor - your print and bed are conductive, maybe you could just probe height with your printhead?

Are you sure? yes | no

That's an awesome idea. Thank you. Will test it ASAP.

Are you sure? yes | no

I thought about it and unfortunately the printhead and buildplate are always connected through the transformer, so that it will not be as easy to do as with a cnc tool length sensor. There is also the AC voltage on the printhead and buildplate which could damage the Arduino without a protective circuit.

But after hours of thinking about it I found a current sensing switch on Amazon, which could be used to trigger the probe pin when the current increases due to the nozzle touching the build plate.

Are you sure? yes | no

Why not just have a switch for isolating the printhead/buildplate?

Are you sure? yes | no

Hi,

I thought about that. I would actually need two switches/relays. One for disconnecting the work circuit and one for disconnecting the probe circuit after probing to protect the controller board from AC voltage. But I came to the conglusion that it would be easier to just use a proximity sensor or maybe even simpler the current sensing switch (from which I don't know whether it works, yet).

Are you sure? yes | no

Nice :) I would like to see a very basic but functional shape, like a hook or bracket.

Also --- maybe active cooling? maybe it would be bad to spray water into an arc welding system, but you're the expert :)

Are you sure? yes | no

Yes good idea :) I will do so after testing the proximity sensor.

I thought about that for bridging, but I don't know how to do it at a temperature around 1450°C+ created underneat the nozzle. I think it would reach this temperature even if it would be submerged in a cooled non conductive fluid.

The reason for this is: It's not arc welding, but a sort of resistance welding which heats the wire directly. It works below 3V with multiple hundreds of amps. The 230V mains power is transformed to around 3V by a microwave ofen transformer with a 50mm2 cable as secondary coil for low voltage high ampere output.

I'm really no expert. I'm doing trial and error the whole time to get it to work :)

Are you sure? yes | no

SUCCESS! That's friggin' awesome! That last layer looks VERY good to me. Could you maybe try doing cold fusion next? ;)

Are you sure? yes | no

Thank you :)

Hope that when the leveling is like it should be and the rest of the settings are right every layer including the lower layers has the same good quality.

I heard about cold fusion that someone has archieved it in a lab with a simple setup, but I don't know whether it was just a rumor or it really happened. Think I will wait and see what the people at Wendelstein 7X and Iter can archieve over the next few years.

The thing I would like to do next is sharing all the informations of the Wire Printer Project, so that everyone who want can build it.

I really hope that someone builds it, to show that it works and maybe someone else has new ideas for this printing method. E.g. someone with more experience in 3D printing could find better settings or someone with experience in welding could archieve stronger parts with shielding gas, different heating setting or material or someone who sells CHEAP 3D printers can optimize the design and start to sell this sort of printers. Just to give everyone access to cheap metal 3D Printers.

I think that's the idea behind open source. Developing something to give everyone access to something new to start other projects without the barrier of commercialization.

But it can only work if someone uses it...

Are you sure? yes | no

That's why I've submitted your project to front page. I'd want to play with such printer, but that will be possible only next year. If no one will try to use this, I will.

Are you sure? yes | no

Thank you very much :)

Are you sure? yes | no